EN 13693:2004

(Main)Precast concrete products - Special roof elements

Precast concrete products - Special roof elements

This standard identifies the requirements, the basic performance criteria and the evaluation of conformity for special precast roof elements made of reinforced or prestressed normal weight concrete, used for the construction of buildings, with or without separating function with respect to fire resistance.

NOTE The title of special roof elements refers to thin-walled structural elements with deformable transverse profile, such as folded plates, or shell elements, the intended use being specific for roofings with their typical loads. This type of elements combines the overall flexural behaviour along the main span with a complex distribution of in-plane forces and local moments.

Other types of elements can be used in roofing, such as ribbed units, floor slabs, ... . For these elements reference shall be made to their respective product standards.

Secondary structural components, possibly used in combination with the main roof elements, such as load bearing shuttering plates and shells, roof light frames, ..., shall refer to their respective product standard or technical approval.

The standard covers terminology, performance criteria, tolerances, relevant physical properties, test methods, and aspects of transport and erection.

This standard does not deal with seismic behaviour.

This standard does not cover load bearing capacity determined by testing.

Betonfertigteile - Besondere Fertigteile für Dächer

Dieses Dokument legt die Anforderungen, die grundlegenden Leistungskriterien und die Bewertung der Konformität für besondere Fertigteile für Dächer aus Stahl- oder Spannbeton fest, die im Hochbau mit oder ohne raumabschließende Funktion hinsichtlich des Feuerwiderstands eingesetzt werden.

ANMERKUNG Der Titel "besondere Fertigteile für Dächer" bezieht sich auf dünnwandige tragende Bauteile mit verformbarem Querschnitt, wie Faltwerke oder Schalen, wobei die vorgesehene Verwendung für Überdachungen mit deren typischen Belastungen charakteristisch ist. Diese Art von Fertigteilen vereint das Gesamtbiegeverhalten längs der Hauptstützweite mit einer in gegenseitigem Zusammenhang stehenden Verteilung von Scheibenkräften und örtlichen Momenten.

Für Dächer können auch andere Fertigteilarten verwendet werden, wie z. B. Deckenplatten mit Stegen, Deckenplatten, usw.. Für diese Fertigteile sind die entsprechenden Produktnormen heranzuziehen.

Ergänzungsbauteile für Tragwerke, die möglicherweise in Verbindung mit den Hauptfertigteilen für Dächer verwendet werden, wie z. B. tragende Fertigteilplatten und Schalen, Rahmen für Dachfenster usw., müssen sich auf die dafür geltende Produktnorm oder eine technische Zulassung beziehen.

In diesem Dokument werden Begriffe, Leistungskriterien, Toleranzen, die maßgebenden physikalischen Eigenschaften, Prüfverfahren und Aspekte von Transport und Montage festgelegt.

Dieses Dokument gilt nicht für das Verhalten bei Erdbeben.

Die durch Prüfung bestimmte Tragfähigkeit ist nicht Gegenstand dieses Dokumentes.

Produits préfabriqués en béton - Éléments spéciaux de toiture

La présente norme spécifie les prescriptions, les critères relatifs aux performances de base et l'évaluation de la conformité pour les éléments préfabriqués de toiture spéciaux en béton de granulats courants armé ou précontraint, utilisés pour la construction de bâtiments, avec ou sans fonction de séparation liée à la résistance au feu.

NOTE Le titre «Éléments spéciaux de couverture» fait référence à des éléments structurels à parois minces avec des profils transversaux déformables, tels que des plaques plissées ou des éléments en coque, l'utilisation prévue étant spécifique aux toitures avec leurs charges type. Ce type d'éléments associe le comportement global en flexion le long de la portée principale avec une distribution complexe de forces coplanaires et de moments localisés.

D'autres types d'éléments peuvent être utilisés en toitures, tels que des éléments nervurés, dalles de plancher, etc. Pour ces éléments, il doit être fait référence aux normes de produits correspondantes.

Les composants structurels secondaires éventuellement utilisés en combinaison avec les éléments de toiture principaux, tels que des plaques et coques de coffrage portantes, structures pour éclairage zénithal, etc. doivent faire référence aux normes de produits correspondantes ou à leur agrément technique.

La présente norme couvre la terminologie, les critères de performance, les tolérances, les propriétés physiques pertinentes, les méthodes d'essai et les aspects relatifs au transport et à la mise en �uvre.

La présente norme ne traite pas du comportement sismique.

La présente norme ne couvre pas la capacité portante déterminée par essais.

Montažni betonski izdelki - Specialni strešni elementi

General Information

- Status

- Withdrawn

- Publication Date

- 01-Sep-2004

- Withdrawal Date

- 28-Jul-2009

- Technical Committee

- CEN/TC 229 - Precast concrete products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 29-Jul-2009

- Completion Date

- 29-Jul-2009

Not Harmonized89/106/EEC - Construction productsOJ Ref: C 139, C 319, C 139, C 319, C 139, C 319, C 139, C OJ Date: 14-Dec-2005

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13693:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Precast concrete products - Special roof elements". This standard covers: This standard identifies the requirements, the basic performance criteria and the evaluation of conformity for special precast roof elements made of reinforced or prestressed normal weight concrete, used for the construction of buildings, with or without separating function with respect to fire resistance. NOTE The title of special roof elements refers to thin-walled structural elements with deformable transverse profile, such as folded plates, or shell elements, the intended use being specific for roofings with their typical loads. This type of elements combines the overall flexural behaviour along the main span with a complex distribution of in-plane forces and local moments. Other types of elements can be used in roofing, such as ribbed units, floor slabs, ... . For these elements reference shall be made to their respective product standards. Secondary structural components, possibly used in combination with the main roof elements, such as load bearing shuttering plates and shells, roof light frames, ..., shall refer to their respective product standard or technical approval. The standard covers terminology, performance criteria, tolerances, relevant physical properties, test methods, and aspects of transport and erection. This standard does not deal with seismic behaviour. This standard does not cover load bearing capacity determined by testing.

This standard identifies the requirements, the basic performance criteria and the evaluation of conformity for special precast roof elements made of reinforced or prestressed normal weight concrete, used for the construction of buildings, with or without separating function with respect to fire resistance. NOTE The title of special roof elements refers to thin-walled structural elements with deformable transverse profile, such as folded plates, or shell elements, the intended use being specific for roofings with their typical loads. This type of elements combines the overall flexural behaviour along the main span with a complex distribution of in-plane forces and local moments. Other types of elements can be used in roofing, such as ribbed units, floor slabs, ... . For these elements reference shall be made to their respective product standards. Secondary structural components, possibly used in combination with the main roof elements, such as load bearing shuttering plates and shells, roof light frames, ..., shall refer to their respective product standard or technical approval. The standard covers terminology, performance criteria, tolerances, relevant physical properties, test methods, and aspects of transport and erection. This standard does not deal with seismic behaviour. This standard does not cover load bearing capacity determined by testing.

EN 13693:2004 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13693:2004 has the following relationships with other standards: It is inter standard links to EN 13693:2004+A1:2009, EN 13693:2004/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13693:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/100. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13693:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Precast concrete products - Special roof elementsMontažni betonski izdelki - Specialni strešni elementiProduits préfabriqués en béton - Éléments spéciaux de toitureBetonfertigteile - Besondere Fertigteile für Dächer91.100.30Beton in betonski izdelkiConcrete and concrete products91.060.20StreheRoofsICS:SIST EN 13693:2004en,fr,deTa slovenski standard je istoveten z:EN 13693:200401-oktober-2004SIST EN 13693:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13693September 2004ICS 91.100.30 English versionPrecast concrete products - Special roof elementsProduits préfabriqués en béton - Éléments spéciaux decouvertureBetonfertigteile - Besondere Fertigteile für DächerThis European Standard was approved by CEN on 24 June 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13693:2004: E

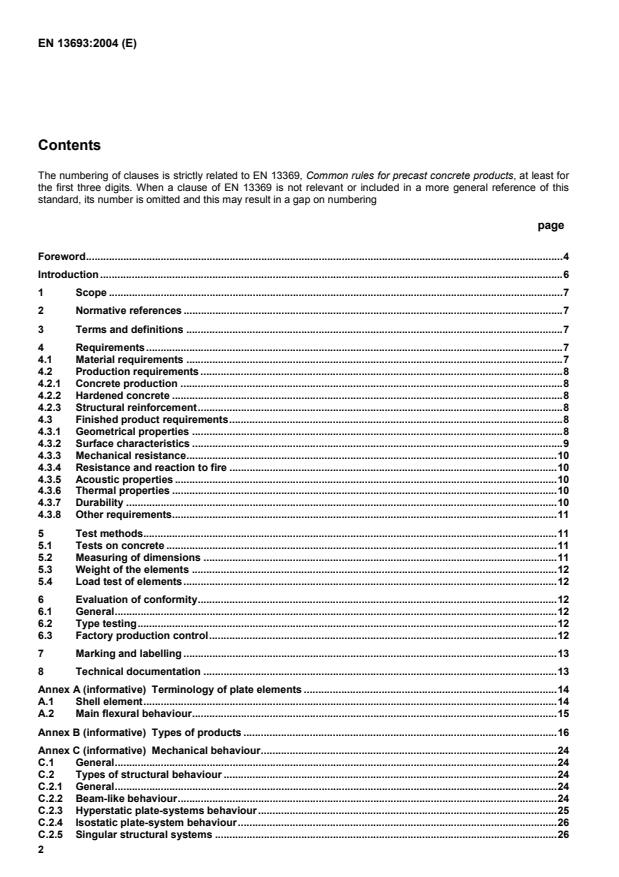

2 Contents

The numbering of clauses is strictly related to EN 13369, Common rules for precast concrete products, at least for the first three digits. When a clause of EN 13369 is not relevant or included in a more general reference of this standard, its number is omitted and this may result in a gap on numbering

page Foreword.4 Introduction.6 1 Scope.7 2 Normative references.7 3 Terms and definitions.7 4 Requirements.7 4.1 Material requirements.7 4.2 Production requirements.8 4.2.1 Concrete production.8 4.2.2 Hardened concrete.8 4.2.3 Structural reinforcement.8 4.3 Finished product requirements.8 4.3.1 Geometrical properties.8 4.3.2 Surface characteristics.9 4.3.3 Mechanical resistance.10 4.3.4 Resistance and reaction to fire.10 4.3.5 Acoustic properties.10 4.3.6 Thermal properties.10 4.3.7 Durability.10 4.3.8 Other requirements.11 5 Test methods.11 5.1 Tests on concrete.11 5.2 Measuring of dimensions.11 5.3 Weight of the elements.12 5.4 Load test of elements.12 6 Evaluation of conformity.12 6.1 General.12 6.2 Type testing.12 6.3 Factory production control.12 7 Marking and labelling.13 8 Technical documentation.13 Annex A (informative)

Terminology of plate elements.14 A.1 Shell element.14 A.2 Main flexural behaviour.15 Annex B (informative)

Types of products.16 Annex C (informative)

Mechanical behaviour.24 C.1 General.24 C.2 Types of structural behaviour.24 C.2.1 General.24 C.2.2 Beam-like behaviour.24 C.2.3 Hyperstatic plate-systems behaviour.25 C.2.4 Isostatic plate-system behaviour.26 C.2.5 Singular structural systems.26

Serviceability and resistance verifications.29 D.1 Biaxial strength of concrete.29 D.2 Biaxial strength of shell element.30 D.2.1 General.30 D.2.2 Compressive strength of thin plates.30 D.2.3 Tensile strength of thin plates.30 D.2.4 Shear strength of thin plates.31 D.2.5 Flexural strength of thin plates.31 D.3 Global flexural strength of the cross section.32 Annex E (informative)

Flexural test of elements.33 E.1 General.33 E.2 Load test under service conditions - symmetrical loading.34 E.2.1 General.34 E.2.2 Settling cycle.34 E.2.3 First cycle.34 E.2.4 Second cycle.35 E.2.5 Interpretation of the results.35 E.3 Load test under service conditions - dissymmetrical loading.36 E.3.1 General.36 E.3.2 Third cycle.36 E.3.3 Fourth cycle.37 E.3.4 Interpretation of the results.37 E.4 Load test up to failure conditions.37 E.4.1 General.37 E.4.2 Final cycle.37 E.4.3 Interpretation of the results.38 Annex Y (Informative)

Choice of CE marking method.40 Y.1 General.40 Y.2 Method 1.40 Y.3 Method 2.40 Y.4 Method 3.40 Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of EU Directives.41 ZA.1 Scope and relevant characteristics.41 ZA.2 Procedure for attestation of conformity of precast prestressed concrete roof elements.42 ZA.2.1 System of attestation of conformity.42 ZA.2.2 EC Certificate and Declaration of conformity.43 ZA.3 CE marking and labelling.44 ZA.3.1 General.44 ZA.3.2 Declaration of geometrical data and material properties.45 ZA.3.3 Declaration of product properties.47 ZA.3.4 Declaration of compliance with a given design specification.50 Bibliography.52

4 Foreword This document (EN 13693:2004) has been prepared by Technical Committee CEN/TC 229 “Precast concrete products”, the secretariat of which is held by AFNOR. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by March 2005, and conflicting national standards shall be withdrawn at the latest by June 2006. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of Construction Products Directive (89/106/EEC) of European Union (EU). For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document. This standard is one of a series of product standards for precast concrete products. For common aspects reference is made to EN 13369: Common rules for precast products, from which also the relevant requirements of the EN 206-1: Concrete - Part 1: Specification, performances, production and conformity are taken. The references to EN 13369 by CEN/TC229 product standards are intended to make them homogeneous and to avoid repetitions of similar requirements. Eurocodes are taken as a common reference for design aspects. The installation of some structural precast concrete products is dealt with by ENV 13670-1: Execution of concrete structures – Part 1: Common rules, which has at the moment the status of an European prestandard. In all countries it can be accompanied by alternatives for national application and it shall not be treated as a European Standard. The programme of standards for structural precast concrete products comprises the following standards, in some cases consisting of several parts: EN 1168, Precast concrete products - Hollow core slabs prEN 12794, Precast concrete products - Foundation piles EN 12843, Precast concrete products - Masts and poles EN 13224, Precast concrete products - Ribbed floor elements EN 13225, Precast concrete products - Linear structural elements EN 13693, Precast concrete products - Special roof elements prEN 13747, Precast concrete products - Floor plates for floor systems prEN 13978, Precast concrete products - Precast concrete garages prEN 14843, Precast concrete products – Stairs prEN 14844, Precast concrete products - Box culverts prEN 14991, Precast concrete products - Foundation elements prEN 14992, Precast concrete products - Wall elements: Products properties and performances

6 Introduction The evaluation of conformity given in this standard refers to the completed precast elements which are supplied to the market and covers all the production operations carried out in the factory. For design rules and resistance to fire principal reference is made to EN 1992-1-1 and EN 1992-1-2. Additional complementary rules are provided where necessary. In Clause 4.3.3 and 4.3.4 this document includes specific provisions resulting from the application of EN 1992-1-1 and EN 1992-1-2 rules to the concerned product. The use of these provisions is consistent with a design of works made with EN 1992-1-1 and EN 1992-1-2.

1-2: General rules - Structural fire design. EN 13369:2004, Common rules for precast concrete products. 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 13369:2004 and the following apply.

NOTE 1 See also Annex A. NOTE 2 Annex B gives a review of common types of special precast prestressed concrete roof elements together with some related terminology. 4 Requirements 4.1 Material requirements For general aspects, constituent materials of concrete, reinforcing and prestressing steel, inserts and connections, the relevant clauses of EN 13369:2004 4.1 shall apply. In particular the ultimate tensile and tensile yield strength of steel shall be considered.

8 4.2 Production requirements 4.2.1 Concrete production Clause 4.2.1 of EN 13369:2004 shall apply. In particular the compressive strength of concrete shall be considered. 4.2.2 Hardened concrete Clause 4.2.2 of EN 13369:2004 shall apply. 4.2.3 Structural reinforcement In addition to Clause 4.2.3 of EN 13369:2004, the following specific rules shall apply. Special care shall be given to ensure a stable positioning of reinforcement in the thin slabs (t ≤ 100 mm). For welded meshes and isolated bars in thin slabs, concrete covers against formworks shall be ensured by a sufficiently dense distribution of spacers. Access of workers, as well as concrete casting and compacting, shall be made in such a way so to avoid displacements and deformations of steel reinforcement with respect to the intended positioning and shapes. 4.3 Finished product requirements 4.3.1 Geometrical properties 4.3.1.1 Production tolerances The following values of production tolerances shall be used. The values are expressed in mm and refer to the measure described in Figure 1. Tolerances refer to the deviations with respect to the design (nominal) values indicated in project documentation (inclusive of possible cambers). Measurement Tolerance Values (mm) Width "b" and short measurements (b ≤ 2 500) ± ∆b 12 + b/140 Thickness "t" of thin flanges and plates (t ≤ 150) + ∆t − ∆t 10 5 Total depth "h" of any cross section (h < 2 500) ± ∆h 12 + h/140

Bow horizontal mis- alignment of lateral edges ± ε L/700 Camber “v” in vertical plane ± ∆v L/700 For the length "L" and the reinforcement placing "c", the corresponding permitted deviation ∆L and ∆c are given in 4.3.1.1 of EN 13369:2004. For the size of holes and openings 1,5 time the value of ∆b tolerance may be assumed. For the overall positioning of holes and inserts 1,5 time the values of ∆L and ∆b tolerances may be assumed. Other values may be given in project specifications.

Key 1 Vertical 2 Horizontal 3 Cross section Figure 1 — Measure of production tolerances 4.3.1.2 Minimum dimensions Clause 4.3.1.2 of EN 13369:2004 shall apply. 4.3.2 Surface characteristics For surface characteristics, 4.3.2 of EN 13369:2004 shall apply. NOTE In addition to the possible cracking expected from calculation, cracking can occur in roof elements from normal function in some particular areas, such as the end edges of the ribs, the intersection lines of the different plates, the corners around holes or other shape discontinuities. Provided the width and the extension of these cracks are limited and there are no structural consequences, a simple local filling may be applied to restore the surface appearance. Completion works of ready finished elements (such as painting, waterproofing, .) are not covered by this document.

10 4.3.3 Mechanical resistance 4.3.3.1 General For requirements on mechanical strength Clause 4.3.3 of EN 13369:2004 (referring to EN 1990:2002, EN 1992-1-1:2004 and EN 1992-1-2-2004) shall apply, except 4.3.3.4 dealing with verification by testing. In particular, following 4.3.3.3 of EN 13369:2004, due to their structural arrangements with unusual design models, for the special roof elements dealt with in this standard, load tests up to failure on at least two full scale specimens of any type of product shall be performed before starting production (initial type testing – see 6.2) in order to verify the reliability of the design model assumed for calculation.

Specific additional information are given in informative Annex C and D. 4.3.3.2 Detailing Overlapped splices of reinforcement shall be located out of the areas where the full strength is needed for the resistance of the element. In any case they need a minimum dimension of the concrete section, defined by t ≥ 5 ds where

t is the minimum local thickness of the element, and

ds is the diameter of the overlapped bars (or wires). The minimum transverse spacing between two adjacent laps shall be ≥ 10 ds. 4.3.4 Resistance and reaction to fire 4.3.4.1 Resistance to fire Fire resistance, dealing with load-bearing capacity R, integrity E and insulation I of precast prestressed concrete roof elements, expressed in terms of classes, shall be defined following 4.3.4.1, 4.3.4.2 and 4.3.4.3 of EN 13369:2004. NOTE Normally, with respect to fire resistance, the separating function EI is not required for the elements of concern. 4.3.4.2 Reaction to fire For reaction to fire, 4.3.4.4 of EN 13369:2004 shall apply. 4.3.5 Acoustic properties When required, the relevant acoustic properties of roof elements shall be declared following Clause 4.3.5 of EN 13369:2004. 4.3.6 Thermal properties Reference shall be made to 4.3.6 of EN 13369:2004. 4.3.7 Durability Clause 4.3.7 of EN 13369:2004 shall apply.

12 5.3 Weight of the elements Clause 5.3 of EN 13369:2004 shall apply. 5.4 Load test of elements Annex E gives the standard method for flexural load tests on full scale specimens of roof elements. 6 Evaluation of conformity 6.1 General Clause 6.1 of EN 13369:2004 shall apply. 6.2 Type testing Clause 6.2 of EN 13369:2004 shall apply. 6.3 Factory production control NOTE The missing numbers correspond to the clauses of EN 13369 included in the general references made in this subchapter. Clause 6.3 of EN 13369:2004, except 6.3.6.5, shall apply. 6.3.6.5 Finished products Compliance verification on the finished products shall be performed following, in addition to items 3 to 5 of Table D.4.1 of EN 13369:2004, the control chart of Table 1 of this document. Other verifications can be performed where a special necessity arises. The checks shall be carried out at the earliest time possible, preferably in the factory, and never after the precast units have been received and accepted at the site. Table 1 — Finished product inspection

Subject Aspect Method Frequency Registration Elements surface finish visual inspection every element notice of imperfections Elements total length see point 5.2(a) every 10 elements notation in the record form Elements thickness see point 5.2(c) every 10 elements notation in the record form Elements concrete cover see point 5.2(g) every 10 elements notation in the record form Elements camber* see point 5.2(f) every month or 1/100 elements notation in the record form Elements other production tolerances see point 5.2(b)-(d)-(e) every year or 1/600 elements notation in the record form Elements (all types) mechanical strength (failure conditions) see Annex E initial type tests on 2 elements proper report Elements (type f of Annex C) mechanical strength (service conditions) see Annex E every 6 months on 1 element proper report * See 4.3.1.1 and Figure 1.

Clause 7 of EN 13369:2004 shall apply. NOTE For CE marking see Annex ZA. 8 Technical documentation Considering also 4.3.3.2, the detailing of the element, with respect to geometrical data and complementary properties of materials and inserts, shall be given in technical documentation, which includes the construction data, such as the dimensions, the tolerances, the layout of reinforcement, the concrete cover, the expected transient and final support conditions and lifting conditions. The composition of technical documentation is given in Clause 8 of EN 13369:2004.

14 Annex A (informative)

Terminology of plate elements A.1 Shell element As shown in Figure A.1, the internal actions transmitted along the thin walls of a shell structure are represented by eight components referred to its middle surface: In-plane forces normal force along x-axis nx normal force along y-axis ny tangential force nxy Moments bending moment along x-axis mx bending moment along y-axis my twisting moment mxy Transverse forces shearing force along x-axis qx shearing force along y-axis qy The above components are referred to the unit width and represent the proper integral over the plate thickness t of the stresses σx, σy, τxy, τzx, τyz. The first three components nx, ny, nxy are related to the extensional behaviour of the plate, the remaining five mx, my, mxy, qx, qy are related to its flexural behaviour.

Figure A.1 — Components of internal actions A.2 Main flexural behaviour In general the roof elements considered in the present standard are spanning in one main direction between the two end supports. In this longitudinal direction, in analogy to the ordinary theory of beams, the three components M, V, T of the internal force can be referred to the current cross-section, as shown in Figure A.2. These components represent the global effects of the vertical loads in terms of flexural action with its possible eccentricity. When represented by an applied force, prestressing force P can be added with its eccentricity ep.

Local and transverse effects due to the warping of the cross section and to the deformation of its profile are not provided by this representation.

Figure A.2 — Components of the internal force

16 Annex B (informative)

Types of products

B.1a - “V” shape elements

B.1b - Three plates elements

B.1c - Hollow-core elements Figure B.1 - Types of simple wing-elements

B.2a - Simple one-rib elements

B.2b - Hollow one-rib elements

B.2c - Sandwich one-rib elements Figure B.2 - Types of one-rib wing-elements

B.3a - Simple two-ribs elements

B.3b - Sandwich two-ribs elements

B.3c - Straddle two-ribs elements Figure B.3 - Types of two-ribs wing-elements

B.4a

B.4b

B.4c Figure B.4 - Types of box-elements

B.5a

B.5b

B.5c Figure B.5 - Types of roof-light shed-elements

B.6a - Upwards folded-plate elements

B.6b - Overturned folded-plate elements

B.6c - Shed folded-plate elements Figure B.6 - Types of folded-plate elements

B.7a - Simple paraboloid elements

B.7b - Box-shape paraboloid elements

B.7.3 - Sandwich paraboloid elements Figure B.7 - Paraboloid-elements

Figure B.8 - "Y" shape elements

Key 1 Thermal insulation 2 Waterproof layer 3 Protective cover 4 Edge angle 5 Painted finish 6 Skylight sheets (added in situ) Figure B.9 - Typical ready finish of the product

The examples given in Annex B for roof elements and their ready finish are not intended to cover all the possible types of common production.

24 Annex C (informative)

Mechanical behaviour C.1 General In general, referring to the overall flexural behaviour along their main span and to the combined twist action, roof element can be classified as follows: a) core-beam elements, provided with a central solid core or box profile where the flow of tangential stresses can develop to give a circulatory torsional resistance (Figure C.1 a)); b) biflexural-beam systems, where twist actions are decomposed into two opposite combined flexures applied to the longitudinal ribs (Figure C.1 b)); c) folded-plate systems, made of three or more non convergent plates, where twist actions are decomposed into a complex combination of flexures of the single plates (Figure C.1 c)); d) star-plate systems, such as V or Y profiles, with the different plates convergent in a single axis, where the twist actions are decomposed into twisting moments of the single plates (Figure C.1 d)); e) special-shape elements, that is singular solution not covered by the previous definitions (such as thin shells designed in the geometry of a hyperbolic paraboloid, where the prestressing tendons are placed along the straight lines of the surface - Figure C.1 e)); f) integrated systems, such as sandwich elements, where the resistance of the structural part is improved by the completion parts of the unit (Figure C.1 f)). With reference to the transmission of vertical loads to the end supports, the following two principal types of elements can be distinguished. Web-shear systems, where the presence of vertical or quasi-vertical webs extended till over the bearings allows a beam-like transmission of the shear forces over the supports. Arch-tie systems, where the longitudinal shape, with possible variable depth, leads to an arch mechanism connected with the lower tie of the incorporated reinforcement. Other special types of elements can be produced and properly designed to allow the transmission of vertical loads to the end supports through different mechanisms (e.g. suspension systems, .). C.2 Types of structural behaviour C.2.1 General With reference to the U.L.S. - Ultimate Limit State to be verified by calculation and testing in order to ensure the due resistance of the elements, the following cases are distinguished. C.2.2 Beam-like behaviour For types "a" and "b" of C.1 the ordinary beam-model covered by EN 1992-1-1 can be in general applied with proper verifications.

Figure C.1 — Types of roof elements Possible deviations of the ultimate mechanism of the section of the maximum bending moment can derive from the small thicknesses of the compression wings. This can be checked on the basis of the experimental results of the initial type testing (load tests up to failure) and represented by mean of a modified constitutive law σ-ε of the concrete (additional γ′c factor and/or reduced εcu deformation) to be employed in the ordinary equations for the consequent routine calculations. Other possible deviations (e.g. for shear and torsion) can be pointed out on the basis of the experimental results of the initial type testing. Transverse flexural effects of the loads (e.g. fixed-end bending moments of the cantilever wings) can be locally computed and verified in addition to the main longitudinal calculations (see also Annex D). C.2.3 Hyperstatic plate-systems behaviour For type "c" of C.1 a complete "folded-plate" analysis shall be performed, inclusive of transverse flexural effects due to loads and to the deformation of the cross profile. This analysis can be referred to an elastic model comprehensive of the extensional and flexural behaviours of the plates.

26 Finite Strip method can be applied for units with constant cross section or, in the general case, Finite Element method can be applied. The response of the above analytical models defines the distribution of the internal actions in terms of the eight components listed in A.1. For U.L.S a local verification will be consequently made following the criteria of Annex D. For regular shapes a beam-like routine calculation can be set-up for the main longitudinal behaviour, adjusted with the results of initial type calculations made with the more precise analytical models. Transverse flexural effects can be given by tabulations derived from the same initial type calculations. In any case the analytical models and their possible routine simplified derivations shall be verified by initial type testing (load tests up to failure). C.2.4 Isostatic plate-system behaviour Generally roof elements of type "d" of C.1 can be designed on the base of the ordinary beam model, calibrated by initial type testing (load tests up to failure) and followed by the verification of transverse flexural effects as specified in C.2.2. Since the torsional resistance of the plates is essential for stability, detailing of members shall be consistent with the correspondent design criteria as given in EN 1992-1-1. That is the following two solutions can be chosen: proportioning members and prestressing so to ensure in the relevant regions an uncracked behaviour in ultimate limit state, with the principal tensile stress of the concrete limited to the corresponding design strength (σI < fctd); providing each slab for torsion reinforcement made of transverse closed stirrups and longitudinal bars, so to ensure a peripheral truss mechanism at the ultimate cracked state. In the first case U.L.S. verifications are performed with reference to the principal compression stress of concrete as specified in Annex D; in the second case U.L.S. verifications are performed with the relevant equations of Clause 6.3 of EN 1992-1-1. Since "star-plate" systems can have high deformability for torsion, special care shall be given to check the compatibility of twist rotations in service conditions. C.2.5 Singular structural systems Unusual "e" types of roof elements (see C.1) shall rely on special analytical investigations and combined initial type testing (load tests up to failure), so to demonstrate that resistance checks reach at least the same reliability as for traditional design models. C.2.6 Integrated structure-completion systems Non structural completion parts of roof elements, such as upper rigid covering layers, can have a stable connection with the structural part so to improve significantly its resistance. This contribution can be taken into account in U.L.S verifications under the following conditions: the completion part has a documented systematic adequate resistance at least of the same reliability and durability as for the structural part; the structural part by itself has, under the principal load conditions, a resistance equal at least to the 80 % of the required design one and this shall be demonstrated by proper tests and calculations; the load-bearing capacity of the integrated system (type "f" of C.1) is verified, with reference to the required design resistance, by initial type testing (load tests up to failure) and by further sample testing (repeated load tests) with adequate frequency.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...