EN 1317-5:2007+A2:2012

(Main + Amendment)Road restraint systems - Part 5: Product requirements and evaluation of conformity for vehicle restraint systems

Road restraint systems - Part 5: Product requirements and evaluation of conformity for vehicle restraint systems

This European Standard specifies requirements for evaluation of conformity of the following vehicle restraint systems:

a) safety barriers;

b) crash cushions;

c) terminals (will be effective when ENV 1317-4 becomes an EN);

d) transitions (will be effective when ENV 1317-4 becomes an EN);

e) vehicle / pedestrian parapets (only for the vehicle restraint function).

Pedestrian parapet requirements are not covered in this document.

Requirements for the evaluation of durability with respect to weathering are included in this document.

Requirements for other forms of durability (e.g. marine environment, sand abrasion) are not included.

Temporary barriers are not within the scope of this document.

Rückhaltesysteme an Straßen - Teil 5: Anforderungen an die Produkte, Konformitätsverfahren und -bewertung für Fahrzeugrückhaltesysteme

Diese Europäische Norm legt Anforderungen an die Bewertung der Konformität für die folgenden Fahrzeug-Rückhaltesysteme fest:

a) Schutzeinrichtungen;

b) Anpralldämpfer;

c) Anfangs-/Endkonstruktionen (wird wirksam, sobald die ENV 1317 4 eine EN wird);

d) Übergangskonstruktionen (wird wirksam, sobald die ENV 1317 4 eine EN wird);

e) Fahrzeug /Fußgängerbrüstungen (nur für die Funktion zur Fahrzeugrückhaltung).

Anforderungen an Fußgängerbrüstungen sind in diesem Dokument nicht enthalten.

Anforderungen an die Bewertung der Dauerhaftigkeit gegenüber Verwitterung sind in diesem Dokument enthalten.

Anforderungen an andere Formen der Dauerhaftigkeit (z. B. maritime Umgebung, Sandabrieb) werden nicht erfasst.

Temporäre Schutzeinrichtungen fallen nicht in den Anwendungsbereich dieses Dokumentes.

Dispositifs de retenue routiers - Partie 5: Exigences relatives aux produits et évaluation de la conformité pour les dispositifs de retenue pour véhicules

Cette Norme européenne spécifie les exigences relatives à l’évaluation de la conformité des dispositifs de retenue routiers suivants :

a) barrières de sécurité ;

b) atténuateurs de choc ;

c) extrémités (prendra effet lorsque la norme ENV 1317-4 deviendra une norme EN) ;

d) raccordements (prendra effet lorsque la norme ENV 1317-4 deviendra une norme EN) ;

e) barrières ayant la double fonction retenue des véhicules et des piétons (uniquement pour la fonction retenue des véhicules).

Les exigences relatives aux garde-corps ne sont pas couvertes par ce document.

Les exigences relatives à l’évaluation de la durabilité à l’égard des conditions météorologiques sont comprises dans ce document.

Les exigences relatives à d’autres formes de durabilité (par exemple environnement marin, abrasion du sable) ne sont pas comprises.

Les barrières temporaires n’entrent pas dans le champ d’application de ce document.

Oprema cest - 5. del: Zahteve za proizvode in ugotavljanje skladnosti za sisteme za zadrževanje vozil

Ta evropski standard določa zahteve za ugotavljanje skladnosti naslednjih sistemov za zadrževanje vozil:

a) varnostne ovire;

b) blažilniki trkov;

c) priključki (veljati začne, ko bo ENV 1317-4 postal standard EN);

c) prehodi (veljati začne, ko bo ENV 1317-4 postal standard EN);

e) ograje za vozila/pešce (le v zvezi s funkcijo zadrževanja vozil).

Ta dokument ne zajema zahtev za ograje za pešce.

Zahteve za oceno trajnosti v zvezi z izpostavljenostjo vremenskim vplivom so zajete v ta dokument.

Zahteve za druge oblike trajnosti (npr. morsko okolje, obraba s peskom) niso zajete.

Občasne ovire niso zajete v področje uporabe tega dokumenta.

General Information

- Status

- Published

- Publication Date

- 20-Mar-2012

- Withdrawal Date

- 29-Sep-2012

- Technical Committee

- CEN/TC 226 - Road equipment

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 21-Mar-2012

- Completion Date

- 21-Mar-2012

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 18-Jan-2012

- Effective Date

- 18-Jan-2012

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 1317-1:2010 - Road restraint systems - Part 1: Terminology and general criteria for test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1317-5:2007+A2:2012 is a CEN European product standard for road restraint systems that defines product requirements and conformity evaluation procedures for vehicle restraint systems. It covers safety-critical products including safety barriers, crash cushions, terminals, transitions and combined vehicle/pedestrian parapets (vehicle restraint function only). The standard mandates durability assessment with respect to weathering but excludes other durability environments (e.g., marine, sand abrasion) and temporary barriers.

Key Topics and Requirements

- Scope and product coverage

- Safety barriers, crash cushions, terminals*, transitions*, vehicle/pedestrian parapets.

- *Terminals and transitions are subject to ENV 1317‑4 becoming an EN; combined parapet heights reference prEN 1317‑6 when adopted.

- Performance under impact

- Products must be tested and comply with impact test criteria referenced in EN 1317‑1 and the relevant part (EN 1317‑2 for barriers and parapets, EN 1317‑3 for crash cushions, ENV 1317‑4 for terminals/transitions).

- Minimum threshold levels are specified (examples in the standard: crash cushions Class 50; terminals P1; safety barriers/combined parapets N1).

- Durability

- Weathering durability evaluation is required. Manufacturers must declare materials, protective coatings and an assessment of durability (coating specifications, material composition, concrete/precast rules, wood treatment where applicable).

- Other harsh-environment durability (marine, sand) is not covered and must be addressed separately.

- Technical documentation

- Product drawings, component geometries, materials and finishes, parts lists, installation procedures, maintenance and repair instructions, and details of approved modifications.

- Conformity assessment

- Demonstrated by Initial Type Testing (ITT) and ongoing Factory Production Control (FPC). Accredited testing laboratories (EA signatories) are expected for competence.

- Definitions

- Working life, durability, manufacturer responsibilities and testing laboratory competence are defined to support conformity claims.

Applications and Who Uses It

- Road equipment manufacturers seeking CE marking and market access across CEN member states.

- Product designers and engineers developing safety barriers, crash cushions and parapets.

- Road authorities, specifiers and procurers writing performance-based contracts and technical specifications.

- Testing laboratories, certification bodies and quality managers performing ITT and FPC.

- Installers and maintenance teams using the installation and maintenance requirements to ensure in-service performance.

Related Standards

- EN 1317 series: Part 1, Part 2, Part 3, ENV 1317‑4 (terminals/transitions), prEN 1317‑6 (pedestrian parapets)

- Normative references: EN ISO 1461, EN 206‑1, EN 10346, EN 13369, EN 335‑1/2, EN ISO 9001:2008

Keywords: EN 1317-5:2007+A2:2012, road restraint systems, vehicle restraint systems, safety barriers, crash cushions, conformity assessment, durability, Initial Type Testing, Factory Production Control, CEN.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 1317-5:2007+A2:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Road restraint systems - Part 5: Product requirements and evaluation of conformity for vehicle restraint systems". This standard covers: This European Standard specifies requirements for evaluation of conformity of the following vehicle restraint systems: a) safety barriers; b) crash cushions; c) terminals (will be effective when ENV 1317-4 becomes an EN); d) transitions (will be effective when ENV 1317-4 becomes an EN); e) vehicle / pedestrian parapets (only for the vehicle restraint function). Pedestrian parapet requirements are not covered in this document. Requirements for the evaluation of durability with respect to weathering are included in this document. Requirements for other forms of durability (e.g. marine environment, sand abrasion) are not included. Temporary barriers are not within the scope of this document.

This European Standard specifies requirements for evaluation of conformity of the following vehicle restraint systems: a) safety barriers; b) crash cushions; c) terminals (will be effective when ENV 1317-4 becomes an EN); d) transitions (will be effective when ENV 1317-4 becomes an EN); e) vehicle / pedestrian parapets (only for the vehicle restraint function). Pedestrian parapet requirements are not covered in this document. Requirements for the evaluation of durability with respect to weathering are included in this document. Requirements for other forms of durability (e.g. marine environment, sand abrasion) are not included. Temporary barriers are not within the scope of this document.

EN 1317-5:2007+A2:2012 is classified under the following ICS (International Classification for Standards) categories: 13.200 - Accident and disaster control; 93.080.30 - Road equipment and installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1317-5:2007+A2:2012 has the following relationships with other standards: It is inter standard links to EN 1317-5:2007+A1:2008, EN 1317-5:2007+A1:2008/FprA2, EN 1317-3:2010, EN 206:2013+A2:2021, EN 10346:2015, ENV 1317-4:2001, EN ISO 9001:2008, EN 335:2013, EN 13369:2023, EN ISO 1461:2022, EN 1317-1:2010, EN 1317-2:2010, CEN/TR 16303-3:2012, CEN/TR 16303-1:2012, CEN/TR 16303-4:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1317-5:2007+A2:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/111. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1317-5:2007+A2:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Oprema cest - 5. del: Zahteve za proizvode in ugotavljanje skladnosti za sisteme za zadrževanje vozilRückhaltesysteme an Straßen - Teil 5: Anforderungen an die Produkte, Konformitätsverfahren und -bescheinigung für FahrzeugrückhaltesystemeDispositifs de retenue routiers - Partie 5: Exigences relatives aux produits et évaluation de la conformité pour les dispositifs de retenue pour véhiculesRoad restraint systems - Part 5: Product requirements and evaluation of conformity for vehicle restraint systems93.080.30Cestna oprema in pomožne napraveRoad equipment and installations13.200NDWDVWURIAccident and disaster controlICS:Ta slovenski standard je istoveten z:EN 1317-5:2007+A2:2012SIST EN 1317-5:2007+A2:2012en,fr,de01-maj-2012SIST EN 1317-5:2007+A2:2012SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1317-5:2007+A2

March 2012 ICS 13.200; 93.080.30 Supersedes EN 1317-5:2007+A1:2008 English Version

Road restraint systems - Part 5: Product requirements and evaluation of conformity for vehicle restraint systems

Dispositifs de retenue routiers - Partie 5: Exigences relatives aux produits et évaluation de la conformité pour les dispositifs de retenue pour véhicules

Rückhaltesysteme an Straßen - Teil 5: Anforderungen an die Produkte, Konformitätsverfahren und -bewertung für Fahrzeugrückhaltesysteme This European Standard was approved by CEN on 28 September 2006 and includes Amendment 1 approved by CEN on 30 May 2008 and Amendment 2 approved by CEN on 23 January 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1317-5:2007+A2:2012: ESIST EN 1317-5:2007+A2:2012

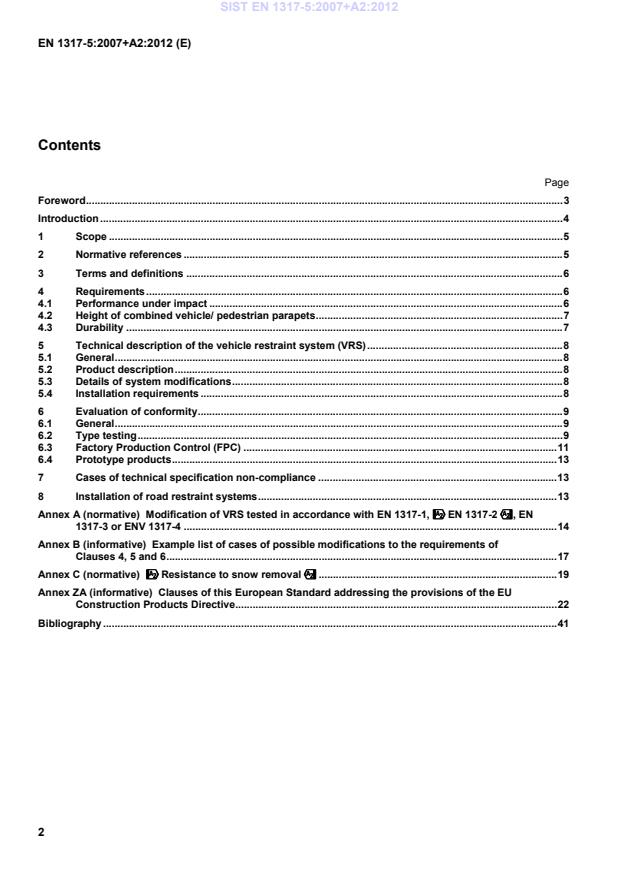

Modification of VRS tested in accordance with EN 1317-1, ####EN 1317-2$$$$, EN 1317-3 or ENV 1317-4 . 14Annex B (informative)

Example list of cases of possible modifications to the requirements of Clauses 4, 5 and 6 . 17Annex C (normative)

####Resistance to snow removal$$$$ . 19Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive . 22Bibliography . 41 SIST EN 1317-5:2007+A2:2012

!" and # $. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document. This European Standard consists of this document and the following parts under the general title: Road restraint systems. Part 1: Terminology and general criteria for test methods Part 2: Performance classes, impact test acceptance criteria and test methods for safety barriers Part 3: Performance classes, impact test acceptance criteria and test methods for crash cushions Part 4: Performance classes, impact test acceptance criteria and test methods for terminals and transitions of safety barriers Part 6: Pedestrian restraint system According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

prEN 1317 part 4 and 7). To ensure the full performance of road restraint systems in use, their production and installation is intended to be controlled in accordance with this document.$ SIST EN 1317-5:2007+A2:2012

#EN 1317-2$. 4.1.3 Crash cushions Crash cushions shall be tested to and shall conform to the requirements of EN 1317-1 and EN 1317-3. 4.1.4 Terminals Terminals shall be tested to and shall conform to the requirements of EN 1317-1 and ENV 1317-4 (will be effective when ENV 1317-4 becomes an EN). SIST EN 1317-5:2007+A2:2012

#EN 1317-2$ and prEN 1317-6 (will be effective when prEN 1317-6 becomes an EN). 4.1.7 Threshold levels Vehicle restraint systems shall conform to the minimum threshold levels defined in Table 1. Table 1 – Minimum threshold levels for vehicle restraint systems Safety barriers EN 1317-2 (in accordance with Table 2) N1 Crash cushions EN 1317-3 (in accordance with Table 3) Class 50 Terminals ENV 1317-4 (in accordance with Table 1) P1 Transitions ENV 1317-4 (in accordance with 4.2) N1 Combined vehicle/parapets EN 1317-2 (in accordance with Table 2) and prEN 1317-6 N1

4.2 Height of combined vehicle/ pedestrian parapets The height of combined vehicle / pedestrian parapets shall conform to prEN 1317-6 (will be effective when

prEN 1317-6 becomes an EN). 4.3 Durability All vehicle restraint systems shall be durable for an economically reasonable working life, for which a reviewable experience-based description and / or related measurements of durability shall be adequate. Road restraint systems can have foundation systems, the economically reasonable working life of which relates to the supporting structure, and this needs to be reported separately to that of the road restraint system if supplied by the VRS manufacturer. a) Manufacturer shall declare the materials and protective coatings used on the road restraint system; b) manufacturer shall declare an assessment of durability including the identification of technical characteristics of materials affecting durability, and the methods of evaluation (e.g. coating mass determination, adhesion testing). Issues affecting durability may include the following examples: c) specification of protective coating in accordance with EN ISO 1461 and EN 10326 and/or level of treatment of materials; d) composition and thickness of material in accordance with EN 206-1 for concrete and EN 13369 for precast concrete; SIST EN 1317-5:2007+A2:2012

#EN 1317-2$ and EN 1317-3 or ENV 1317-4, where it is considered that the selected property/properties is/are common to all road restraint systems within that family (for example, crash cushions conforming to this document). 6.2 Type testing 6.2.1 Initial Type Testing (ITT) 6.2.1.1 General An initial type test is the complete set of tests conforming to EN 1317-1 and #EN 1317-2$,

EN 1317-3 or ENV 1317-4. To demonstrate conformity with this document an ITT shall be performed on each VRS. Modified products shall be evaluated in accordance with 6.2.1.5. 6.2.1.2 Information required in the ITT As a minimum, the manufacturer shall provide the information for assessment in accordance with 5.2 and 5.3, the full-scale vehicle impact test report and the evaluation report of the tested item. 6.2.1.3 Evaluation report of test item The evaluation report shall comprise the following information: a) verification that materials are as specified by the manufacturer in accordance with 5.2; b) verification that geometries and dimensions are as specified by the manufacturer in accordance with 5.2; c) verification of protective treatments, if any; d) soils and foundations report relating to the ITT; e) verification that the product is installed in accordance with the specified layout in accordance with 5.4. 6.2.1.4 Initial Type Test report The ITT report shall include the following information as a minimum: a) impact test report to EN 1317-1, #EN 1317-2$, EN 1317-3 or ENV 1317-4; SIST EN 1317-5:2007+A2:2012

1 For specific products (e.g. for design using Eurocodes) special provisions may apply. SIST EN 1317-5:2007+A2:2012

#EN ISO 9001:2008$, 7.5.1 and 7.5.2 shall be deemed to satisfy the requirements of this clause. 6.3.3.4 Traceability and marking Individual road restraint systems shall be identifiable and traceable with regard to their production origin. The manufacturer shall have procedures ensuring that processes related to affixing traceability codes and/or markings are inspected regularly. Documented traceability records shall be available for at least 5 years from the date of manufacture. Compliance with #EN ISO 9001:2008$, 7.5.3 shall be deemed to satisfy the requirements of this clause. 6.3.3.5 Non-conforming products The manufacturer shall have written procedures, which specify how non-conforming products shall be dealt with. Any such events shall be recorded as they occur and these records shall be kept for the period defined in the manufacturer’s written procedures. Compliance with #EN ISO 9001:2008$, 8.3 shall be deemed to satisfy the requirements of this clause. 6.3.3.6 Corrective action The manufacturer shall have documented procedures that instigate action to eliminate the cause of non-conformities in order to prevent recurrence. Compliance with #EN ISO 9001:2008$, 8.5.2 shall be deemed to satisfy the requirements of this clause. SIST EN 1317-5:2007+A2:2012

Modification of VRS tested in accordance with EN 1317-1, ####EN 1317-2$$$$, EN 1317-3 or ENV 1317-4 A.1 General This annex gives rules for evaluation of conformity concerning Parts 1, 2, 3, 4 of an approved VRS, which has been modified and methods by which to demonstrate the extent to which the modification has changed its performance. NOTE After Initial Type Testing, VRS may be altered on the basis of new technology and knowledge whereby improvements and modification of their components can take place. In some cases, as specified in A.4 and A.5, a VRS may be evaluated by a reduced number of impact tests or by calculations, computer simulations or simple loading tests. A.2 Modified VRS A modified VRS is a VRS that previously conformed to this document, which has been changed by material design or dimension in such a way that can affect characteristics, which are subject to requirements in this document. NOTE 6.2.1.5 of this part provides requirements for evaluating the effect of modifications. A.3 Types of modifications The types of modifications shall be classified in accordance with Table A.1. Table A.1 – Categories of modifications Category Change Description A Slight Modifications requiring no mechanical changes to the VRS. B Moderate Modifications to one or more components where their effects on the performance of the VRS can be determined by static or dynamic analysis or other appropriate means. C Significant Modifications in excess of A or B.

A.5 Reduced test matrix for category C A.5.1 General Where a change requires additional impact tests, the number of tests may be reduced in comparison to the original matrix of EN #EN 1317-2$, EN 1317-3 or ENV 1317-4, in the following cases. A.5.2 Longitudinal barrier or transition The barrier shall be deemed to conform to the requirements of this document without the need to carry out the TB 11 test, provided that modified barrier has passed the TB 32 or higher level test, in accordance with the ITT, and provided that all the following conditions are satisfied: There are no changes made to the external geometry (traffic face), especially the location of the main components and their dimensions, which could modify the interaction with other components or with the light vehicle. In the case of a barrier with only one longitudinal rail, the normalized dynamic deflection2 from the containment level test on the modified product shall not differ by more than +20 % to -10 % from the normalized dynamic deflection determined under the same performance level and conditions in the original ITT. In the case of barriers with more than one rail, the modification shall not affect the rails in contact with the car during the TB11 test and the normalized dynamic deflection2 from the containment level test on the modified product shall not differ by more than +20 % to -10 % from the normalized dynamic deflection determined under the same performance level and conditions in the original ITT. In the case where some of the modified components are subject to controlled failure, it shall be demonstrated that the behaviour with small vehicle is not affected.

2 #Definition can be found in EN 1317-2:2010, 3.5.$ SIST EN 1317-5:2007+A2:2012

Example list of cases of possible modifications to the requirements of Clauses 4, 5 and 6 This list is indicative only and not exhaustive. Barriers Category A − Barrier undergoes repainting. − Pre-cast concrete barrier has additional reinforcement for production reasons. Category B − Metal barrier was originally tested with sloped end terminals and a revised end treatment is provided, maintaining the same anchorage. − Change of type of anchoring bolts in a metal barrier, where they are not designed to yield. − Metal barrier, where component rail length is increased. − Rope barrier, where section length between anchorages is reduced. Category C − Precast concrete barrier with jointed elements, which need to be replaced with revised joints. − Metal barrier where type or grade of metal is changed. − Change of type of bolts in a metal barrier where they are designed to yield.

Crash cushions Category A − Cushion changes to a nose of a type of plastic with similar mechanical properties. − Cushion has changes involving a light plastic shell meant for aesthetic reasons only, not as part of the working energy absorption system. − Cushion undergoes repainting.

Category B − Cushion has changes to slider bolts. − Cushion has changes to the design of the rear backup or use of a concrete in-situ backup. − Cushion is subjected to changes to the size or material of bolts and nuts that do not undergo deformation during an impact. Category C − Cushion has changes to absorbing elements. − Cushion has changes to lateral shielding panels. − Cushion has changes to the yielding anchorages.

Terminals Category A − Terminal nose changes to a type of plastic with similar mechanical properties to the tested item. − Terminal has changes to fixings with the same characteristics but vandal-proofing. Category B − Terminal changes to slider bolts. − Mdular terminal has changes to the intermediate supporting frames. − Terminal is subjected to changes to the sizes or materials of bolts and nuts that do not undergo deformation during impact. Category C − Terminal is subjected to changes to the absorbing elements. − Terminal is subjected to changes to lateral shielding panels. − Terminal changes to yielding anchorages.

####Resistance to snow removal C.1 General Snow removal may damage a safety barrier which has not a sufficient resistance to snow removal.

C.2 Scope This normative annex includes a classification of safety barriers for the resistance to snow removal. It includes the horizontal and vertical pressure of ploughed snow against the rail and minor impacts caused by the plough in the traffic face and upper edge of the rail. A simplified evaluation method is intended for normal steel beam barriers, rope fences and monolithic pre-cast or cast-in-place concrete barriers. A test is possible for other barrier types.

The specifying authority shall decide if classification is required.

This annex is not intended to be used with crash cushions, terminals and transitions. C.3 Requirements Metal beam safety barriers shall be classified into classes on the basis of Table C.1. Table C.1 - Resistance to snow removal of metal beam safety barriers

Class of resistance to snow ploughing Modified material thickness of a rail in steel a Modified section modulus

against horizontal loads a Strength against vertical loads of the connection between a post and a rail Open profile (mm) Tube

(mm) Rail

(cm3) Post

(cm3)

4 ≥ 4

≥ 2,9

≥ 10 ≥ 12 > Shear strength of M10

4,6 bolt 3 ≥ 3 ≥ 2,2

≥ 5 ≥ 9 > Shear strength of M10

4,6 bolt 2 Rope fence 1 Other a The modified material thickness and section modulus is defined in C.4. SIST EN 1317-5:2007+A2:2012

(1) where tmod

is the modified material thickness of the rail; t

is the nominal steel thickness of the rail; fyd

is the design yield strength of the rail material. The nominal material thickness of the rail shall be observed from the drawings.

C.4.2 Modified section modulus The modified section modulus of the post and rail against horizontal loads shall be calculated on the basis of the post and rail profile by using the following equations:

Wmod, rail = Wrail x fyd/(235N/mm2/1.1)

(2)

Wmod, post = Wpost x f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...