EN 16480:2021

(Main)Pumps - Rotodynamic pumps - Minimum required efficiency of water pumps and determination of Minimum Efficiency Index (MEI)

Pumps - Rotodynamic pumps - Minimum required efficiency of water pumps and determination of Minimum Efficiency Index (MEI)

This document specifies performance requirements (methods and procedures for testing and calculating) for determining the Minimum Efficiency Index (MEI) of rotodynamic glanded water pumps for pumping clean water, including where integrated in other products.

The pump types and sizes covered by this document are described in the Annex A. These pumps are designed and produced as duty pumps for pressures up to 16 bar for end suction pumps and up to 25 bar for multistage pumps, for all pumps designed for fluid temperatures between −10 °C and +120°C. Also covered are 4" (10,16 cm) and 6" (15,24 cm) submersible multistage pumps designed for fluid temperatures between 0 °C and 90 °C.

Pumpen - Kreiselpumpen - Geforderte Mindesteffizienz für Wasserpumpen sowie Bestimmung des Mindest-Effizienzindexes (MEI)

Dieses Dokument legt Leistungsanforderungen (Methoden und Verfahren zur Prüfung und Berechnung) zur Bestimmung des Mindest-Effizienzindex (MEI) von Wasserpumpen in Kreiselpumpenbauart mit Stopfbuchsen zum Pumpen von sauberem Wasser einschließlich von Produkten, in welche diese Pumpen integriert sind, fest.

Die Pumpentypen und Pumpengrößen, die von diesem Dokument abgedeckt sind, werden im Anhang A beschrieben. Diese Pumpen werden als Pumpen für Drücke bis 16 bar bei Pumpen mit axialem Eintritt und bis 25 bar bei mehrstufigen Pumpen und bei allen Pumpen für Mediumtemperaturen zwischen −10 °C und +120 °C ausgelegt und hergestellt. Ebenfalls abgedeckt sind mehrstufige Tauchpumpen der Größe 4″ (10,16 cm) oder 6″ (15,24 cm) für Mediumtemperaturen zwischen 0 °C und 90 °C.

Pompes - Pompes rotodynamiques - Rendement minimal requis des pompes à eau et détermination de l'Indice de rendement minimal (MEI)

Le présent document spécifie les exigences de performance (méthodes et modes opératoires d’essais et de calculs) pour la détermination de l’indice de rendement minimal (MEI) des pompes à eau rotodynamiques dotées d’un dispositif d’étanchéité employées pour pomper de l’eau propre, y compris les pompes intégrées dans d’autres produits.

Les types et les gammes de pompe visés par le présent document sont décrits dans l’Annexe A. Ces pompes sont conçues et fabriquées comme des pompes de service pour des pressions inférieures ou égales à 16 bar pour les pompes à aspiration en bout et inférieures ou égales à 25 bar pour les pompes multi-étagées, pour toutes les pompes conçues pour des températures de fluides comprises entre -10 °C et +120 °C. Sont également couvertes les pompes multi-étagées de 10,16 cm (4") et 15,24 cm (6") pour les pompes submersibles multi-étagées à des températures de fluides comprises entre 0 °C et 90 °C.

Črpalke - Centrifugalne črpalke - Minimalna zahtevana učinkovitost vodnih črpalk in določevanje minimalnega indeksa učinkovitostii (MEI)

General Information

- Status

- Published

- Publication Date

- 12-Oct-2021

- Withdrawal Date

- 29-Apr-2022

- Technical Committee

- CEN/TC 197 - Pumps

- Drafting Committee

- CEN/TC 197/SC 3/WG 1 - Water pumps efficiency

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 13-Oct-2021

- Due Date

- 23-Apr-2020

- Completion Date

- 13-Oct-2021

Relations

- Effective Date

- 08-Feb-2017

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16480:2021 - published by CEN - sets the minimum required efficiency methodology for rotodynamic water pumps and specifies how to determine the Minimum Efficiency Index (MEI). The standard applies to glanded rotodynamic (centrifugal) pumps for clean water, including pumps integrated in other products. Covered pump designs and sizes are listed in Annex A. Scope examples: end-suction pumps (pressures up to 16 bar), multistage pumps (up to 25 bar), general fluid temperatures −10 °C to +120 °C, and 4" / 6" submersible multistage pumps (0 °C to 90 °C). EN 16480:2021 supersedes EN 16480:2016 and aligns with CEN/CENELEC adoption and EU ecodesign considerations.

Key topics and requirements

- Minimum Efficiency Index (MEI): Defines MEI as a metric characterizing the mean efficiency of a pump size and links a required mean efficiency to each MEI value.

- House of efficiency: Concept used to describe nominal minimum efficiency values across pump types and operating points (Clause 5).

- Test procedures and conditions (Clause 6): Specifies methods for performance testing and conversion of test data to nominal conditions, referencing EN ISO 9906:2012 for hydraulic acceptance tests.

- Measurement uncertainty and statistical evaluation (Clause 6.4 & Annex C): Requirements for handling measurement fluctuations, uncertainty assessment, confidence intervals and outlier tests when deriving mean efficiencies for a pump size.

- Qualification and proof (Clause 7): Procedures manufacturers use to demonstrate that a pump size meets a specified MEI based on representative samples and statistical criteria.

- Informative annexes: Guidance on pump types in scope, general remarks on efficiency, and methods to determine mean MEI values and confidence intervals.

- Regulatory linkage: Annex ZA explains the relationship with EU Ecodesign Regulation (Commission Regulation (EU) No 547/2012).

Practical applications and users

Who uses EN 16480:2021:

- Pump manufacturers - to test, certify and demonstrate MEI compliance for product lines.

- Test laboratories - to apply standardized test methods and report efficiencies with quantified uncertainty.

- Specifiers and procurement teams - to select pumps meeting energy-efficiency targets (MEI) for buildings, water supply, HVAC, irrigation and industrial systems.

- Regulators and compliance officers - to verify ecodesign and market-entry requirements.

- Design engineers and energy consultants - for product comparison, lifecycle energy assessments and optimizing pump selection.

Practical benefits:

- Ensures consistent pump testing, reliable energy-performance data, and transparent calculation of MEI for energy efficiency improvement and regulatory compliance.

Related standards

- EN ISO 9906:2012 (Rotodynamic pumps - Hydraulic performance acceptance tests) - normative reference used by EN 16480:2021.

- Commission Regulation (EU) No 547/2012 - ecodesign context (see Annex ZA).

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 16480:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Pumps - Rotodynamic pumps - Minimum required efficiency of water pumps and determination of Minimum Efficiency Index (MEI)". This standard covers: This document specifies performance requirements (methods and procedures for testing and calculating) for determining the Minimum Efficiency Index (MEI) of rotodynamic glanded water pumps for pumping clean water, including where integrated in other products. The pump types and sizes covered by this document are described in the Annex A. These pumps are designed and produced as duty pumps for pressures up to 16 bar for end suction pumps and up to 25 bar for multistage pumps, for all pumps designed for fluid temperatures between −10 °C and +120°C. Also covered are 4" (10,16 cm) and 6" (15,24 cm) submersible multistage pumps designed for fluid temperatures between 0 °C and 90 °C.

This document specifies performance requirements (methods and procedures for testing and calculating) for determining the Minimum Efficiency Index (MEI) of rotodynamic glanded water pumps for pumping clean water, including where integrated in other products. The pump types and sizes covered by this document are described in the Annex A. These pumps are designed and produced as duty pumps for pressures up to 16 bar for end suction pumps and up to 25 bar for multistage pumps, for all pumps designed for fluid temperatures between −10 °C and +120°C. Also covered are 4" (10,16 cm) and 6" (15,24 cm) submersible multistage pumps designed for fluid temperatures between 0 °C and 90 °C.

EN 16480:2021 is classified under the following ICS (International Classification for Standards) categories: 23.080 - Pumps. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16480:2021 has the following relationships with other standards: It is inter standard links to EN 16480:2016, EN ISO 9906:2012, EN 17038-2:2019, EN 17038-4:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16480:2021 is associated with the following European legislation: EU Directives/Regulations: 2009/125/EC, 547/2012; Standardization Mandates: M/498. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16480:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2021

Nadomešča:

SIST EN 16480:2016

Črpalke - Centrifugalne črpalke - Minimalna zahtevana učinkovitost vodnih črpalk

in določevanje minimalnega indeksa učinkovitostii (MEI)

Pumps - Rotodynamic pumps - Minimum required efficiency of water pumps and

determination of Minimum Efficiency Index (MEI)

Pumpen - Kreiselpumpen - Geforderte Mindesteffizienz für Wasserpumpen sowie

Bestimmung des Minimum Effizienz Indexes (MEI)

Pompes - Pompes rotodynamiques - Rendement minimal requis des pompes à eau et

détermination de l'Indice de rendement minimal (MEI)

Ta slovenski standard je istoveten z: EN 16480:2021

ICS:

23.080 Črpalke Pumps

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16480

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2021

EUROPÄISCHE NORM

ICS 23.080 Supersedes EN 16480:2016

English Version

Pumps - Rotodynamic pumps - Minimum required

efficiency of water pumps and determination of Minimum

Efficiency Index (MEI)

Pompes - Pompes rotodynamiques - Rendement Pumpen - Kreiselpumpen - Geforderte Mindesteffizienz

minimal requis des pompes à eau et détermination de für Wasserpumpen sowie Bestimmung des Minimum

l'Indice de rendement minimal (MEI) Effizienz Indexes (MEI)

This European Standard was approved by CEN on 11 July 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16480:2021 E

worldwide for CEN national Members.

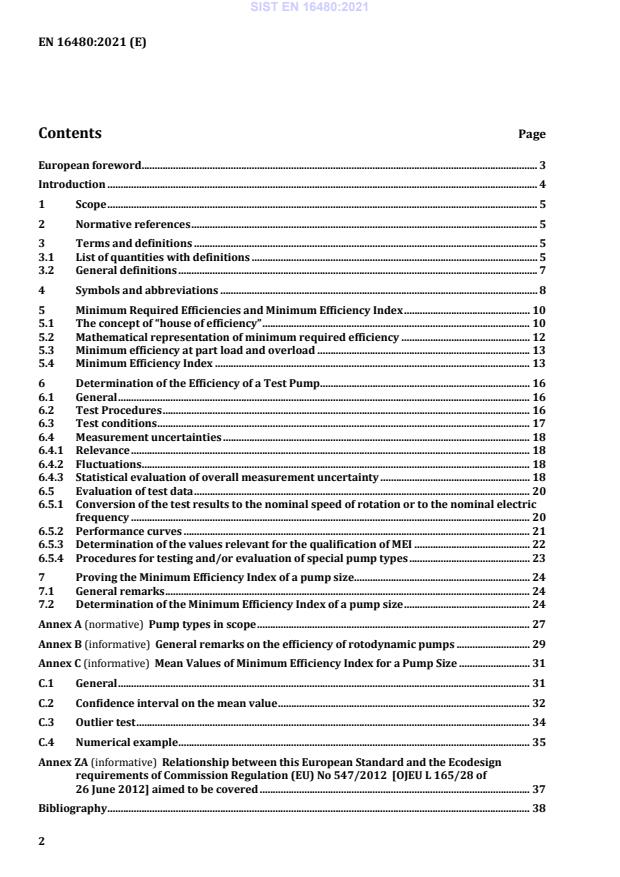

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

3.1 List of quantities with definitions . 5

3.2 General definitions . 7

4 Symbols and abbreviations . 8

5 Minimum Required Efficiencies and Minimum Efficiency Index . 10

5.1 The concept of “house of efficiency” . 10

5.2 Mathematical representation of minimum required efficiency . 12

5.3 Minimum efficiency at part load and overload . 13

5.4 Minimum Efficiency Index . 13

6 Determination of the Efficiency of a Test Pump . 16

6.1 General . 16

6.2 Test Procedures . 16

6.3 Test conditions . 17

6.4 Measurement uncertainties . 18

6.4.1 Relevance . 18

6.4.2 Fluctuations . 18

6.4.3 Statistical evaluation of overall measurement uncertainty . 18

6.5 Evaluation of test data . 20

6.5.1 Conversion of the test results to the nominal speed of rotation or to the nominal electric

frequency . 20

6.5.2 Performance curves . 21

6.5.3 Determination of the values relevant for the qualification of MEI . 22

6.5.4 Procedures for testing and/or evaluation of special pump types . 23

7 Proving the Minimum Efficiency Index of a pump size . 24

7.1 General remarks . 24

7.2 Determination of the Minimum Efficiency Index of a pump size . 24

Annex A (normative) Pump types in scope . 27

Annex B (informative) General remarks on the efficiency of rotodynamic pumps . 29

Annex C (informative) Mean Values of Minimum Efficiency Index for a Pump Size . 31

C.1 General . 31

C.2 Confidence interval on the mean value . 32

C.3 Outlier test . 34

C.4 Numerical example . 35

Annex ZA (informative) Relationship between this European Standard and the Ecodesign

requirements of Commission Regulation (EU) No 547/2012 [OJEU L 165/28 of

26 June 2012] aimed to be covered . 37

Bibliography . 38

European foreword

This document (EN 16480:2021) has been prepared by Technical Committee CEN/TC 197 “Pumps”, the

secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by April 2022, and conflicting national standards shall be withdrawn at

the latest by April 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16480:2016.

The main changes compared to the previous edition are as follows:

— the title and scope have been modified by the removal of the verification aspect throughout this document;

— Clause 3 on Terms and Definitions has been modified;

— Clause 6 on the determination of the Efficiency of a Test Pump has been updated;

— informative Annex D dealing with methods recommended for manufacturers to determine the mean

values of hydraulic quantities of a size relevant for MEI has been deleted;

— informative Annex E giving a numerical example and informative Annex F describing the application of

mathematical statistics on tests have been deleted;

— informative Annexes G, H and I, dealing with measurement uncertainties, the methodology of the

verification procedure and the reporting of test results, respectively, have been deleted;

— the Annex ZA showing the relationship between this European Standard and the Ecodesign requirements

of Commission Regulation (EU) No 547/2012 has been updated.

This document has been prepared under a Standardization Request given to CEN by the European Commission

and the European Free Trade Association, and supports essential requirements of EU Directive(s) /

Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part of

this document.

Any feedback and questions on this document should be directed to the users’ national standards body. A

complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia,

Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

Introduction

Purpose and content of this document

The water pumps within the scope of this document are typically produced and sold by pump manufacturers

as series of large to very large numbers. The performance characteristics of pumps of one size produced by a

manufacturer show some scatter caused by manufacturing tolerances but are described by mean values and

curves which represent that size.

The total consumption of electric energy by water pumps installed in applications within the scope of this

document depends on the total number of installed pumps of each size and on its mean efficiency. The quality

of a size in respect to its mean efficiency is quantitatively described by the Minimum Efficiency Index (MEI)

which is defined and used in this document. To achieve a certain value of the Minimum Efficiency Index (MEI),

a corresponding minimum value of the mean efficiency of a size is required.

This document defines – for each pump type and size within the scope of this document - the minimum

required value of efficiency regarding a certain value of the Minimum Efficiency Index (MEI).

Normally, the qualification of a pump size for a certain MEI value done by the manufacturer will be based on

tests and evaluations made on a sample of pumps of this size. Tests and evaluations carried out for the purpose

of qualifying the corresponding size should fulfil certain requirements:

— From the tests on the sample pumps, it becomes possible to predict for the corresponding size the

confidence intervals within which the true mean values of efficiencies which are relevant for the

qualification are enclosed with a sufficiently high probability. Only in that way, the qualification of the size

in respect to a required and/or indicated value of Minimum Efficiency Index (MEI) will ensure that the

aspired effect of energy saving will be reached;

— This document provides manufacturers with a test procedure which confidently provides the MEI value

which is representative of the pump size.

Caused by technical alignment procedures of the single pump components e.g. bearings or shaft seals the

performance of the pump is gained after a certain running-in time.

Ways to prove the Minimum Efficiency Index (MEI) of a pump size

This document describes different ways how manufacturers can achieve the qualification of a pump size for a

certain value of the Minimum Efficiency Index (MEI)

The MEI value shall be based on the mean value of the type series. Annex C describes methods to determine

the mean value of MEIs and their confidence intervals.

A test to determine MEI-values on pumps of the size in question according to the requirements given in 6.2 to

6.4 of this document as well as evaluations as described in 6.5 of this document needs application of the

methodology and procedure described in Clause 5 of this document.

Relevance of clauses of this document for qualification

Clause 5 describes nominal values of minimum required efficiency for a certain value of the Minimum

Efficiency Index (MEI) and is generally relevant when applying this document.

Clause 6 specifies test procedures, test conditions and evaluations and has to be applied to determine mean

values of a size by tests on sample pumps of a certain size.

Clause 7 describes the procedure to be applied by a manufacturer in order to determine particular threshold

values of efficiency for a certain value of the Minimum Efficiency Index (MEI) of a size and to prove the

justification of this MEI value by the fulfilment of criteria for the mean efficiency values.

1 Scope

This document specifies performance requirements (methods and procedures for testing and calculating) for

determining the Minimum Efficiency Index (MEI) of rotodynamic glanded water pumps for pumping clean

water, including where integrated in other products.

The pump types and sizes covered by this document are described in the Annex A. These pumps are designed

and produced as duty pumps for pressures up to 16 bar for end suction pumps and up to 25 bar for multistage

pumps, for all pumps designed for fluid temperatures between −10 °C and +120 °C. Also covered are 4”

(10,16 cm) and 6” (15,24 cm) submersible multistage pumps designed for fluid temperatures between 0 °C

and 90 °C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN ISO 9906:2012, Rotodynamic pumps — Hydraulic performance acceptance tests — Grades 1, 2 and 3 (ISO

9906:2012)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

1)

3.1 List of quantities with definitions

3.1.1

reynolds number

dimension less number that gives a measure of the ratio of inertial forces to viscous forces and consequently

quantifies the relative importance of these two types of forces for given flow conditions; in this document, it

is defined by the relation:

Du⋅

imp

Re =

ν

where u is the peripheral velocity at the outer impeller diameter D

imp

3.1.2

(volume) rate of flow

external rate of flow of the pump, i.e. the rate of flow discharged into the pipe from the outlet branch of the

pump

Note 1 to entry: Losses or abstractions inherent to the pump, i.e.:

— discharge necessary for hydraulic balancing of axial thrust;

1)

3.1 gives specific definitions of terms - in deviation of EN ISO 9906:2012 - used in this document, together with any

associated symbols which have been allocated and is based on ISO 80000.

— cooling of bearings of the pump itself;

— water seal to the packing;

Note 2 to entry: Leakage from the fittings, internal leakage, etc., is not to be reckoned in the rate of flow. On the

contrary, all derived flows for other purposes, such as cooling of the motor bearings; cooling of a gear box (bearings, oil

cooler), etc. are to be reckoned in the rate of flow.

Note 3 to entry: Whether and how these flows shall be taken into account depends on the location of their derivation

and of the section of flow-measurement respectively.

3.1.3

motor power input

power (P ) absorbed by the pump driver

3.1.4

pump efficiency

P Pump power output

hyd

η

P Pump power input

3.1.5

motor efficiency

P

Pump power input

η

mot

P Motor power input

3.1.6

overall efficiency

P

Pump power output

hyd

η

tot

Motor power input

P

3.1.7

specific speed

dimensional number characterising the impeller type (radial, semi-axial, axial) of rotodynamic pumps

Q

BEP

nn⋅

sN

0,75

H

BEP

Note 1 to entry: For multistage pumps, H is the head per stage which results from dividing the total pump head at

BEP

the point of best efficiency by the number of stages i.

Note 2 to entry: The specific speed of an individual pump or the mean specific speed of a pump size is a (dimensional)

value which characterizes the impeller shape (radial, semi-axial, axial) of the pump or the size. The numerical value of

the specific speed is defined by a formula given in this Clause by using special units for the quantities contained in this

formula. As described in Clause 5, the specific speed is one of the parameters, which the nominal values of minimum

required efficiency depend on.

Note 3 to entry: Specific speed can be interpreted as the rotational speed of the pump with a flow of 1 m /s and the

head of 1m and is described in [1/min], although this is not due to the balance of units.

=

==

==

==

3.1.8

minimum efficiency index (MEI)

value which determines the minimum required efficiency for the qualification criteria and, thereby, is a

measure of the quality of a pump size in respect to efficiency

Note 1 to entry: Dimensionless scale unit for hydraulic pump efficiency at BEP, PL and OL.

Note 2 to entry: The MEI is the result of a statistical analysis of the performances of a large number of commercial

pump sizes, and corresponds to the various “quartiles” of the statistical distribution.

EXAMPLE MEI = 0,40 corresponds to the efficiency performance level that 40 % of the pumps on the market do not

[ ]

meet 7 .

3.2 General definitions

3.2.1

qualification

procedure where the manufacturer of the pump size proves, by appropriate methods, a given value of the MEI

(e.g. the value on the nameplate)

Note 1 to entry: Generally, the qualification criteria refer to the mean values of the size which are valid for the full

impeller diameter and which will be determined by tests and evaluations on pumps of the respective size. These mean

efficiency values and their confidence intervals are compared to nominal values of minimum required efficiency. Also,

these values depend on parameters (see Clause 5) the values of which partly result from the tests and are determined

with some uncertainty or tolerance.

3.2.2

minimum required efficiency η

min,requ

value of efficiency that shall be reached in order to fulfil a particular MEI value

Note to entry: The value of minimum required efficiency depends on certain properties of the pump size (pump type,

nominal speed of rotation, flow rate at best efficiency point and specific speed) and on the Minimum Efficiency Index

(MEI). For one size, different minimum required efficiencies are relevant at best efficiency point, at specified part load

and overload operating points, respectively.

3.2.3

particular threshold values of efficiency (η )

threshold

nominal values calculated from the minimum required efficiency respecting random sample scatter and

measurement uncertainty

3.2.4

pump size

range of pumps characterized by certain dimensions and performance (e.g. nominal diameter of discharge

flange and nominal impeller diameter for end-suction and multistage pumps, number of stages for multistage

pumps, nominal outer casing diameter in the case of submersible multistage pumps) and given in catalogues

by a manufacturer

Note to entry: In a Q-H-chart each pump size covers a certain range of Q- and H-values. Within this range each duty point

can be served by a pump of the corresponding pump size through adapting its Q-H-curve by impeller trimming, i.e. by

cutting down the outer impeller diameter to an appropriate value. The upper limit of the Q-H-range covered by one pump

size is determined by the full diameter of the impeller corresponding to this size.

3.2.5

full impeller diameter of a pump size

impeller with the maximum diameter for which performance characteristics are given for a pump size in the

catalogues of a water pump manufacturer

3.2.6

best efficiency point, BEP

operating point where the greatest value of pumps efficiency is obtained, at nominal speed of rotation

3.2.7

part load PL

particular operating point in the range of operating points with lower flow than best efficiency point, at

nominal speed of rotation

3.2.8

overload OL

particular operating point in the range of operating points with higher flow than best efficiency point, at

nominal speed of rotation

4 Symbols and abbreviations

Table 1 gives an alphabetical list of symbols used and Table 2 gives a list of subscripts. As far as possible, the

quantities, definitions and symbols used in this document comply with those used in EN ISO 9906:2012.

Quantities, definitions and symbols used in EN ISO 9906:2012, but not needed in this document are not

contained in Clause 5 and Tables 1 and 2 while these tables contain some quantities, definitions and symbols

which are not used in EN ISO 9906:2012.

In this document all formulae are given in coherent SI-units.

Table 1 — Alphabetical list of basic letters used as symbols

Symbol Quantity Unit

A Area 2

m

C Constant pure number

D Diameter m

e Measurement uncertainty, relative value pure number

f Frequency −1

s , Hz

g Acceleration due to gravity 2

m/s

H Pump total head m

k Number of instrument readings or sample pure number

pumps

m Mass kg

M Number of pumps of a sample pure number

n Speed of rotation −1 −1

s , min

N Number of instrument readings pure number

n Specific speed −1

s min

p Pressure Pa

p Probability pure number

P Power W

Symbol Quantity Unit

Q (Volume) rate of flow 3

m /s

s Standard deviation of a sample according to special quantity

t Tolerance factor, relative value pure number

t Time s

t Student’s factor pure number

T Torque Nm

u Peripheral velocity m/s

U Mean velocity m/s

U Voltage V

v Local velocity m/s

V Volume 3

m

x General quantity according to special quantity

y General quantity according to special quantity

z Height above reference plane m

z Number of produced pumps pure number

η Efficiency pure number

θ Temperature °C

ν Kinematic viscosity 2

m /s

ρ Density 3

kg/m

ω Angular velocity rad/s

σ Standard deviation of normal distribution according to special quantity

NOTE For a list of concise designations (short-term description) of pump types in scope, see Annex B.

Table 2 — List of letters and figures used as subscripts

Subscript Meaning

1 electrical

2 mechanical

abs absolute

amb ambient

annual per year

curve on fitting curve

BEP at best efficiency point

mot motor

D datum

exp experimentally determined

Subscript Meaning

G guaranteed

H pump total head

I numbering index

J numbering index

imp impeller

man manufacturing

max maximum permissible

mean mean value of pump series

min,requ minimum required

N nominal

OL overload

Pd pre-defined

P power

PL part load

Q (volume) flow rate

R random

S specific, systematic

sync synchronous

tot total, overall

true true value

T torque

T translated

v vapour

x of quantity x

y % for probability of y %

η Efficiency

hyd hydraulic

5 Minimum Required Efficiencies and Minimum Efficiency Index

5.1 The concept of “house of efficiency”

To achieve the goal of energy saving by replacing less energy efficient pumps with pumps which are qualified

in respect to fulfilling criteria of minimum required efficiency, two important aspects shall be taken into

account:

1) The required minimum values of η shall be fulfilled by the mean values of the qualified pump sizes

min,req

which are produced and sold in large numbers. Therefore, these mean values and their confidence

intervals shall be determined by appropriate methods and then be compared to minimum required values

(Formula 4) which are based on general physical interrelations (see Annex B) as well as on a statistical

evaluation of existing pumps of ”state of the art” design and manufacturing quality.

2) Not only the value of η is relevant for energy consumption and saving by pumps, but also the efficiency

BEP

in the part load and overload ranges of operation. This is caused by two reasons:

The product program of pump manufacturers for a certain pump type is – from economic reasons –

subdivided into a limited number of different pump sizes which each cover a certain range of flow rate Q

and pump head H. This leads to the effect that most unlikely for any Q-H duty point (i.e. the operating point

specified by the pump user which normally is the most probable point of operation) for a pump

application, a pump size will exist for which its best efficiency point is identical to the required duty point.

The selection of the “best choice” size for a given application will most often cause the duty point to be a

slight “off-design”, i.e. part load or overload, point of the selected size. (For more information to aspects

of pump selection, see Annex B)

Even if the best efficiency point of a pump size fits exactly to a required duty point, the pump will normally

be operated in a range of operation and not only at its duty point. This can result from changes or

variations of the hydraulic resistance of the circuit (caused either by varying demand of system flow rate

or by long time effects as, e.g. internal incrustation of pipes) or, in the case of parallel operation of pumps,

from variable operation conditions when different numbers of pumps are running.

Therefore, the qualification of a pump size in respect to minimum required efficiency is based on the so-called

concept “house of efficiency” which includes two criteria A and B.

Criterion A is the minimum efficiency requirement at the best efficiency point (BEP) of the pump size:

A. (1)

ηη≥

( ) ( )

BEP BEP

mean min, requ

Criterion B is the minimum efficiency requirement at specified part load (PL) and overload (OL) operating

points of the pump size:

ηη≥

B. (2)

( ) ( )

PL PL

mean min,requ

ηη≥ (3)

( ) ( )

OL OL

mean min,requ

In this document, the operating points which shall be representative for the efficiency in the part load and

overload range are fixed at Q = 0,75 Q and Q = 1,1 Q .

PL BEP OL BEP

All efficiency values in the criteria given above are mean values of the pump size and are to be taken for pumps

of this size with full impeller diameter.

As a result, the mean efficiency curve of the size has to show a high maximum and a broad width at high level

to fulfil the criteria for qualification.

In Figure 1, the representation of the two criteria is shown in a Q-η diagram. To be qualified, the mean

efficiency curve of the size with its maximum at the best efficiency point shall not penetrate into the “roof” of

the “house of efficiency”.

Key

η pump efficiency

Figure 1 — “House of Efficiency” — explanatory representation

5.2 Mathematical representation of minimum required efficiency

The minimum required efficiency values for pump sizes fulfilling the qualification criteria A and B are based

on scientific analyses of the attainable efficiency of rotodynamic pumps as well on a statistical evaluation of

data collected from several questionnaires sent to European pump manufacturers in 2007.

The collected data comprises all pump types within the scope of this document. The specific speed n of the

s

−1 −1

pumps forming the database ranges from 6 min to 110,5 min and the range of flow rate at best efficiency

3 3

Q is from 1,82 m /h to 1 200 m /h. The performance data supplied by the European manufacturers were

BEP

assumed to be valid for the full diameter of the respective pump sizes.

In respect of the general physical dependency of attainable mean values of efficiency on main parameters (see

Annex B), the collected data have been ordered according to a representation in the form η = f (n , Q )

BEP s BEP

for each pump type and nominal speed within the scope. This correlation is described by mathematical

Formula (4). The form of the formula is based on previous investigations. The various steps to come from the

collected data to the quantitative description of the relation η = f (n , Q ) in the form of a 3-dimensional

BEP s BEP

quadratic polynomial approximation are presented in more detail in the final report of the evaluation study.

The mathematical formula describing the relation η = f (n , Q ) is the following:

BEP s BEP

2 2

η =−11, 48 ln n −⋅0, 85 ln Q −⋅0,38 ln nQ⋅ ln + 88,59ln n + 13, 46⋅ ln Q − C (4)

( ) ( ) ( ) ( ) ( ) ( )

( ) ( )

BEP s BEP s BEP s BEP

where

η is expressed in [%];

BEP

−1

n is expressed in [min ];

s

Q is expressed in [m /h];

BEP

C: constant is expressed in [%], depending on Minimum Efficiency Index (MEI), see 5.4.

The result calculated from Formula (4) has to be rounded to the 1st digit after the decimal point.

−1 −1

NOTE 1 The mathematical range of validity of the formula is6 min ≤ n ≤ 120 min

s

3 3

2 m /h ≤ Q ≤ 1 000 m /h.

BEP

The physical range of validity of the formula is η ≤ 88 %

BEP

NOTE 2 The limitation of the physical range of validity to a maximum value of η results from the fact that the

BEP

hydraulic and mechanical losses in commercially designed and manufactured rotodynamic pumps cannot fall below a

lowest limit.

NOTE 3 Further reduction of losses would need special measures in design and manufacturing which would lead to

unacceptable efforts and costs and/or would be incompatible with other pump operating requirements as, for example,

reliability, good cavitation performance, low noise and vibration levels.

Formula (4) is valid for all pump types within the scope of this document pumping clean cold water. In the

case of vertical multistage pumps (MS-V), it is valid for a minimum stage number of 3, in the case of

submersible multistage pumps (MSS) for a minimum stage number of 9. Generally, the formula is valid for the

full impeller diameter of a pump size.

The efficiency values concern pump efficiency only, not the overall efficiency (wire-to-water) even in the case

of close coupled pump-motor units.

5.3 Minimum efficiency at part load and overload

In [7], the pump data given by the manufacturers was also evaluated at selected part load (0,75 Q ) and

BEP

overload (1,10 Q ) operating points.

BEP

Part load and overload coefficients are defined by Formula (5):

η η

PL OL

xx; (5)

PL OL

η η

BEP BEP

were calculated for each pump type. The mean value of these coefficients was found to be x = 0,947 and

PL

x = 0,985 for all pump types in good approximation.

OL

Using the relation described in 5.2 for η , the minimum efficiency requirements for the selected operating

BEP

points at part load and overload are calculated by Formulae (6) and (7):

(6)

ηη0, 947⋅

( ) ( )

PL BEP

min, requ min, requ

(7)

ηη0, 985⋅

( ) ( )

OL BEP

min, requ min,requ

5.4 Minimum Efficiency Index

By varying the constant C in the formula for η , the curves resulting from Formula (4) and plotted in a n -

BEP s

η - diagram for constant values of Q are shifted in the vertical η-direction (see Figure 3 as an

min,requ BEP

example). With a chosen value of C for a pump type and rotational speed within the scope, the existing pumps

of this type produced by the European manufacturers are split into a percentage of the total number of pump

sizes which already fulfil the corresponding minimum efficiency requirement (in respect to criteria A and B)

and the (complementary) percentage of those which do not fulfil this requirement., Consequently, pumps not

fulfilling the requirement will be replaced on the market by pumps which are qualified in respect to the criteria

A and B. The quantitative effect of the qualification criteria (finally determined by the value C) on the market

and energy saving effect is characterized by the Minimum Efficiency Index (MEI). In the statistical evaluation

=

=

==

[7], the Minimum Efficiency Index (MEI) was determined such that its value, multiplied by 100, indicates the

percentage of existing pump sizes which do not fulfil the qualification criteria A and B for the corresponding

value of C. To come to these results, the data for each pump given by the pump manufacturer were taken as

being representative for the total number of pumps of the corresponding size with full impeller diameter.

NOTE 1 The Minimum Efficiency Index (defined as described above) is a measure for the quality of a pump size in

respect to efficiency. At the lower limit MEI = 0, the corresponding efficiencies of pump sizes can be achieved on a low

level of design and manufacturing. For values of MEI > 0,7 the corresponding efficiencies of pump sizes can only be

achieved by a very special hydraulic design which only aims at high efficiency and does not respect other hydraulic

aspects as, e.g. good cavitation performance, and additionally by exceptional measures in mechanical design and

manufacturing.

NOTE 2 The maximum effect of reducing energy consumption by using pumps with high MEI will only be achieved if

the pumps are carefully selected for required duties (see Annex B).

Table 3 shows the values of C for the pump types within the scope and for different values of the Minimum

Efficiency Index (MEI).

Table 3 — Values of the constant C for different values of the Minimum Efficiency Index (MEI)

Minimum Efficiency Index

0,10 0,20 0,30 0,40 0,50 0,60 0,70

C (ESOB 1450) 132,58 130,68 129,35 128,07 126,97 126,10 124,85

C (ESOB 2900) 135,60 133,43 131,61 130,27 129,18 128,12 127,06

C (ESCC 1450) 132,74 131,20 129,77 128,46 127,38 126,57 125,46

C (ESCC 2900) 135,93 133,82 132,23 130,77 129,86 128,80 127,75

C (ESCCi 1450) 136,67 134,60 133,44 132,30 131,00 130,32 128,98

C (ESCCi 2900) 139,45 136,53 134,91 133,69 132,65 131,34 129,83

C (MS-V 2900) 138,19 135,41 134,89 133,95 133,43 131,87 130,37

C (MSS 2900) 134,31 132,43 130,94 128,79 127,27 125,22 123,84

Examples of efficiency values resulting from Formula (4) for certain values of MEI are shown in Figures 2

and 3.

-1

Figure 2 — Two-dimensional representation of η = f (n ,Q ) for ESOB, n = 2 900 min and

BEP s BEP

MEI = 0,70 (see Table 3)

3 −1

Figure 3 — η = f (n ) for ESOB with Q = 32 m /h, 2 900 min and for different values of MEI

BEP s BEP

(see Table 3)

For the choice of the value of MEI within the qualification procedure, the following applies:

1) the value of the Minimum Efficiency Index (MEI) can be chosen (and proven by a qualification procedure)

by the pump manufacturer to indicate the quality of a pump size in respect to efficiency;

2) minimum values of MEI can be fixed by law, or EU regulations for market acceptance in order to reduce

overall energy consumption.

Examples of graphical representations for one pump type and rotational speed are given in Figures 2 and 3.

Figure 2 shows the principal dependence of η on the specific speed n and on the flow rate at best

min,requ s

efficiency Q . In Figure 3, the effect of varying the value of MEI on η is demonstrated.

BEP min,requ

In the frame of qualification of a pump size, the values of Q and n — which η depends on — shall

BEP s min,requ

themselves be determined by tests on sample pumps and are not known a priori nor do they result from the

tests as exact or true values. The determination of Q and n from tests on sample pumps is subjected to

BEP s

effects of manufacturing tolerances within the size (see Annex C) and of measurement uncertainties (see

Clause 6). Therefore, the values of Q and n can only be determined to be confined to corresponding

BEP s

confidence intervals. When calculating η by the means of Formula (4) the uncertainties of Q and

min,requ BEP

n propagate into the result. In this document, the value of η which is calculated by the means of

s min,requ

Formula (4) using as input the measured (and – in the case of a sample of M > 1 pumps – arithmetically

averaged) values of Q and n is called nominal value of minimum required efficiency.

BEP s

6 Determination of the efficiency of a test pump

6.1 General

This clause specifies performance tests and evaluations on test pumps drawn at random out of a size which

are carried out by a manufacturer in the case he has decided to qualify this size in respect to a certain value of

Minimum Efficiency Index (MEI) by applying these tests and evaluations.

Such tests and evaluations shall provide the necessary information on the actual performance values of test

pumps needed for the qualification procedure described in Clause 7. These values comprise:

1) the flow rate at best efficiency point Q from which also the values of flow rate Q and Q at specified

BEP PL OL

part load and overload operating points (defined in 5.1), respectively, can be derived,

2) the maximum efficiency η at Q and the values of efficiency η and η at the corresponding

BEP BEP PL OL

values of flow rate Q and Q ,

PL OL

3) the specific speed n which is needed to determine the minimum required efficiencies (see 5.2 to 5.4).

s

Regarding the requirements on test installations and measuring equipment, EN ISO 9906:2012 is to be

applied.

6.2 Test procedures

Test procedure and measurement instrumentation shall be in accordance with EN ISO 9906:2012 grade 2. The

acceptance grade should not be used. The exception for input power of 10 kW and below (see

EN ISO 9906:2012, 4.4.2) shall not be considered.

For pumps (P ) < 1 kW it is strongly recommended to test a sample number higher than 3 in order to ensure

a higher reliability to determine mean values and keep confidence intervals small.

1) Tests shall be carried out on test stands of the manufacturer or of laboratories in accordance to the

methods and in the test arrangements, specified in EN ISO 9906:2012;

2) the pump performance shall be determined between the pump’s inlet flange and discharge flange.

The conditions necessary to ensure satisfactory measurement of the performance characteristics are defined

in 6.3.

Recommendations and general guidance about suitable pipe arrangements to ensure satisfactory

measurements for flow and head are given in EN ISO 9906:2012, A.3 and, if necessary, they can be used in

conjunction with the ISO Standards on measurement of flow rates in closed conduits concerning the different

methods (see EN ISO 9906:2012, A.1).

As explained in EN ISO 9906:2012, A.1.4, the pump power input which is needed to determine the pump

efficiency can be experimentally determined either:

— by measurements of rotational speed and torque, or

— by electric power measurements.

Where the electrical power input to an electric motor coupled directly to the pump is used as a means of

determining the pump power input, the motor should be operated only under conditions where the efficiency

is known with sufficient accuracy. Motor efficiency should be determined in accordance with the

recommendations of IEC 60034-2-1:2014, IEC 60034-2-2:2010, or IEEE 112:2017 method B and should be

stated by the motor manufacturer or derived through a unit specific motor test.

In the case of testing a pump with an integrated electric motor in the frame of the MEI Determination, the

motor efficiency dependent on the motor load shall be found out in a suitable way, e.g. by information given

by the motor manufacturer or by disassembling the test pump and calibrating the motor as described in the

previous paragraph.

For sizes of multistage pumps which are offered and sold by the manufacturer with different numbers of

stages, the tests on test pumps which should be representative (in respect to the efficiency) for the size shall

be carried out on pump versions with at least 3 stages for multistage pumps (MS-V) and with at least 9 stages

for submersible multistage pumps (MSS).

The test pumps taken out of a pump size shall have an impeller with the full diameter of the corresponding

pump size.

NOTE Trimming a pump of a given size by cutting down the impeller diameter will reduce the pump efficiency

compared to the efficiency of the same pump size with full diameter but overall saves energy as the trimmed impeller

suits the required duty point in the pumping system.

The test results shall be summarized in a report. Further guidance regarding the contents of a test report and

a suitable pump test sheet is given in EN ISO 9906:2012.

6.3 Test conditions

Tests shall be carried out with clean cold water. The duration of the test shall be sufficient to obtain repeatable

results; especially run-in effects shall be considered.

Run-in effects may take up to one day operating time.

All measurements shall be made under steady-state conditions (see 6.4).

The tests should be conducted under conditions where cavitation does not affect the performance of the pump.

NOTE If cavitation exists to a remarkable extent in the test pump during the tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...