EN 1870-18:2013

(Main)Safety of woodworking machines - Circular sawing machines - Part 18: Dimension saws

Safety of woodworking machines - Circular sawing machines - Part 18: Dimension saws

This European Standard deals with all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to stationary and displaceable dimensions saws, hereinafter referred to as “machines”, designed to cut solid wood, chipboard, fibreboard, plywood and also these materials, if they are covered with plastic edging and/or plastic/light alloy laminates, when they are used as intended and under the conditions foreseen by the manufacturer including reasonably foreseeable misuse.

Machines which are designed to work wood based materials may also be used for working rigid plastic materials with similar physical characteristics as wood.

The machine may have any of the following features:

a) facility for the saw blade and scoring saw blade (if any) to be raised and lowered;

b) facility to tilt the main saw blade and scoring saw blade (if any) for angled cutting;

c) facility for scoring;

d) facility for grooving with milling tool;

e) demountable power feed unit;

f) post-formed edge pre-cutting unit;

g) power operated sliding table;

h) workpiece clamping.

NOTE 1 For the definition of stationary and displaceable machine, see 3.10 and 3.11.

NOTE 2 Dimension saws are used for ripping, cross cutting, dimensioning and grooving.

The requirements of this document apply also to machines designed for grooving with a width not exceeding 20 mm in one pass by using a milling tool.

This document is not applicable to dimension saws which are manufactured before the date of its publication as a European Standard.

NOTE 3 Machines covered by this document are listed under 1.1 of Annex IV of the Machinery Directive.

Sicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 18: Formatkreissägemaschinen

Diese Europäische Norm behandelt alle im Abschnitt 4 aufgeführten signifikanten Gefährdungen, Gefährdungs¬situationen und Gefährdungsereignisse, die auf stationäre und verschiebbare Formatkreissägemaschinen zutreffen — im Folgenden als „Maschinen“ bezeichnet —, die konstruiert sind zum Schneiden von Massivholz, Spanplatten, Faserplatten, Sperrholz sowie diesen Werkstoffen, wenn sie mit Kunststoffkanten und/oder mit Laminaten aus Kunststoff/Leichtmetalllegierung beschichtet sind, wenn sie bestimmungs¬gemäß und entsprechend den durch den Hersteller vorhersehbaren Bedingungen einschließlich vernünftigerweise vorhersehbarem Fehlverhalten verwendet werden.

Maschinen, die zur Bearbeitung von Holzwerkstoffen konstruiert sind, können auch zur Bearbeitung von Hartkunststoff mit ähnlichen physikalischen Eigenschaften wie Holz verwendet werden.

Die Maschine kann jegliche der folgenden Merkmale aufweisen:

a) eine Einrichtung zum Anheben und Absenken des Sägeblattes und des Ritzsägeblattes (sofern vorhanden);

b) eine Einrichtung zum Schrägstellen des Hauptsägeblattes und des Ritzsägeblattes (sofern vorhanden) für Winkelschnitte;

c) eine Einrichtung zum Ritzsägen;

d) eine Einrichtung zum Nuten mit einem Fräswerkzeug;

e) einen abnehmbaren Vorschubapparat;

f) eine Einrichtung zum Postforming-Schneiden;

g) einen kraftbetriebenen Schiebetisch;

h) Werkstückspannvorrichtung.

ANMERKUNG 1 Hinsichtlich der Definition von einer stationären und einer verschiebbaren Maschine siehe 3.10 und 3.11.

ANMERKUNG 2 Formatkreissägemaschinen werden zum Längs-, Quer- und Formatschneiden und zum Nuten eingesetzt.

Die Anforderungen in diesem Dokument gelten auch für Maschinen, die konstruiert sind, mittels eines Fräswerkzeugs in einem Arbeitsgang Nuten von einer Breite, die 20 mm nicht übersteigt, zu fräsen.

Dieses Dokument gilt nicht für Formatkreissägemaschinen, die vor seiner Veröffentlichung als eine Europäische Norm hergestellt wurden.

ANMERKUNG 3 Die von diesem Dokument erfassten Maschinen sind in 1.1 des Anhangs IV der Maschinenrichtlinie aufgeführt.

Sécurité des machines pour le travail du bois - Machines à scies circulaires - Partie 18: Scies au format

La présente Norme européenne traite de tous les phénomènes dangereux, situations et événements

dangereux significatifs, tels qu’énumérés à l’Article 4, qui sont applicables aux scies au format fixes et

transportables, ci-après désignées "machines", conçues pour la coupe de bois massif, de panneaux de

particules, de panneaux de fibres, de contreplaqué ainsi que ces matériaux lorsque leurs surfaces ou leurs

chants sont recouverts de matière plastique et/ou de plastique/alliages légers stratifiés, lorsqu’elles sont

utilisées comme prévu et dans les conditions prévues par le fabricant, incluant une mauvaise utilisation

raisonnablement prévisible.

Les machines qui sont conçues pour travailler les matériaux à base de bois peuvent également être utilisées

pour travailler les matières plastiques rigides présentant des caractéristiques physiques similaires à celles du

bois.

La machine peut comporter les équipements suivants :

a) équipement pour élever et abaisser la lame de scie et la lame de scie d'incision (s'il y en a une) ;

b) équipement pour incliner la lame de scie principale et la lame de scie d'incision (s'il y en a une) pour la

coupe angulaire ;

c) équipement pour l'incision ;

d) équipement pour faire des rainurages avec un outil de fraisage ;

e) unité d'avance mécanisée démontable ;

f) unité de précoupe de chant postformé ;

g) table mobile mécanisée ;

h) bridage de pièce.

NOTE 1 Pour la définition de machine fixe et de machine transportable, voir 3.10 et 3.11.

NOTE 2 Les scies au format sont utilisées pour le délignage, pour le tronçonnage, pour la coupe au format et pour le

rainurage.

Les prescriptions du présent document s’appliquent également aux machines conçues pour le rainurage avec

une largeur ne dépassant pas 20 mm par passage d’un outil de fraisage.

Le présent document n’est pas applicable aux scies au format qui ont été fabriquées avant sa date de

publication comme Norme européenne.

NOTE 3 Les machines couvertes par le présent document sont énumérées dans la Directive Machines, Annexe IV,

1.1.

Varnost lesnoobdelovalnih strojev - Krožne žage - 18. del: Formatne žage

Ta dokument obravnava vsa večja tveganja, nevarne razmere in dogodke iz točke 4, ki se nanašajo na stacionarne in premostljive formatne žage, v nadaljnjem besedilu »stroji«, ki so namenjene rezanju polnega lesa, ivernih plošč, vlaknenih plošč, vezanih plošč in teh materialov, prevlečenih s plastično obrobo in/ali plastjo iz plastike/lahkih zlitin, kadar se uporabljajo v skladu z namenom in pod pogoji, ki jih je predvidel proizvajalec, vključno z razumno predvideno nepravilno uporabo.

OPOMBA 1: Za definicijo stacionarnega in premostljivega stroja glej točki 3.10 in 3.11.

OPOMBA 2: Formatne žage se uporabljajo za trganje, prečno rezanje, rezanje na mero in zarezovanje. Zahteve tega dokumenta veljajo tudi za stroje, namenjene zarezovanju, pri čemer se upošteva širina, ki ne presega 20 mm v enem prehodu in pri čemer se uporablja orodje za rezkanje. Ta dokument se ne uporablja za:

a) stroje na delovni mizi ali njej podobni mizi, ki so namenjeni delu v stacionarnem položaju in jih lahko z roko dvigne ena oseba. Delovna miza je lahko sestavni del stroja, če ima noge na tečajih, ki jih je mogoče podaljšati navzdol;

b) ročne lesnoobdelovalne stroje in njihovo prilagajanje, ki omogoča uporabo na drugačen način, npr. namestitev na delovno mizo.

OPOMBA 3: Premična električna orodja z motornim upravljanjem so obravnavana v zahtevah standarda EN 61029-1:2009 skupaj s standardom EN 61029-2-1:2009; ročna motorna električna orodja z motornim upravljanjem in žage z delovno mizo za sestavo integrirane celote z ročnimi električnimi orodji z motornim upravljanjem so obravnavani v standardu EN 60745-1: 2009 skupaj s standardom EN 60745-2-5: 2009. Ta dokument se ne uporablja za formatne žage, ki so bile izdelane, preden je bil objavljen kot standard EN.

OPOMBA 4: Stroji, obravnavani v tem dokumentu, so navedeni v točki 1.1 Priloge IV k direktivi o strojih.

General Information

- Status

- Withdrawn

- Publication Date

- 23-Apr-2013

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 142 - Woodworking machines - Safety

- Drafting Committee

- CEN/TC 142/WG 4 - Circular sawing machines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Aug-2017

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Replaced By

EN ISO 19085-5:2017 - Woodworking machines - Safety - Part 5: Dimension saws (ISO 19085-5:2017) - Effective Date

- 30-Aug-2017

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 60825-1:2007 - Safety of laser products - Part 1: Equipment classification and requirements - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 1870-18:2013 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of woodworking machines - Circular sawing machines - Part 18: Dimension saws". This standard covers: This European Standard deals with all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to stationary and displaceable dimensions saws, hereinafter referred to as “machines”, designed to cut solid wood, chipboard, fibreboard, plywood and also these materials, if they are covered with plastic edging and/or plastic/light alloy laminates, when they are used as intended and under the conditions foreseen by the manufacturer including reasonably foreseeable misuse. Machines which are designed to work wood based materials may also be used for working rigid plastic materials with similar physical characteristics as wood. The machine may have any of the following features: a) facility for the saw blade and scoring saw blade (if any) to be raised and lowered; b) facility to tilt the main saw blade and scoring saw blade (if any) for angled cutting; c) facility for scoring; d) facility for grooving with milling tool; e) demountable power feed unit; f) post-formed edge pre-cutting unit; g) power operated sliding table; h) workpiece clamping. NOTE 1 For the definition of stationary and displaceable machine, see 3.10 and 3.11. NOTE 2 Dimension saws are used for ripping, cross cutting, dimensioning and grooving. The requirements of this document apply also to machines designed for grooving with a width not exceeding 20 mm in one pass by using a milling tool. This document is not applicable to dimension saws which are manufactured before the date of its publication as a European Standard. NOTE 3 Machines covered by this document are listed under 1.1 of Annex IV of the Machinery Directive.

This European Standard deals with all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to stationary and displaceable dimensions saws, hereinafter referred to as “machines”, designed to cut solid wood, chipboard, fibreboard, plywood and also these materials, if they are covered with plastic edging and/or plastic/light alloy laminates, when they are used as intended and under the conditions foreseen by the manufacturer including reasonably foreseeable misuse. Machines which are designed to work wood based materials may also be used for working rigid plastic materials with similar physical characteristics as wood. The machine may have any of the following features: a) facility for the saw blade and scoring saw blade (if any) to be raised and lowered; b) facility to tilt the main saw blade and scoring saw blade (if any) for angled cutting; c) facility for scoring; d) facility for grooving with milling tool; e) demountable power feed unit; f) post-formed edge pre-cutting unit; g) power operated sliding table; h) workpiece clamping. NOTE 1 For the definition of stationary and displaceable machine, see 3.10 and 3.11. NOTE 2 Dimension saws are used for ripping, cross cutting, dimensioning and grooving. The requirements of this document apply also to machines designed for grooving with a width not exceeding 20 mm in one pass by using a milling tool. This document is not applicable to dimension saws which are manufactured before the date of its publication as a European Standard. NOTE 3 Machines covered by this document are listed under 1.1 of Annex IV of the Machinery Directive.

EN 1870-18:2013 is classified under the following ICS (International Classification for Standards) categories: 79.120.10 - Woodworking machines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1870-18:2013 has the following relationships with other standards: It is inter standard links to EN 1870-1:2007+A1:2009, EN ISO 19085-5:2017, EN 50525-2-21:2011, EN 61800-5-2:2007, EN 50370-1:2005, EN 60529:1991, EN 60439-1:1999/A1:2004, EN 60825-1:2007, EN 60529:1991/A1:2000, EN 60439-1:1999, EN 61310-1:2008, EN 614-1:2006+A1:2009, EN 894-2:1997+A1:2008, EN 847-1:2005+A1:2007, EN ISO 4414:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1870-18:2013 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1870-18:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnost lesnoobdelovalnih strojev - Krožne žage - 18. del: Formatne žageSicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 18: FormatkreissägemaschinenSécurité des machines pour le travail du bois - Machines à scies circulaires - Partie 18: Scies au formatSafety of woodworking machines - Circular sawing machines - Part 18: Dimension saws79.120.10Lesnoobdelovalni strojiWoodworking machines25.080.60Strojne žageSawing machinesICS:Ta slovenski standard je istoveten z:EN 1870-18:2013SIST EN 1870-18:2013en,fr,de01-junij-2013SIST EN 1870-18:2013SLOVENSKI

STANDARDSIST EN 1870-1:2007+A1:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1870-18

April 2013 ICS 79.120.10 Supersedes EN 1870-1:2007+A1:2009English Version

Safety of woodworking machines - Circular sawing machines - Part 18: Dimension saws

Sécurité des machines pour le travail du bois - Machines à scies circulaires - Partie 18: Scies au format

Sicherheit von Holzbearbeitungsmaschinen - Kreissägemaschinen - Teil 18: FormatkreissägemaschinenThis European Standard was approved by CEN on 7 March 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1870-18:2013: ESIST EN 1870-18:2013

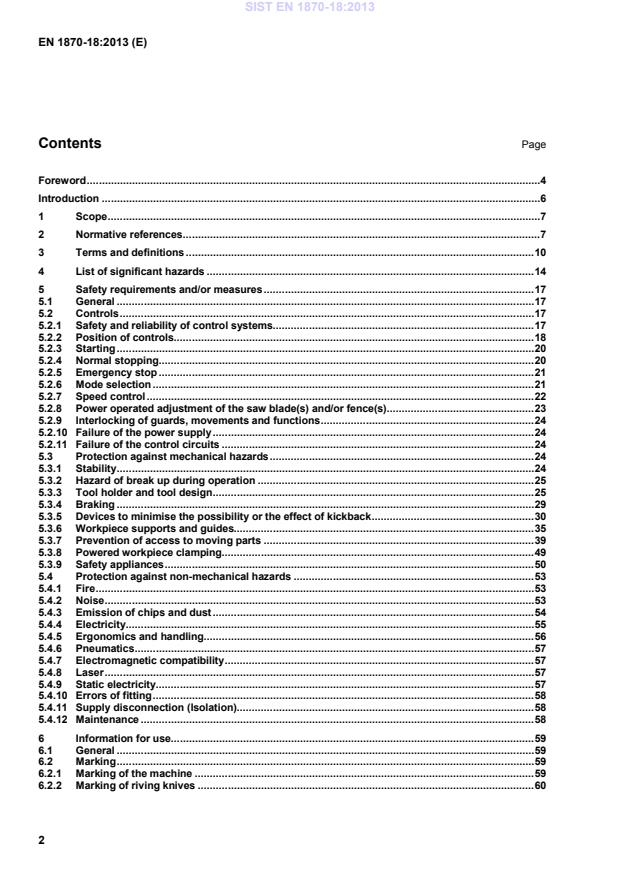

Saw spindle dimensional tolerances . 65 Annex B (normative)

Riving knife mounting strength test . 66 Annex C (normative)

Riving knife lateral stability test . 67 Annex D (normative)

Minimum dimensions of the machine table, extension table . 68 Annex E (normative)

Saw blade guard stability test . 69 E.1 General . 69 E.2 Separately from riving knife mounted saw blade guards . 69 E.2.1 Saw blade guards with lead-in . 69 E.2.2 Saw blade guards with in-feed rollers . 70 E.3 Riving knife mounted saw blade guards . 71 Annex F (normative)

Impact test method for guards . 73 F.1 General . 73 F.2 Test method . 73 F.2.1 Preliminary remarks . 73 F.2.2 Testing equipment. 73 F.2.3 Projectile for guards . 73 F.2.4 Sampling . 73 F.2.5 Test procedure . 73 F.3 Results . 74 F.4 Assessment . 74 F.5 Test report . 74 F.6 Test equipment for impact test . 74 Annex G (normative)

Braking tests . 76 G.1 Conditions for all tests . 76 G.2 Tests . 76 G.2.1 Un-braked run-down time . 76 G.2.2 Braked run-down time . 76 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 77 Bibliography . 80

a) facility for the saw blade and scoring saw blade (if any) to be raised and lowered; b) facility to tilt the main saw blade and scoring saw blade (if any) for angled cutting; c) facility for scoring; d) facility for grooving with milling tool; e) demountable power feed unit; f) post-formed edge pre-cutting unit; g) power operated sliding table; h) workpiece clamping. NOTE 1 For the definition of stationary and displaceable machine, see 3.10 and 3.11. NOTE 2 Dimension saws are used for ripping, cross cutting, dimensioning and grooving.

The requirements of this document apply also to machines designed for grooving with a width not exceeding 20 mm in one pass by using a milling tool. This document is not applicable to dimension saws which are manufactured before the date of its publication as a European Standard. NOTE 3 Machines covered by this document are listed under 1.1 of Annex IV of the Machinery Directive. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and general principles EN 847-1:2005+A1:2007, Tools for woodworking — Safety requirements — Part 1: Milling tools, circular saw blades EN 894-1:1997+A1:2008, Safety of machinery — Ergonomics requirements for the design of displays and control actuators — Part 1: General principles for human interactions with displays and control actuators SIST EN 1870-18:2013

1) EN 60439-1:1999 is impacted by EN 60439-1:1999/A1:2004. 2) EN 60529:1991 is impacted by EN 60529:1991/A1:2000. SIST EN 1870-18:2013

a) facility for the saw blade and scoring saw blade (if any) to be raised and lowered; b) facility to tilt the main saw blade and scoring saw blade (if any) for angled cutting; c) facility for scoring; d) facility for grooving with milling tool; e) demountable power feed unit; f) post-formed edge pre-cutting unit; g) power operated sliding table; h) workpiece clamping.

Key 1 riving knife

9 extension table 2 saw blade(s) guard 10 controls 3 saw blade guard support 11 saw blade guard support (may include pipe for chips and dust extraction) 4 fixed guard beneath table 12 push stick 5 rip fence 13 sliding table 6 clamping shoe 14 cross-cutting fence 7 table insert 15 sliding table handle

8 machine table 16 moveable control panel

17 additional controls at the rear side of the sliding table

Figure 1 — Example of a dimension saw SIST EN 1870-18:2013

Note 2 to entry: If monitoring systems are used for diagnostics they are considered as SRP/C.

[SOURCE: EN ISO 13849-1:2008, 3.1.1]

3.18 embedded software (SRESW) software that is part of the system supplied by the control manufacturer and which is not accessible for modification by the user of the machinery Note 1 to entry: Firmware or system software are examples of embedded software.

[SOURCE: EN ISO 13849-1:2008, 3.1.37] Note 2 to entry: Manufacturer means manufacturer of the system. Note 3 to entry: For example the operating system of a speed monitoring device. 3.19 application software (SRASW) software specific to the application, implemented by the machine manufacturer, and generally containing logic sequences, limits and expressions that control the appropriate inputs, outputs, calculations and decisions necessary to meet the SRP/CS requirements

[SOURCE: EN ISO 13849-1:2008, 3.1.36]

3.20 information of the supplier statements, sales literature, leaflets or other documents, in which a manufacturer (supplier) declares either the characteristics of e.g. a material or product or the conformity of the material or product to a relevant standard SIST EN 1870-18:2013

[SOURCE: EN ISO 13849-1:2008, 3.1.23] 3.22 chipable material material which upon collision with a running tool will not mechanically generate sparks and will not result in a damage of the tool 4 List of significant hazards This clause contains all significant hazards, hazardous situations and events (see EN ISO 12100:2010), identified by risk assessment as significant for the machines as defined in the scope and which require action to eliminate or reduce the risk. This document deals with these significant hazards by defining safety requirements and/or measures or by reference to relevant standards. These hazards are listed in Table 1. SIST EN 1870-18:2013

Table 1 — List of significant hazards

No Hazards, hazardous situations and hazardous events EN ISO 12100:2010 Relevant sub-clause of this document 1 Mechanical hazards related to:

- machine parts or workpieces due to:

a) shape; 6.2.2.1, 6.2.2.2, 6.3 5.3.3, 5.3.5, 5.3.6, 5.3.7, 5.3.8, 5.4.5, 5.4.11

b) relative location; 5.2.2, 5.2.6, 5.2.7, 5.2.8, 5.2.10, 5.3.6, 5.3.7, 5.3.8

d) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion); 5.2.3, 5.2.4, 5.2.6, 5.2.8, 5.3.4, 5.3.7, 5.4.5

e) mechanical strength; 5.3.2, 5.3.3, 5.3.4, 5.3.6, 5.3.7, 5.3.9, Annex B, Annex C, Annex E, Annex F

- accumulation of the energy inside the machinery:

f) liquids and gases under pressure; 6.2.10, 6.3.5.4 5.3.3, 5.3.8 1.1 Crushing hazard

5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.2.8, 5.3.4, 5.3.5, 5.3.6, 5.3.7, 5.3.8, 5.3.9, 5.4.12, 6.3 1.2 Shearing hazard 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.2.8, 5.3.4, 5.3.5, 5.3.6, 5.3.7, 5.3.8, 5.3.9, 5.4.12, 6.3 1.3 Cutting or severing hazard 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.2.8, 5.3.4, 5.3.5, 5.3.6, 5.3.7, 5.3.9, 5.4.12, 6.3 1.4 Entanglement hazard 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.2.8, 5.3.4, 5.3.6, 5.3.7, 5.4.12, 6.3 1.5 Drawing-in or trapping hazard 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.2.8, 5.3.4, 5.3.6, 5.3.7, 5.4.12, 6.3 1.6 Impact hazard 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.2.8, 5.3.4, 5.3.6, 5.3.7, 5.4.12, 6.3 1.8 Friction or abrasion hazard 5.2.3, 5.2.4, 5.2.5, 5.3.4, 5.3.7, 5.4.12, 6.3 1.9 High pressure fluid injection or ejection hazard 5.3.8, 5.4.6, 5.4.7 SIST EN 1870-18:2013

5.4.3, 6.3 7.2 Fire hazard 6.2.4

5.4.1 8 Hazards generated by neglecting ergonomic principles in machinery design: 8.1 Unhealthy postures or excessive effort 6.2.7, 6.2.8, 6.2.11.12, 6.3.5.5, 6.3.5.6 5.2.2, 5.4.5 8.2 Hand-arm or foot-leg anatomy 6.2.8.3 5.4.5 8.4 Local lighting 6.2.8.6 6.3 8.5 Mental overload and underload, stress 6.2.8.5 6.3 8.6 Human error, human behaviour 6.2.8, 6.2.11.8, 6.2.11.10, 6.3.5.2, 6.4 6.3 8.7 Design, location or identification of manual controls 6.2.8.f, 6.2.11.8 5.2.2 8.8 Design or location of visual display units 6.2.8, 6.4.2 5.2.2 9 Combination of hazards 6.3.2.1 5.2.3, 5.2.5, 5.2.6, 5.2.7, 5.2.10, 5.3.5, 5.4.10, 5.4.11 10 Unexpected start up, unexpected overrun/overspeed (or any similar malfunction) from: 10.1 Failure/disorder of the control system 6.2.11, 6.3.5.4

5.2.1, 5.2.11, 5.4.12 10.2 Restoration of energy supply after an interruption 6.2.11.4

5.2.10, 5.4.6, 5.4.7 10.3 External influences on electrical equipment 6.2.11.11 5.2.1, 5.4.8 10.5 Errors in the software 6.2.11.7 5.2.1 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6) 6.2.8, 6.2.11.8, 6.2.11.10, 6.3.5.2, 6.4 5.2.6, 6.3 11 Impossibility of stopping the machine in the best possible conditions 6.2.11.1, 6.2.11.3, 6.3.5.2

5.2.4, 5.2.5, 5.4.12 12 Variations in the rotational speed of tools 6.2.2.2, 6.2.3 5.2.7 13 Failure of the power supply 6.2.11.1, 6.2.11.4 5.2.10 14 Failure of the control circuit 6.2.11, 6.3.5.4

5.2.11 15 Errors of fitting 6.2.7, 6.4.5 5.4.11 16 Break-up during operation 6.2.3 5.3.2 17 Falling or ejected objects or fluids 6.2.3, 6.2.10

5.3.5 18 Loss of stability / overturning of machinery 6.3.2.6

5.3.1

An emergency stop control required by 5.2.5 shall be situated near by to the start control for the saw blade(s) except for a start control situated at the rear end of the sliding table (if fitted). An additional control device(s) for starting of the saw blade(s) along with a stop control can be provided at the rear side of the sliding table.

Key

A maximum distance between the edge of the sliding table and extreme position of moveable control panel B maximum distance between the saw line and extreme position of moveable control panel C distance between the rear end of the sliding table support and front edge of the fixed table L width of the fixed table R rear end of the sliding table H minimum height of controls Figure 2 — Position of controls

Table 2 — Choice of positions of emergency stop controls when required according to 5.2.5 C mm Without movable control panel With movable control panel B ≤ 850 mm B > 850 mm A ≤ 1 300 mm A > 1 300 mm

0 ≤ C ≤ 300

2 or 1 and 3 or

1 and 4

1 and 5 or 2 and 5

2 and 5

C > 300

2 or 1 and 3 or

1 and 4

1 and 5

1 and 3 and 5 or 1 and 4 and 5

Start or restart shall only be possible by actuation of the start control device provided for that purpose. Closure of movable interlocked guards shall not lead to an automatic restart of hazardous movements. The safety related part of the control systems (also see 5.2.1) for starting and the interlocking arrangements as indicated in 5.2.7, 5.2.8, 5.3.6, 5.3.7 shall be at least PL = c in accordance with the requirements of

EN ISO 13849-1:2008. When fitted with a unit for scoring and/or post-formed edge pre-cutting, the scoring saw blade spindle drive motor or the post-formed edge pre-cutting saw blade drive motor shall not be capable of being started before the main saw blade drive motor. For electrically operated machines, the requirements of 9.2.5.2 of EN 60204-1:2006 apply but the exceptions described in 9.2.5.2 of EN 60204-1:2006 are not relevant. The safety related part of the control systems (also see 5.2.1) for interlocking between starting of the main saw blade drive motor and starting of the scoring saw blade spindle drive motor or the post-formed edge pre-cutting saw blade drive motor shall be at least PL = c in accordance with the requirements of

EN ISO 13849-1:2008 (see also 5.2.6, 5.3.7). Verification: By checking the relevant drawings and/or circuit diagrams, inspection of the machine and relevant functional testing of the machine. 5.2.4 Normal stopping The machine shall be fitted with a stop control whereby all saw blades and – if fitted – a demountable power feed unit can be stopped (see also 5.2.8). The stopping shall include disconnection from energy supply of the corresponding actuators except workpiece clamping unless STO in accordance with EN 61800-5-2:2007 is used. For normal stopping of PDS(SR) (power drive system, safety related) see 4.2.2.2 "safe torque off (STO)” and 4.2.2.3 “safe stop 1 (SS1)” of EN 61800-5-2:2007. If the machine is fitted with a spring operated mechanical brake, this stop control shall be of category 0 in accordance with the requirements of 9.2.2 of EN 60204-1:2006. If the machine is fitted with any other type of brake e.g. electrical brake, this stop control shall be of category 1 in accordance with the requirements of 9.2.2 of EN 60204-1:2006. Wher

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...