EN 17141:2020

(Main)Cleanrooms and associated controlled environments - Biocontamination control

Cleanrooms and associated controlled environments - Biocontamination control

This document establishes the requirements, recommendations and methodology for microbiological contamination control in clean controlled environments. It also sets out the requirements for establishing and demonstrating microbiological control in clean controlled environments.

This document is limited to viable microbiological contamination and excludes any considerations of endotoxin, prion and viral contamination.

There is specific guidance given on common applications, including Pharmaceutical and BioPharmaceutical, Medical Devices, Hospitals and Food.

Reinräume und zugehörige Reinraumbereiche - Biokontaminationskontrolle

Dieses Dokument legt die Anforderungen, Empfehlungen und Methodiken für die mikrobiologische Kontaminationskontrolle in auf Sauberkeit kontrollierten Bereichen fest. Darüber hinaus legt dieses Dokument die Anforderungen an die Erstellung und den Nachweis der mikrobiologischen Kontrolle in auf Sauberkeit kontrollierten Bereichen fest.

Dieses Dokument beschränkt sich auf lebensfähige mikrobiologische Kontamination und schließt alle Betrachtungen endotoxiner, proteinös-infektiöser und viraler Kontamination aus.

Es bestehen spezifische Leitfäden zu gemeinsamen Anwendungen, einschließlich Pharma/Biopharma, Medizinprodukte, Krankenhäuser und Lebensmittel.

Salles propres et environnements maîtrisés apparentés - Maîtrise de la biocontamination

Le présent document établit les exigences, les recommandations et la méthodologie relatives à la maîtrise de la contamination microbiologique en environnement propre maîtrisé. Il définit également les exigences à mettre en œuvre pour établir et démontrer la maîtrise microbiologique en environnement propre maîtrisé.

Le présent document se limite à la contamination microbiologique viable et exclut toute considération quant à la contamination par endotoxine, par prion et par virus.

Il fournit des recommandations spécifiques concernant certains domaines d‘activités courants, comme les secteurs pharmaceutiques et biopharmaceutiques, les dispositifs médicaux, les hôpitaux et l’agro alimentaire.

Čiste sobe in podobna nadzorovana okolja - Kontrola biokontaminacije

General Information

- Status

- Published

- Publication Date

- 11-Aug-2020

- Withdrawal Date

- 27-Feb-2021

- Technical Committee

- CEN/TC 243 - Cleanroom technology

- Drafting Committee

- CEN/TC 243/WG 5 - Biocontamination control

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 12-Aug-2020

- Due Date

- 28-Nov-2019

- Completion Date

- 12-Aug-2020

Relations

- Effective Date

- 19-Aug-2020

- Effective Date

- 19-Aug-2020

- Effective Date

- 15-Jul-2020

- Effective Date

- 28-Jan-2026

Overview

EN 17141:2020 - published by CEN - defines requirements, recommendations and a methodology for microbiological (viable) contamination control in cleanrooms and associated controlled environments. The standard focuses on establishing and demonstrating microbiological control in clean controlled environments and explicitly excludes endotoxin, prion and viral contamination. It provides targeted guidance for common sectors: pharmaceutical and biopharmaceutical, medical devices, hospitals (healthcare) and food.

Key topics and requirements

- Establishment of microbiological control systems

- Formal system design, quality attributes and documentation requirements.

- Identification of potential sources and routes of viable microbiological contamination.

- Risk assessment to determine controls and monitoring scope.

- Microbiological environmental monitoring (EM)

- Development of EM plans: monitoring locations, frequencies, and sampling strategies.

- Setting alert and action limits and procedures for Out Of Specification (OOS) events.

- Measurement and sampling methods

- Guidance on choice and validation of sampling methods (air samplers, settle plates, contact plates, swabs, sponges).

- Culture media, incubation and incubator guidance for culture-based methods.

- Verification and revalidation of volumetric air samplers and sampler collection efficiencies.

- Data, trending and verification

- Data recording, integrity, tracking and trend analysis to demonstrate ongoing control.

- Investigation and corrective actions for excursions.

- Rapid and alternative methods

- Framework for implementing Rapid Microbiological Methods (RMMs) and Alternative Microbial Methods (AMMs), including validation and acceptance considerations.

- Personnel and documentation

- Training and competency expectations; robust documentation and record-keeping.

Practical applications and who uses it

EN 17141:2020 is used by organizations that design, operate or qualify clean controlled environments where viable microbiological contamination is a concern:

- Pharmaceutical & biopharmaceutical manufacturers - to support sterile and non‑sterile product risk assessment and EM strategies.

- Medical device manufacturers - for sterile-processing areas and classification of device-related microbiological risk.

- Hospitals and healthcare facilities - operating room and critical area contamination control.

- Food manufacturers - for hygienic design and environmental monitoring of production zones.

- Cleanroom engineers, QA/QC, microbiologists, validation specialists and compliance teams - to establish controls, demonstrate compliance and guide investigations.

Related standards

- Issued by CEN; EN 17141:2020 supersedes EN ISO 14698‑1:2003 and EN ISO 14698‑2:2003.

- Complementary to other cleanroom and GMP guidance used in regulated industries.

Keywords: EN 17141:2020, cleanrooms, biocontamination control, microbiological contamination control, environmental monitoring, pharmaceutical cleanroom, medical device cleanroom, food hygiene, rapid microbiological methods.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 17141:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Cleanrooms and associated controlled environments - Biocontamination control". This standard covers: This document establishes the requirements, recommendations and methodology for microbiological contamination control in clean controlled environments. It also sets out the requirements for establishing and demonstrating microbiological control in clean controlled environments. This document is limited to viable microbiological contamination and excludes any considerations of endotoxin, prion and viral contamination. There is specific guidance given on common applications, including Pharmaceutical and BioPharmaceutical, Medical Devices, Hospitals and Food.

This document establishes the requirements, recommendations and methodology for microbiological contamination control in clean controlled environments. It also sets out the requirements for establishing and demonstrating microbiological control in clean controlled environments. This document is limited to viable microbiological contamination and excludes any considerations of endotoxin, prion and viral contamination. There is specific guidance given on common applications, including Pharmaceutical and BioPharmaceutical, Medical Devices, Hospitals and Food.

EN 17141:2020 is classified under the following ICS (International Classification for Standards) categories: 13.040.35 - Cleanrooms and associated controlled environments. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17141:2020 has the following relationships with other standards: It is inter standard links to EN ISO 14698-2:2003/AC:2006, EN ISO 14698-1:2003, EN ISO 14698-2:2003, EN ISO 14644-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17141:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2020

Nadomešča:

SIST EN ISO 14698-1:2004

SIST EN ISO 14698-2:2004

SIST EN ISO 14698-2:2004/AC:2007

Čiste sobe in podobna nadzorovana okolja - Kontrola biokontaminacije

Cleanrooms and associated controlled environments - Biocontamination control

Reinräume und zugehörige Reinraumbereiche - Biokontaminationskontrolle

Salles propres et environnements maîtrisés apparentés - Maîtrise de la biocontamination

Ta slovenski standard je istoveten z: EN 17141:2020

ICS:

13.040.35 Brezprašni prostori in Cleanrooms and associated

povezana nadzorovana controlled environments

okolja

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17141

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2020

EUROPÄISCHE NORM

ICS 13.040.35

English Version

Cleanrooms and associated controlled environments -

Biocontamination control

Salles propres et environnements maîtrisés apparentés Reinräume und zugehörige Reinraumbereiche -

- Maîtrise de la biocontamination Biokontaminationskontrolle

This European Standard was approved by CEN on 4 November 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17141:2020 E

worldwide for CEN national Members.

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Establishment of microbiological control . 11

4.1 General . 11

4.2 Establishing a formal system for microbiological control . 11

4.3 Microbiological contamination control system quality attributes . 12

4.4 Identification of all potential sources and routes of microbiological contamination . 12

4.4.1 General . 12

4.4.2 Sources of microbiological contamination . 13

4.4.3 Routes of transfer of microbiological contamination . 13

4.5 Risk assessment . 14

4.6 Establishment of microbiological environmental monitoring plan . 14

4.6.1 General . 14

4.6.2 Monitoring locations . 14

4.6.3 Monitoring frequencies . 14

4.7 Establishment of alert and action limits . 15

4.8 Establishment of documentation system . 15

4.9 Personnel education and training . 15

5 Demonstration of microbiological control . 16

5.1 Trending . 16

5.2 Verification of the formal microbiological control system . 16

5.2.1 General . 16

5.2.2 Out of specification (OOS) investigation . 16

5.2.3 Records . 16

5.2.4 Sample tracking . 17

5.2.5 Integrity of results . 17

5.2.6 Data recording . 17

5.2.7 Data evaluation . 17

5.2.8 Trend analysis . 18

6 Microbiological measurement methods . 18

6.1 General . 18

6.2 Choice of sampling method. 18

6.3 Volumetric air samplers . 19

6.4 Culture media and incubation . 19

6.5 Incubators . 19

Annex A (informative) Guidance for life science pharmaceutical and biopharmaceutical

applications . 20

A.1 Introduction . 20

A.2 Risk/impact assessment . 21

A.3 Demonstrating control . 21

Annex B (informative) Guidance for life science medical device applications . 22

B.1 Introduction . 22

B.2 Risk assessment . 22

B.2.1 General . 22

B.2.2 Example 1: Sterile - terminal sterilisation is possible from a packaged product . 24

B.2.3 Example 2: Sterile – No terminal sterilisation is possible due to product properties . 25

B.2.4 Example 3: Non-sterile products . 25

B.3 Establishing Microbiological Control . 26

B.3.1 Microbiological contamination limits . 26

B.3.2 Additional microbiological control considerations . 27

B.4 Demonstrating microbiological control . 27

B.4.1 Enumeration as part of measurement methods (Clause 6) . 27

B.4.2 Methods for sampling . 27

B.4.3 Microbiological Environmental Monitoring (EM) plan . 27

B.5 Other informative annexes for Medical Device applications . 29

Annex C (informative) Guidance for healthcare/hospital applications . 30

C.1 Introduction . 30

C.2 Establishing control in a healthcare/hospital application . 30

C.3 Risk assessment for operating room hospital applications . 30

Annex D (informative) Guidance for food applications . 31

D.1 Introduction . 31

D.2 Establishment of microbiological control . 31

D.3 Microbiological cleanliness levels for monitoring . 32

D.4 Demonstration of microbiological control . 33

D.5 Example for food manufacture . 33

Annex E (informative) Guidance on culture based microbiological measurement methods

and sampler verification . 35

E.1 General . 35

E.2 Air sampling . 35

E.2.1 Volumetric air samplers. 35

E.2.2 Settle plates. 37

E.3 Surface sampling . 37

E.3.1 General . 37

E.3.2 Contact plates and strips . 37

E.3.3 Swabs and sponges . 38

E.4 Microbiological growth media . 38

E.4.1 General . 38

E.4.2 Media suitability (media sterility and ability to support growth) . 38

E.4.3 Media dehydration . 39

E.4.4 Media disinfectant inhibition . 39

E.4.5 Plate incubation . 39

E.5 Validation of air samplers . 39

E.5.1 General . 39

E.5.2 Physical collection efficiency. 39

E.5.3 Biological collection efficiency . 40

E.6 Experimental method . 40

E.6.1 Aerosol chamber method . 40

E.6.2 Simplified laboratory method . 42

E.6.3 Incubation . 43

E.6.4 Collection efficiency calculations from testing results . 43

E.6.5 Air sampler revalidation . 44

Annex F (informative) Rapid microbiological methods (RMM) and alternative real time

microbiological detection methods (AMMs) . 45

F.1 General . 45

F.2 Implementation of RMMs and AMMs . 45

F.3 Validation of RMMs and AMMs . 46

F.3.1 General . 46

F.3.2 Acceptance criteria considerations . 47

F.3.3 Verification test execution considerations . 47

F.4 Action and alert levels . 47

F.4.1 Setting action and alert levels . 47

F.4.2 Result outside of action and alert levels . 47

Bibliography . 48

European foreword

This document (EN 17141:2020) has been prepared by Technical Committee CEN/TC 243 “Cleanroom

technology”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2021, and conflicting national standards

shall be withdrawn at the latest by February 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN ISO 14698-1:2003, EN ISO 14698-2:2003 and

EN ISO 14698-2:2003/AC:2006.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

Clean controlled environments are used to control and limit microbiological contamination where there

is a risk to product quality, patient or consumer.

In this document the term “clean controlled environments” is used to cover cleanrooms, clean zones,

controlled zones, clean areas and clean spaces.

This document gives guidance on best practice for establishing and demonstrating control of airborne

and surface microbiological contamination in clean controlled environments. This document describes

the requirements for microbiological contamination control and provides guidance on the qualification

and verification of clean controlled environments.

In order to establish microbiological control, it is important to understand the risks of microbiological

contamination. This is achieved by considering the sources of microbiological contamination, the

associated microbiological concentrations and the likelihood of transfer and the impact on product

quality, the patient or the consumer.

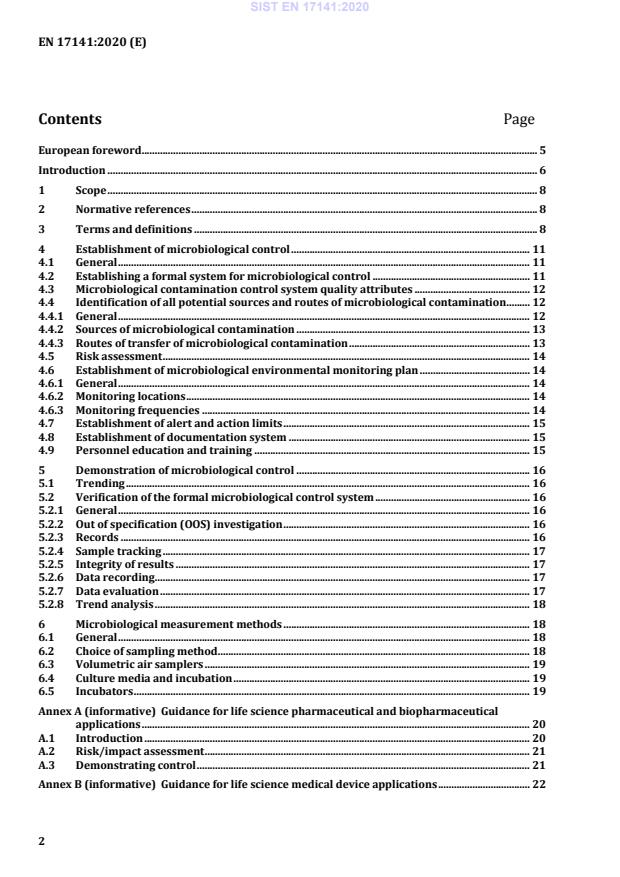

A formal system of microbiological control identifies, controls and monitors microbiological

contamination on an ongoing basis. This is a process of continuous improvement and the principles of

Plan – Do – Check – Act (PDCA) apply, as shown in Figure 1.

Figure 1 — Application of PDCA as the system for microbiological control

This document provides general guidance and considerations for a number of different applications. It

is expected to have particular use in the Pharmaceutical, Biopharmaceutical, Medical Devices and other

Life Science industries, as well as in Healthcare and Hospitals, Food, and related applications which use

clean controlled environments.

In the regulated Pharmaceutical and Biopharmaceutical manufacturing sector there are already many

applicable standards and regulatory guidelines. These include the EU Annex 1 GMP [31] guidance on the

manufacture of Sterile Medicinal products and the FDA Aseptic Processing guidance [32]. The European

and United States Pharmacopoeias also provide some guidance on certain related topics. There are

numerous other documents and technical papers available from industry associations including the

Parenteral Drugs Association (PDA), International Society of Pharmaceutical Engineering (ISPE) and

Pharmaceutical Healthcare Sciences Society (PHSS). While there are regulations and standards on risk

management of medical devices, for example EN ISO 14971 [2], there is less guidance on the

microbiological control of clean controlled environments.

In the Healthcare and Hospital sector there are EU Directives, including the Tissue and Blood Directives

for specialist and similar clean controlled environments. There are national standards and guidelines

for specialised Operating Theatres, Isolation units, Immuno-compromised wards as part of infection

control. In addition, Hospital Pharmacy aseptic compounding units, Radiopharmacies and specialist

laboratories such as Stem Cell typically refer to Life Science industry guidance documents.

In the Food and consumer related industries, while there are regulations and standards on food,

beverages and cosmetics for example there is insufficient guidance regarding microbiological control in

clean controlled environments.

This document includes a number of informative annexes that provide further guidance on

biocontamination control in specific applications, and includes, for example:

— tables of microbiological cleanliness levels for monitoring of microbiological contamination in

certain types of clean controlled environments;

— guidance in specific areas of microbiological control relating to the choice of environmental

monitoring (EM) sampling methods, the management and trending of collected data and the role of

alternative and real time microbiological detection systems;

— appropriate methods for establishing control, selecting appropriate alert and action levels and

target levels as necessary;

— establishing a microbiological environmental monitoring plan as part of demonstrating control of

the clean controlled environment.

1 Scope

This document establishes the requirements, recommendations and methodology for microbiological

contamination control in clean controlled environments. It also sets out the requirements for

establishing and demonstrating microbiological control in clean controlled environments.

This document is limited to viable microbiological contamination and excludes any considerations of

endotoxin, prion and viral contamination.

There is specific guidance given on common applications, including Pharmaceutical and

BioPharmaceutical, Medical Devices, Hospitals and Food.

2 Normative references

The following document is referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 14644-1:2015, Cleanrooms and associated controlled environments — Part 1: Classification of air

cleanliness by particle concentration (ISO 14644-1:2015)

3 Terms and definitions

For the purposes of this document, biocontamination control and microbiological control are

synonymous, and the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia. available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

action level

level set by the user in the context of controlled environments, which, when exceeded, requires

immediate intervention, including investigation of cause, and corrective action

3.2

alert level

level set by the user in the context of controlled environments, giving early warning of a drift from

normal conditions, which, when exceeded, should result in increased attention to the process

3.3

clean controlled environment

defined zone in which microbiological contamination is controlled by specified means

3.4

cleanroom

room within which the number concentration of airborne particles is controlled and classified, and

which is designed, constructed and operated in a manner to control the introduction, generation, and

retention of particles inside the room

Note 1 to entry: The class of airborne particle concentration is specified.

Note 2 to entry: Levels of other cleanliness attributes such as chemical, viable or nanoscale concentrations in

the air, and also surface cleanliness in terms of particle, nanoscale, chemical and viable concentrations may also be

specified and controlled.

Note 3 to entry: Other relevant physical parameters may also be controlled as required, e.g. temperature,

humidity, pressure, vibration and electrostatic.

[SOURCE: EN ISO 14644-1:2015, 3.1.1, [1]]

3.5

clean zone

defined space within which the number concentration of airborne particles is controlled and classified,

and which is constructed and operated in a manner to control the introduction, generation, and

retention of contaminants inside the space

Note 1 to entry: The class of airborne particle concentration is specified.

Note 2 to entry: Levels of other cleanliness attributes such as chemical, viable or nanoscale concentrations in

the air, and also surface cleanliness in terms of particle, nanoscale, chemical and viable concentrations may also be

specified and controlled.

Note 3 to entry: A clean zone(s) may be a defined space within a cleanroom or may be achieved by a separative

device. Such a device may be located inside or outside a cleanroom.

Note 4 to entry: Other relevant physical parameters may also be controlled as required, e.g. temperature,

humidity, pressure, vibration and electrostatic.

[SOURCE: EN ISO 14644-1:2015, 3.1.2, [1]]

3.6

colony forming unit

formation of a single macroscopic colony after the introduction of one or more microorganisms to

microbiological growth media

Note 1 to entry: One colony forming unit is expressed as 1 cfu.

3.7

critical control point

specific point, procedure, or step in the process at which control can be exercised to reduce, eliminate,

or prevent the possibility of microbiological contamination

3.8

critical zone

designated space within the clean controlled environment used to control microbiological

contamination

3.9

culturable

having the ability to grow and form colony forming units (cfu), using microbiological culturing

techniques

3.10

environmental monitoring

EM

measurement of specified parameters at periodic intervals within a clean controlled environment

3.11

microorganism

entity of microscopic size encompassing bacteria fungi protozoa and viruses

Note 1 to entry: Microbe is synonymous with microorganism.

Note 2 to entry: The use of the term microorganism in this standard includes bacteria, yeast and moulds only.

[SOURCE: ISO 17665-1:2006, 3.25, [50]]

3.12

microorganism of interest

microbiological contamination that has been identified as harmful to the product or the process, or the

intended recipient of the product within the clean controlled environment

Note 1 to entry: This includes commonly used terms such as objectionable species, microorganism of concern

or Pathogenic microorganisms or specified microorganisms.

3.13

risk assessment

actions to determine the likelihood and consequences of microbiological contamination within the clean

controlled environment

3.14

sterile

free from viable microorganisms

[SOURCE: ISO/TS 11139:2018, [51]]

3.15

sterilisation

validated process used to render a product free from viable microorganisms

[SOURCE: ISO/TS 11139:2018, [51]]

3.16

target level

defined level set by the user as a goal for routine operations, for the user's own purpose

3.17

validation

confirmation, through the provision of objective evidence that the requirements for a specific intended

use or application have been fulfilled

Note 1 to entry: The objective evidence needed for a validation is the result of a test or other form of

determination such as performing alternative calculations or reviewing documents.

Note 2 to entry: The word “validated” is used to designate the corresponding status.

Note 3 to entry: The use conditions for validation can be real or simulated.

[SOURCE: EN ISO 9000:2015]

3.18

verification

confirmation, through the provision of objective evidence, that specified requirements have been

fulfilled

Note 1 to entry: The objective evidence needed for a verification can be the result of an inspection or of other

forms of determination such as performing alternative calculations or reviewing documents.

Note 2 to entry: The activities carried out for verification are sometimes called a qualification process.

Note 3 to entry: The word “verified” is used to designate the corresponding status.

[SOURCE: ISO 9000:2015]

3.19

viable

microorganism, alive and either culturable or non culturable

3.20

viable particle

particle that contains one or more living microorganism

4 Establishment of microbiological control

4.1 General

When the clean controlled environment is classed as a cleanroom or clean zone the requirements of

EN ISO 14644-1, shall be complied with.

4.2 Establishing a formal system for microbiological control

A system to maintain appropriate microbiological contamination control shall be established,

implemented and maintained. The system shall identify, control and monitor factors that can affect

microbiological contamination of the product. The outputs of the system shall be documented

There are a number of accepted microbiological contamination control systems that utilise a quality

risk management approach [2], [3], [5], [6], [8] [9]; the selected system shall be appropriate and

verified.

4.3 Microbiological contamination control system quality attributes

The microbiological contamination control system shall consider the following steps:

a) identification of all potential microbiological contamination sources and routes of contamination in

the clean controlled environment, deemed microorganisms of interest;

b) assessment of the risk from these sources and routes and, where appropriate, introduce or improve

microbiological contamination control methods to reduce the identified risks;

c) establishment of a monitoring schedule, with valid sampling methods, to monitor the

microbiological contamination source, or their control methods or both;

d) establishment of alert and action levels, and where appropriate target levels, with measures to be

taken when required, if these levels are exceeded;

e) verification on a continuing basis, that the microbiological contamination control system is effective

and meeting agreed performance parameters by reviewing product contamination rates,

environmental monitoring results, risk assessment methods, control methods and monitoring

limits and, where appropriate, modify them accordingly;

f) establishment and maintenance of appropriate documentation;

g) education and training of all staff involved with the clean controlled environment.

4.4 Identification of all potential sources and routes of microbiological contamination

4.4.1 General

Before the risk assessment process can start the nature of the process should be investigated and

understood.

All potential microbiological contaminants, and their routes of transfer, that pose a risk to the product,

patient or consumer shall be identified.

Microbiological contamination can come from people and what they wear, materials, equipment,

services and processes, the physical condition of the facility and surrounding environment as well as

the supply air, airflow patterns and movement within the clean controlled environment, and ongoing

cleaning. When there is a risk of product or process contamination from particular types of

microorganisms these can be considered as microorganisms of interest.

Microorganisms of interest shall be identified during the risk assessment process.

The following factors should be considered as part of the risk assessment:

a) clean controlled environment application, (e.g. pharmaceutical, medical device, food, cosmetics);

b) microbiological species, (e.g. survival possibility, or associated toxins);

c) potential for causing microbiological contamination of the product and/or harm to the intended

recipient, (e.g. spoilage of product prior to end of shelf life in food);

d) product form (e.g. does the product contain preservatives, or any potential growth substrates that

may prevent growth);

e) intended product target population (e.g. patient, infant, immuno-compromised recipient);

The presence of moulds and other microbiological contamination, including microorganisms of interest,

can be indicators of poor cleaning or poor design and increase the risk of product and/or process

contamination.

Arising from a risk assessment, action and alert, and if appropriate target levels for routine monitoring

can be set for total microbiological concentrations without reference to the microorganisms of interest

or by consideration of both.

When the initial qualification of a new non-operating premises or where the activity is not yet

representative of normal operation, microbiological contamination may not be sufficiently

representative. It may therefore be necessary to re-evaluate the risk in normal operation.

4.4.2 Sources of microbiological contamination

4.4.2.1 General

Sources of microbiological contamination can be prime and derived or associated.

4.4.2.2 Prime sources

The following are examples of prime sources:

— People - A major source of contamination;

— Supply Air - Air supplied into clean controlled environments. (re-circulated or fresh make up);

— Product Materials - Product in solid or liquid form, containers and packaging;

— Utilities - Compressed air, nitrogen, propane, oxygen, WFI;

— Machines - Processing and packaging equipment.

4.4.2.3 Derived or associated sources

The following are examples of derived or associated sources:

— Air Within - Air within clean controlled environments;

— Contact Parts- Product contacting parts such as pipework and closure hoppers;

— Surfaces - Clean controlled environment floors, walls, workstation surfaces, barrier gauntlets,

trolleys, buckets, balances, disinfectant containers, monitoring devices;

— Adjacent Areas - Change rooms, corridors, pass through transfer hatches.

4.4.3 Routes of transfer of microbiological contamination

There are 3 routes of transfer of microbiological contamination to the product or critical zone in a clean

controlled environment:

— airborne deposition;

— surface contact;

— liquid.

NOTE The transfer of potential sources of microbiological contamination via the liquid route is not part of the

scope of this document.

4.5 Risk assessment

A fundamental part of quality risk management is risk assessment. There are a number of ISO standards

that address the subject of quality risk management and risk assessment in different applications.

IEC 31010 [28] gives a list of verified risk assessment methodologies.

The hazard analysis critical control point (HACCP) system [4], [5], [6], [7], fault tree analysis (FTA) [8],

failure mode and effect analysis (FMEA) system [9], or any other verified system can be used.

IEC 31010:2019 [28] provides more information on risk assessment methods

Risk assessment shall be carried out to identify, assess, eliminate, where possible and control

microbiological contamination risks that have a detrimental impact on product quality, patient or

consumer. Risk assessment shall identify the variables in the clean controlled environment that have to

be monitored and what microbiological contamination needs to be measured, see 4.3, Microbiological

contamination control system quality attributes.

The results of the risk assessment shall be documented and include a scientific rationale for decisions

taken in relation to mitigating risks and residual risk. The results of the risk assessment shall be

reviewed regularly as part of on-going quality management, during change control and during the

periodic product quality review of the microbiological control programme.

4.6 Establishment of microbiological environmental monitoring plan

4.6.1 General

A microbiological environmental monitoring plan shall be established that specifies the types of

measurements to be taken as well as the location and frequency, specify appropriate measured levels

that should not be exceeded, and specify the actions to be taken when the levels are exceeded.

The microbiological control system shall specify the associated measurement methods.

There are a number of industry guidelines and ISO standards that address the subject of microbiological

environmental monitoring in different applications. Refer to informative Annexes A, B, C and D as well

as the Bibliography.

4.6.2 Monitoring locations

The monitoring locations in the clean controlled environment and the associated number shall be

determined as part of the risk assessment and related to the degree of risk.

Personnel gowning and material transfer airlocks as well as product pass through hatches shall be

carefully considered and may require proportionally more monitoring because of the higher risk

associated with the materials and personnel that are moving into the clean controlled environment.

The risk assessment should take into consideration the type of product manufactured and the nature of

the manufacturing process and/or activity undertaken in the clean controlled environment e.g. a

terminally sterilised product or a process with a low contamination risk to the patient or consumer will

require less microbiological environmental monitoring than an aseptically prepared product or process.

The application of the Plan-Do-Check-Act continuous improvement process may revise the selection of

the optimum microbiological monitoring locations and associated number, as a result of the

microbiological control information gathered.

4.6.3 Monitoring frequencies

The frequency of sampling shall be related to the degree of risk and shall be specified in the

microbiological environmental monitoring plan as either continuous or periodic, daily, weekly, monthly

or another agreed period. The frequency of sampling shall be specified for each source, or its control

method, or both.

In setting the frequency of sampling it should be recognised that too frequent sampling could

potentially introduce further risk due to possible intrusion of sampling personnel into a critical zone. It

is necessary to strike a balance between sufficient sampling and the potential introduction of

contamination and/or taking the necessary control steps to reduce contamination risks.

4.7 Establishment of alert and action limits

The microbiological environmental monitoring plan shall specify the levels of measured concentrations

of microorganisms of interest in air and on surfaces that should not be exceeded. Alert and action limits

shall be set with the alert levels set lower values than the action level. Target levels can also be

established as appropriate. An alert level shall be used to indicate that the microbiological

contamination is higher than expected and give an early warning of potential loss of control.

The microbiological environmental monitoring plan shall specify the alert conditions under which

action is to be taken.

When an action level is exceeded immediate investigation is required to identify the cause and, if

necessary, corrective action. The microbiological environmental monitoring plan shall specify what

action is to be taken as a result in order to regain microbiological control.

It is necessary to carry out microbiological monitoring for a period of time in order to set alert and

action levels that are not continuously exceeded.

In some highly contained clean controlled environments the microbiological contamination can be very

low and may not conform to normal distributions. In such cases parameters such as average or

standard deviations may not be suitable to establish action and alert levels. Instead levels that are likely

to be exceeded at defined frequencies should be considered more appropriate for setting action and

alert levels.

4.8 Establishment of documentation system

The microbiological control system and associated environmental monitoring plan as well as the

reporting requirements shall be documented, regularly reviewed and updated, as necessary to

incorporate any changes implemented.

Reports shall provide a review and analysis of the microbiological environmental monitoring results

and any deviations from the expected results. When action levels are exceeded these shall be reported,

as well as the actions taken to correct the deviations, or the explanations as to why no action was

necessary.

NOTE In some cases, alert levels can also be reported, particularly those associated with a multiple or

unusual occurrence.

4.9 Personnel education and training

Personnel shall be competent and have the necessary education, experience, skills and training to

ensure performance of their assigned functions. Personnel shall perform only those activities for which

they are qualified and authorised to carry out.

All personnel shall be trained and retrained as specified in order to perform their assigned

responsibilities adequat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...