EN 1555-1:2010

(Main)Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 1: General

Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 1: General

This part of EN 1555 specifies the general aspects of polyethylene (PE) piping systems in the field of the supply of gaseous fuels.

It also specifies the test parameters for the test methods referred to in this standard.

In conjunction with Parts 2 to 5 of EN 1555 it is applicable to PE pipes, fittings, and valves, their joints and to joints with components of other materials intended to be used under the following conditions:

a) a maximum operating pressure, MOP, up to and including 10 bar );

b) an operating temperature of 20 °C as reference temperature.

NOTE 1 For other operating temperatures, derating coefficients should be used, see EN 1555-5 [6].

EN 1555 (all parts) covers a range of maximum operating pressures and gives requirements concerning colours and additives.

NOTE 2 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national regulations and installation practices or codes.

Kunststoff-Rohrleitungssysteme für die Gasversorgung - Polyethylen (PE) - Teil 1: Allgemeines

Dieser Teil der EN 1555 legt allgemeine Anforderungen an Rohrleitungssysteme aus Polyethylen (PE) fest,

die für die Gasversorgung eingesetzt werden.

Er legt auch die Prüfparameter für die Prüfverfahren fest, auf die in dieser Norm verwiesen wird.

In Verbindung mit den Teilen 2 bis 5 der EN 1555 gilt dieser Teil für Rohre, Formstücke und Armaturen aus

PE, deren Verbindungen untereinander sowie mit Rohrleitungsteilen aus anderen Werkstoffen, die für die

Verwendung unter den folgenden Bedingungen vorgesehen sind:

a) der maximal zulässige Betriebsdruck MOP beträgt höchstens 10 bar1).

b) es gilt eine Betriebstemperatur von 20 °C als Bezugstemperatur.

ANMERKUNG 1 Für andere Betriebstemperaturen sollten Minderungsfaktoren verwendet werden, siehe EN 1555-5 [6].

EN 1555 (alle Teile) enthält Festlegungen zu den maximal zulässigen Betriebsdrücken und legt Anforderungen

an die Einfärbung von Rohrleitungsteilen sowie die Verwendung von Zusatzstoffen fest.

ANMERKUNG 2 Der Anwender bzw. Auftraggeber ist unter Berücksichtigung der eigenen Anforderungen sowie der

geltenden nationalen Festlegungen und Verlegepraktiken für die entsprechende Auswahl dieser Kriterien verantwortlich.

Systèmes de canalisations en plastique pour la distribution de combustibles gazeux - Polyéthylène (PE) - Partie 1 : Généralités

La présente partie de l’EN 1555 spécifie les aspects généraux des systèmes de canalisations en polyéthylène

(PE) dans le domaine de la distribution de combustibles gazeux.

Elle spécifie également les paramètres d'essai des méthodes d'essai auxquelles il est fait référence dans la

présente norme.

Conjointement avec les parties 2 à 5 de l’EN 1555, elle s'applique aux tubes, raccords et robinets en PE et à

leurs assemblages, ainsi qu'aux assemblages avec des composants en d'autres matières, destinés à être

utilisés dans les conditions suivantes :

a) une pression maximale de service, MOP, jusqu'à et y compris 10 bar1 ;

b) une température de service de 20 °C, comme température de référence.

NOTE 1 Pour d'autres températures de service, il convient d’utiliser des facteurs de réduction, voir l’EN 1555-5 [6].

L’EN 1555 (toutes les parties) couvre une gamme de pressions maximales de service et donne les exigences

concernant les couleurs et les additifs.

NOTE 2 Il est de la responsabilité de l'acheteur ou du prescripteur de faire les choix appropriés de ces différents

aspects, en tenant compte des exigences particulières et des règlements nationaux correspondants, ainsi que des

pratiques ou des codes de pose.

Cevni sistemi iz polimernih materialov za oskrbo s plinastimi gorivi - Polietilen (PE) - 1. del: Splošno

Ta del EN 1555 določa splošne vidike cevnih sistemov iz polietilena (PE) na področju oskrbe s plinastimi gorivi. Določa tudi preskusne parametre za preskusne metode, navedene v tem standardu. Skupaj z 2. do 5. delom EN 1555 velja za PE cevi, fitinge in ventile, njihove spoje in spoje s komponentami iz drugih materialov, namenjenih za uporabo pod naslednjimi pogoji: a) najvišji obratovalni tlak MOP do in vključno z 10 bari; b) obratovalna temperatura 20 °C kot referenčna temperatura. EN 1555 (vsi deli) zajema razpon najvišjih obratovalnih tlakov in podaja zahteve glede barv in aditivov.

General Information

- Status

- Withdrawn

- Publication Date

- 07-Sep-2010

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 155 - Plastics piping systems and ducting systems

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 07-Jul-2021

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 13-Sep-2010

- Effective Date

- 14-Jul-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1555-1:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 1: General". This standard covers: This part of EN 1555 specifies the general aspects of polyethylene (PE) piping systems in the field of the supply of gaseous fuels. It also specifies the test parameters for the test methods referred to in this standard. In conjunction with Parts 2 to 5 of EN 1555 it is applicable to PE pipes, fittings, and valves, their joints and to joints with components of other materials intended to be used under the following conditions: a) a maximum operating pressure, MOP, up to and including 10 bar ); b) an operating temperature of 20 °C as reference temperature. NOTE 1 For other operating temperatures, derating coefficients should be used, see EN 1555-5 [6]. EN 1555 (all parts) covers a range of maximum operating pressures and gives requirements concerning colours and additives. NOTE 2 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national regulations and installation practices or codes.

This part of EN 1555 specifies the general aspects of polyethylene (PE) piping systems in the field of the supply of gaseous fuels. It also specifies the test parameters for the test methods referred to in this standard. In conjunction with Parts 2 to 5 of EN 1555 it is applicable to PE pipes, fittings, and valves, their joints and to joints with components of other materials intended to be used under the following conditions: a) a maximum operating pressure, MOP, up to and including 10 bar ); b) an operating temperature of 20 °C as reference temperature. NOTE 1 For other operating temperatures, derating coefficients should be used, see EN 1555-5 [6]. EN 1555 (all parts) covers a range of maximum operating pressures and gives requirements concerning colours and additives. NOTE 2 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and any relevant national regulations and installation practices or codes.

EN 1555-1:2010 is classified under the following ICS (International Classification for Standards) categories: 01.040.23 - Fluid systems and components for general use (Vocabularies); 01.040.91 - Construction materials and building (Vocabularies); 23.040.01 - Pipeline components and pipelines in general; 91.140.40 - Gas supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1555-1:2010 has the following relationships with other standards: It is inter standard links to EN 1555-1:2002, EN 1555-1:2021, ISO 11414:2009, ISO 11357-6:2008, ISO 13953:2001, ISO 6259-3:1997, ISO 11413:2008, EN 1555-2:2010, EN ISO 1167-1:2006, EN ISO 12162:2009, EN ISO 6259-1:2015, EN ISO 1183-1:2025, EN 1555-3:2025, EN ISO 1183-2:2019, EN ISO 472:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1555-1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

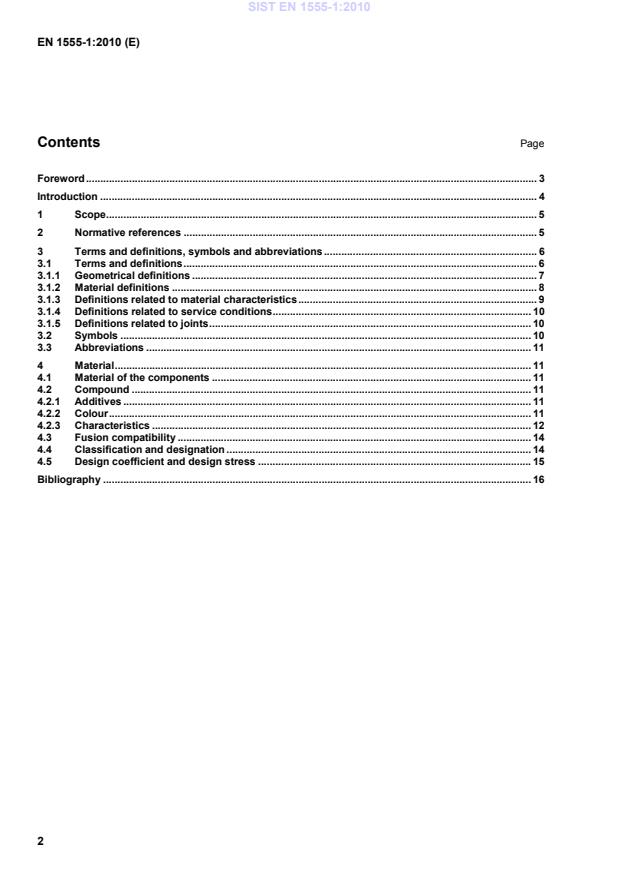

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Cevni sistemi iz polimernih materialov za oskrbo s plinastimi gorivi - Polietilen (PE) - 1. del: SplošnoKunststoff-Rohrleitungssysteme für die Gasversorgung - Polyethylen (PE) - Teil 1: AllgemeinesSystèmes de canalisations en plastique pour la distribution de combustibles gazeux - Polyéthylène (PE) - Partie 1: GénéralitésPlastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 1: General91.140.40Sistemi za oskrbo s plinomGas supply systems83.140.30Cevi, fitingi in ventili iz polimernih materialovPlastics pipes, fittings and valvesICS:Ta slovenski standard je istoveten z:EN 1555-1:2010SIST EN 1555-1:2010en,fr,de01-december-2010SIST EN 1555-1:2010SLOVENSKI

STANDARDSIST EN 1555-1:20031DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1555-1

September 2010 ICS 01.040.23; 01.040.91; 23.040.01; 91.140.40 Supersedes EN 1555-1:2002English Version

Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE) - Part 1: General

Systèmes de canalisations en plastique pour la distribution de combustibles gazeux - Polyéthylène (PE) - Partie 1 : Généralités

Kunststoff-Rohrleitungssysteme für die Gasversorgung - Polyethylen (PE) - Teil 1: Allgemeines This European Standard was approved by CEN on 30 July 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1555-1:2010: ESIST EN 1555-1:2010

EN 1555-1, Plastics piping systems for the supply of gaseous fuels Polyethylene (PE) Part 1: General (this standard); EN 1555-2, Plastics piping systems for the supply of gaseous fuels Polyethylene (PE) Part 2: Pipes; EN 1555-3, Plastics piping systems for the supply of gaseous fuels Polyethylene (PE) Part 3: Fittings; prEN 1555-4, Plastics piping systems for the supply of gaseous fuels Polyethylene (PE) Part 4: Valves; EN 1555-5, Plastics piping systems for the supply of gaseous fuels Polyethylene (PE) Part 5: Fitness for purpose of the system; CEN/TS 1555-7, Plastics piping systems for the supply of gaseous fuels Polyethylene (PE) Part 7: Guidance for assessment of conformity. NOTE EN 12007-2:2000 [1] prepared by CEN/TC 234 “Gas infrastructure” deals with the recommended practice for installation of plastics pipes system in accordance with EN 1555 (all parts). According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. SIST EN 1555-1:2010

Symbols and abbreviated terms

Part 1: Basic polymers and their special characteristics (ISO 1043-1:2001) EN ISO 1133, Plastics

Determination of the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of thermoplastics (ISO 1133:2005) EN ISO 1167-1:2006, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the resistance to internal pressure — Part 1: General method (ISO 1167-1:2006) EN ISO 1167-2, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids — Determination of the resistance to internal pressure — Part 2: Preparation of pipe test pieces (ISO 1167-2:2006) EN ISO 1183-1, Plastics

Methods for determining the density of non-cellular plastics

Part 1: Immersion method, liquid pyknometer method and titration method (ISO 1183-1:2004)

1) 1 bar = 0,1 MPa. SIST EN 1555-1:2010

Methods for determining the density of non-cellular plastics

Part 2: Density gradient column method (ISO 1183-2:2004) EN ISO 6259-1, Thermoplastics pipes

Determination of tensile properties

Part 1: General test method (ISO 6259-1:1997) prEN ISO 9080, Plastics piping and ducting systems - Determination of the long-term hydrostatic strength of thermoplastics materials in pipe form by extrapolation (ISO/DIS 9080:2010) EN ISO 12162, Thermoplastics materials for pipes and fittings for pressure applications — Classification, designation and design coefficient (ISO 12162:2009) EN ISO 13477, Thermoplastics pipes for the conveyance of fluids — Determination of resistance to rapid crack propagation (RCP) — Small-scale steady-state test (S4 test) (ISO 13477:2008) EN ISO 13478, Thermoplastics pipes for the conveyance of fluids — Determination of resistance to rapid crack propagation (RCP) — Full-scale test (FST) (ISO 13478:2007) EN ISO 13479, Polyolefin pipes for the conveyance of fluids — Determination of resistance to crack propagation — Test method for slow crack growth on notched pipes (ISO 13479:2009) EN ISO 15512, Plastics

Determination of water content (ISO 15512:2008) EN ISO 16871, Plastics piping and ducting systems

Plastics pipes and fittings

Method for exposure to direct (natural) weathering (ISO 16871:2003) ISO 6259-3, Thermoplastics pipes — Determination of tensile properties — Part 3: Polyolefin pipes ISO 6964, Polyolefin pipes and fittings — Determination of carbon black content by calcination and pyrolysis — Test method and basic specification ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT) ISO 11413:2008, Plastics pipes and fittings

Preparation of test piece assemblies between a polyethylene (PE) pipe and an electrofusion fitting ISO 11414:2009, Plastics pipes and fittings

Preparation of polyethylene (PE) pipe/pipe or pipe/fitting test piece assemblies by butt fusion ISO 13953, Polyethylene (PE) pipes and fittings

Determination of the tensile strength and failure mode of test pieces from a butt-fused joint ISO 13954, Plastics pipes and fittings

Peel decohesion test for polyethylene (PE) electrofusion assemblies of nominal outside diameter greater than or equal to 90 mm ISO 18553, Method for the assessment of the degree of pigment or carbon black dispersion in polyolefin pipes, fittings and compounds 3 Terms and definitions, symbols and abbreviations 3.1 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 472:2001 and

EN ISO 1043-1:2001 and the following apply. SIST EN 1555-1:2010

(= 3,142), rounded to the next greater 0,1 mm 3.1.1.5 minimum mean outside diameter dem,min minimum value for the mean outside diameter as specified for a given nominal size 3.1.1.6 maximum mean outside diameter dem,max maximum value for the mean outside diameter as specified for a given nominal size 3.1.1.7 out-of-roundness

ovality difference between the maximum and the minimum outside diameter in the same cross-section of a pipe or spigot 3.1.1.8 nominal wall thickness en numerical designation of the wall thickness of a component, which is a convenient round number, approximately equal to the manufacturing dimension in millimetres (mm) NOTE For thermoplastics components conforming to the different parts of EN 1555, the value of the nominal wall thickness, en, is identical to the specified minimum wall thickness at any point, emin. 3.1.1.9 wall thickness at any point e wall thickness at any point around the circumference of a component rounded to the next greater 0,1 mm NOTE The symbol for the wall thickness of the fittings and valves body at any point is E. SIST EN 1555-1:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...