EN 15807:2021

(Main)Railway applications - Pneumatic half couplings

Railway applications - Pneumatic half couplings

This document applies to pneumatic half couplings designed to couple either the brake pipes or main reservoir pipes of railway vehicles, without taking the type of vehicles and track-gauge into consideration.

This document gives the requirements for the design, dimensions, testing and quality assurance of pneumatic half couplings.

Bahnanwendungen - Bremskupplungen

Dieses Dokument ist für Bremskupplungen anzuwenden, die so gestaltet sind, dass sie entweder die Hauptluft¬leitung oder die Hauptluftbehälterleitung von Schienenfahrzeugen miteinander verbinden, unabhängig von der Fahrzeugbauart und der Spurweite.

Dieses Dokument legt die Anforderungen an die Konstruktion, die Abmessungen, die Prüfung sowie die Qualitätssicherung der Bremskupplungen fest.

Applications ferroviaires - Demi-accouplements pneumatiques

Le présent document s'applique aux demi-accouplements pneumatiques conçus pour réaliser l'accouplement de la conduite générale de frein ou de la conduite principale des véhicules ferroviaires, indépendamment du type de véhicule et de l'écartement des voies.

Le présent document spécifie les exigences à satisfaire en matière de conception, de dimensions, d’essais et d’assurance qualité des demi-accouplements pneumatiques.

Železniške naprave - Pnevmatske polspojke

General Information

- Status

- Published

- Publication Date

- 09-Mar-2021

- Withdrawal Date

- 29-Sep-2021

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 47 - Braking

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 10-Mar-2021

- Due Date

- 18-Dec-2020

- Completion Date

- 10-Mar-2021

Relations

- Effective Date

- 17-Mar-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

ISO 188:2011 - Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 9227:2017 - Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227:2017) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 45545-1:2013 - Railway applications - Fire protection on railway vehicles - Part 1: General - Effective Date

- 28-Jan-2026

Overview

EN 15807:2021 - Railway applications: Pneumatic half couplings (CEN) specifies requirements for the design, dimensions, testing and quality assurance of pneumatic half couplings used to couple brake pipes or main reservoir pipes on railway vehicles. The standard applies regardless of vehicle type or track gauge and supersedes EN 15807:2011. It brings updated tolerances, test additions (kink resistance, oil influence), and aligns fire-behaviour requirements with EN 45545.

Key topics and technical requirements

EN 15807:2021 covers the full product lifecycle and quality controls for pneumatic half couplings, including:

Design & dimensions

- Geometry and physical characteristics for coupling heads, nipples, sealing washers and flexible hoses.

- Requirements for materials and external appearance.

Testing and type tests

- Type-test protocols for hoses, sealing washers and assembled half couplings (bend, pressure, burst, adhesion, impact, kink resistance, ozone resistance, low-temperature deflection).

- Hydraulic tests, leakage measurements and pull tests for mechanical strength.

- Routine and in-service assessment methods, sampling and documentation.

Environmental & operational conditions

- Compressed air quality classifications and expectations.

- Ambient temperature and environmental corrosion conditions per railway applications.

- Fire behaviour requirements adapted to EN 45545-1 and EN 45545-2.

Quality assurance & marking

- Production and inspection routines, test records and identification/marking rules for traceability.

Notable additions in the 2021 revision include tests for kink resistance and influence of oil, plus explicit clauses for nipple and hose clip components.

Applications and who uses it

EN 15807:2021 is used by:

- Manufacturers of pneumatic half couplings and hoses (design, production control, type approval).

- Railway OEMs and rolling-stock designers specifying couplings for brake and main reservoir systems.

- Maintenance and workshop teams for acceptance testing, in-service assessment and replacement guidance.

- Procurement and certification bodies to define compliance, interoperability and safety criteria.

- Testing laboratories performing type and routine tests referenced by the standard.

Practical benefits include improved safety and reliability of braking and reservoir air systems, interchangeability across fleets, reduced leakage and consistent fire-safety performance.

Related standards

EN 15807 references and aligns with several standards, notably:

- EN 45545-1 / EN 45545-2 (fire protection for railway vehicles)

- EN 50125-1 (environmental conditions)

- EN ISO 8033, EN ISO 9227, ISO 37, ISO 1817 (hose and rubber test methods)

Keywords: EN 15807:2021, pneumatic half couplings, railway standard, brake pipe coupling, main reservoir pipe, CEN, testing, design, quality assurance.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 15807:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Pneumatic half couplings". This standard covers: This document applies to pneumatic half couplings designed to couple either the brake pipes or main reservoir pipes of railway vehicles, without taking the type of vehicles and track-gauge into consideration. This document gives the requirements for the design, dimensions, testing and quality assurance of pneumatic half couplings.

This document applies to pneumatic half couplings designed to couple either the brake pipes or main reservoir pipes of railway vehicles, without taking the type of vehicles and track-gauge into consideration. This document gives the requirements for the design, dimensions, testing and quality assurance of pneumatic half couplings.

EN 15807:2021 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15807:2021 has the following relationships with other standards: It is inter standard links to EN 15807:2011, ISO 1431-1:2012, ISO 37:2017, ISO 188:2011, ISO 48-2:2018, EN 50125-1:2014, ISO 8573-1:2010, ISO 10619-2:2017, FprCEN ISO/TS 20451, EN ISO 9227:2017, EN ISO 8033:2017, EN 15185:2023, EN 1562:2019, prEN 14363-3, EN 45545-1:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15807:2021 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 2016/797/EU; Standardization Mandates: M/483, M/591. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15807:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2021

Nadomešča:

SIST EN 15807:2011

Železniške naprave - Pnevmatske polspojke

Railway applications - Pneumatic half couplings

Bahnanwendungen - Bremskupplungen

Applications ferroviaires - Demi-accouplements pneumatiques

Ta slovenski standard je istoveten z: EN 15807:2021

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15807

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2021

EUROPÄISCHE NORM

ICS 45.040 Supersedes EN 15807:2011

English Version

Railway applications - Pneumatic half couplings

Applications ferroviaires - Demi-accouplements Bahnanwendungen - Bremskupplungen

pneumatiques

This European Standard was approved by CEN on 25 January 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15807:2021 E

worldwide for CEN national Members.

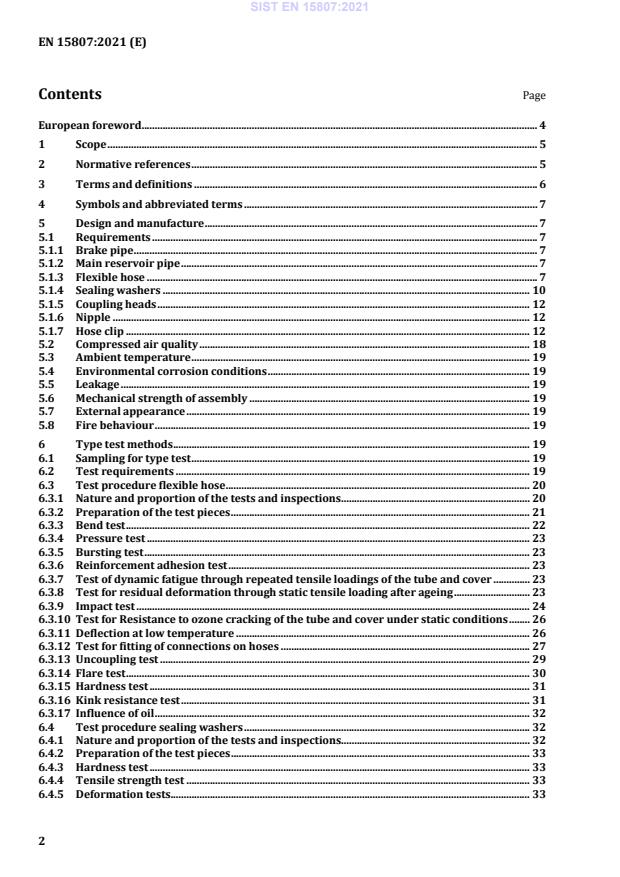

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols and abbreviated terms . 7

5 Design and manufacture . 7

5.1 Requirements . 7

5.1.1 Brake pipe . 7

5.1.2 Main reservoir pipe . 7

5.1.3 Flexible hose . 7

5.1.4 Sealing washers . 10

5.1.5 Coupling heads . 12

5.1.6 Nipple . 12

5.1.7 Hose clip . 12

5.2 Compressed air quality . 18

5.3 Ambient temperature . 19

5.4 Environmental corrosion conditions . 19

5.5 Leakage . 19

5.6 Mechanical strength of assembly . 19

5.7 External appearance . 19

5.8 Fire behaviour . 19

6 Type test methods . 19

6.1 Sampling for type test . 19

6.2 Test requirements . 19

6.3 Test procedure flexible hose . 20

6.3.1 Nature and proportion of the tests and inspections. 20

6.3.2 Preparation of the test pieces . 21

6.3.3 Bend test . 22

6.3.4 Pressure test . 23

6.3.5 Bursting test . 23

6.3.6 Reinforcement adhesion test . 23

6.3.7 Test of dynamic fatigue through repeated tensile loadings of the tube and cover . 23

6.3.8 Test for residual deformation through static tensile loading after ageing . 23

6.3.9 Impact test . 24

6.3.10 Test for Resistance to ozone cracking of the tube and cover under static conditions . 26

6.3.11 Deflection at low temperature . 26

6.3.12 Test for fitting of connections on hoses . 27

6.3.13 Uncoupling test . 29

6.3.14 Flare test . 30

6.3.15 Hardness test . 31

6.3.16 Kink resistance test . 31

6.3.17 Influence of oil . 32

6.4 Test procedure sealing washers . 32

6.4.1 Nature and proportion of the tests and inspections. 32

6.4.2 Preparation of the test pieces . 33

6.4.3 Hardness test . 33

6.4.4 Tensile strength test . 33

6.4.5 Deformation tests. 33

6.4.6 Water tightness test . 35

6.4.7 Influence of oil . 36

6.5 Test procedure pneumatic half coupling . 36

6.5.1 Principle . 36

6.5.2 Check of physical and geometrical characteristics . 37

6.5.3 Hydraulic test of the assembly at given pressure . 37

6.5.4 Leakage . 37

6.5.5 Corrosion test . 39

6.5.6 Pull test . 39

6.6 Documentation . 40

7 Routine test . 40

8 In-service assessment . 41

9 Identification and marking . 41

Annex A (informative) MRP pneumatic half coupling for use in the United Kingdom . 42

A.1 Main reservoir pipe hose incorporating pneumatic half coupling with sealing star

valve. 42

A.2 MRP rescue hoses . 44

A.3 MRP rescue coupling head . 44

A.4 MRP rescue coupling head identification . 44

Annex B (informative) In-service trial . 45

B.1 General . 45

B.2 Test set-up and sampling . 45

B.3 Procedure . 45

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2016/797/EU aimed to be covered . 46

Bibliography . 48

European foreword

This document (EN 15807:2021) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2021, and conflicting national standards shall

be withdrawn at the latest by September 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15807:2011.

— the document has been revised generally;

— tolerances, tables and figures have been updated;

— 5.8 “Fire behaviour” has been adapted due to EN 45545-1:2013 and EN 45545-2:2020;

— 5.1.3.5 “Adhesion of the reinforcement”: Nominal values have been adapted due to material

parameters of the requested fire resistant material;

— 5.1.3.15 and 6.3.16 “Kink resistance test” has been added;

— 5.1.3.16 and 6.3.17 “Influence of oil” has been added;

— 5.1.4.6 “Oil resistance of the sealing washer” has been added;

— 5.1.6 “Nipple” and 5.1.7 “Hose clip” have been added;

— 6.4.7 “Influence of oil” has been added;

— Annex A “Vacuum withstand” has been removed;

— Annex ZA has been updated.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

Directive 2016/797/EU.

For relationship with EU Directive 2016/797/EU, see informative Annex ZA, which is an integral part of

this document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document applies to pneumatic half couplings designed to couple either the brake pipes or main

reservoir pipes of railway vehicles, without taking the type of vehicles and track-gauge into

consideration.

This document gives the requirements for the design, dimensions, testing and quality assurance of

pneumatic half couplings.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1562:2019, Founding - Malleable cast irons

EN 1563:2018, Founding - Spheroidal graphite cast irons

EN 14478:2017, Railway applications - Braking - Generic vocabulary

EN 45545-1:2013, Railway applications - Fire protection on railway vehicles - Part 1: General

EN 45545-2:2020, Railway applications - Fire protection on railway vehicles - Part 2: Requirements for fire

behavior of materials and components

EN 50125-1:2014, Railway applications - Environmental conditions for equipment - Part 1: Rolling stock

and on-board equipment

EN ISO 228-1:2003, Pipe threads where pressure-tight joints are not made on the threads - Part 1:

Dimensions, tolerances and designation (ISO 228-1:2000)

EN ISO 8033:2017, Rubber and plastics hoses - Determination of adhesion between components

(ISO 8033:2016)

EN ISO 9227:2017, Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227:2017)

ISO 37:2017, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 48-2:2018, Rubber, vulcanized or thermoplastic — Determination of hardness — Part 2: Hardness

between 10 IRHD and 100 IRHD

ISO 1817:2015, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO 188:2011, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 815-1:2019, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 1: At

ambient or elevated temperatures

ISO 815-2:2019, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 2: At low

temperatures

ISO 1431-1:2012, Rubber, vulcanized or thermoplastic — Resistance to ozone cracking — Part 1: Static and

dynamic strain testing

ISO 1431-3:2017, Rubber, vulcanized or thermoplastic — Resistance to ozone cracking — Part 3: Reference

and alternative methods for determining the ozone concentration in laboratory test chambers

ISO 2285:2019, Rubber, vulcanized or thermoplastic — Determination of tension set under constant

elongation, and of tension set, elongation and creep under constant tensile load

ISO 8573-1:2010, Compressed air — Part 1: Contaminants and purity classes

ISO 10619-2:2017, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness —

Part 2: Bending tests at sub-ambient temperatures

ISO 23529:2016, Rubber — General procedures for preparing and conditioning test pieces for physical test

methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 14478:2017 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

brake coupling head

components that, when mechanically coupled together, allow a flow of pressurised air between them

3.2

nipple

component at one end of the pneumatic half coupling that connects it to the end cock, or pipe, located on

the vehicle

3.3

hose clip

component that mechanically fixes the hose to the coupling head or the nipple in order to assembly the

pneumatic half coupling

3.4

sealing washer

component that is installed in the coupling head to prevent unacceptable loss of air when two coupling

heads are connected to one another

3.5

flexible hose

component that is connected between the brake coupling head and the nipple to convey the pressurised

air and give the required flexibility between vehicles, and that is generally made up of an elastic tube,

textile reinforcement inlay and elastomeric cover bonded together

3.6

tube

inner layer of the flexible hose which is supplied by the compressed air

3.7

reinforcement

intermediate layer that provides the strength to maintain the general shape of the hose whilst giving the

flexibility

3.8

cover

outer layer of the flexible hose which protects the interior constituents from mechanical and

environmental damage

4 Symbols and abbreviated terms

BP Brake Pipe

IRHD International Rubber Hardness Degree

L0 a length of 20 mm marked on the calibrated part of the test piece

MRP Main Reservoir Pipe

5 Design and manufacture

5.1 Requirements

5.1.1 Brake pipe

The pneumatic half couplings for the automatic air brake pipe shall conform to Figure 1, Figure 3, Figure 5

and Figure 9. The length of the assembled pneumatic half coupling, dimension X-X in Figure 1, is specified

to suit the application, but the recommended length is 730 mm. The nipple to connect to the end cock

shall be in accordance with 5.1.6.

5.1.2 Main reservoir pipe

The pneumatic half couplings for the main reservoir pipe shall conform to Figure 2, Figure 4, Figure 5 and

Figure 9 for interoperable traffic. The length of the assembled pneumatic half coupling, dimension X-X in

Figure 2, is specified to suit the application, but the recommended length is 730 mm. The nipple to

connect to the end cock shall be in accordance with 5.1.6.

NOTE An alternative design of the MRP half coupling, as described in Annex A, is permitted for use in the United

Kingdom.

5.1.3 Flexible hose

5.1.3.1 General

The nominal internal diameter of the coupling hoses for both pipes shall be 28 mm. The length of the

flexible hose is varied to suit the application, but should be the standard 620 mm to give the

recommended length of 730 mm for dimension X-X as shown in Figure 1 and Figure 2. The recommended

length of these hoses when used with a swing head autocoupler should be increased to give an assembled

length of the pneumatic half coupling of 1 080 mm for the automatic air brake pipe and 930 mm for the

main reservoir pipe. Elastomeric composite hoses having a textile reinforcement inlay shall be used for

these couplings (see Figure 10). It shall be avoided that textile reinforcement inlay is destroyed by

humidity (e.g. by using of hydrophobic textile materials). The flexible hose shall conform to the

dimensions defined in Figure 10. The choice of elastomers for elastomeric composite hoses is the choice

of a manufacturer to meet the requirements of this specification. The elastomer used during a serial

production shall conform with regard to the formulation of materials and characteristics to those

products tested in the assessment procedure.

The tolerances for the overall length of the pneumatic half couplings shall be:

— < 1 000 mm ±5 mm,

— 1 000 mm to 2 499 mm ±10 mm,

— 2 500 mm to 6 000 mm ±30 mm,

— > 6 000 mm ±0,8 %.

The requirements 5.1.3.2 to 5.1.3.16 concern the elastomeric composite hoses.

5.1.3.2 Bending

It shall be possible to bend the hose to form approximately a torus, without using a total force greater

than 130 N for this operation, without folds appearing on the peripheral surface and without the

maximum flattening recorded amounting to more than 16 % of the nominal external diameter of the hose.

This requirement shall be tested in accordance with 6.3.3.

5.1.3.3 Behaviour under pressure

After being subjected to an internal pressure of 13 bar for a period of 5 min, there shall be no apparent

leak, swelling, or tear on the hose. The dimensional variations admitted under pressure conditions shall

be as follows:

— variation in external diameter ±10 %;

— variation in length ≤ 3,5 %;

— twist ≤ 20 °/m.

In addition, after discontinuation of the test pressure after a waiting period of 3 min, the max. permanent

deformation to the initial state of the hose shall be as follows:

— variation in external diameter ±2 %;

— variation in length ±2 %.

This requirement shall be tested in accordance with 6.3.4.

5.1.3.4 Bursting pressure

The bursting pressure, measured on the hose in delivery condition, shall not be less than 70 bar.

This requirement shall be tested in accordance with 6.3.5.

5.1.3.5 Adhesion of the reinforcement

The mean value of the force needed to separate the reinforcement and each of the layers:

— shall not be less than 2,5 N/mm for hoses tested in accordance with EN ISO 8033:2017, type 1 and

type 2 in delivery condition, and

— shall not be less than 2,5 N/mm for hoses tested in accordance with EN ISO 8033:2017, type 1 and

type 2 after ageing for 7 days at 70 °C, and

— should not be less than 2,5 N/mm for hoses tested in accordance with EN ISO 8033:2017, type 1 and

type 2 after interaction with oil in accordance with 6.3.17.

This requirement shall be tested in accordance with 6.3.6.

If the methods from EN ISO 8033:2017, type 1 or type 2 are not appropriate to a specific design of half

coupling, another method from EN ISO 8033:2017 may be used. The criteria of acceptance is then defined

before the test on a case-by-case basis.

5.1.3.6 Resistance of the tube and cover of the hose to repeated tensile loads

The tube and cover of the hose, when subjected to successive repeated tensile loads, shall withstand, in

accordance with the conditions defined in 6.3.7

— 400 tensile loadings for hoses tested in delivery condition,

— 350 tensile loadings for hoses tested after ageing for 7 days at 70 °C.

This requirement shall be tested in accordance with 6.3.7.

5.1.3.7 Residual deformation through static tensile loading of the tube of the hose

After tensile loading, the test piece taken from the tube of the hose and tested after ageing for 7 days at

70 °C, shall not be more than L0 + 12 % in length.

This requirement shall be tested in accordance with 6.3.8.

5.1.3.8 Impact resistance

After being subjected to the impact of a weight of 10 kg dropped from a height of 1 m, the bursting

pressure of the hose shall not be less than 70 bar.

This requirement shall be tested in accordance with 6.3.9.

5.1.3.9 Resistance to ozone cracking of the tube and cover of the hose under static conditions

The tube and cover of the hose, after exposure to an ozone-enriched atmosphere, shall not show signs of

cracking visible with a magnifying glass with a magnifying power of 7 X.

This requirement shall be tested in accordance with 6.3.10.

5.1.3.10 Behaviour at low temperature

The deflection of the hose as measured at the end of a length of 250 mm, 3 s after application of a load of

20 N at −30 °C, shall not be less than 10 mm.

If the brake coupling is used for temperatures down to −40 °C, an additional temperature test shall be

performed.

This requirement shall be tested in accordance with 6.3.11.

After bending and regaining ambient temperature, the hose shall pass a burst pressure test in accordance

with 5.1.3.4.

5.1.3.11 Ease of assembly of connections on the hoses

It shall be possible for the connections to be easily mounted on the hoses under the conditions stipulated

in 6.3.12 so that the end of the hose makes clean contact with the shoulder of the connection. The centre

lines of the hose and connection shall be in alignment after assembly.

This requirement shall be tested in accordance with 6.3.12.

5.1.3.12 Resistance to uncoupling of connections on the hoses

Uncoupling of the connection of the hose to the end fittings shall not occur when the pressure is less than

20 bar when the hose has been inserted as prescribed in 5.1.3.11 and the hose clip has been tightened

using the minimum force prescribed in the assembly instructions for the pneumatic half coupling.

This requirement shall be tested in accordance with 6.3.13.

5.1.3.13 Elongation resistance

After an elongation, the linings and layers shall neither tear nor become detached. The inspection shall

cover the visible outer surfaces, and it shall be performed with the naked eye.

The measured residual widening in any part of the hose shall not exceed 2 % after a waiting period of

(120 + 20) s.

This requirement shall be tested in accordance with 6.3.14.

5.1.3.14 Hardness

Requirements for hardness are the following:

— Hardness in delivery condition at (23 ± 2) °C: Manufacturers stated nominal IRHD with a tolerance

of ± 5 IRHD.

— Hardness after ageing for 7 days at 70 °C: Hardness recorded after ageing shall not deviate by more

than ± 5 IRHD from the value recorded before ageing.

This requirement shall be tested in accordance with 6.3.15.

5.1.3.15 Kink resistance

There shall be no observable permanent deformation or structural damage and no hose delamination

after the kink resistance test.

NOTE When the hose is bent at too sharp an angle, it can kink and shorten the effective hose life, and any such

kinking is not an acceptable or safe practice, but it happens. The requirement for a kink resistance test is included

to prevent potential problems with hose kinking in actual field use.

The requirement shall be tested in accordance with 6.3.16.

5.1.3.16 Oil resistance of the flexible hose

If required, by the technical specification, oil resistance test should be performed in accordance with

6.3.17.

5.1.4 Sealing washers

5.1.4.1 Dimensions

The dimensional specifications of the sealing washers shall be in accordance with Figure 9.

5.1.4.2 Hardness

Requirements for hardness are the following:

— Hardness in delivery condition at (23 ± 2) °C: 65 IRHD with a tolerance of ± 5 IRHD.

— Hardness after ageing for 7 days at 70 °C: Hardness recorded after ageing shall not deviate by more

than 5 IRHD from the value recorded before ageing.

This requirement shall be tested in accordance with 6.4.3.

5.1.4.3 Tensile characteristics

a) In delivery condition:

1) ultimate tensile strength ≥ 10 MPa;

2) elongation at break ≥ 300 %;

b) After ageing for 7 days at 70 °C:

Characteristics recorded after ageing shall not deviate from those recorded prior to ageing by more

than:

1) 20 % for ultimate tensile strength,

2) 30 % for elongation at break.

This requirement shall be tested in accordance with 6.4.4.

5.1.4.4 Deformation resistance

Deformation tests shall be carried out at high and low temperature. The test set out in 5.1.4.4, a) or those

specified in 5.1.4.4, b) shall be performed:

a) Deformation under tensile test:

1) tension set under 50 % elongation for 24 h at 70 °C: ≤ 10 %;

2) flexibility test at −25 °C and under 50 % compression, carried out in delivery condition: ≤ 8 %.

b) Deformation under compression test:

1) compression set following compression for 22 h at 70 °C: ≤ 25 %;

2) compression set following compression for 22 h at −30 °C: ≤ 60 %.

This requirement shall be tested in accordance with 6.4.5.

5.1.4.5 Water tightness

Two coupling heads, fitted with sealing washers and joined together to simulate service conditions and

immersed in water, shall be watertight round the sealing washers and allow no visible leakage (no air

bubbles) under the effect of 0,5 bar air pressure.

This requirement shall be tested in accordance with 6.4.6.

5.1.4.6 Oil resistance of the sealing washer

Under the influence of the oil indicated in technical specification, the variation in hardness and volume of

test pieces shall be in conformity with technical specification.

This requirement shall be tested in accordance with 6.4.7.

5.1.5 Coupling heads

The coupling head for the BP shall conform to Figure 3, Figure 5 and Figure 6 or Figure 7. The coupling

head for the MRP shall conform to Figure 4, Figure 5 and Figure 6 or Figure 7. All the figures show the

mandatory dimensions to ensure coupling, but the shape and the other dimensions are able to be varied,

provided the heads are designed to offer the least possible resistance to airflow. The sealing washer

shown in Figure 9 shall be used.

The material of the coupling heads shall be one of the following:

— EN-GJS-400-15 or EN-GJS-500-7 in accordance with EN 1563:2018;

— EN-GJMB-350-10 or EN-GJMW-400-05 in accordance with EN 1562:2019;

— other material if equivalent characteristics are demonstrated.

NOTE An alternative design of the MRP coupling head, as described in Annex A, is permitted for use in the

United Kingdom.

5.1.6 Nipple

The nipple to connect to the end cock shall be as shown in Figure 6 or Figure 7 and Figure 8, and shall

have a truncated internal pipe thread of size G 1 1/4 in accordance with EN ISO 228-1:2003.

The figures show the mandatory dimensions, but the shape and the other dimensions are able to be

varied, provided the nipples are designed to offer the least possible resistance to airflow.

The material of the nipple shall be one of the following:

— EN-GJS-400-15 or EN-GJS-500-7 in accordance with EN 1563:2018;

— EN-GJMB-350-10 or EN-GJMW-400-05 in accordance with EN 1562:2019;

— other material if equivalent characteristics are demonstrated.

5.1.7 Hose clip

The design of the hose clip shall ensure that the pneumatic half coupling withstands the mechanical

strength requirements as defined in 5.6.

Key

X - X length of the assembled pneumatic half coupling

Figure 1 — Brake pipe pneumatic half coupling

Key

X - X length of the assembled pneumatic half coupling

Figure 2 — Main reservoir pneumatic half coupling

Dimensions in millimetres

Key

1 alternative view in direction of arrow B

2 part view in direction of arrow C

3 part view in direction of arrow B

4 alternative view in direction of arrow C

a

mandatory dimension

Figure 3 — Brake pipe coupling head

Dimensions in millimetres

Key

1 alternative view in direction of arrow B

2 part view in direction of arrow C

3 part view in direction of arrow B

4 alternative view in direction of arrow C

a

mandatory dimension

Figure 4 — Main reservoir pipe coupling head

Dimensions in millimetres

Key

a

mandatory dimension

Figure 5 — Groove for the sealing washer

Dimensions in millimetres

Figure 6 — Nipple end (coupling head shown in Figure 3 and Figure 4)

Dimensions in millimetres

Figure 7 — Alternative nipple end geometry

Dimensions in millimetres

Figure 8 — Nipple base geometry

Dimensions in millimetres

All dimensions are mandatory.

Figure 9 — Sealing washer

Dimensions in millimetres

a) Detail A: preferred arrangement b) Detail A: alternative arrangement

Key

B bore of hose

C outer diameter of hose

D wall thickness of hose

E textile reinforcement inlay

F tube

F cover

G area of hose where the identification marking is to be located

L length of hose

Figure 10 — Flexible hose

5.2 Compressed air quality

It shall be possible to operate the pneumatic half coupling without restrictions with at least the

compressed air quality in accordance with the following classes defined by ISO 8573-1:2010:

— class 4 – for the maximum particle size and the maximum concentration of solid contaminants;

— class 4 – for the water dewpoint;

— class 4 – for the maximum total (droplets, aerosols and vapours) oil concentration.

5.3 Ambient temperature

The pneumatic half coupling shall be able to operate within the temperature classes T1 and TX as

specified by EN 50125-1:2014, where the upper limit for TX is +70 °C external air temperature.

NOTE A higher or lower temperature value can be specified if operational constraints demand it.

5.4 Environmental corrosion conditions

The pneumatic half coupling shall withstand the external corrosion due to normal atmospheric pollutants

such that its function is unaffected. The pneumatic half coupling shall be tested in accordance with 6.5.5.

5.5 Leakage

The sealing arrangement with the pneumatic half coupling assembly shall prevent any significant loss of

air dependent on the temperature. Between −25 °C and +70 °C the pneumatic half coupling shall not leak

at a greater rate than 0,030 Nl/min when tested at a pressure of 10 bar. This requirement shall be tested

in accordance with 6.5.4.2.

Between −40 °C and −25 °C, a pair of pneumatic half couplings shall have a leakage rate of not greater

than 0,2 Nl/min when tested at a pressure of 10 bar in accordance with 6.5.4.3.

5.6 Mechanical strength of assembly

The pneumatic half coupling shall withstand an overpressure of 15 bar for 15 min and 40 bar for 15 s

without detachment of the hose from the coupling head or from the nipple, and no leakage shall be

generated. This requirement shall be tested in accordance with 6.5.3.

The pneumatic half coupling shall withstand a pull test when the coupling head is screwed on to a fixture

and the nipple is pulled with a force of 5 kN for 30 s. The hose shall not move on the nipple or coupling

head. The hose shall not suffer damage and there shall be no leakage generated. This requirement shall

be tested in accordance with 6.5.6.

5.7 External appearance

The external surfaces of the pneumatic half coupling shall be free of sharp edges that could be a danger

to those persons handling the pneumatic half coupling or to other equipment in the proximity of the

pneumatic half coupling. This requirement shall be checked while testing the other constructional

features in accordance with 6.5.2.

5.8 Fire behaviour

If applicable in accordance with EN 45545-1:2013, the fire behaviour of the pneumatic half coupling shall

be consistent with EN 45545-2:2020.

6 Type test methods

6.1 Sampling for type test

A sample of ten pneumatic half couplings shall be taken from the production.

6.2 Test requirements

If not otherwise specified, all the type tests shall be performed at (20 ± 5) °C and the air quality of the

compressed air class 4-4-4 specified in ISO 8573-1:2010.

For all test values without specific tolerances, the tolerances of ± 5 % shall be applied.

6.3 Test procedure flexible hose

6.3.1 Nature and proportion of the tests and inspections

The hoses shall be subjected to the tests and inspections indicated in Table 1 and Table 2 as shown. The

batch size the samples are taken from is unlimited, provided measures shall be taken to provide identical

material for the whole batch.

Table 1 — Testing of flexible hose – example of sample selection

Nature of the Corresponding Corresponding Number of tested hoses per batch

tests and test subclause requirement

1 2 3 4 5 6 7 8 9 10 11 12

inspections subclause

Dimensional — 5.1.3.1 General

x x x x x x x x x x x x

check

Bend test 6.3.3 Bend test 5.1.3.2 Bending x x x

Deformation 6.3.11 Deflection 5.1.3.10

test at low at low Behaviour at low x x x

temperature temperature temperature

Elongation 6.3.14 Flare test 5.1.3.13

test Elongation x x x

resistance

Hardness test 6.3.15 Hardness 5.1.3.14

x x x

test Hardness

Impact test 6.3.9 Impact test 5.1.3.8 Impact

x x x

resistance

Connection 6.3.12 Test for 5.1.3.11 Ease of

assembly test fitting of assembly of

connections on connections on

hoses the hoses

6.3.13 5.1.3.12 x x x

Uncoupling test Resistance to

uncoupling of

connections on

the hoses

Kink 6.3.16 Kink 5.1.3.15 Kink

resistance resistance test resistance x x

test

Pressure test 6.3.4 Pressure 5.1.3.3

test Behaviour under x x

pressure

Bursting test 6.3.5 Bursting 5.1.3.4 Bursting

x x

test pressure

Oil resistance 6.3.17 Influence 5.1.3.16 Oil x x

test of oil resistance of the

flexible hose

Table 2 — Sample testing of test pieces

Nature of the tests Corresponding Corresponding Number of Shape and

and inspections test subclause requirement tested pieces dimensions of

subclause per batch the test pieces

Reinforcement 6.3.6 5.1.3.5 Adhesion

adhesion test: Reinforcement of the

adhesion test reinforcement

– in delivery condition 3

Test pieces: hose

section 35 mm

– after ageing 3

to 40 mm in

length

Test for dynamic 6.3.7 Test of 5.1.3.6 Resistance

fatigue through dynamic fatigue of the tube and

repeated tensile through repeated cover of the hose

loadings: tensile loadings of to repeated

the tube and tensile loads

cover

Dumb-bell

– in delivery condition 3 per cover

shaped test

3 per tube

pieces in

– after ageing 3 per cover accordance with

3 per tube 6.3.2

Test pieces of the 6.3.8 Test for 5.1.3.7 Residual

Dumb-bell

tube for residual residual deformation

shaped test

deformation deformation through static

3 pieces in

through static through static tensile loading of

accordance with

tensile loading after tensile loading the tube of the

6.3.2

ageing after ageing hose

Test for resistance 6.3.10 Test for 5.1.3.9 Resistance

Dumb-bell

to ozone cracking of Resistance to to ozone cracking

shaped test

the tube and cover ozone cracking of of the tube and 3 per cover

pieces in

under static the tube and cover of the hose 3 per tube

accordance with

conditions cover under static under static

6.3.2

conditions conditions

6.3.2 Preparation of the test pieces

The test pieces required for the tests provided in 6.3.7, 6.3.8, 6.3.10 and 6.3.17 shall be of type 2 in

accordance with ISO 37:2017; they are taken from the hose in the circumferential direction. Alternatively,

samples from calendered plates may be used. The sampling shall be positioned on these plates so that the

loading direction goes across to the direction of calendering.

The test pieces for testing after accelerated ageing shall be placed in an oven at 70 °C for 7 days. These

operations shall be carried out in accordance with ISO 188:2011. The other test pieces shall be tested in

delivery condition.

6.3.3 Bend test

The bend test shall be carried out by means of two handles and a disc as shown in Figure 11. The disc

shall contain a small A-shaped opening for insertion of the recording instrument in order to determine

the flattening of the hose during bending. The length of the hose is 620 mm.

The bending force F is measured at a distance J from the hose end.

During bending, no axial force shall be applied on the hose ends.

The result shall be consistent with those stipulated in 5.1.3.2.

Dimensions in millimetres

Key

A shaped opening for measuring diameter = (30 ± 2) mm

B hos

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...