EN 13525:2005

(Main)Forestry machinery - Wood chippers - Safety

Forestry machinery - Wood chippers - Safety

This document specifies safety requirements and their verification for design and construction of transportable, i.e. self-propelled, mounted, semi-mounted and trailed, wood chippers used in forestry, agriculture, horticulture and landscaping.

This document applies to chippers, used when stationary, which are manually loaded with wood through a horizontal or near horizontal infeed chute at the end of which mechanical infeed components (or chipping components acting as mechanical infeed components) draw the wood into the machine. The included wood chippers may be powered either by an external power source such as a tractor power take-off, hydraulics, etc or by an integral power source such as an internal combustion engine or an electric motor.

This document does not cover:

- requirements relating to national road regulations arising from transport between work sites;

- hazards arising from any self-propelled function;

- hazards arising from the transmission of power from an external power source - e.g. power take-off drive shafts;

- any machines where the infeed chute is fitted with an extension table;

- hazards arising from the engine pull starting of an integral power source;

- hazards arising from mechanical loading;

- vertical infeed chute chippers;

- electromagnetic aspects of the chippers

- shredders/chippers to be covered by EN 13683.

This document deals with all significant hazards, hazardous situations and events relevant to wood chippers, when they are used as intended and under the conditions foreseen by the manufacturer (see Annex A).

In addition, it specifies the type of information to be provided by the manufacturer on the safe use of these machines.

It is not applicable to environmental hazards (except noise).

This document is not applicable to wood chippers which are manufactured before the date of publication of this document by CEN.

Forstmaschinen - Buschholzhacker - Sicherheit

Dieses Dokument enthält Sicherheitsanforderungen und deren Überprüfung für die Konstruktion und den Bau von beweglichen z. B. selbstfahrenden, angebauten, aufgesattelten und gezogenen Buschholzhackern, die in der Land- und Forstwirtschaft, dem Gartenbau und der Landschaftspflege eingesetzt werden.

Dieses Dokument gilt für stationär betriebene Buschholzhacker, die von Hand mit Holz über einen waagerechten oder nahezu waagerechten Zuführtrichter beschickt werden. Am Ende des Zuführtrichters befinden sich mechanische Zuführelemente (oder Hackwerkzeuge, die als mechanische Zuführelemente fungieren), die das Holz in die Maschine einziehen. Die in den Anwendungsbereich fallenden Buschholzhacker können durch eine externe Antriebsquelle wie z. B. der Zapfwelle eines Traktors, hydraulisch usw. oder durch eine integrierte Antriebsquelle wie z. B. einem Verbrennungs- oder Elektromotor angetrieben werden.

Dieses Dokument behandelt nicht:

- nationale straßenverkehrstechnische Anforderungen, die für den Transport zwischen zwei Einsatzorten gelten;

- Gefahren in Hinblick auf die Selbstfahrfunktion;

- Gefahren in Verbindung mit der Kraftübertragung durch externe Antriebsquellen, z. B. Gelenkwellen;

- Maschinen, bei denen der Zuführtrichter mit einem Verlängerungstisch ausgerüstet ist;

- Gefahren in Verbindung mit Seilzug-Starteinrichtungen von integrierten Antriebsquellen;

- Gefahren in Verbindung mit mechanischem Beschicken;

- Buschholzhacker mit senkrechtem Zuführtrichter;

- Gesichtspunkte der elektromagnetischen Verträglichkeit von Buschholzhackern;

- Gartenhäcksler nach EN 13683.

Dieses Dokument behandelt alle signifikanten Gefahren, Gefahrensituationen und Gefahrenereignisse, die bei Buschholzhackern auftreten können, wenn Sie bestimmungsgemäß und unter den vom Hersteller vorgesehenen Bedingungen verwendet werden (siehe Anhang A).

Zusätzlich nennt Sie die Informationen, die vom Hersteller für den sicheren Gebrauch dieser Maschinen zur Verfügung zu stellen sind.

U

Machines forestières - Déchiqueteuses - Sécurité

La présente norme détermine les prescriptions de sécurité et les vérifications pour la conception et la construction des déchiqueteuses mobiles employées en foresterie, agriculture, horticulture et paysagisme. Cette norme s'applique aux déchiqueteuses ayant des éléments d'alimentation mécaniques ou des éléments de déchiquetage agissant comme des éléments d'alimentation mécaniques et qui sont alimentées dans une direction horizontale ou presque horizontale et conçues pour être chargées manuellement.

Gozdarski stroji - Sekalniki - Varnost

General Information

- Status

- Withdrawn

- Publication Date

- 18-Jan-2005

- Withdrawal Date

- 15-May-2007

- Technical Committee

- CEN/TC 144 - Tractors and machinery for agriculture and forestry

- Drafting Committee

- CEN/TC 144/WG 8 - Forestry machinery

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 16-May-2007

- Completion Date

- 16-May-2007

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

ECOCERT

Organic and sustainability certification.

Rainforest Alliance Certification

Sustainable agriculture and forestry certification.

Sponsored listings

Frequently Asked Questions

EN 13525:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Forestry machinery - Wood chippers - Safety". This standard covers: This document specifies safety requirements and their verification for design and construction of transportable, i.e. self-propelled, mounted, semi-mounted and trailed, wood chippers used in forestry, agriculture, horticulture and landscaping. This document applies to chippers, used when stationary, which are manually loaded with wood through a horizontal or near horizontal infeed chute at the end of which mechanical infeed components (or chipping components acting as mechanical infeed components) draw the wood into the machine. The included wood chippers may be powered either by an external power source such as a tractor power take-off, hydraulics, etc or by an integral power source such as an internal combustion engine or an electric motor. This document does not cover: - requirements relating to national road regulations arising from transport between work sites; - hazards arising from any self-propelled function; - hazards arising from the transmission of power from an external power source - e.g. power take-off drive shafts; - any machines where the infeed chute is fitted with an extension table; - hazards arising from the engine pull starting of an integral power source; - hazards arising from mechanical loading; - vertical infeed chute chippers; - electromagnetic aspects of the chippers - shredders/chippers to be covered by EN 13683. This document deals with all significant hazards, hazardous situations and events relevant to wood chippers, when they are used as intended and under the conditions foreseen by the manufacturer (see Annex A). In addition, it specifies the type of information to be provided by the manufacturer on the safe use of these machines. It is not applicable to environmental hazards (except noise). This document is not applicable to wood chippers which are manufactured before the date of publication of this document by CEN.

This document specifies safety requirements and their verification for design and construction of transportable, i.e. self-propelled, mounted, semi-mounted and trailed, wood chippers used in forestry, agriculture, horticulture and landscaping. This document applies to chippers, used when stationary, which are manually loaded with wood through a horizontal or near horizontal infeed chute at the end of which mechanical infeed components (or chipping components acting as mechanical infeed components) draw the wood into the machine. The included wood chippers may be powered either by an external power source such as a tractor power take-off, hydraulics, etc or by an integral power source such as an internal combustion engine or an electric motor. This document does not cover: - requirements relating to national road regulations arising from transport between work sites; - hazards arising from any self-propelled function; - hazards arising from the transmission of power from an external power source - e.g. power take-off drive shafts; - any machines where the infeed chute is fitted with an extension table; - hazards arising from the engine pull starting of an integral power source; - hazards arising from mechanical loading; - vertical infeed chute chippers; - electromagnetic aspects of the chippers - shredders/chippers to be covered by EN 13683. This document deals with all significant hazards, hazardous situations and events relevant to wood chippers, when they are used as intended and under the conditions foreseen by the manufacturer (see Annex A). In addition, it specifies the type of information to be provided by the manufacturer on the safe use of these machines. It is not applicable to environmental hazards (except noise). This document is not applicable to wood chippers which are manufactured before the date of publication of this document by CEN.

EN 13525:2005 is classified under the following ICS (International Classification for Standards) categories: 65.060.80 - Forestry equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13525:2005 has the following relationships with other standards: It is inter standard links to EN 13525:2005+A1:2007, EN 13525:2005/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13525:2005 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13525:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2005

Gozdarski stroji - Sekalniki - Varnost

Forestry machinery - Wood chippers - Safety

Forstmaschinen - Buschholzhacker - Sicherheit

Machines forestieres - Déchiqueteuses - Sécurité

Ta slovenski standard je istoveten z: EN 13525:2005

ICS:

65.060.80 Gozdarska oprema Forestry equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 13525

NORME EUROPÉENNE

EUROPÄISCHE NORM

January 2005

ICS 65.060.80

English version

Forestry machinery - Wood chippers - Safety

Machines forestières - Déchiqueteuses - Sécurité Forstmaschinen - Buschholzhacker - Sicherheit

This European Standard was approved by CEN on 8 December 2004.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2005 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13525:2005: E

worldwide for CEN national Members.

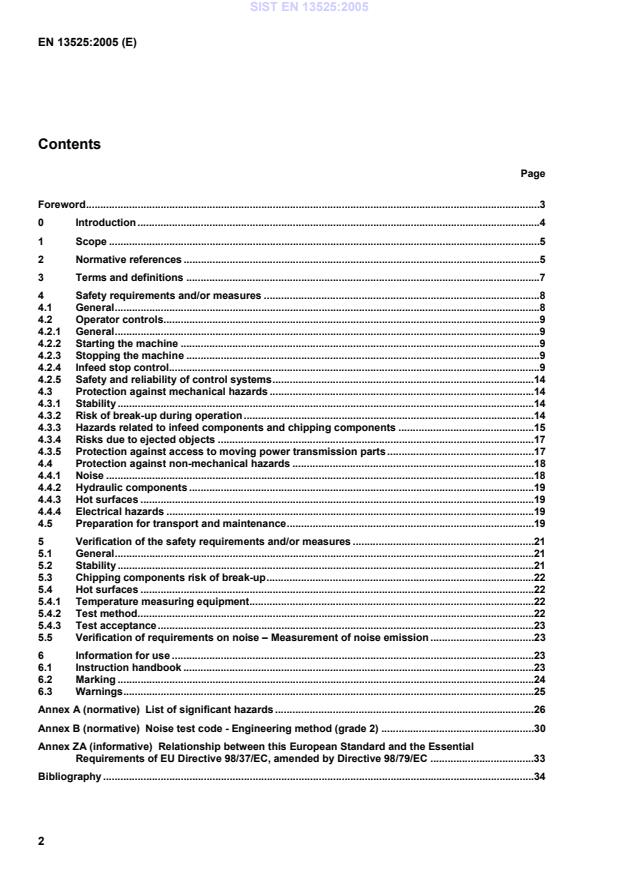

Contents

Page

Foreword.3

0 Introduction.4

1 Scope .5

2 Normative references .5

3 Terms and definitions .7

4 Safety requirements and/or measures .8

4.1 General.8

4.2 Operator controls.9

4.2.1 General.9

4.2.2 Starting the machine .9

4.2.3 Stopping the machine .9

4.2.4 Infeed stop control.9

4.2.5 Safety and reliability of control systems.14

4.3 Protection against mechanical hazards .14

4.3.1 Stability .14

4.3.2 Risk of break-up during operation.14

4.3.3 Hazards related to infeed components and chipping components .15

4.3.4 Risks due to ejected objects .17

4.3.5 Protection against access to moving power transmission parts .17

4.4 Protection against non-mechanical hazards .18

4.4.1 Noise .18

4.4.2 Hydraulic components .19

4.4.3 Hot surfaces .19

4.4.4 Electrical hazards .19

4.5 Preparation for transport and maintenance.19

5 Verification of the safety requirements and/or measures .21

5.1 General.21

5.2 Stability .21

5.3 Chipping components risk of break-up.22

5.4 Hot surfaces .22

5.4.1 Temperature measuring equipment.22

5.4.2 Test method.22

5.4.3 Test acceptance.23

5.5 Verification of requirements on noise – Measurement of noise emission .23

6 Information for use .23

6.1 Instruction handbook .23

6.2 Marking .24

6.3 Warnings.25

Annex A (normative) List of significant hazards .26

Annex B (normative) Noise test code - Engineering method (grade 2) .30

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 98/37/EC, amended by Directive 98/79/EC .33

Bibliography .34

Foreword

This document (EN 13525:2005) has been prepared by Technical Committee CEN/TC 144 “Tractors and

machinery for agriculture and forestry”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by July 2005, and conflicting national standards shall be withdrawn at the

latest by July 2005.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland

and United Kingdom.

0 Introduction

This document is a type C standard as stated in EN ISO 12100-1.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are

indicated in the scope of this document.

When provisions of this type C standard are different from those, which are stated in type A or B standards,

the provisions of this type C standard take precedence over the provisions of the other standards, for

machines that have been designed and built according to the provisions of this type C standard.

1 Scope

This document specifies safety requirements and their verification for design and construction of transportable,

i.e. self-propelled, mounted, semi-mounted and trailed, wood chippers used in forestry, agriculture, horticulture

and landscaping.

This document applies to chippers, used when stationary, which are manually loaded with wood through a

horizontal or near horizontal infeed chute at the end of which mechanical infeed components (or chipping

components acting as mechanical infeed components) draw the wood into the machine. The included wood

chippers may be powered either by an external power source such as a tractor power take-off, hydraulics, etc

or by an integral power source such as an internal combustion engine or an electric motor.

This document does not cover:

requirements relating to national road regulations arising from transport between work sites;

hazards arising from any self-propelled function;

hazards arising from the transmission of power from an external power source – e.g. power take-off drive

shafts;

any machines where the infeed chute is fitted with an extension table;

hazards arising from the engine pull starting of an integral power source;

hazards arising from mechanical loading;

vertical infeed chute chippers;

electromagnetic aspects of the chippers;

shredders/chippers to be covered by EN 13683.

This document deals with all significant hazards, hazardous situations and events relevant to wood chippers,

when they are used as intended and under the conditions foreseen by the manufacturer (see Annex A).

In addition, it specifies the type of information to be provided by the manufacturer on the safe use of these

machines.

It is not applicable to environmental hazards (except noise).

This document is not applicable to wood chippers which are manufactured before the date of publication of

this document by CEN.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 294:1992, Safety of machinery – Safety distance to prevent danger zones being reached by the upper limbs

EN 563:1994, Safety of machinery – Temperatures of touchable surfaces – Ergonomics data to establish

temperature limit values for hot surfaces

EN 811:1996, Safety of machinery – Safety distances to prevent danger zones being reached by the lower limbs

EN 953:1997, Safety of machinery – Guards – General requirements for the design and construction of fixed and

movable guards

EN 954-1:1996, Safety of machinery – Safety-related parts of control systems – Part 1: General principles for

design

EN 982:1996, Safety of machinery – Safety requirements for fluid power systems and their components –

Hydraulics

EN 1175-2:1998, Safety of industrial trucks – Electrical requirements – Part 2: General requirements of

internal combustion engine powered trucks

EN 10025-2:2004, Hot rolled products of structural steels - Part 2: Technical delivery conditions for non-alloy

structural steels

EN 60204-1:1997, Safety of machinery – Electrical equipment of machines – Part 1: General requirements (IEC

60204-1:1997)

EN 60529:1991, Degrees of protection provided by enclosures (IP Code) (IEC 60529:1989)

EN 60947-5-1:2004, Low-voltage switchgear and controlgear – Part 5-1: Control circuit devices and switching

elements – Electromechanical control circuit devices (IEC 60947-5-1:2003)

EN ISO 3744:1995, Acoustics – Determination of sound power levels of noise sources using sound pressure -

Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994)

EN ISO 4871:1996, Acoustics – Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 9614-1:1995, Acoustics – Determination of sound power levels of noise sources using sound intensity

– Part 1: Measurements at discrete points (ISO 9614-1:1993)

EN ISO 9614-2:1996, Acoustics - Determination of sound power levels of noise sources using sound intensity

- Part 2: Measurement by scanning (ISO 9614-2:1996)

EN ISO 11201:1995, Acoustics – Noise emitted by machinery and equipment – Measurement of emission

sound pressure levels at a work station and at other specified positions – Engineering method in an

essentially free field over a reflecting plane (ISO 11201:1995)

EN ISO 11204:1995, Acoustics – Noise emitted by machinery and equipment – Measurement of emission

sound pressure levels at a work station and at other specified positions – Method requiring environmental

corrections (ISO 11204:1995)

EN ISO 11688-1:1998, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100-1:2003, Safety of machinery – Basic concepts, general principles for design – Part 1: Basic

terminology, methodology (ISO 12100-1:2003)

EN ISO 12100-2:2003, Safety of machinery – Basic concepts, general principles for design – Part 2: Technical

principles (ISO 12100-2:2003)

ISO 4413:1998, Hydraulic fluid power – General rules relating to systems

ISO 11684:1995, Tractors, machinery for agriculture and forestry, powered lawn and garden equipment – Safety

signs and hazard pictorials – General principles

IEC 60245-1:2003, Rubber insulated cables – Rated voltages up to and including 450/750 V – Part 1: General

requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100-1:2003 and the following

apply.

3.1

wood chipper

machine designed to reduce wood into chips

3.2

chipping components

rotating disc or drum or similar device with cutting tools or screw arrangement that performs the chipping

operation and may perform also the infeed operation

3.3

infeed components

rollers and/or conveyors which feed wood into the chipping components

3.4

loading

method of presenting wood to the machine

3.4.1

horizontal loading

method where the wood is presented to the machine from its side in a horizontal direction

3.4.2

manual loading

method where the wood is presented to the machine is done manually by the operator

3.5

infeed chute

device through which wood is fed and guided to the chipping components and which may also provide the

required safety distances

3.6

integrated feed conveyor

belt or similar conveyor, either in front of the infeed chute, or integral to the infeed chute which presents the

wood to the infeed chute or to the infeed components

3.7

discharge chute

device through which the chipped material is guided away from the chipping components and which may also

provide the required safety distances

3.8

run down time

time elapsed from the actuation of the stop control device until the chipping and/or infeed components come

to a complete stop

3.9

reference plane

vertical imaginary plane (a) normal to the feed direction, at a point nearest to the operator (b) during the action

of infeeding, where the distance between the infeed components is 25 mm or where the separation of the

infeed components is at its minimum if this is greater than 25 mm or where the infeed is achieved by the

chipping components alone, the point nearest the operator where the chipping components are accessible

3.10

type A machines

machines where, on level ground and with the infeed chute in its designated working position, the outermost

lower edge of the infeed chute is 600 mm or more from the ground, see Figure 2

3.11

type B machines

machines where, on level ground and with the infeed chute in its designated working position, the outermost

lower edge of the infeed chute is less than 600 mm from the ground, see Figure 3

3.12

tool tip circle

path described by the outermost point of the cutting tools when rotating around their axis

Dimensions in millimetres

Key

a Reference plane

b Operator

NOTE This example is a functional representation of a wood chipper and does not illustrate the safety measures

required by this document.

Figure 1 – Example of wood chipper and reference plane

4 Safety requirements and/or measures

4.1 General

Machines shall comply with the safety requirements and/or protective measures of this clause. In addition, the

machine shall be designed according to the principles of EN ISO 12100 for hazards relevant but not significant,

which are not dealt with by this document (e.g. sharp edges).

Unless otherwise specified in this document all opening and safety distances shall comply with Tables 1, 3, 4

and 6 of EN 294:1992 and other aspects shall comply with the relevant parts of EN ISO 12100.

4.2 Operator controls

4.2.1 General

All machines shall have separate controls for starting/stopping the chipping components and for

starting/stopping the infeed action meeting the requirements given below in 4.2.2, 4.2.3, 4.2.4. The safety and

reliability of control system shall meet the requirements given in 4.2.5. Controls for stopping the chipping

components shall also stop the infeed action.

4.2.2 Starting the machine

4.2.2.1 Where the machine is powered by an external power source, e.g. a tractor power take-off or a

hydraulic system, the tractor power-take-off start control or hydraulic system control is regarded as the

operator's control for starting the chipping components, infeed components and integral conveyors (where

fitted).

4.2.2.2 Where the machine is powered by an integral power source, e.g. an internal combustion engine

or an electric motor, the engine or motor start is regarded as the operator's control for starting the chipping

components, infeed components and integral conveyors (where fitted).

4.2.2.3 Where an electric starter is used to start the integral power source, unauthorised activation of the

starter shall be avoided by using one or more of the following methods:

a key operated ignition or starting switch;

a lockable cover for the ignition or starting switch;

a security ignition or starting lock;

a lockable battery disconnection switch.

4.2.3 Stopping the machine

4.2.3.1 Where the machine is powered by an external power source, e.g. tractor power take-off or

hydraulic system, the external power source stopping controls such as the tractors engine stop control, the

tractor power take-off control or hydraulic system control are regarded as the operator's control for stopping

the machine.

4.2.3.2 Where the machine is powered by an integral power source, e.g. an internal combustion engine

or electric motor, the engine or motor stop is regarded as the operator's control for stopping the machine.

4.2.3.3 Where integral power source is an internal combustion engine, the engine stop control shall not

require sustained manual pressure for its operation and when once actuated it shall not be possible to restart

the engine unless the control has been reset.

4.2.4 Infeed stop control

4.2.4.1 General

All machines shall have an infeed stop control. The design, position and function of the infeed stop control

shall allow the operator when in the designated operating position, if entangled in the wood being fed into the

machine, to stop the infeed action. The operator shall be able to engage the infeed stop control, in the

direction of infeed, by using parts of the body other than just the hands (e.g. shoulder, elbow, torso, hip, legs

etc.). To achieve this, it shall meet the positional requirements given in 4.2.4.2 and functional requirements in

4.2.4.3.

Whilst these requirements shall be fulfilled, the design, position and function of the infeed stop control shall

seek to minimise inadvertent activation (nuisance tripping) by wood and branches as they are fed into the

machine; and opportunities for the operator to remove, disconnect, disable, defeat, or jam the control.

4.2.4.2 Positional requirements

4.2.4.2.1 The infeed stop control shall be located in accordance with either 4.2.4.2.2, see Figure 2 or

4.2.4.2.3, see Figure 3, as appropriate to the height of the outermost lower edge of the infeed chute. At the

infeed chute vertical edges, the infeed stop control shall cover a minimum of 0,75 x h. At the relevant

horizontal edge, top or bottom, the infeed stop control shall cover the entire width of the edge.

4.2.4.2.2 For type A machines, the infeed stop control shall be located at the sides and at the lower edge of

the chute, see Figure 2.

Dimensions in millimetres

Key

h Height of the chute side

Figure 2 – Location and coverage of the infeed stop control on type A machines

4.2.4.2.3 For type B machines, the infeed stop control shall be located at the sides and at the upper edge

of the chute, see Figure 3.

Dimensions in millimetres

Key

h Height of the chute side

Figure 3 – Location and coverage of the infeed stop control on type B machines

4.2.4.2.4 In either location, the position of the infeed stop control in relation to the outermost edge of the

infeed chute shall be in accordance with the appropriate Figure 4 or Figure 5 such that:

all positions of the infeed stop control that allow or cause infeed action are in front of the outermost edge

of the infeed chute, i.e. zone B;

from those positions, the infeed stop control shall be able to be moved to a position known as the

‘emergency stop position’, i.e. position C; and

this emergency stop position is in the position closest to the outermost edge of infeed chute but

sufficiently in front of that edge for the emergency stop position to be successfully engaged, i.e. the

respective operation completed, by the operator in the manner described in 4.2.4.1 in the event of

entanglement.

4.2.4.2.5 The positions/functions of the infeed stop control shall be clearly indicated on both sides of the

infeed chute and also in the instruction handbook. The colour of the infeed stop control shall be preferably red

or yellow. Where other colours are used, they shall be bright and in contrast to the background colour of the

infeed chute.

4.2.4.2.6 In the case of machines with an integrated feed conveyor, the infeed stop control shall meet the

requirements of 4.2.4.2.4. Instead of meeting the location requirements of 4.2.4.2.1 the infeed stop controls

shall be provided at the sides and at the outer end of the conveyor. Any reverse action of the conveyor shall

have a hold-to-run control located within reach of the operator but outside of reach to the danger zones and in

a position providing good visibility of the conveyor and the infeed components.

Key

AA Behind the outermost edge of the infeed chute

BB In front of the outermost edge of the infeed chute

A Infeed chute

B Zone for all positions of infeed stop control that allow or cause infeed or reverse action

C Emergency stop position

D Outermost lower edge of the infeed chute

E Optional additional position for the infeed stop control where the only permitted function is reverse of a hold-to-run

type

F Direction of infeed

G Operator’s position

Figure 4 — Schematic representation of the relationship between the positions of the infeed stop

control, the outermost lower edge of the infeed chute and the position of the operator when feeding

type A machines

Key

AA Behind the outermost edge of the infeed chute

BB In front of the outermost edge of the infeed chute

A Infeed chute

B Zone for all positions of infeed stop control that allow or cause infeed or reverse action

C Emergency stop position

D Outermost upper edge of the infeed chute

E Optional additional position for the infeed stop control where the only permitted function is reverse of a hold-to-run

type

F Direction of infeed

G Operator’s position

H Position of the infeed stop control where the only permitted functions are stop or reverse

Figure 5 — Schematic representation of the relationship between the positions of the infeed stop

control, the outermost upper edge of the infeed chute and the position of the operator when feeding

type B machines

4.2.4.3 Functional requirements

4.2.4.3.1 All machines shall comply with 4.2.4.3.2 to 4.2.4.3.6 inclusive. Type B machines shall also meet

the requirements of 4.2.4.3.7. Where the infeed stop control incorporates other functions for controlling the

infeed components, they shall meet the appropriate requirements of 4.2.4.3.8 to 4.2.4.3.10.

4.2.4.3.2 Actuation of any part of the infeed stop control shall have the same functional result.

4.2.4.3.3 Movement of the infeed stop control from zone B to position C, as defined in 4.2.4.2.4, shall stop

infeed action. Actuation to the emergency stop position shall have priority over any other controls used to

operate the infeed components as defined in 4.2.4.3.6.

4.2.4.3.4 The force required to actuate the infeed stop control from zone B to position C (see Figures 4 and

5) shall not exceed 150 N on the horizontal part of the infeed stop control (including those provided on

machines with an integrated feed conveyor) and 200 N on other parts along the length 0,75 x h as specified in

4.2.4.2.1. The force required shall be measured in a horizontal direction ±15°, or in the case of a pivoting

infeed stop control, in the tangential direction of its movement.

4.2.4.3.5 On actuation of the infeed stop control to position C, the time taken for infeed action to stop shall

be as short as practicable and in all instances less than the minimum time for wood to travel from the nearest

position of the infeed stop control to the reference plane.

4.2.4.3.6 When actuated to position C, the operator shall not be able to restart infeed action by solely

returning the infeed stop control to any position in zone B. The operator shall only be able to restart infeed

action by deliberate actuation of a separate control provided for this purpose.

4.2.4.3.7 In addition to meeting the requirements of 4.2.4.3.2 to 4.2.4.3.6, for type B machines the infeed

stop control shall stop or reverse infeed action when pulled to its outermost position against the direction of

feed, i.e. to position H.

4.2.4.3.8 Where the infeed stop control incorporates a control position for reversing the infeed action, the

operation of that function shall be hold-to-run if it is behind the outermost edge of the infeed chute, i.e. at

position E, see Figure 4 or Figure 5 as appropriate. Position E shall be as close as possible to the outermost

chute edge of the infeed chute.

4.2.4.3.9 For type A machines, in respect of the infeed direction from the operator to the outermost edge,

all positions of the infeed stop control in zone B, which allow or cause infeed action, shall be before any

position which stops infeed action.

4.2.4.3.10 For type A machines, where the infeed stop control provides other functions to control the infeed

components, examples of permitted control patterns include:

reference plane infeed direction operator

optional reverse (hold-to-run), [chute edge], emergency stop function, infeed;

optional reverse (hold-to-run), [chute edge], emergency stop function, reverse, infeed;

optional reverse (hold-to-run), [chute edge], emergency stop function, infeed, reverse;

optional reverse (hold-to-run), [chute edge], emergency stop function, reverse, stop, infeed.

4.2.4.3.11 For type B machines, where the infeed stop control provides other functions to control the infeed

components (including the requirements of 4.2.4.3.7) examples of permitted control patterns include:

reference plane infeed direction operator

optional reverse (hold-to-run), [chute edge], emergency stop function, infeed, stop;

optional reverse (hold-to-run), [chute edge], emergency stop function, infeed, reverse;

optional reverse (hold-to-run), [chute edge], emergency stop function, infeed, reverse, stop;

optional reverse (hold-to-run), [chute edge], emergency stop function, reverse, infeed, stop;

optional reverse (hold-to-run), [chute edge], emergency stop function, infeed, stop.

4.2.5 Safety and reliability of control systems

4.2.5.1 The safety related control systems shall comply with category 1 of EN 954-1:1996, 6.2.

4.2.5.2 The electrical components shall comply with:

EN 60947-5-1:2004, Clause 3, for control switches with automatically opening contacts used as

mechanically operated position switches for interlocking circuits and for relays used in control circuits;

EN 60947-5-1 for electromechanical protection devices and engine starting motors used in main circuits;

IEC 60245-1 for rubber-insulated leads.

4.3 Protection against mechanical hazards

4.3.1 Stability

4.3.1.1 Machines shall be stable when operated in accordance with their specified conditions of use (i.e.

within the specified limitations of factors affecting stability such as angle of slope, ground conditions, size of

material being chipped etc.). In particular:

except for the main transport wheels, supporting devices (e.g. jockey wheels, stands, outriggers, etc.)

shall have a bearing surface designed to limit the ground pressure to a maximum of 400 kPa;

chippers which are self-standing during the chipping operation, shall be stable with the largest size of

wood being fed in.

4.3.1.2 When stored according to the instruction handbook on a concrete surface, with an inclination of

up to 8,5° in any direction, the machine shall be capable of resisting a force of 400 N applied in any direction

without tilting. This requirement shall be met for all combinations of the following, when any or all:

fuel, oil or other tanks are empty;

fuel, oil or other tanks are full;

chutes are in their transport or folded position(s);

chutes are in their working position(s);

guards are in their closed position;

guards are in their open position.

4.3.2 Risk of break-up during operation

4.3.2.1 The chipping components and their attachments shall be designed to withstand twice the

operating speed whilst unloaded. This requirement shall be verified according to 5.2.

4.3.2.2 The casing enclosing the chipping components shall prevent parts of the chipping components

from being ejected through the casing by centrifugal force. If steel plate of grade S235JR according to

EN 10025-2 is used as casing material, the total wall thickness in areas where chipping component parts may

be thrown shall comply with the requirements of Table 1. Figures given in Table 1 are based on tool rotational

-1

frequency of 1 000 min .

Table 1 – Total wall thickness for steel casing

Dimensions in millimetres

Diameter of the chipping components

tool tip circle

Minimum steel thickness (S235JR)

d

d ≤ 600 4

600 < d ≤ 800 6

800 < d ≤ 1 000 8

d > 1 000 10

-1

In case the rotational speed exceeds 1 000 min or other materials or designs such as screw-type chippers

are used, the casing shall provide equivalent protection.

4.3.3 Hazards related to infeed components and chipping components

4.3.3.1 Machines with infeed components

4.3.3.1.1 For type A machines where the working position of the outermost lower edge of the infeed chute

is equal to or more than 1 000 mm from the ground, the minimum horizontal distance from the chute outer

edge to the reference plane shall be according to EN 294:1992, Table 2, see Figure 6.

Dimensions in millimetres

Key

a Reference plane

Figure 6 – Infeed chute length, high chute location

Machines with an infeed chute not more than 700 mm wide shall meet the dimensions given in Figure 7

whereby:

the distance from the outermost lower edge of infeed chute to the reference plane shall be at least

1 200 mm;

the distance from the outermost upper edge of the infeed chute to where the floor of the chute meets the

infeed components shall be at least 1 000 mm;

the distance between the outermost lower and upper edges measured in parallel with the reference plane

shall be not more than 400 mm. For infeed chutes designed as in Figure 7 it shall not be possible for the

infeed chutes to be used in positions lower than 1 000 mm.

Dimensions in millimetres

Key

a Reference plane

Figure 7 – Infeed chute length, high chute location, alternative design

4.3.3.1.2 For type A machines where the working position of the lower edge of the infeed chute is between

600 mm to 1 000 mm from the ground, the minimum horizontal distance shall be 1 500 mm from the reference

plane to any part of the chute outer edges below 1 000 mm. Where the chute outer edges extend above

1 000 mm, EN 294:1992, Table 2 applies. See Figure 8.

Dimensions in millimetres

Key

a Reference plane

Figure 8 – Infeed chute length, low chute location

4.3.3.1.3 In machines where the working position of the lower edge of the infeed chute is less than 600 mm

from the ground, type B machines, the minimum horizontal distance from the chute outer edge to the

reference plane shall be 1 200 mm at the whole chute edge, see Figure 8. In addition the following

requirements apply:

the height from the centre line of the infeed control to the lower edge of the chute shall be not greater

than 1 000 mm; and

the bottom of the chute shall be sloping away from the infeed components towards the chute outer edge.

Dimensions in millimetres

Key

a Reference plane

Figure 9 – Infeed chute length and control to chute lower edge height, type B machines

4.3.3.2 Guarding of chipping components

For guarding the chipping components from directions other than the infeed chute the following applies.

The access to chipping components shall be prevented by use of either:

a fixed guard where the time required to remove it is longer than the run-down time of the chipping

components; or

an interlocking guard with guard locking, in accordance with EN 953.

In case of a fixed guard, visual means, e.g. a dual-colour axle end under a transparent cover, shall be

provided to indicate whether the chipping components are moving or not.

4.3.4 Risks due to ejected objects

4.3.4.1 The chipper shall not eject wood or chips from the infeed chute, which by virtue of their shape,

size, velocity or direction, pose a risk to an operator or bystander.

NOTE Means of achieving this requirement will be considered at the next revision of this document.

4.3.4.2 Where a machine provides for reversing of the infeed components, the speed of wood, when

reversed, shall not exceed 1,0 m/s if the control for engaging reverse function is positioned where the operator

may be at risk of being struck by wood as it is reversed.

4.3.4.3 The discharge chute shall be designed to minimise the risk of ejected objects to workers. Means

shall be provided to prevent discharge towards the infeed area of the chipper, e.g. by limiting the discharge

chute movement.

4.3.5 Protection against access to moving power transmission parts

4.3.5.1 All moving parts of the power transmission system shall be designed, constructed, positioned or

otherwise provided with guards or protective devices to prevent all risk of contact.

4.3.5.2 To ensure protection against hazards related to accessible moving power transmission parts, the

machines shall be fitted with guards according to EN 953.

Moving power transmission parts not required to be accessed during use shall be fitted with fixed guards.

Moving power transmission parts required to be accessed during use for maintenance or machine adjustment

shall be guarded as follows:

if the moving parts can be brought to a stop immediately by either a fixed guard or an interlocked guard;

if the moving parts cannot be brought to a stop immediately by either a fixed guard or an interlocked

guard with guard locking.

The time taken for the removal of any fixed guard shall be longer than the run-down time of any of the moving

parts which those guards are protecting against access. Fixed guards shall remain attached to the machine

when opened for example by means of hinges and automatically lock in the closed position without the use of

a tool.

4.3.5.3 Guards according to EN ISO 5674 and EN 12965 can also be used to protect drive shafts within

the machinery.

4.3.5.4 Transmission of power from external power sources

On machines powered via a power take-off (PTO) drive shaft, the straight line overlap of the PTO drive shaft

guard with the power input connection (PIC) guard shall be not less than 50 mm. This minimum overlap shall

also apply to protection devices of wide-angle PTO drive shafts and when using clutches or other elements.

Suitable fixing points shall be provided for the restraining device used to prevent the rotation of the drive shaft

guard.

The machine shall be supplied with a support for the PTO drive shaft when the machine is uncoupled, but this

shall not be the device used to prevent the rotation of the PTO drive shaft guard.

The PIC guard shall be so constructed and attached to the machine that, in conjunction with the PTO drive

shaft guard, it encloses the drive shaft on all sides up to the first fixed bearing housing of the machine, whilst

allowing for fitting and articulation of the PTO drive shaft.

4.4 Protection against non-mechanical hazards

4.4.1 Noise

4.4.1.1 Noise reduction as a safety requirement

4.4.1.1.1 Noise reduction at source by design and by protective measures

The machine shall generate a noise level as low as practicable. The methodology for designing low-noise

machinery described in EN ISO 11688-1 shall be used.

NOTE EN ISO 11688-2 gives useful information on noise generation mechanisms in machinery.

The main sources causing noise in wood chippers include e.g.:

infeed mechanism;

chipping components;

chip discharge;

power source.

The noise reduction measures by design include e.g.:

selecting low noise components e.g. engine;

selecting proper materials;

selecting proper thickness and coating of surfaces;

optimisation the knife mounting configuration;

optimisation of the knife/feeding angle;

selecting low noise exhaust system.

4.4.1.1.2 Noise reduction by information

If after taking all possible technical measures for reducing noise at the design stage a manufacturer considers

that further protection of the operator is necessary, then the instruction handbook shall:

recommend the use of low-noise operating modes, and/or limited time operation;

give a warning of the noise level and recommend the use of ear protection.

4.4.2 Hydraulic components

Hydraulic systems shall be designed and constructed in accordance with ISO 4413.

Hydraulic lines and fittings shall meet the requirements of EN 982.

Pressurised hoses, lines and components shall be located or shielded so that in the event of rupture, the fluid

cannot be discharged directly on to the operator.

4.4.3 Hot surfaces

A guard shall be provided to prevent accidental contact with any exposed engine exhaust components larger

than 10 cm which have a surface temperature greater than 80 °C at (20 + 3) °C ambient temperature during

normal starting and operation of the machine. This requirement shall be tested according to 5.2.

NOTE The temperature of 80 °C is to be reviewed at the next revision of this document taking into account any relevant

values given in EN 563.

4.4.4 Electrical hazards

4.4.4.1 The electrical equipment of electrically driven machines shall comply with EN 60204-1.

4.4.4.2 Casing of the switch gear or the control gear equipment shall at least comply with IP 54, casing of

motors shall comply at least with IP 44 according to EN 60529.

4.4.4.3 The electrical and related mechanical safety requirements for the design and construction of the

electrical installation on machines with integral internal combustion engines shall meet the requirements of EN

1175-2.

4.5 Preparation for transport and maintenance

4.5.1 Folding or displacing the infeed or discharge chutes, e.g. for transport, shall only be possible when the

chipping components and/or infeed components are stationary or if the following safety distances/openings

are met during the folding/displacement of the chute and when the chute is in its folded/displaced position:

the requirements set out in 4.3.3; or

the values of EN 294:1992, Tables 3, 4 and 6; and

for infeed chutes on type B machines the values of EN 811:1996, Table 1.

Once the respective chute is in its folded or displaced position, it shall not be possible to start the chipping

components and/or infeed components unless the safety distances/openings specified in this clause continue

to be met.

4.5.2 The instruction handbook shall describe all the tools, work practices, safety/auxiliary devices, and

personal protective equipment required when carrying

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...