EN 1005-5:2007

(Main)Safety of machinery - Human physical performance - Part 5: Risk assessment for repetitive handling at high frequency

Safety of machinery - Human physical performance - Part 5: Risk assessment for repetitive handling at high frequency

This European Standard presents guidance to the designer of machinery or its component parts and the writer of type C standards in assessing and controlling health and safety risks due to machine-related repetitive handling at high frequency.

This European Standard specifies reference data for action frequency of the upper limbs during machinery operation, and it presents a risk assessment method intended for risk reduction option analysis.

This European Standard applies to machinery for professional operation by the healthy adult working population. This European Standard is not applicable for repetitive movements and related risks of the neck, back and lower limbs.

Sicherheit von Maschinen - Menschliche körperliche Leistung - Teil 5: Risikobeurteilung für kurzzyklische Tätigkeiten bei hohen Handhabungsfrequenzen

Diese Europäische Norm bietet Leitlinien für den Konstrukteur von Maschinen oder Maschinenteilen und den Autor von C-Normen hinsichtlich der Bewertung und Beherrschung von Gesundheits- und Sicherheitsrisiken, die durch maschinenbezogene repetitive Tätigkeiten bei hohen Handhabungsfrequenzen entstehen.

In dieser Norm werden Referenzdaten für die Betätigungssfrequenz der oberen Gliedmaßen während der Bedienung von Maschinen festgelegt, und es wird ein Verfahren zur Risikobeurteilung vorgestellt, das für die Analyse der Möglichkeiten einer Risikominderung vorgesehen ist.

Diese Norm gilt für Maschinen für die berufsmäßige Bedienung durch die gesunde erwachsene Arbeitsbevölkerung. Diese Norm gilt nicht für Haltungen des Oberarms über Schulterhöhe.

Die Festlegungen in diesem Dokument sind nicht auf Maschinen anwendbar, die vor dem Datum der Veröffentlichung dieses Dokuments durch CEN hergestellt wurden.

Sécurité des machines - Performance physique humaine - Partie 5: Appréciation du risque relatif à la manipulation répétitive à fréquence élevée

La présente Norme européenne présente au concepteur de machines ou de leurs éléments, ainsi qu'au rédacteur de normes de type C, un principe directeur permettant d'apprécier et de prévenir les risques pour la santé et la sécurité dus à une manipulation répétitive, à fréquence élevée, impliquant l’utilisation de machines.

La présente Norme européenne spécifie les éléments de référence relatifs à la fréquence des actions des membres supérieurs au cours de l’utilisation des machines et présente une méthode d’appréciation des risques destinée à l’analyse des options de réduction des risques.

La présente Norme européenne s’applique aux machines à usage professionnel utilisées par la population active adulte en bonne santé. Elle ne s’applique pas aux mouvements répétitifs, ni aux risques associés pour le cou, le dos et les membres inférieurs.

Varnost strojev - Človeške fizične zmogljivosti - 5. del: Ocena tveganja rokovanja z veliko pogostostjo ponavljanja

General Information

- Status

- Published

- Publication Date

- 27-Feb-2007

- Withdrawal Date

- 30-Aug-2007

- Technical Committee

- CEN/TC 122 - Ergonomics

- Drafting Committee

- CEN/TC 122/WG 4 - Biomechanics

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 20-Sep-2022

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1005-5:2007 - Safety of machinery - Human physical performance - Part 5: Risk assessment for repetitive handling at high frequency (CEN) provides guidance for designers and standards writers on assessing and controlling health risks from machine-related repetitive handling at high frequency. The standard specifies reference data for upper‑limb action frequency and presents a two‑level risk assessment method intended to support risk reduction option analysis for professional machinery operation by the healthy adult working population. It does not cover repetitive movement risks for the neck, back or lower limbs.

Key topics and requirements

- Scope and applicability

- Targets repetitive, high‑frequency upper‑limb tasks linked to machinery operation.

- Applies to professional users (healthy adults); excludes neck/back/lower‑limb risks.

- Risk assessment framework

- Two assessment routes:

- Method 1 - simple estimation and initial evaluation of repetitive handling at high frequency.

- Method 2 - detailed evaluation for risk reduction and option analysis (includes multi‑task and mono‑task procedures).

- Two assessment routes:

- Reference data and metrics

- Defines technical actions, cycle time, frequency of actions, and how to count actions (Annex A).

- Supplies reference data for action frequency and computation of reference technical actions.

- Ergonomic multipliers and indices

- Uses multipliers for posture, repetitiveness, force, recovery and duration to calculate exposure (examples in Annex F/H).

- Includes the OCRA index (Annex D) and its association with upper‑limb work‑related musculoskeletal disorders (UL‑WMSDs) to classify exposure areas and recommended actions.

- Supporting procedures and guidance

- Posture and movement descriptions (Annex B), force assessment methods (biomechanical and psychophysical approaches in Annex C).

- Examples, verification steps and multi‑task analysis case studies (Annexes E–H).

Applications and users

- Primary users

- Machine designers and OEMs seeking to minimize operator musculoskeletal risk.

- Writers of type C standards and conformity assessment teams.

- Ergonomists, occupational health & safety professionals, and risk assessors evaluating high‑frequency manual tasks at machinery.

- Practical uses

- Designing interfaces, tooling and workstations to reduce repetitive action frequency, force and awkward postures.

- Comparing design alternatives using Method 2 to prioritize risk‑reduction measures.

- Preparing conformity documentation and user information addressing repetitive handling hazards.

Related standards

- EN 1005 series: Parts 1–4 (terms, manual handling, recommended force limits, posture evaluation)

- EN 1050 (Principles for risk assessment)

- EN ISO 12100‑1 / ‑2 (Basic concepts and principles for machinery safety)

- EN ISO 14738 (Anthropometric requirements for workstations)

Keywords: EN 1005-5, risk assessment, repetitive handling, high frequency, safety of machinery, ergonomics, OCRA index, technical actions, upper limbs.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 1005-5:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Human physical performance - Part 5: Risk assessment for repetitive handling at high frequency". This standard covers: This European Standard presents guidance to the designer of machinery or its component parts and the writer of type C standards in assessing and controlling health and safety risks due to machine-related repetitive handling at high frequency. This European Standard specifies reference data for action frequency of the upper limbs during machinery operation, and it presents a risk assessment method intended for risk reduction option analysis. This European Standard applies to machinery for professional operation by the healthy adult working population. This European Standard is not applicable for repetitive movements and related risks of the neck, back and lower limbs.

This European Standard presents guidance to the designer of machinery or its component parts and the writer of type C standards in assessing and controlling health and safety risks due to machine-related repetitive handling at high frequency. This European Standard specifies reference data for action frequency of the upper limbs during machinery operation, and it presents a risk assessment method intended for risk reduction option analysis. This European Standard applies to machinery for professional operation by the healthy adult working population. This European Standard is not applicable for repetitive movements and related risks of the neck, back and lower limbs.

EN 1005-5:2007 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 13.180 - Ergonomics. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1005-5:2007 has the following relationships with other standards: It is inter standard links to EN ISO 14738:2002, EN 1005-4:2005, EN 614-2:2000+A1:2008, EN ISO 12100:2010, EN 1005-3:2002, EN 1005-2:2003+A1:2008, EN 614-1:2006+A1:2009, EN 1009-1:2020, EN 1005-4:2005+A1:2008, EN 1612-1:1997+A1:2008, EN 1612:2019, EN 1005-1:2001+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1005-5:2007 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1005-5:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Safety of machinery - Human physical performance - Part 5: Risk assessment for repetitive handling at high frequencySécurité des machines - Performance physique humaine - Partie 5: Appréciation du risque relatif a la manipulation répétitive a fréquence élevéeSicherheit von Maschinen - Menschliche körperliche Leistung - Teil 5: Risikobeurteilung für kurzzyklische Tätigkeiten bei hohen HandhabungsfrequenzenTa slovenski standard je istoveten z:EN 1005-5:2007SIST EN 1005-5:2007en,fr,de13.180ErgonomijaErgonomics13.110Varnost strojevSafety of machineryICS:SLOVENSKI

STANDARDSIST EN 1005-5:200701-september-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1005-5February 2007ICS 13.110; 13.180 English VersionSafety of machinery - Human physical performance - Part 5:Risk assessment for repetitive handling at high frequencySécurité des machines - Performance physique humaine -Partie 5: Appréciation du risque relatif à la manipulationrépétitive à fréquence élevéeSicherheit von Maschinen - Menschliche körperlicheLeistung - Teil 5: Risikobeurteilung für kurzzyklischeTätigkeiten bei hohen HandhabungsfrequenzenThis European Standard was approved by CEN on 16 December 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1005-5:2007: E

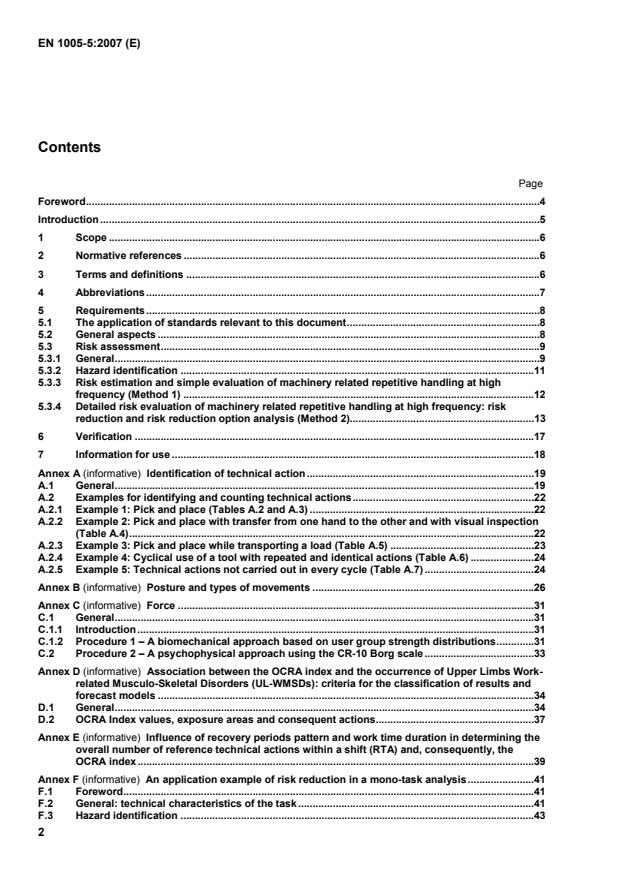

Identification of technical action.19 A.1 General.19 A.2 Examples for identifying and counting technical actions.22 A.2.1 Example 1: Pick and place (Tables A.2 and A.3).22 A.2.2 Example 2: Pick and place with transfer from one hand to the other and with visual inspection (Table A.4).22 A.2.3 Example 3: Pick and place while transporting a load (Table A.5).23 A.2.4 Example 4: Cyclical use of a tool with repeated and identical actions (Table A.6).24 A.2.5 Example 5: Technical actions not carried out in every cycle (Table A.7).24 Annex B (informative)

Posture and types of movements.26 Annex C (informative)

Force.31 C.1 General.31 C.1.1 Introduction.31 C.1.2 Procedure 1 – A biomechanical approach based on user group strength distributions.31 C.2 Procedure 2 – A psychophysical approach using the CR-10 Borg scale.33 Annex D (informative)

Association between the OCRA index and the occurrence of Upper Limbs Work-related Musculo-Skeletal Disorders (UL-WMSDs): criteria for the classification of results and forecast models.34 D.1 General.34 D.2 OCRA Index values, exposure areas and consequent actions.37 Annex E (informative)

Influence of recovery periods pattern and work time duration in determining the overall number of reference technical actions within a shift (RTA) and, consequently, the OCRA index.39 Annex F (informative)

An application example of risk reduction in a mono-task analysis.41 F.1 Foreword.41 F.2 General: technical characteristics of the task.41 F.3 Hazard identification.43

Definition and quantification of additional risk factors.58 Annex H (informative)

Risk assessment by Method 2 when designing “multitask” jobs.60 H.1 OCRA index calculation when two or more repetitive tasks should be assessed.60 H.2 An application example: assessing repetitive tasks at a machine.61 H.2.1 Description of characteristics of two tasks.61 H.2.2 Definition of the corresponding multipliers.62 H.2.3 Mono- task analysis separately for task A and B: computation of the overall number Actual Technical Actions (ATA) in task A (Table H.3) and task B (Table H.4).62 H.2.4 Mono- task analysis: computation of the overall number of reference technical actions within a shift (RTA) in task A (Table H.5) and task B (Table H.6).65 H.2.5 Mono- task analysis: computation of the OCRA index in task A (Table H.5) and task B (Table H.6).65 H.3 Multi-tasks analysis.67 H.3.1 Computation of the overall number of Actual Technical Actions (ATA) in task A and task B (Table H.7).67 H.3.2 Computation of the overall number of reference technical actions (RTA) in task A and task B (Table H.7).68 H.3.3 Computation of the overall number of reference technical actions within a shift in task A and task B (Table H.7).69 H.4 Conclusion.70 Bibliography.71

1 Scope This European Standard presents guidance to the designer of machinery or its component parts and the writer of type C standards in assessing and controlling health and safety risks due to machine-related repetitive handling at high frequency. This European Standard specifies reference data for action frequency of the upper limbs during machinery operation, and it presents a risk assessment method intended for risk reduction option analysis. This European Standard applies to machinery for professional operation by the healthy adult working population. This European Standard is not applicable for repetitive movements and related risks of the neck, back and lower limbs. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 614-1, Safety of machinery — Ergonomic design principles — Part 1: Terminology and general principles EN 614-2, Safety of machinery — Ergonomic design principles — Part 2: Interactions between the design of machinery and work tasks EN 1005-2, Safety of machinery — Human physical performance — Part 2: Manual handling of machinery and component parts of machinery EN 1005-3:2002, Safety of machinery — Human physical performance — Part 3: Recommended force limits for machinery operation EN 1005-4:2005, Safety of machinery — Human physical performance — Part 4: Evaluation of working postures and movements in relation to machinery EN 1050, Safety of machinery — Principles for risk assessment EN ISO 12100-1, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003) EN ISO 14738:2002, Safety of machinery — Anthropometric requirements for the design of workstations at machinery (ISO 14738:2002) ISO/IEC Guide 51, Safety aspects — Guidelines for their inclusion in standards 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. NOTE Terms and definitions used in EN and ISO standards referred to in this European Standard are also valid for this European Standard.

Legend for abbreviations AdM

Additional factors Multiplier

ATA

Number of Actual Technical Actions within a shift

CF

“Constant of Frequency” of technical actions per minute D

net Duration in minutes of each repetitive task DuM

Duration Multiplier

FCT

Foreseeable duration of the Cycle Time (in seconds)

Foreseeable Frequency of technical actions per minute

FoM

Force Multiplier

j

generic repetitive tasks

MSDs

Musculo-Skeletal Disorders n

Number of repetitive task/s performed during shift

NEP

Number of Exposed Persons

NPA

Number of Persons Affected by one or more UL-WMSDs

NTC

Number of technical actions in the work cycle

OCRA

OCcupational Repetitive Action

PA

Prevalence (%) of persons Affected RF

Reference Frequency of technical actions per minute PoM

Posture Multiplier RcM

Recovery Multiplier

ReM

Repetitiveness Multiplier RTA

Number of Reference Technical Actions within a shift S.E.

Standard Error

UL-WMSDs

Upper Limb Work-related Musculo-Skeletal Disorders 5 Requirements 5.1 The application of standards relevant to this document The designer shall consider the principles given in EN 1050, EN 614-1 and EN 614-2, EN 1005-2, EN 1005-3, EN 1005-4, EN ISO 12100-1 and EN ISO 12100-2 and EN ISO 14738. 5.2 General aspects The designer of a machine is required to: a) conduct an assessment of risk of musculoskeletal disorders due to machine related repetitive work; b) take account in the assessment of the single and combined effects from the most relevant risk factors as repetitiveness, force, working postures, foreseen work duration, lack of recovery periods and additional factors; c) if possible try to avoid risk ‘at the source’ or alternatively to minimise these health risks by changes in the machinery design (automation, technical aids); d) when all is done to minimize the risk it is an obligation to inform about residual risks in instructions for use. Machines and related tasks shall be designed in a way, so that activities demanding high frequency can be performed adequately with respect to the force required, the posture of the limbs and the foreseeable presence of recovery periods. In addition machines and related tasks shall be designed to allow for variations in movements. Additional factors (see 3.11) have to be considered. When designing machinery and work tasks, the designer shall ensure that the following ergonomics characteristics of well-designed work tasks are fulfilled. These characteristics take into account the differences and dynamic characteristics of the intended operator population, and shall be pursued by designing machinery and machinery related work tasks in interaction (EN 614-2).

Figure 1 — Risk assessment model

[12, 14], as described in Table 1 and Annex B; iii) the kinds of grasp are “power grip”, or “pinch lasting no more than 1/3 of the cycle time”, as described in Table 1 and Annex B [12, 15, 26]. c) Low repetitiveness. This is true if [40, 41]: i) the cycle time is more than 30 s. ii) the same kinds of technical action are not repeated for more than 50 % of the cycle time. d) Frequency of technical actions for both upper limbs is less than 40 technical actions per minute. If the frequency is higher than 40 actions per minute for at least one upper limb then move on to Method 2. In order to compute the frequency of technical actions/min (see Annex A for identification of technical action), use the following equation: FCTNTCFF60⋅= (1) where FF

is the foreseeable frequency of technical actions per minute; FCT

is foreseeable duration of the cycle time in seconds; NTC is the number of technical actions (for each upper limb) in the work cycle needed to carry out the task.

is foreseeable duration of the cycle time in seconds; NTC is the number of technical actions (for each upper limb) needed to carry out the task during one cycle. The following equation calculates the reference frequency (number per minute) of technical actions (RF) on a work cycle base: ()MMMMMMDuRcFoAdRePoCFRF××××××= where CF

is the “constant of frequency” of technical actions per minute = 30; PoM; ReM; AdM; FoM are multipliers for the risk factors postures, repetitiveness, additional, force; RcM

is the multiplier for the risk factor “lack of recovery period”;

is the multiplier for the overall duration of repetitive task(s) during a shift. When designing a machinery related task, evaluate reference frequency of the technical actions within a work cycle that is representative of the task under examination. The analyses shall include the main risk factors that the designer can influence with the consequent choice of a specific multiplier for each risk factor. These multipliers will decrease from 1 to 0 as the risk level increases. The risk factors and the corresponding multiplier, influenced by the designer, are: awkward or uncomfortable postures or movements (posture multiplier) (PoM), see 5.3.4.1.2; high repetition of the same movements (repetitiveness multiplier) (ReM), see 5.3.4.1.3; presence of additional factors (additional multiplier) (AdM), see 5.3.4.1.4; frequent or high force exertions (force multiplier) (FoM), see 5.3.4.1.5. The other factors considered in the equation (RcM × DuM) are generally out of the direct influence of the designer and consequently they will be considered, in this context, as a constant, reflecting a common condition of repetitive task duration of 240 min to 480 minutes/shift with 2 breaks of 10 min plus the lunch break. In practice, to determine the reference frequency (per minute) of technical actions (RF), proceed as follows: start from CF (30 actions per minute); CF (the frequency constant) has to be weighted (by the respective multipliers) considering the presence and degree of the following risk factors: force (FoM), posture (PoM), repetitiveness (ReM) and additional (AdM); apply the constant that considers the multiplier for repetitive task duration (DuM) and the multiplier for recovery periods (RcM); Thus the value obtained represents the reference frequency (per minute) of technical actions (RF) for the examined task in the common condition of at least 2 breaks of 10 min (plus the lunch break) in a shift of maximal 480 min. 5.3.4.1.2 Posture Multiplier (PoM) If the conditions for posture are the same as in Method 1, the multiplier is 1. If those conditions are not present, use the indications in Table 1 for obtaining the specific multiplier factor (PoM) (see also Annex B): When considering awkward postures and movements of operators in Table 1, it is important to determine the range of body dimensions of the user population and the general design principles, which are described in EN 614-1. Early in the design process a comparison shall be made between the body dimensions of the user population and the machinery dimensions. This can be done by means of standards (EN 547-1, EN 547-2, EN 547-3 and EN ISO 14738), body templates or computer manikins.

Portion of the cycle time Awkward posture [12] See Figures B.1 and B.2 Less than 1/3 from 1 % to 24 %

1/3 from 25 % to 50 %

2/3 from 51 % to 80 %

3/3 more than 80 % Elbow supination (≥ 60°) Wrist extension (≥ 45°) or flexion (≥ 45°) Hand pinch or hook grip or palmar grip (wide span) 1 0,7 0,6 0,5 Elbow pronation(≥ 60°) or flexion/extension (≥ 60°) Wrist radio-ulnar deviation (≥ 20°) Hand power grip with narrow span (≤ 2 cm) 1 1 0,7 0,6 At the end of the analysis of awkward postures, select the lowest multiplier PoM in accordance with the foreseen postures and movements of elbow, wrist and hand (type of grip) for calculating the equation. The designer, at this step, shall consider also shoulder postures and movements (for details see EN 1005-4,

EN ISO 14738). NOTE Any movement above shoulder height should be avoided. At this moment there is no available data for identifying a specific PoM for shoulders: consequently PoM for shoulders cannot be included in the OCRA index computation procedure. Annex B gives further explanation how to analyse postures and movements of the upper limbs. 5.3.4.1.3 Repetitiveness multiplier (ReM) When the task requires the performance of the same technical actions of the upper limbs for at least 50 % of the cycle time or when the cycle time is shorter than 15 s, the corresponding multiplier factor (ReM) is 0,7. Otherwise ReM is equal to 1. 5.3.4.1.4 Additional factors multiplier (AdM) The main additional factors are (non exhaustive list): use of vibrating tools, gestures implying counter shock (such as hammering), requirement for absolute accuracy, localized compression of anatomical structures, exposure to cold, use of gloves interfering with handling ability, high pace completely determined by the machinery. If additional factors as listed above are absent for most of the task duration, the additional factor multiplier (AdM) equals 1. Otherwise the additional factor multiplier (AdM) equals: AdM = 1, if additional factor(s) are present at the same time for less than 25 % of the cycle time; AdM = 0,95, if additional factor(s) are present at the same time for 1/3 (from 25 % to 50 %) of the cycle time; AdM = 0,90, if additional factor(s) are present at the same time for 2/3 (from 51 % to 80 %) of the cycle time; AdM = 0,80, if additional factor(s) are present at the same time for 3/3 (more than 80 %) of the cycle time. Annex G further explains how to identify and evaluate the different additional factors.

in % of Fb

5 10 20 30 40 ≥ 50 CR-10 Borg 0,5 1 2 3 4 ≥ 5 Score very, very weak very weak weak moderate somewhat strong strong/very strong Force multiplier (FoM) 1 0,85 0,65 0,35 0,2 0,01

5.3.4.1.6 Predetermined value (Constant) for the repetitive task duration multiplier (DuM) and the multiplier for recovery periods (RcM) Since the multipliers (DuM and RcM), considered in the equation, are generally out of the direct influence of the designer, they are here considered as unique constant, reflecting a common condition as: DuM

= 1 (multiplier for overall repetitive task duration of 240 min to 480 min); RcM

= 0,6 (for a foreseeable presence of 2 breaks of 10 minutes and a lunch break in a repetitive task duration of 240 min to 480 min per shift). Therefore: (RcM × DuM) = 0,6 If the risk analysis of the machine shows that the risk is not acceptable when the total task duration exceeds a specific value or the recovery time is shorter than a specific value, this shall be mentioned in the "information for use", see Annex E. 5.3.4.1.7 Risk reduction analysis When the result of the risk evaluation shows an unacceptable risk level the designer should reduce it by optimising one or more of the following factors: • number of technical actions needed in a work cycle; • cycle time;

Zone Risk evaluation ≤ 2,2 Green

Acceptable 2,3 to 3,5 Yellow Conditionally acceptable > 3,5 Red Not acceptable When a 'conditionally acceptable' condition occurs, the designer shall: reconsider the design of the machinery and of the task in order to obtain an acceptable condition; refer to Annex E which gives the criteria about recovery periods and daily duration of the task as a basis or details in the information for use. Annex D reports information about the criteria adopted for OCRA index classification and about forecasting models of the expected percentage of Persons Affected (PA) by one or more Upper Limb Work Related Musculo-Skeletal Disorders (UL-WMSDs) at a given OCRA index value. Annex F provides a full example for the use of Method 2. 6 Verification For each safety requirement and/or protective measure, except if it is self-evident, a method of verification shall be established: • a) by testing (e.g. functional test of a new sequence of technical actions); • b) by measurement (e.g. measurement of required forces and postures versus time); • c) by calculation (e.g. recalculation of OCRA Index after improvements); • d) by any other method of verification, if testing and calculation are not adequate (e.g. by visual inspection).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...