EN 15283-2:2008

(Main)Gypsum boards with fibrous reinforcement - Definitions, requirements and test methods - Part 2: Gypsum fibre boards

Gypsum boards with fibrous reinforcement - Definitions, requirements and test methods - Part 2: Gypsum fibre boards

This European Standard specifies the characteristics and performance of gypsum fibre boards intended to be used in building construction works including those intended for secondary manufacturing operations. It includes boards designed to receive either direct surface decoration or gypsum plaster.

Gypsum fibre boards are selected for use according to their type, size, thickness and edge profile. The boards may be used for example, to provide dry lining finishes to walls, to fixed and suspended ceilings, to partitions, or as cladding to structural columns and beams. Other uses may be for floors and sheathing applications.

This European Standard covers the following product performance characteristics: reaction to fire, water vapour permeability, flexural strength, and thermal resistance.

The following performance characteristics are linked to systems assembled with gypsum fibre boards: shear strength, fire resistance, impact resistance, direct airborne sound insulation, acoustic absorption. If required, tests have to be done according to the corresponding European test methods on assembled systems simulating the end use conditions.

This European Standard also covers additional technical characteristics that are of importance for the use and acceptance of the product and the reference tests for these characteristics.

It provides for evaluation of conformity of the product to this EN.

This European Standard does not cover gypsum fibre boards that have been subject to any secondary manufacturing operations (e.g. insulating composite panels, boards with thin lamination etc.).

Products covered by EN 520 or EN 13815 are excluded.

Faserverstärkte Gipsplatten - Begriffe, Anforderungen und Prüfverfahren - Teil 2: Gipsfaserplatten

Diese Europäische Norm legt Eigenschaften und Leistungsmerkmale für Gipsfaserplatten fest, die für die

Verwendung im Hochbau vorgesehen sind, einschließlich derer, die zur Weiterverarbeitung bestimmt sind. Sie

gilt auch für Platten, die zur Aufnahme einer direkten dekorativen Beschichtung oder eines Gipsputzes

vorgesehen sind.

Für die Anwendung werden Gipsfaserplatten entsprechend ihres Typs, ihrer Größe, Dicke und Kantenausbildung

ausgewählt. Die Platten können z. B. als Trockenputz für Wände, für direkt befestigte Deckenbekleidungen

oder abgehängte Decken, für Trennwände oder als Bekleidung von Stützen und Trägern

verwendet werden. Sie können auch für Böden und Beplankungen eingesetzt werden.

Diese Europäische Norm erfasst folgende Leistungsmerkmale des Produktes: Brandverhalten, Wasserdampfdurchlässigkeit,

Biegefestigkeit und Wärmedurchlasswiderstand.

Die folgenden Leistungsmerkmale beziehen sich auf Systeme, die unter Verwendung von Gipsfaserplatten

hergestellt wurden: Schubfestigkeit, Feuerwiderstand, Stoßfestigkeit, Luftschalldämmung und Schallabsorption.

Falls gefordert, sind die Prüfungen nach den entsprechenden europäischen Prüfverfahren an zusammengebauten

Systemen, die den Gebrauchszustand nachbilden, durchzuführen.

Diese Europäische Norm behandelt auch zusätzliche technische Eigenschaften, die für die Anwendung und

Akzeptanz des Produktes wichtig sind und die Referenzprüfverfahren für diese Eigenschaften.

Ferner legt sie die Bewertung der Konformität des Produktes mit dieser EN fest.

Diese Norm gilt nicht für Gipsfaserplatten, die weiterverarbeitet wurden (z. B. zu Verbundplatten zur Schallund

Wärmedämmung, Gipsplatten mit dünner Beschichtung usw.).

Produkte, die in EN 520 oder EN 13815 behandelt werden, sind ausgeschlossen.

Plaques de plâtre armées de fibres - Définitions, spécifications et méthodes d'essai - Partie 2: Plaques de plâtre fibrées

La présente Norme européenne spécifie les caractéristiques et les performances des plaques de plâtre fibrées conçues pour être utilisées dans des ouvrages de construction y compris celles conçues pour des opérations de fabrication secondaires. Elle inclut les plaques destinées à recevoir directement une finition sur leur surface ou un enduit au plâtre. Les plaques de plâtre fibrées sont sélectionnées pour leur utilisation conformément à leur type, à leur taille et à leur épaisseur, ainsi qu’au profil des bords. Les plaques peuvent être utilisées par exemple pour créer une finition par habillage des murs, des plafonds fixes et suspendus, des cloisons, ou pour la protection et l’habillage des poteaux et des poutres. Elles peuvent également être utilisées pour la pose en sous bardage. La présente Norme européenne couvre les caractéristiques de performance suivantes du produit : réaction au feu, perméabilité à la vapeur d’eau, résistance à la flexion et résistance thermique. Les caractéristiques de performance suivantes sont liées à des systèmes assemblés avec des plaques de plâtre fibrées : résistance au cisaillement, résistance au feu, résistance aux chocs, isolation acoustique aux bruits aériens, absorption acoustique. Au besoin, des essais doivent être effectués conformément aux méthodes d'essai européennes correspondantes sur des systèmes assemblés qui simulent les conditions d'utilisation finale. La présente norme européenne couvre également les caractéristiques techniques supplémentaires qui ont une incidence sur l’utilisation et la réception du produit, ainsi que les essais de référence de ces caractéristiques. Elle permet l’évaluation de la conformité du produit à la présente EN. La présente Norme européenne ne couvre pas les plaques de plâtre fibrées qui ont subi des opérations de transformation secondaires diverses (par exemple les complexes d’isolation, les plaques avec revêtements minces etc.).

Mavčne plošče, ojačene z vlakni - Definicije, zahteve in preskusne metode - 2. del: Mavčne plošče z vlakni

General Information

- Status

- Withdrawn

- Publication Date

- 19-Feb-2008

- Withdrawal Date

- 18-Aug-2009

- Technical Committee

- CEN/TC 241 - Gypsum and gypsum based products

- Drafting Committee

- CEN/TC 241/WG 3 - Board products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 19-Aug-2009

- Completion Date

- 19-Aug-2009

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 18-Jan-2023

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Nonprofit organization that performs technical evaluations of building products.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

BBA (British Board of Agrément)

UK construction product certification.

Sponsored listings

Frequently Asked Questions

EN 15283-2:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gypsum boards with fibrous reinforcement - Definitions, requirements and test methods - Part 2: Gypsum fibre boards". This standard covers: This European Standard specifies the characteristics and performance of gypsum fibre boards intended to be used in building construction works including those intended for secondary manufacturing operations. It includes boards designed to receive either direct surface decoration or gypsum plaster. Gypsum fibre boards are selected for use according to their type, size, thickness and edge profile. The boards may be used for example, to provide dry lining finishes to walls, to fixed and suspended ceilings, to partitions, or as cladding to structural columns and beams. Other uses may be for floors and sheathing applications. This European Standard covers the following product performance characteristics: reaction to fire, water vapour permeability, flexural strength, and thermal resistance. The following performance characteristics are linked to systems assembled with gypsum fibre boards: shear strength, fire resistance, impact resistance, direct airborne sound insulation, acoustic absorption. If required, tests have to be done according to the corresponding European test methods on assembled systems simulating the end use conditions. This European Standard also covers additional technical characteristics that are of importance for the use and acceptance of the product and the reference tests for these characteristics. It provides for evaluation of conformity of the product to this EN. This European Standard does not cover gypsum fibre boards that have been subject to any secondary manufacturing operations (e.g. insulating composite panels, boards with thin lamination etc.). Products covered by EN 520 or EN 13815 are excluded.

This European Standard specifies the characteristics and performance of gypsum fibre boards intended to be used in building construction works including those intended for secondary manufacturing operations. It includes boards designed to receive either direct surface decoration or gypsum plaster. Gypsum fibre boards are selected for use according to their type, size, thickness and edge profile. The boards may be used for example, to provide dry lining finishes to walls, to fixed and suspended ceilings, to partitions, or as cladding to structural columns and beams. Other uses may be for floors and sheathing applications. This European Standard covers the following product performance characteristics: reaction to fire, water vapour permeability, flexural strength, and thermal resistance. The following performance characteristics are linked to systems assembled with gypsum fibre boards: shear strength, fire resistance, impact resistance, direct airborne sound insulation, acoustic absorption. If required, tests have to be done according to the corresponding European test methods on assembled systems simulating the end use conditions. This European Standard also covers additional technical characteristics that are of importance for the use and acceptance of the product and the reference tests for these characteristics. It provides for evaluation of conformity of the product to this EN. This European Standard does not cover gypsum fibre boards that have been subject to any secondary manufacturing operations (e.g. insulating composite panels, boards with thin lamination etc.). Products covered by EN 520 or EN 13815 are excluded.

EN 15283-2:2008 is classified under the following ICS (International Classification for Standards) categories: 91.100.10 - Cement. Gypsum. Lime. Mortar. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15283-2:2008 has the following relationships with other standards: It is inter standard links to EN 15283-2:2008+A1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15283-2:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/106. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15283-2:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gypsum boards with fibrous reinforcement - Definitions, requirements and test methods - Part 2: Gypsum fibre boardsPlaques de plâtre armées de fibres - Définitions, spécifications et méthodes d'essai - Partie 2: Plaques de plâtre fibréesFaserverstärkte Gipsplatten - Definitionen, Anforderungen und Prüfverfahren - Teil 2: GipsfaserplattenTa slovenski standard je istoveten z:EN 15283-2:2008SIST EN 15283-2:2008en,fr,de91.100.10ICS:SLOVENSKI

STANDARDSIST EN 15283-2:200801-april-2008

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15283-2February 2008ICS 91.100.10 English VersionGypsum boards with fibrous reinforcement - Definitions,requirements and test methods - Part 2: Gypsum fibre boardsPlaques de plâtre armées de fibres - Définitions,spécifications et méthodes d'essai - Partie 2: Plaques deplâtre fibréesFaserverstärkte Gipsplatten - Begriffe, Anforderungen undPrüfverfahren - Teil 2: GipsfaserplattenThis European Standard was approved by CEN on 28 December 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15283-2:2008: E

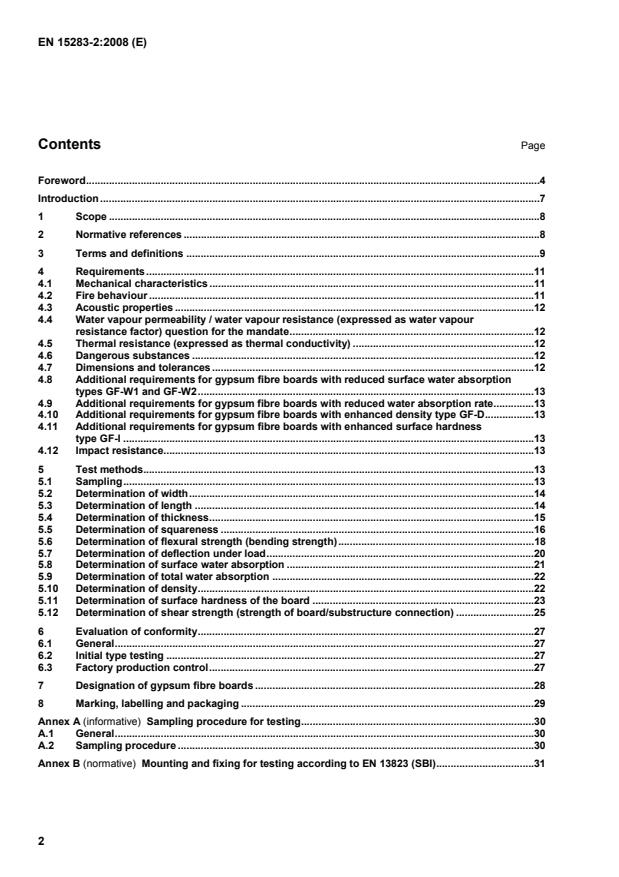

Sampling procedure for testing.30 A.1 General.30 A.2 Sampling procedure.30 Annex B (normative)

Mounting and fixing for testing according to EN 13823 (SBI).31

Clauses of this European Standard addressing the provisions of EU Construction Products Directive.33 ZA.1 Scope and relevant characteristics.33 ZA.2 Procedure of attestation of conformity of gypsum fibre boards.34 ZA.3 CE marking and labelling.37 Bibliography.40

Diagram 1 — Families of gypsum products

Diagram 2 — Family of ancillary products

EN 14195, Metal framing components for gypsum plasterboard systems — Definitions, requirements and test methods EN 20535, Paper and board — Determination of water absorptiveness — Cobb method (ISO 535:1991)

When required and subject to regulatory requirements, the deflection under load shall be determined in accordance to the test method described in 5.7. The calculation of the modulus of elasticity is given in 5.7. 4.2 Fire behaviour 4.2.1 Reaction to fire When the intended use of gypsum fibre boards is for exposed situations in building construction works, the reaction to fire of gypsum fibre boards shall be classified in accordance with EN 13501-1. Testing of the gypsum fibre boards in the EN 13823 test requires the product to be mounted in a manner which is representative of end use applications. The method for mounting and fixing is given in Annex B. 4.2.2 Resistance to fire Resistance to fire is a property of an assembled system and not of the product in isolation. When required and subject to regulatory requirements, the fire resistance of a system including gypsum fibre boards shall be classified in accordance with EN 13501-2.

The difference between individual thickness measurements on any individual board shall not exceed 0,4 mm. For C2 boards: Tolerances for boards of nominal thickness below 15 mm are ± 0,5 mm. For boards of nominal thickness equal or greater than 15 mm, the tolerance is ± (0,05 × thickness) in mm. The difference between individual thickness measurements on any individual board shall not exceed 1,0 mm for a nominal thickness below 15 mm and shall not exceed (0,1 × thickness) for boards of nominal thickness equal or greater than 15 mm, 4.7.4 Squareness The deviation from squareness measured as described in 5.5 shall not exceed 2,5 mm per metre of width. 4.8 Additional requirements for gypsum fibre boards with reduced surface water absorption types GF-W1 and GF-W2 The surface water absorption of the water exposed sides of boards, determined by the method described in 5.8 shall not be greater than 300 g/m2 for Type GF-W1 and not greater than 1 500 g/m2 for Type GF-W2. 4.9 Additional requirements for gypsum fibre boards with reduced water absorption rate type GF-H The total water absorption of boards, determined by the method described in 5.9, shall not be greater than 5 %. 4.10 Additional requirements for gypsum fibre boards with enhanced density type GF-D The density of boards, determined by the method described in 5.10, shall be at least 1,4 × 103 kg/m3. 4.11 Additional requirements for gypsum fibre boards with enhanced surface hardness type GF-I The surface hardness of board is characterised by the diameter of the depression produced in the surface according to the test method described in 5.11. The diameter of the depression shall not be more than 15 mm. 4.12 Impact resistance NOTE Impact resistance is a characteristic dependent on an assembled system and not of the product in isolation. When required and subject to regulatory requirements, the impact resistance of a system including gypsum fibre board shall be determined in accordance with ISO 7892. 5 Test methods These methods shall be followed completely. Where they cannot be followed for practical reasons, deviation from the standard method shall be recorded with the results. 5.1 Sampling Testing requires three boards of each type and thickness on which tests 5.2 to 5.5 are carried out.

1) to the nearest mm, one near each end and one near the middle of the board.

Figure 1 — Determination of width 5.2.4 Expression of results Each measured value expressed in millimetres is recorded. 5.3 Determination of length 5.3.1 Principle The length is measured at three points. 5.3.2 Apparatus A metal rule or tape with reading to 1 mm divisions.

Figure 2 — Determination of length 5.3.3 Procedure Take three measurements between the extremities of the board (see Figure 2) to the nearest millimetre, one near each edge and one near the middle. 5.3.4 Expression of results Each measured value expressed in millimetres in recorded and compared to the nominal length of the board. 5.4 Determination of thickness 5.4.1 Principle The thickness of the board is measured at six points near to one end of the board. 5.4.2 Apparatus A micrometer, dial gauge, or callipers with an anvil diameter not less than 10 mm and permitting a reading to 0,05 mm. 5.4.3 Procedure Take six measurements (see Figure 3) to the nearest 0,05 mm across one end at approximately equal intervals across the width and at least 25 mm from the end and 100 mm from the edges. For boards of nominal width not greater than 600 mm, three measurements are sufficient.

Figure 3 — Determination of thickness 5.4.4 Expression of results Record each individual measurement. Record to the nearest 0,1 mm the thickness as the average of the values obtained for each board. 5.5 Determination of squareness 5.5.1 Principle Method a: Two boards are compared with each other and the squareness is measured. Method b: The two diagonals of a board are measured. 5.5.2 Apparatus A metal rule or tape with 1 mm divisions.

Figure 4 — Determination of squareness Method a: Place one board on top of another so that they coincide along one edge and at one corner (circled in Figure 4). Measure to the nearest 1 mm the distance ∆1 (see Figure 4) between the ends of the opposite edges. Turn the top board over so that the same ends coincide as for the first measurement and ensure that the corner of the top board coincides with that corner of the lower board used in the first measurement (circled in Figure 4). Measure the new distance ∆2 between the ends of the opposite edges. Method b: Measure the length (l) of the board and the lengths of the two diagonals d1 and d2 to the nearest millimetre. 5.5.4 Expression of results Method a: The squareness is characterised for one of the boards by the half sum w221∆∆+ and for other by the half difference w212∆∆+ expressed in millimetres per metre.

1) Constant mass is defined as two successive weightings 24 h apart, differing by less than 0,1 %.

Key 1 zone for sampling other specimens

Figure 5 — Sampling of specimens for the determination of flexural breaking load

(example for 1 200 mm wide board)

²2.31maxtblFFm⋅⋅= (2) where Fmax is the maximum load in Newtons; l1 is the span (distance between the centres of support

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...