EN 14225-2:2005

(Main)Diving suits - Part 2: Dry suits - Requirements and test methods

Diving suits - Part 2: Dry suits - Requirements and test methods

This document specifies the construction and performance, of dry suits for wear by divers for underwater activities where the user is breathing underwater. Marking, labelling, information to be provided at the point of sale, and instructions for use are also specified.

Laboratory and practical performance tests are specified.

Tauchanzüge - Teil 2: Trockentauchanzüge - Anforderungen und Prüfverfahren

Dieses Dokument legt die Konstruktion und die Leistungsfähigkeit von Trockentauchanzügen fest, die von Tau-

chern bei Tätigkeiten unter Wasser zu tragen sind, bei denen der Benutzer unter Wasser atmet. Kennzeichnung,

Etikettierung, mitzuliefernde Informationen beim Verkauf und eine Gebrauchsanweisung werden auch festgelegt.

Es werden Laborprüfungen und praktische Leistungsprüfungen festgelegt.

Vêtements de plongée - Partie 2 : Combinaisons étanches - Prescriptions et méthodes d'essai

La présente norme européenne spécifie les prescriptions relatives à la construction et aux performances des

vêtements étanches destinés à être portés par les plongeurs dans le cadre d'activités subaquatiques, au

cours desquelles l'utilisateur respire sous l'eau. Le marquage, l'étiquetage, les informations à fournir sur le

point de vente et la notice d'instructions sont également spécifiés.

Des essais réalisés en laboratoire et des essais pratiques de performance sont mentionnés par ailleurs.

Potapljaške obleke – 2. del: Suhe obleke – Zahteve in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 29-Mar-2005

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 162 - Protective clothing including hand and arm protection and lifejackets

- Drafting Committee

- CEN/TC 162/WG 12 - Diving suits

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Dec-2017

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 02-Oct-2010

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 14225-2:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Diving suits - Part 2: Dry suits - Requirements and test methods". This standard covers: This document specifies the construction and performance, of dry suits for wear by divers for underwater activities where the user is breathing underwater. Marking, labelling, information to be provided at the point of sale, and instructions for use are also specified. Laboratory and practical performance tests are specified.

This document specifies the construction and performance, of dry suits for wear by divers for underwater activities where the user is breathing underwater. Marking, labelling, information to be provided at the point of sale, and instructions for use are also specified. Laboratory and practical performance tests are specified.

EN 14225-2:2005 is classified under the following ICS (International Classification for Standards) categories: 97.220.40 - Outdoor and water sports equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14225-2:2005 has the following relationships with other standards: It is inter standard links to EN 14225-2:2017, ISO 1817:1999, EN 14126:2003, EN 340:2003, EN 772-19:2000, EN ISO 15027-3:2002, EN ISO 105-E02:1996, EN ISO 13995:2000, EN 250:2000, EN ISO 6529:2001, EN ISO 13935-2:1999, EN 1809:1997, EN ISO 105-X12:2002, EN 14225-1:2005, EN 14225-3:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14225-2:2005 is associated with the following European legislation: EU Directives/Regulations: 2016/425, 89/686/EEC, 93/68/EEC, 93/95/EEC, 96/58/EC; Standardization Mandates: M/031. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14225-2:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Diving suits - Part 2: Dry suits - Requirements and test methodsPotapljaške obleke – 2. del: Suhe obleke – Zahteve in preskusne metodeVetements de plongée - Partie 2 : Combinaisons étanches - Prescriptions et méthodes d'essaiTauchanzüge - Teil 2: Trockentauchanzüge - Anforderungen und Prüfverfahren97.220.40Oprema za športe na prostem in vodne športeOutdoor and water sports equipmentICS:SIST EN 14225-2:2005enTa slovenski standard je istoveten z:EN 14225-2:200501-julij-2005SIST EN 14225-2:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14225-2March 2005ICS 97.220.40English versionDiving suits - Part 2: Dry suits - Requirements and test methodsVêtements de plongée - Partie 2 : Combinaisons étanches- Prescriptions et méthodes d'essaiTauchanzüge - Teil 2: Trockentauchanzüge -Anforderungen und PrüfverfahrenThis European Standard was approved by CEN on 14 February 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14225-2:2005: E

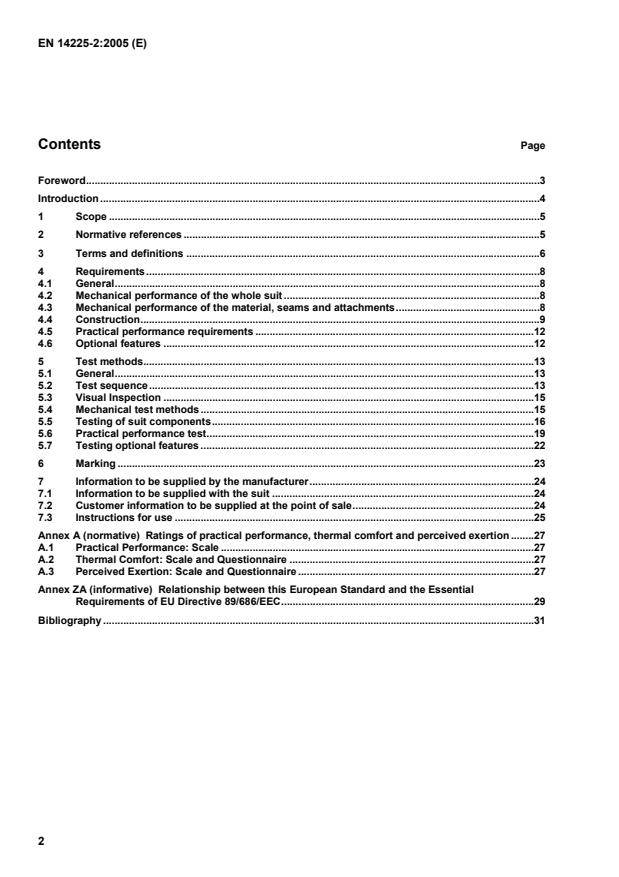

Ratings of practical performance, thermal comfort and perceived exertion.27 A.1 Practical Performance: Scale.27 A.2 Thermal Comfort: Scale and Questionnaire.27 A.3 Perceived Exertion: Scale and Questionnaire.27 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 89/686/EEC.29 Bibliography.31

the International Maritime Organisation (IMO)

a dry suit

(100 100+) N without visible evidence of permanent deformation or tearing, when visually inspected according to 5.3.

Whole Suit Sizing 4.4.1 5.6.7.3 a) Leakage resistance 4.4.4 5.5.2

Resistance to hot and cold storage and inflation resistance 4.2.1 5.4.2.1 Sea water resistance 4.2.2 5.4.2.2 Resistance to cleaning, disinfection and decontamination 4.2.3 5.4.2.3

Practical performance 4.5 5.6

Suit Materials Resistance to puncture and dynamic tearing 4.3.1 5.4.3.1 Seam strength 4.3.2 ISO 13935-2:1999 Joint strength of attachments 4.3.3 5.4.3.2 Compactness of slide fasteners 4.3.4 5.5.2

Inflation hose Tensile load resistance 4.4.2.2 5.5.1.1 Flexibility 4.4.2.2 5.5.1.1 Leakage resistance 4.4.2.2 EN 250

Inflation device(s) Strength of bond to suit 4.4.2.3 5.5.1.2 a) Reliability

4.4.2.3 5.5.1.2 e) Air flow rate 4.4.2.3 5.5.1.2 b) Leakage resistance 4.4.2.3 5.5.1.2 f) and 5.5.2 Connector strength 4.4.3 5.5.3

Deflation Devices Strength of bond to suit 4.4.2.4 5.5.1.3 a) Leakage resistance 4.4.2.4 5.5.1.3 b) and 5.5.2 Connector strength 4.4.3 5.5.3 Marking and Information Marking Clause 6 5.3 and 5.6 Information to be supplied by manufacturer Clause 7 5.3 and 5.6

4.4.2.3 Inflation device(s) When each inflation device is tested in accordance with 5.5.1.2 f) and 5.5.2 the inflation device shall not leak. When a suit incorporating a manually operated inflation device is tested in accordance with 5.6, it shall be possible to activate the device with a single gloved hand, when the diver is wearing three finger gloves,

(620+) mm thickness, double lined, or the gloves permanently or separately attached to the suit. When the joint between each suit inflation device and the suit is tested in accordance with 5.5.1.2 a) the bond shall not show visible signs of damage and the suit shall not leak. When tested in accordance with 5.5.1.2 b), the inflation device shall provide an airflow rate of >100 l⋅min-1 when corrected to a standard temperature and pressure of 273,15 K and 1,013 bar.

Feature Requirement specified in clause

Test method

Symbol

Thermal insulation – material – suit 4.6.2.1

EN 14225-1:2005, 5.4.3 5.6.7.5 TH Protection against chemicals 4.6.2.2 5.7.1.2 HZ Protection against micro-organisms 4.6.2.3 EN 14126:2003, 4.1.4.1 and 4.1.4.2 BIO Suits to aid visibility 4.6.3 EN ISO 105-E02:1996 EN ISO 105-X12:2002 EN ISO 15027-3:2002 VIS

4.4.2.4 Deflation device(s) The dry suit intended to be fitted with valves shall be provided with at least an automatic overpressure device and a manually operated deflation device. These two devices may be integrated into one unit. When the suit incorporating a manually operated deflation device is tested in accordance with 5.6 it shall be possible to activate the deflation device with a single gloved hand when the diver is wearing three finger gloves, (620+) mm thickness, double lined, or the gloves permanently attached to the suit. The opening of the deflation device on the inside of the suit shall be guarded in such a way as to ensure free gas flow to the device when tested according to 5.3. When tested in accordance with 5.6 it shall be possible to deflate the suit using the manual deflation device. When the joint between each suit deflation device and the suit is tested in accordance with 5.5.1.3 a) the suit shall not leak. When the suit is tested in accordance with 5.6 the deflation device shall not allow water ingress into the suit. When the air leakage test is carried out in accordance with 5.5.1.3 b) the amount of water introduced into the manometer over the 1 h test period shall not exceed 1 000 ml. When the flow test is carried out in accordance with 5.5.1.3 b) the pressure shall not exceed 25 mbar. The flow capacity of the overpressure device shall exceed the flow capacity of the inflation device, with a maximum pressure of 40 mbar inside the suit when tested according to 5.5.1.4 a). If the overpressure device is of the non-adjustable type, the pressure inside the suit during the actuation of the inflation device shall not exceed 40 mbar when tested according to 5.5.1.4 b). If the overpressure device is of the adjustable type, the pressure inside the suit during the actuation of the inflation device shall not exceed

25 mbar when the valve is at its minimum opening pressure setting, and 40 mbar when at its maximum setting when tested according to 5.5.1.4 c).

4.6.3.1 Colour If the suit manufacturer claims the suit to have a colour enhancing the visibility, this property shall be documented and include an area of the suit not less than 50 % of the total suit area when tested in accordance with 5.3. This enhanced visibility shall be for the relevant use environment. The colour fastness (dry and wet) of suit material when determined in accordance with ISO 105-A02:1993 shall be resistant to rubbing (wet and dry), when tested in accordance with EN ISO 105-X12:2002 to at least step 4, and to salt water when tested in accordance with EN ISO 105-E02:1996 to at least step 4. 4.6.3.2 Retroreflective material There shall be affixed to the suit surface a total area of at least 400 cm2 of material, which is retroreflective to light and which conforms to the requirements detailed in SOLAS:1974, as amended, Chapter III as amended by IMO Resolution MSC 47(66) and LSA Code, adopted by Res. A.658(16), Annex 2, issued by

the International Maritime Organisation (IMO). These retroreflective areas shall be located in at least two positions of the suit. Preference shall be given to the upper body, and parts of the suit that will not be covered by attachment or by other parts of the diving equipment. When retroreflective material attached to a suit, and the same material that has not been attached to a suit are tested in accordance with EN ISO 15027-3:2002, 3.11.6.4.2, there shall be no difference in retroreflectivity between the two samples. 5 Test methods 5.1 General At least three dry suits of different sizes including the largest and the smallest sizes, as stated by the manufacturer, together with material samples shall be submitted for visual inspection (see 5.3) and testing. One suit and suit material samples where appropriate shall undergo laboratory tests in accordance with 5.4 and 5.5, and all three suits shall undergo leakage test (5.5.2) and practical performance tests under realistic conditions in accordance with 5.6. 5.2 Test sequence The tests shall be conducted in accordance with the flow chart shown in Figure 1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...