EN 13383-2:2002

(Main)Armourstone - Part 2: Test methods

Armourstone - Part 2: Test methods

This European Standard specifies test methods for natural, artificial and recycled aggregates for use as armourstone.

Wasserbausteine - Teil 2: Prüfverfahren

Die vorliegende Europäische Norm legt Prüfverfahren für natürliche, künstliche und rezyklierte Gesteinskörnungen für die Verwendung als Wasserbausteine fest.

Enrochements - Partie 2 : Méthodes d'essai

La présente Norme européenne spécifie des méthodes d'essai pour les granulats naturels, artificiels et recyclés destinés à être utilisés comme enrochement au moment de la livraison.

Kamen za obloge pri vodnih zgradbah in drugih gradbenih delih - 2. del: Preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 16-Apr-2002

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 154 - Aggregates

- Drafting Committee

- CEN/TC 154/SC 4 - Hydraulic bound and unbound aggregates

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 05-Jun-2019

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13383-2:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Armourstone - Part 2: Test methods". This standard covers: This European Standard specifies test methods for natural, artificial and recycled aggregates for use as armourstone.

This European Standard specifies test methods for natural, artificial and recycled aggregates for use as armourstone.

EN 13383-2:2002 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13383-2:2002 has the following relationships with other standards: It is inter standard links to EN 13383-2:2013, EN 13383-2:2019, EN 933-1:2012, EN 933-2:2020, EN 15316-4-6:2007, EN 1097-5:2008, EN 932-1:1996, EN 932-5:2012, EN 16236:2018, EN 16236:2013, EN 13383-1:2002; is excused to EN 13383-1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13383-2:2002 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/125. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13383-2:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kamen za obloge pri vodnih zgradbah in drugih gradbenih delih - 2. del: Preskusne metodeWasserbausteine - Teil 2: PrüfverfahrenEnrochements - Partie 2 : Méthodes d'essaiArmourstone - Part 2: Test methods91.100.15Mineralni materiali in izdelkiMineral materials and productsICS:Ta slovenski standard je istoveten z:EN 13383-2:2002SIST EN 13383-2:2002en01-september-2002SIST EN 13383-2:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13383-2April 2002ICS 91.100.15English versionArmourstone - Part 2: Test methodsEnrochements - Partie 2: Méthodes d'essaiWasserbausteine - Teil 2: PrüfverfahrenThis European Standard was approved by CEN on 30 December 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13383-2:2002 ESIST EN 13383-2:2002

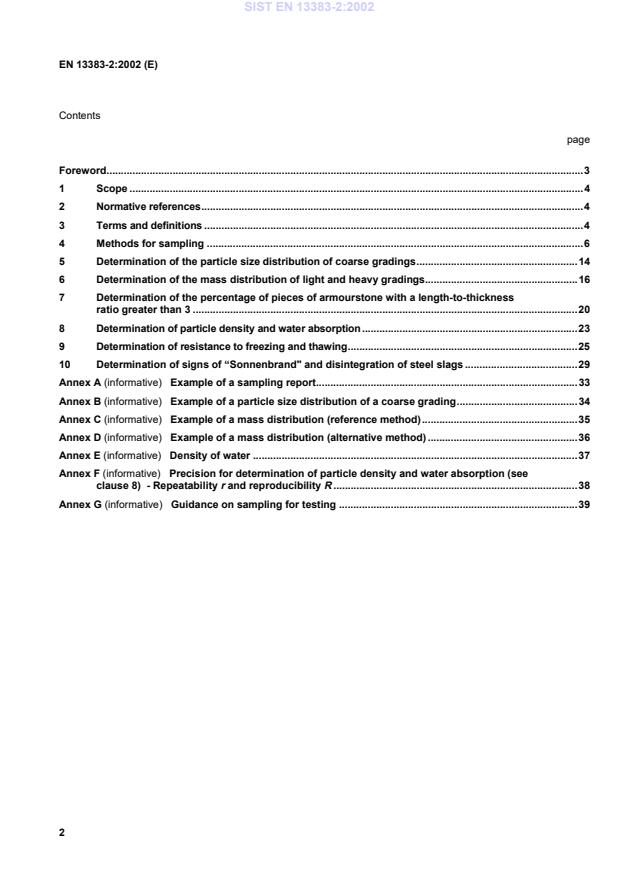

Example of a sampling report.33Annex B (informative)

Example of a particle size distribution of a coarse grading.34Annex C (informative)

Example of a mass distribution (reference method).35Annex D (informative)

Example of a mass distribution (alternative method).36Annex E (informative)

Density of water.37Annex F (informative)

Precision for determination of particle density and water absorption (seeclause 8)

- Repeatability r and reproducibility R.38Annex G (informative)

Guidance on sampling for testing.39SIST EN 13383-2:2002

The correct use of the specified apparatus and methods helps to avoid biased sampling inclusivethe possibility of human bias introduced by visual selection.

Sampling variation caused by the heterogeneityof the batch shall be reduced to an acceptable level by taking an adequate number of sampling increments.NOTESee annex G for guidance on numbers and sizes of samples and test portions for testing armourstone asspecified in EN 13383-1:2002.Sampling increments are selected at random from all parts of the batch that the samples are to represent.Armourstone from which no sampling increment can be taken (because it is not accessible, or for some otherpractical reason) shall not be considered to be part of the batch that is represented by the samples. Forexample, if sampling increments are taken from armourstone discharged from a silo, the samples representthe armourstone that has been discharged, not the armourstone remaining in the silo.The sampler shall be informed of the aim of the sampling.4.3 Sampling planA sampling plan shall be prepared, prior to sampling, taking into account the grading type, the nature andsize of the batch, the local circumstances and the purposes of sampling.

It shall include:a) the type of the armourstone;b) the aim of the sampling including a list of the properties to be tested;c) the identification of the sampling points;d) the mass or number of stones of sampling increments;e) the number of sampling increments;f) the sampling apparatus to be used;g) the methods of sampling and sample reduction with reference to the clauses of this EuropeanStandard;h) the relevant marking, packaging and dispatch of the samples.SIST EN 13383-2:2002

Grab, fitted to either a crane or a hydraulic machine.4.4.2.2

Bucket or fork, fitted to a wheeled loader or a hydraulic machine.4.4.2.3

Truck, for receiving and/or transport of samples.4.4.2.4

Lifting equipment and lifting aids, for stones that cannot be moved manually.4.4.3 Apparatus for sample reduction and transport4.4.3.1

A floor area, upon which samples can be deposited and tested.

The floor shall be sufficiently cleanand close-textured to be able to distinguish and recover the material of the sample from the floor material.4.4.3.2

Shovels.4.4.3.3

Rectangular sampling buckets, of sufficent size and of width not less than three times the nominalupper grading limit.4.4.3.4

Suitable plates and wires, for sample reduction.4.4.3.5

Containers for transport, such as bags, buckets or other suitable containers.4.5 Sampling methods4.5.1 GeneralSampling for the determination of particle size and mass distributions shall preferably be undertakenimmediately preceding or during loading for transport or unloading after transport.Regulations for safety and ergonomics shall be followed.NOTE 1Some sampling methods will inevitably involve the samplers working close to processing plant and movingvehicles. Those involved in the planning and execution of sampling should work closely with the operationalmanagement to ensure safe working practices.NOTE 2Mechanically selected gradings should preferably be sampled from a stationary conveyor belt or from thestream of material.

Sampling increments should be taken at regular intervals througout the period the batch is in motion.Gradings of which the pieces of armourstone are individually handled can be sampled at the most convenient location.NOTE 3Sampling from static batches should be avoided wherever possible since it is difficult to satisfy the principleof taking sampling increments at random from all parts of the batch, and hence segregation is likely to cause thesampling to produce biased results.During sampling, grabs or other extraction equipment shall be filled to a minimum such that the degree offilling does not adversely affect the representativity of the sample or sampling increment.SIST EN 13383-2:2002

At the beginning and the ending of thesampling the edge of the bucket shall pass the cross-section of the stream as fast as possible.NOTE 1Where appropriate, sampling should only be started after a preliminary run to ensure that possibleirregularities in the pass do not lead to unrepresentative samples.NOTE 2Samples can also be taken at the discharge from a screen by the same method.4.5.2.3 Sampling from stationary conveyor beltsAll sampling increments shall be taken at the same sampling point. In every sampling increment all materialbetween two cross-sections shall be taken.

The distance between the cross-sections shall be determined bythe required quantity of the sampling increment.NOTESampling should only be started after a preliminary run to ensure that possible irregularities in the pass donot lead to unrepresentative samples.4.5.2.4 Sampling from a siloSampling at a silo outlet shall be carried out in accordance with 4.5.2.2.NOTEDuring filling of a silo the material segregates and as a result the finer material tends to be found in thecentre of the silo with the coarser material along the wall sides.

Alternating loading and discharging of a silo leads to acomplex segregation pattern in the silo and this segregation causes variations in the particle size distribution of thedischarged material.

The number of sampling increments should be related to this variation.4.5.2.5 Sampling from stockpilesWhen sampling from a segregated stockpile, from which material is being collected for transporting, asampling increment shall be taken from the material which is being taken from the stockpile.

For thispurpose, the contents of one or more loader buckets, grabs, lorries or any other means of handling ortransport shall be taken.

The period during which the sampling is done shall be divided into a number ofequal intervals and a sampling increment shall be taken in the middle of each interval.If at the time of sampling no material of a segregated stockpile is undergoing routine removal, the removal ofmaterial shall be simulated so as not to distort the representativity of the sampling increment with thesegregation effects associated with the initiation of stockpile extraction.

The sampling increments shall betaken at random or at equal distances around the stockpile or part thereof to be sampled.When sampling from a non-segregated stockpile, a sampling increment shall be taken as indicated for asegregated stockpile or by taking a quantity of material from a random location which is easily reached withthe equipment available.SIST EN 13383-2:2002

/

h56h' =

/

h16h' =

/

h1 2h' =

/

h1 2h' =

/

h1 6h' =

/

h56A - AA3/12 l4/12 l4/12 l1/12 l1/12 l4/12 l4/12 l3/12 llAh'h1Key1SampleFigure 1 — Sampling locations in a loadSIST EN 13383-2:2002

/

h1 2

Key1SampleFigure 2 — Sampling locations in a non-segregated loadSIST EN 13383-2:2002

Forproperties for which testing of aggregate is permitted, sampling shall be carried out in accordance withEN 932-1.SIST EN 13383-2:2002

When such samplesare not available, the sampling increments shall be taken from the batch to be tested.Sampling increments shall be selected by one of the following methods:a) using random numbers (see EN 932-1:1996, annex D);b) taking pieces of armourstone in a sequence of predetermined positions relative to a randomlychosen starting point in a static batch;c) taking pieces of armourstone from random sieve fractions or parts thereof during or after thedetermination of the particle size distribution using two samplers, one being a blindfoldedselector and the other performing the actions;d) taking pieces of armourstone at a time or number interval when the material to be sampled ispassing in a random sequence of the stones, for instance during the determination of themass distribution.NOTEIf individual pieces of armourstone are significantly larger than the minimum size or mass required for thetest(s) to be executed, a portion of appropriate size or mass can be obtained by breaking a representative piece.

(Theobjective is to obtain laboratory samples representative of the batch to be tested but to have carried sample reduction atsource so as to minimize transport costs and reduce unnecessary sample reduction at the testing laboratory.)4.6 Sample reduction4.6.1 GeneralWherever possible, samples shall be reduced to produce samples for testing of appropriate size at thesampling location.If a sampling increment of a coarse grading is too large as test portion, one of the procedures as described in4.6.1.1 or 4.6.1.2 shall be used for the reduction of the sampling increment.If a sampling increment of a light grading is too large for the preparation of the bulk sample, the procedure asspecified in 4.6.1.2 shall be used for the reduction of the sampling increment.4.6.1.1 Reduction using bucketsDischarge the sample over one or more sample buckets.When discharging a sample from a loader bucket, arrange the receiver bucket(s) to catch all the materialfrom a cross-sectional segment or from one side of an imaginary cross-sectional plane in the centre of theloader bucket.When discharging a sample from a grab, catch all the material from one symmetrical quarter or half of thegrab content in one or more buckets.If further reduction is required, tip the bucket(s) containing the reduced sample over two adjoining bucketsand discard the contents of one bucket.

Repeat this procedure until the required size of test portion isobtained.4.6.1.2 Reduction using plates or wiresDischarge the sample over one or two vertically set plates.

The distance between two parallel set platesshall be at least three times the sieve size of the nominal upper grading limit.When discharging a sample from a loader bucket, take all the material from a cross-sectional segment orfrom one side of an imaginary cross-sectional plane in the centre of the loader bucket, discharged betweentwo parallel and vertically set plates or at one side of a vertically set plate.SIST EN 13383-2:2002

Where segregation is present in onedirection of the deposited sample, place the wires in the same direction (see Figure 5) and take thesubsample by removing all stones located, or for the largest part located, between the imaginary verticalplanes projected by the wires.NOTE 1A sample to be reduced by using wires should be spread in a layer of not greater than twice the nominalupper size of the material to facilitate the reduction procedure.NOTE 2Where no segregation of the material has occurred, the subsample can be limited to half the separated strip.4.7 Marking, packaging and dispatch of samplesThe laboratory samples or containers in which they are transported shall be clearly and durably marked.Marking shall include:a) a unique code; orb) identification of the laboratory samples, place of sampling, date of sampling and designationof the material.Laboratory samples shall be transported in such a way that pieces of armourstone are not broken in transit.SIST EN 13383-2:2002

The aperture sizes and the number of sieves shall be appropriate for the natureof the sample and the accuracy required.The cumulative mass of the pieces of armourstone passing each sieve shall be expressed as a percentageof the total mass of the material.5.2 Apparatus5.2.1

All apparatus, unless otherwise stated, shall conform to the general requirements of EN 932-5.5.2.2

Steel rod sieves, with square openings of 250 mm, 180 mm, 125 mm, 90 mm and 63 mm, fitting onreceivers, and a single opening sieve, 360 mm.These sieves shall comprise steel rods of 12 mm diameter welded together at right angles, forming squareopenings, with dimensions equating to the nominal sieve sizes with tolerances of ± 2,0 mm for the 360 mm,250 mm, 180 mm and 125 mm sieves and ± 1,0 mm for the 90 mm and 63 mm sieves.

In all cases the63 mm sieve shall be used.5.2.3

Test sieves, apertures conforming to ISO 3310-2 with apertures smaller than 63 mm.5.2.4

Receivers, with a volume of at least 0,1 m3, on which the steel rod sieves will fit.5.2.5

Weighing equipment, with a weighing capacity of at least 150 kg, accurate to 0,5 kg.5.2.6

Shovels, and brushes.5.2.7

A floor area, upon which the test portion can be deposited and tested. The floor shall be sufficientlyclean and close-textured to be able to distinguish and recover the material of the test portion from the floormaterial.SIST EN 13383-2:2002

Place the 360 mm sieve over the stones retained on the250 mm sieve.Brush off, where present, any adhesive materials from the pieces of armourstone and catch the fine materialin the receiver under the 63 mm sieve.NOTEEnsure that all pieces of armourstone which may pass the sieve in any orientation have so passed before theretained material is placed on the subsequent sieve.Remove the fraction which passes the 63 mm sieve and weigh its mass (m1).If this mass is greater than 80 kg, split the fraction, taking and weighing a representative part of at least 40 kg(m2).

Execute the split by discharging the homogenised material over two adjoining receivers taking care toavoid any loss of material.Sieve the fraction that passes the 63 mm sieve, or the representative part thereof, in accordance withEN 933-1.Weigh the material retained on each sieve separately (Mi) and weigh the fraction which passes the sieve withthe smallest aperture size (m3) to

0,5 kg.5.4.2 Wet sievingWet sieving shall be used if fine particles are attached to the surface of the pieces of armourstone or arepresent in form of larger lumps than the smallest sieve aperture, in such a way that breaking of the adhesionby brushing is not possible.Weigh the mass of the sample (Mi + m3) to

0,5 kg.Carry out the sieving procedure in accordance with 5.4.1 with the following modifications:a) treat the sample during sieving by hosing with water and brushing in such a way that theeffect of adhesion between the fine particles and the surface of the armourstone is removed;b) sieve all the fraction passing the 63 mm sieve;c) allow the material retained on each sieve to drain and weigh the mass retained on each sieveseparately (Mi) to

0,5 kg;d) discard the fraction which passes the sieve with the smallest aperture.5.5 Calculation and expression of resultsRecord the various masses on a test data sheet (see annex B).SIST EN 13383-2:2002

The average mass of the pieces of armourstone is derived by dividing thetotal mass excluding fragments by the number of pieces of armourstone.SIST EN 13383-2:2002

In cases ofdispute the reference method should be used.6.2 Apparatus6.2.1

All apparatus, unless otherwise stated, shall conform to the general requirements of EN 932-5.6.2.2

Weighing equipment, accurate to 2 % of the nominal lower limit of the grading to be tested.NOTEFor the alternative test method, the weighing equipment should be accurate to 1 % of the test portion or partsthereof when weighing the test portion in several parts.6.2.3

Lifting equipment and lifting aids, for armourstone that cannot be moved manually.6.2.4

A floor area, upon which the test portion can be deposited and tested.

The floor shall be sufficientlyclean and close-textured to be able to distinguish and recover the material of the test portion from the floormaterial.6.3 Preparation of test portionThe sample shall be reduced if necessary in accordance with the requirements of clause 4 to produce therequired test portion.The number of pieces of armourstone heavier than fragments in the test portion of heavy and light gradingsshall be as specified in Table 1.Table 1 — Number of pieces of armourstone in test portionsfor determination of mass distributionGradingkgMinimum number of pieces ofarmourstone heavier than fragmentsHeavy grading: 10 000 to 15 000Heavy grading: 6 000 to 10 000Heavy grading: 3 000 to 6 000Heavy grading: 1 000 to 3 000Heavy grading: 300 to 1 000Light gradings253060901402006.4 Procedure6.4.1 Reference methodWeigh each piece of armourstone heavier than a fragment separately (Mi) to

2 % of the nominal lower limitof the grading.Weigh all fragments together (Mf) to

2 % of the nominal lower limit of the grading.Count and record the total number of pieces of armourstone heavier than a fragment (n).SIST EN 13383-2:2002

1 %.Weigh each piece of armourstone heavier than a fragment separately with the exception of the pieces in thefraction with a mass between two successive limit masses for which requirements are set.

This fraction shallbe the fraction with the presumed largest number of pieces of armourstones.

Weigh each piece ofarmourstone (Mi) to

2 % of the nominal lower limit of the grading.Weigh all fragments together (Mf) to

2 % of the nominal lower limit of the grading.Count and record the total number of pieces of armourstone heavier than a fragment (n).NOTEUsing this method, the complete sample could, for example, be weighed, if necessary in parts, on aweighbridge, either in the bucket of a wheeled loader or on a lorry.

It forms an attractive method for heavier gradingsthan 10 kg to 60 kg, for gradings with a limited number of requirements for the mass distribution and where only a limitednumber of requirements for the mass distribution has to be inspected.The average mass of the pieces of armourstone does not require weighing of all the individual pieces of armourstone.The method demands a careful working procedure in counting pieces of armourstones and visual assessment of whichpieces of armourstone fall within the limits between which the pieces of armourstone are not weighed individually.

Thevisual assessment should be controlled through check weighing.

This method can be found useful for production control.6.5 Calculation and expression of results6.5.1 Reference methodRecord the various masses on a test data sheet (see example given in annex C).Calculate the cumulative mass of pieces of armourstone including fragments (Mn) with a mass smaller thaneach specified mass in the mass distribution.Calculate, to the nearest whole number, the cumulative percentage of pieces of armourstone (Pn) with amass smaller than each specified mass in the mass distribution in accordance with the following equation:100finnMMMP(1)whereMnis the cumulative mass of the pieces of armourstone including fragments with a

mass smaller than each specified mass in the mass distribution, in kilograms;Miis the cumulative mass of all the pieces of armourstone larger than a fragment, in

kilograms;Mfis the mass of the fragments, in kilograms.Calculate the average mass of the pieces of armourstone heavier than a fragment (M) in kilograms to thenearest 1 kg in accordance with the following equation:nMMi(2)where:Miis the cumulative mass of all the pieces of armourstone larger than a fragment;in kilograms;nis the number of the pieces of armourstone heavier than a fragment.SIST EN 13383-2:2002

=

Mb - Mf - Mi(3)whereMbis the mass of the test portion, in kilograms;Mfis the mass of the fragments, in kilograms;Miis the cumulative mass of all the weighed pieces of armourstone larger than a

fragment, in kilograms.Calculate the cumulative mass of the pieces of armourstone (Mn) with a mass smaller than each specifiedmass in the mass distribution, from the masses of the individually weighed pieces of armourstone (Mi), themass of fragments (Ms) and the mass of pieces of armourstone not weighed individually (Mc).Calculate, to the nearest whole number, the cumulative percentage of pieces of armourstone (Pn) with amass smaller than each specified mass in the mass distribution in accordance with the following equation:bnnMMP100(4)where:Mbis the mass of the test portion, in kilograms;Mnis the cumulative mass of the pieces of armourstone with a mass smaller than

each specified mass in the mass distribution, in kilograms.Calculate the average mass of the pieces of armourstone heavier than a fragment (M) in kilograms to thenearest kg in accordance with the following equation:nMMMfb(5)whereMbis the mass of the test portion, in kilograms;Mfis the mass of the fragments, in kilograms;nis the number of pieces of armourstone heavier than a fragment.6.6 Test report6.6.1 Required dataThe test report shall include the following information:a) reference to this European Standard;b) identity of laboratory;c) identification of the sample;d) number of pieces of armourstone heavier than fragments in the test portion;e) method of test (reference method or alternative method);f) cumulative percentages of pieces of armourstone with a mass smaller than each specifiedmass in the mass distribution;SIST EN 13383-2:2002

asdetermined by visual inspection, by using straight laths and a carpenter's rule or a tape-measure, or by usinga calliper.7.2 Apparatus7.2.1

All apparatus, unless otherwise stated, shall conform to the general requirements of EN 932-5.7.2.2

Two straight laths, of length greater than the largest thickness (E) of a piece of armourstone to betested.7.2.3

Carpenter's rule or tape-measure, readable to

3 % of the largest length (L) of a piece of armourstoneto be tested.7.2.4

Calliper, as shown in Figure 6.7.2.5

Weighing equipment, accurate to 2 % of the masses to be weighed.LE12Key1Tape measure2L-steelFigure 6 — CalliperSIST EN 13383-2:2002

Fragments shall be discarded.The number of pieces of armourstone in a test portion shall be as specified in Table 2.Table 2 — Number of pieces of armourstone in test portions for determination of shape characteristicsGradingkgMinimum number of pieces ofarmourstoneHeavy grading: 10 000 to 15 000Heavy grading: 6 000 to 10 000Heavy grading: 3 000 to 6 000Heavy grading: 1 000 to 3 000Heavy grading: 300 to 1 000Light gradings and coarse gradings25306090140200NOTE 1

Test portions obtained for the determination of the mass distribution (clause 6) ofa light or heavy mass grading can be used for this test.NOTE 2

For coarse gradings the test can be performed on representative parts of sievefractions obtained from

the determination of the particle size distribution (clause 5)containing a sufficient number of armourstones.7.4 Procedure7.4.1 Measurement of stonesShould unambiguous assessment of L/E > 3 of any piece of armourstone not be possible by visualinspection, position the armourstone with its two extremities between the two straight laths positioned parallelto each other and at right angles to the longest dimension (length L). The longest dimension of a cuboidalblock is between diametrically opposite corners.

Measure the length L at right angles to the laths using thecarpenter's rule or the tape-measure.

Measure the thickness E by positioning the two straight laths parallelto each other and tangential to the smallest dimension (thickness: E).

Measure the thickness E at rightangles to the laths using the carpenter's rule or the tape-measure.Measure the dimensions L and E to

3 %. If this accuracy cannot be met using the above procedure thecalliper (7.2.4) shall be used.NOTEThe measurement L/E is based on aspect ratio, and as such it is fundamentally different from axis-basedmeasurements such as the dimensions or axis ratios of an enclosing cuboid.7.4.2 Heavy gradingsFor heavy gradings count the number of pieces of armourstone (N1) with a L/E ratio greater than 3 and thetotal number of pieces of armourstone tested (N2).7.4.3 Light gradingsFor light gradings weigh the total mass of the pieces of armourstone (M1) with a L/E ratio greater than 3 andthe total mass of the pieces of armourstone tested (M2).SIST EN 13383-2:2002

than 3, in kilograms;M2is the total mass of the pieces of armourstone tested, in kilograms.Record the percentage to the nearest whole number.7.5.3 Coarse gradingsCalculate the percentage of pieces of armourstone with a length-to-thickness ratio greater than 3 inaccordance with the following equation:ntnsnts21t1s1itisi.VMMVMMVMMVMM22n1iwhereMsiis the mass of the pieces of armourstone with a L/E ratio greater than 3 in each size

fraction;Mtiis the total mass of the pieces of armourstone tested in each size fraction;Viis the percentage by mass of size fraction i in the test portion (derived from the

determination of the particle size distribution specified in clau

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...