EN 15254-4:2008

(Main)Extended application of results from fire resistance tests - Non-loadbearing walls - Part 4: Glazed constructions

Extended application of results from fire resistance tests - Non-loadbearing walls - Part 4: Glazed constructions

This European standard provides guidance and, where appropriate, defines procedures for variations of certain parameters and factors associated with the design of fire resistant glazed elements which have been tested in accordance with EN 1364-1, and classified according to EN 13501-2.

Extended application of fire resistant glazed elements shall be based on test evidence.

This standard only applies to vertically installed fire resistant glazed elements.

This standard does not apply to doorsets and openable windows according to EN 1634.

Glass block assemblies and paver units and channel-shaped glass as defined in EN 1051-1 and EN 572-7 are excluded. There is currently insufficient information available to enable rules for extended application to be developed for these products.

NOTE Some partition walls use a combination of fire resistant glass, non-translucent and other opaque products. The extended application in this case only covers the glass when it replaces these products - see clause 8.2.

Erweiterter Anwendungsbereich der Ergebnisse von Feuerwiderstandsprüfungen - Nichttragende Wände - Teil 4: Verglaste Konstruktionen

Diese Europäische Norm gibt eine Anleitung und definiert, wo zutreffend, Verfahren für Änderungen von bestimmten Parametern und Faktoren, die mit der Ausführung von feuerwiderstandsfähigen verglasten Bauteilen in Verbindung stehen, die nach EN 1364 1 geprüft und nach EN 13501 2 klassifiziert wurden.

Erweiterte Anwendungsbereiche der feuerwiderstandsfähigen verglasten Bauteile basieren auf Prüfdaten.

Diese Norm bezieht sich nur auf vertikal eingebaute feuerwiderstandsfähige verglaste Bauteile.

Diese Norm gilt nicht für Tore, Türen und zu öffnende Fenster mit Feuer- und/oder Rauchschutzeigenschaften nach EN 1634 1.

Bausätze aus Glasbausteinen und Betongläsern sowie Profilbaugläser, wie in EN 1051 1 und EN 572 7 definiert, sind ausgeschlossen. Hierzu liegen gegenwärtig keine ausreichenden Informationen vor, um Regeln für den erweiterten Anwendungsbereich für diese Produkte zu erstellen.

ANMERKUNG Einige Trennwände bestehen aus einer Kombination von feuerwiderstandsfähigem Glas, nicht durchscheinenden oder anderen undurchsichtigen Bauteilen. Im Falle solcher Konstruktionen gilt der erweiterte Anwendungsbereich nur dann für das Glas, wenn es diese Produkte ersetzt – siehe 8.2.

Extension du champ d'application des résultats des essais de résistance au feu - Éléments non-porteurs - Partie 4 : Constructions vitrées

La présente Norme européenne fournit des conseils et, le cas échéant, définit des procédures pour les variations de certains paramètres et facteurs liés à la conception d'éléments vitrés résistant au feu qui ont été testés conformément à l'EN 1364-1, et classés conformément à l'EN 13501-2.

L'application étendue d'éléments vitrés résistant au feu doit être basée sur une preuve obtenue par des essais.

La présente norme s'applique uniquement aux éléments vitrés résistant au feu installés verticalement.

La présente norme ne s'applique pas aux portes et aux fenêtres ouvrantes conformes à l'EN 1634.

Les ensembles de bloc de verre, les unités de pavage et le verre profilé en U tels que définis dans les normes EN 1051 1 et EN 572 7 sont exclus. Les informations disponibles actuellement sont insuffisantes pour permettre de développer des règles relatives aux applications étendues pour ces produits.

NOTE Certaines cloisons de séparation utilisent une combinaison de produits résistant au feu en verre, non translucides et autres produits opaques. Dans ce cas, l'application étendue couvre uniquement le verre lorsqu'il remplace ces produits . voir paragraphe 8.2.

Razširjena uporaba rezultatov preskusov požarne odpornosti - Nenosilne stene - 4. del: Zastekljena konstrukcija

General Information

- Status

- Withdrawn

- Publication Date

- 19-Feb-2008

- Withdrawal Date

- 05-Jul-2011

- Technical Committee

- CEN/TC 127 - Fire safety in buildings

- Drafting Committee

- CEN/TC 127/WG 1 - Structural and separating elements

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Jul-2011

- Completion Date

- 06-Jul-2011

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 13-Jun-2009

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 15254-4:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Extended application of results from fire resistance tests - Non-loadbearing walls - Part 4: Glazed constructions". This standard covers: This European standard provides guidance and, where appropriate, defines procedures for variations of certain parameters and factors associated with the design of fire resistant glazed elements which have been tested in accordance with EN 1364-1, and classified according to EN 13501-2. Extended application of fire resistant glazed elements shall be based on test evidence. This standard only applies to vertically installed fire resistant glazed elements. This standard does not apply to doorsets and openable windows according to EN 1634. Glass block assemblies and paver units and channel-shaped glass as defined in EN 1051-1 and EN 572-7 are excluded. There is currently insufficient information available to enable rules for extended application to be developed for these products. NOTE Some partition walls use a combination of fire resistant glass, non-translucent and other opaque products. The extended application in this case only covers the glass when it replaces these products - see clause 8.2.

This European standard provides guidance and, where appropriate, defines procedures for variations of certain parameters and factors associated with the design of fire resistant glazed elements which have been tested in accordance with EN 1364-1, and classified according to EN 13501-2. Extended application of fire resistant glazed elements shall be based on test evidence. This standard only applies to vertically installed fire resistant glazed elements. This standard does not apply to doorsets and openable windows according to EN 1634. Glass block assemblies and paver units and channel-shaped glass as defined in EN 1051-1 and EN 572-7 are excluded. There is currently insufficient information available to enable rules for extended application to be developed for these products. NOTE Some partition walls use a combination of fire resistant glass, non-translucent and other opaque products. The extended application in this case only covers the glass when it replaces these products - see clause 8.2.

EN 15254-4:2008 is classified under the following ICS (International Classification for Standards) categories: 13.220.50 - Fire-resistance of building materials and elements. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15254-4:2008 has the following relationships with other standards: It is inter standard links to EN 15254-4:2008+A1:2011, EN 15269-7:2009, EN 15254-4:2008/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15254-4:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/117. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15254-4:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Razširjena uporaba rezultatov preskusov požarne odpornosti - Nenosilne stene - 4. del: Zastekljena konstrukcijaErweiteter Anwendungsbereich der Ergebnisse aus Feuerwiderstandsprüfungen - Nichttragende Wände - Teil 4: Verglaste KonstruktionenApplication étendue des résultats d'essais de résistance au feu - Murs non porteurs - Partie 4 : Constructions vitréesExtended application of results from fire resistance tests - Non-loadbearing walls - Part 4: Glazed construction91.060.10Stene. Predelne stene. FasadeWalls. Partitions. Facades13.220.50Požarna odpornost gradbenih materialov in elementovFire-resistance of building materials and elementsICS:Ta slovenski standard je istoveten z:EN 15254-4:2008SIST EN 15254-4:2008en01-april-2008SIST EN 15254-4:2008SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15254-4February 2008ICS 13.220.50 English VersionExtended application of results from fire resistance tests - Non-loadbearing walls - Part 4: Glazed constructionsExtension du champ d'application des résultats des essaisde résistance au feu - Éléments non-porteurs - Partie 4 :Constructions vitréesErweiterter Anwendungsbereich der Ergebnisse vonFeuerwiderstandsprüfungen - Nichttragende Wände - Teil4: Verglaste KonstruktionenThis European Standard was approved by CEN on 15 December 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15254-4:2008: ESIST EN 15254-4:2008

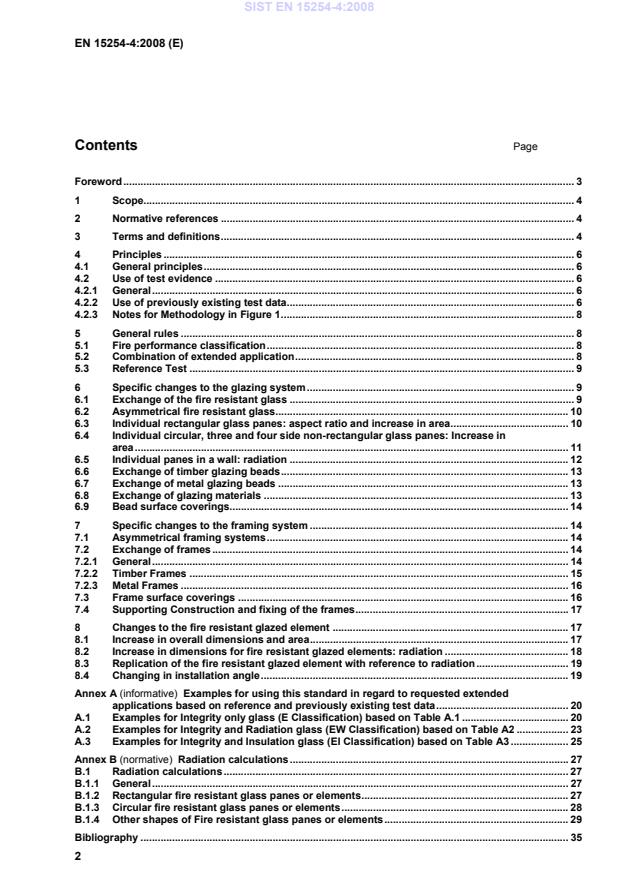

Examples for using this standard in regard to requested extended applications based on reference and previously existing test data.20 A.1 Examples for Integrity only glass (E Classification) based on Table A.1.20 A.2 Examples for Integrity and Radiation glass (EW Classification) based on Table A2.23 A.3 Examples for Integrity and Insulation glass (EI Classification) based on Table A3.25 Annex B (normative)

Radiation calculations.27 B.1 Radiation calculations.27 B.1.1 General.27 B.1.2 Rectangular fire resistant glass panes or elements.27 B.1.3 Circular fire resistant glass panes or elements.28 B.1.4 Other shapes of Fire resistant glass panes or elements.29 Bibliography.35 SIST EN 15254-4:2008

This standard does not apply to doorsets and openable windows according to EN 1634-1. Glass block assemblies and paver units and channel-shaped glass as defined in EN 1051-1 and EN 572-7 are excluded. There is currently insufficient information available to enable rules for extended application to be developed for these products. NOTE Some partition walls use a combination of fire resistant glass, non-translucent and other opaque products. The extended application in this case only covers the glass when it replaces these products – see clause 8.2. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 357:2004, Glass in building — Fire resistant glazed elements with transparent or translucent glass products — Classification of fire resistance EN 1363-1:1999, Fire resistance tests — Part 1: General requirements EN 1363-2, Fire resistance tests — Part 2: Alternative and additional procedures EN 1364-1, Fire resistance tests for non-loadbearing elements — Part 1: Walls EN 1995-1-2, Eurocode 5: Design of timber structures - Part 1-2: General - Structural fire design EN 13501-2, Fire classification of construction products and building elements — Part 2: Classification using data from fire resistance tests, excluding ventilation services 3 Terms and definitions For the purposes of this document the terms and definitions given in EN 357:2004 and EN 13501-2, together with the following apply. 3.1 fire resistant glass glass product group, monolithic, multiple layers or insulating glass unit, when used in a fire resistant glazed element, can be classified in accordance with EN 13501-2 NOTE 1 The glass can be classified for the purposes of CE marking according to the glass product group determined by the glass manufacturer and tested as a virtual assembly. Classification of fire resistant glass is a mandated requirement within the European Community. NOTE 2 The term “insulating” when used as an insulating glass unit according to EN 1279–1, should not be confused with the term “insulation” used in EN 13501–-2 classification standard for fire resistant glazed element. SIST EN 15254-4:2008

fire performance classification (integrity E, integrity with radiation EW or integrity with insulation EI);

maximum pane area and dimensions for the fire resistant glass;

maximum dimensions of the fire resistant glazed element for each type of frame material. The reference test may also provide other data to assist in determining the following: permitted dimensional changes to the framing system; changes to the glazing system. 3.6 overrun time time of fire resistance in minutes beyond the classification time achieved in the reference test, which is the subject of the extended application. The overrun time in the reference test only applies to dimensional changes to the glass and the glazed element. It does not apply to changes to the glazing beads, materials and glazing strips 3.7 previously existing test data test data generated by fire resistance tests that have been undertaken by an accredited and/or Notified Test Laboratory in accordance with European and/or former and current national standards based on the temperature-time curve identical to the one specified in EN 1363-1 (and defined in ISO 834). Previously existing test data is acceptable even though the test may not have been carried out using the plate thermometer. This data can only be used as described in this standard NOTE Previously existing test data is acceptable provided that there has been no change to the product since this data was generated.

3.8 glass product group different fire resistant glasses combined in a group, defined and produced by the same manufacturer and described in their product description together with a complete list of all components used in the assembly NOTE The manufacturers product description should contain all relevant properties required for CE marking. SIST EN 15254-4:2008

3.10 characterisation process in which the limits of the glazing and framing system are separately defined. It shall be based on the reference test and supported by previously existing test data where appropriate 3.11 fire performance classification classification of the fire resistant glazed element in accordance with EN 13501-2 with respect to integrity E, radiation W and insulation I NOTE In previously existing test data the fire resistance is given by time to failure (not by fire performance classification above) in terms of integrity, integrity and insulation. The test data may also contain information concerning the measurement of radiation. 4 Principles 4.1 General principles Extended application is a prediction of the expected fire resistance of fire resistant glazed elements. It may be based on interpolation between or extrapolation from test data. The fundamental consideration shall be that the fire resistant glazed element after extension would achieve the required fire performance if it were to be tested according to EN 1364-1. The specific principles and methodology governing the extended application for fire resistant glazed elements are given in Figure 1. Fire resistant glazed elements function as an integral system in which the individual components (glass panes, glazing materials, frames and frame fixings) are combined in such a way that they are effective in meeting the defined fire resistance criteria. However, in this document fire resistant glazed elements are separately characterised as the glazing system and the framing system (see Figure B.1). 4.2 Use of test evidence 4.2.1 General The applicant for the extended application shall either be the “owner” (i.e. sponsor) of all reference test and previously existing test data being submitted for the extension, or have written permission from the owner to use the submitted test evidence.

4.2.2 Use of previously existing test data

Previously existing test data may be used to support extended application, for instance to evaluate the influence of a particular component (e.g. glazing material) or aspect of the design (e.g. direction of fire exposure) or to establish which design variations affect the performance in the most or least onerous way. If this can be identified, then a reference test on the most onerous design may be undertaken. If the product achieves the required classification then the other less onerous variations will be covered. The relevant clauses state when previously existing test data may be used. SIST EN 15254-4:2008

Glazing system

Change of glass type and thickness Replacement of glasses within the same glass product group 6.1 Symmetry of the glass construction Symmetric / asymmetric glasses 6.2 Rectangular panes Increase in pane area and aspect ratio 6.3

Circular and three- and (non-rectangular) four-sided glass panes Increase in area 6.4 Glass panes with EW classification Increase in area 6.5 Timber beads

Exchange of timber species / bead fixing / bead shape and dimensions 6.6 Metal beads Exchange of bead fixing / bead shape and dimensions 6.7 Exchange of glazing materials Gaskets/glazing strips / setting blocks 6.8 Bead surface coverings Changes or adding surface coverings 6.9

Framing system

Symmetry of the framing construction Symmetrical / asymmetrical frames 7.1 Exchange of frames (general)

Type of material / junction types / edge cover 7.2.1 Timber frames Thickness / profile / timber type (char rate / density) 7.2.2 Metal frames Frame materials / sections / thickness of chamber walls 7.2.3 Frame surface covering Changes or adding frame surface coverings 7.3 Supporting construction and fixing High density, low density, rigid, flexible 7.4 Fire resistant glazed element

Glazed elements classified to E or EI Increase in dimensions / area 8.1 Glazed element classified EW Increase in dimensions / area 8.2

Replication of whole element with EW classification 8.3 Installation angle Change in installation angle 8.4

Step 1 : Define the fire-resistant glazed element which is under consideration for EXAP - e.g. by detailed drawings, component description and specification

Step 2 : Characterise the fire performance limits of the Glazing System and Framing System - e.g. by reference test(s) in accordance with EN 1364-1, and where SIST EN 15254-4:2008

2a Glazing System • Maximum glass pan area • Maximum individual pane dimensions

- in both height and width

Notes (1) & (2) 2b Framing System • At the desired maximum element size • Including all the desired frame junctions

- and measure total frame deflection

Notes (3),(4), (5)

Step 3 : Check compliance with general rules

- by reference to the general rules given in 5.1 and 5.2

Step 4 : Undertake extended application • Determine each individual extended application separately

- by reference to the specific rules given in 6, 7 and 8

Figure 1 — Methodology for determining the extended application of fire resistant glazed elements 4.2.3 Notes for Methodology in Figure 1 1: Define glass, bead type, fixings and glazing material, etc. 2: Maximum dimensions not necessarily established in the same pane (e.g. maximum height, maximum width, maximum area).

It is not allowed to combine dimensions from different panes. 3: Frame type to be the same as step 2a (e.g. material specification and fire performance). 4: Bead, fixing, glass and glazing material have to be the same as those in step 2a. 5: When the fire resistant glazed element to be considered is greater than 3 m × 3 m then the

fire resistance test specimen has to be a minimum of 3 m × 3 m. 5 General rules 5.1 Fire performance classification In the extended application, an increase in the classification time (e.g. from 30 min to 45 min) and changes to the fire performance classification (e.g. from E to EW to EI) shall not be permitted.

5.2 Combination of extended application Each extended application shall be the subject of a separate evaluation. Within this application it is allowed to produce a combination of extensions provided these combinations can be substantiated by the supporting test evidence and/or previously existing test data (see Annex A for an example). SIST EN 15254-4:2008

NOTE 1 Non rectangular glass panes do not need their own reference test if they are cut out from within the rectangular pane covered by the reference test. The rectangular pane can be extended according to the rules given in this standard before cutting takes place. Circular, triangular or 4 sided shapes can then be cut from within this extended rectangular size. All other non irregular shapes, can only be cut from the tested original sized rectangular pane (According to the Direct Field of Application rules of EN 1364-1). These shapes cannot be further extended. NOTE 2 In the case of the reference test in which a number of glass panes of different sizes and aspect ratios have been tested in a glazed contruction, the extension in any dimension or area is only applicable to a single pane.

For example, for a rectangular pane of height H1 = 2000 mm and width B1 = 1500 mm and another pane of height H2 = 2500 mm and width B2 = 1000 mm it is not allowed to apply an extension to a hypothetical pane of height H2 = 2500 mm and width B1 = 1500 mm because the area before extension is greater than either of the tested panels and the aspect ratio is not equivalent to either of the tested panels. 6 Specific changes to the glazing system 6.1 Exchange of the fire resistant glass The exchange (replacement) of the glass, as tested in the reference test, for another fire resistant glass is allowed, provided that it can be demonstrated that both glasses are within the same glass product group (same manufacturer) and have at least the same or increased nominal thickness.

When the reference glass is being exchanged (replaced), the replacement glass (new glass) must have evidence that it achieves at least the same fire resistance classification (or equivalent fire resistance) as the reference glass (such as previously existing test data).

If the replacement glass was tested (previously existing test data) at a smaller or the same size/area as in the reference test (before extension) then the size/area of the replacement glass cannot be changed from its tested size/area. If the replacement glass was tested at the same size/area as in the reference test (after extension) then this size/area of replacement glass can be used to replace the reference glass. If the replacement glass was tested at a larger size/area than in the reference test (after extension) then the maximum size/area of the replacement glass can be no greater than the extended size/area of the glass as tested in the reference test. When making an exchange of one glass for a thicker glass from the same glass product group (same manufacturer), the structural stability of the whole glazed element must be maintained.

NOTE When exchanging one EI glass for another EI glass the transmission/absorption values only marginally influence the fire resistance performance of the glass. It is the incorporation of one or more special interlayer(s) that governs the fire resistance not the type of glass used. SIST EN 15254-4:2008

Table 2 — Required Overrun time on rectangular glass panes Classification Time (min) Overrun required

≤ 20 At least 3 min 30 and 45 and 60 At least 6 min

a

≥ 90 At least 10 % of the classification time

a

a For overrun times between 3 min and 6 min or 5 % and 10 % see explanations below (after the equations 1 to 3).

The basis for the extension is the reference test. The width or height may be increased in accordance with equations 1 or 2 respectively. Where both width and height are increased the maximum extended area shall be in accordance with equation 3. wext ≤ wmax = wo × 1,20 (1) hext ≤ hmax = ho × 1,20 (2) Aext ≤ Amax = Ao × 1,21 (3) where

wo , ho , Ao

is the width (m), height (m) and area (m2) of the tested pane;

wext , hext , Aext is the extended width (m), height (m) and area (m2) of pane;

wmax , hmax , Amax

is the maximum extended width (m), height (m) and area (m2) of pane. For the classification times 30 min, 45 min and 60 min, if the overrun time achieved in the reference test is 3 min or more but less than 6 min, all glass extensions in width, height and area can be increased according to equations 1 to 3. However, the increase in any dimension is restricted to a maximum of 50 % of the calculated increase using these equations. For the classification times ≥ 90 min, if the overrun time achieved in the reference test is 5 % or more but less than 10 %, all glass extensions in width, height and area can be increased according to equations 1 to 3. However, the increase in any dimension is restricted to a maximum of 50 % of the calculated increase using these equations. SIST EN 15254-4:2008

A change in the aspect ratio of rectangular panes is allowed provided that the pane fits within the extended pane dimensions defined above. For glass where the EW classification is relevant, the criteria applying to radiation defined in 6.5 shall apply. Any extension in pane area is only allowed if the requirements for radiation are still satisfied. It shall be confirmed in the extended application report that the framing system under consideration is able to support the additional weight due to the increased pane area. The frame manufacturer should supply this confirmation. Furthermore, all of the relevant frame junctions shall have been tested in accordance with EN 1364-1(see also Figure 2 in 7.2.1.). 6.4 Individual circular, three and four side non-rectangular glass panes: Increase in area If a reference test report is available for circular, triangular or 4 sided shaped glass then an increase in area may,be allowed provided the length of overrun time in the reference test is as shown in Table 3 below. Table 3 — Required Overrun time on circular, three and four side non-rectangular glass panes Classification Time (min) Overrun required

≤ 20 At least 3 min 30 and 45 and 60 At least 6 mina

≥ 90 At least 10 % of the classification time

a

a For overrun times between 3 min and 6 min or 5 % and 10 % see explanation below (after equation 4)

The basis for the extension is the reference test. SIST EN 15254-4:2008

(4) where Ao is the area (m2) of the tested pane;

Aext

is the extended area (m2) of pane; Amax is the max. extended area (m2) of pane.

The extended pane shall be of the same orientation and shape as the tested pane. For the classification times 30 min/45 min/60 min, if the overrun time achieved in the reference test is 3 min or more but less than 6 min, the glass area can be increased according to equation 4. However, the increase in any dimension is restricted to a maximum of 50 % of the calculated increase using this equation. For the classification times ≥ 90 min, if the overrun time achieved in the reference test is 5 % or more but less than 10 %, the glass area can be increased according to equation 4. However, the increase in area is restricted to a maximum of 50 % of the calculated increase using this equation. It shall be confirmed in the extended application report that the framing system under consideration is able to support the additional weight due to the increased pane area. Furthermore, all of the relevant frame junctions shall have been tested in accordance with EN 1364-1 (see also Figure 2 in 7.2.1.) 6.5 Individual panes in a wall: radiation For fire resistant glass with an EW classification the rules 6.1 to 6.4 apply together with the following. NOTE 1 For fire resistant glass with an EI classification, rules for determination of radiation do not apply. The radiation (W) shall be measured (in accordance with EN 1363-2) along the centre line at a distance of one metre from the centre of the test specimen. According to EN 13501-2, the radiation classification shall be determined by the time for which the measured radiation W0 does not exceed wmax as defined in Annex B. This is also applicable for the radiation value wext calculated for the pane with the extended area. For extended rectangular and circular panes wext can be calculated according to the following equation Wext= Wo × [ϕext/ϕ0] ≤ wmax (5) where the definition is given in Annex B. The basis for the extension is the reference test. The extension in area for EW classified glasses for all other shapes is allowed by the method described in B.1.4 which is based on the area of a rectangle prescribed around the shape. The relevant calculation shall be provided in the extended application report. NOTE 2 No equations currently exist for the calculation of radiation for the extended area for non-rectangular and non-circular shapes.

NOTE 3 A radiometer as described in EN 1363-2 is not designed to measure the radiation from an individual pane within a multi-paned fire resistant glazed element.

NOTE 4 The given limitations in Wext may also limit the extension of the area Aext of the fire resistant glass pane according to 6.3 or 6.4 or the W-classification will be lost. SIST EN 15254-4:2008

In all cases, exchange of timber species should be on the basis of density and/or comparative char rate tests (when available), calculations according to EN 1995-1-2 or reference values. These shall demonstrate that the fire performance of the replacement timber bead is either the same or better than that used in the reference test. If the beads in the reference test were fixed by nails, then screw fixing of similar length and distance is permitted as an alternative. However, a bead fixed by screws shall not be exchanged by a clipped or nailed bead unless this possibility has been shown to work, e.g. by previously existing test data. The bead height may be increased provided that increased edge cover on the glass can be demonstrated not to have a detrimental effect on its fire performance. The edge cover shall remain within the limits determined by the reference test or as determined by previously existing test data. A reduction of the bead height is not allowed. For EI classification of fire resistant glazed elements, exchange of the bead profile from a sloped or chamfered bead to a flat bead of the same height is allowed without further testing (see Figure B.2). For E and EW classified fire resistant glazed elements, exchange of the bead profile from a sloped or chamfered bead to a flat profile bead is not allowed unless suitably demonstrated by a reference test or previously existing test data.

Exchange of a flat bead profile to a sloped or chamfered bead profile of the same height is allowed for all fire resistant glazed elements. But in this case the subsequent reduction in a bead cross section is only allowed where it can be demonstrated not to have a detrimental effect on the fire performance. Previously existing test data are allowed. Reduction in bead depth is only allowed if it can be demonstrated not to have a detrimental effect on the fire performance. Previously existing test data is allowed. The bead depth may be increased without restriction (see Figure B.3 item 7). NOTE the timber bead can have a major influence on the integrity performance of a timber-glazed system incorporating fire resistant glass with an E or EW classification. This is because it is possible for the timber bead to flame under the influence of radiation immediately adjacent to the glass surface on the side away from the fire. Charring of the timber also occurs at radiation intensities much less than those required to cause flaming. Fire resistant glazed elements with an EI classification significantly reduce the possibility of this occurrence by reducing the transmitted radiation directly at the glazing surface to low levels. 6.7 Exchange of metal glazing beads It is not allowed to exchange the type of material used for the glazing beads. Changes in bead shape are only allowed if it can be demonstrated not to have a detrimental effect on the fire performance. Previously existing test data is allowed. Clipped beads can be replaced by screw fixed or riveted beads but not vice-versa. Bead depth can be increased (see also Figure B.3, item 7). Reductions in bead depth are only allowed if it can be demonstrated not to have a detrimental effect on the fire performance. Previously existing test data are allowed. The bead height can be increased provided that the edge cover doesn't change or the increase in edge cover can be shown, e.g. by the reference test and/or by previously existing test data not to have a detrimental effect on the fire performance. 6.8 Exchange of glazing materials

Except for glazing beads, exchange of one glazing material, e.g. gaskets, for another is allowed.

But only if it can be demonstrated in the reference test and/or previously existing test data that the SIST EN 15254-4:2008

If the surface covering is not Class A2 then it has to be proven in reference test data and/or previously existing test data that it does not negatively affect the fire performance. Any coverings on glazed elements classified EI shall be secured using only fixing method(s) proven in the reference test and/or by previously existing test data. 7 Specific changes to the framing system 7.1 Asymmetrical framing systems Fire resistance test evidence shall be provided, were required, for exposure to fire from both directions unless it can be determined which direction is the worst case. If this can be established, then only fire resistance test evidence for the worst case is required. In the absence of this fire resistance test evidence, the framing system shall only be used in the direction of fire exposure as tested. NOTE To demonstrate that the fire performance classification is unaffected by the direction of exposure, a reference test and/or supporting previously existing test data will be necessary.

7.2 Exchange of frames 7.2.1 General It is not allowed to exchange the type of material used to construct the frame (e.g. steel for timber or aluminium for steel). Frames can be manufactured using some or all of the junction types detailed below. But all the junction types considered in the extended application have to be covered in the reference test or previously existing test data. The extension allows the addition of junction types within the frame provided that it can be demonstrated by the reference test and/or from previously existing test data that the new junctions do not negatively affect the fire resistance.

test. 7.2.2 Timber Frames In addition to the general rules given in 7.2.1 the following additional rules apply for timber frames. Exchange of the type of timber species used for the frame is allowed for fire resistant glass from the same glass product group as follows: Timber with the same or higher density and/or moisture content, with the same or lower char rate and identical profile; SIST EN 15254-4:2008

Laminated timber frames shall only be used if it has been proven in a fire test according to EN 1364-1, or previously existing test data evidence may be used. Split timber frames (bolted, glued or nailed) shall be tested unless scaled drawings and representative frame sections can show that there is sufficient timber in the section such that the char line in the required period does not reach the bead fixings. Char data for the timber in question shall be provided to establish this point. At least one test to EN 1364-1 is also required or previously existing test data evidence can be used. 7.2.3 Metal Frames In addition to the general rules given in 7.2.1 the following additional rules apply for steel and aluminium frames. Exchange of steel for steel frames, or aluminium for aluminium frames is allowed provided that: a) Substitute frame has the same material specification as that in the reference test as demonstrated by the appropriate characteristics of the frame (e.g. thermal expansion, thermal conductivity, melting point, strength). The specifications of the two framing systems shall be included in the extended application report for comparison. b) Substitute frame has the same fire performance as the frame in the reference test. This shall be demonstrated by reference to fire test data at the same classification time. Previously existing test data may be used. c) Deflection of the frame that is being considered in the extended application shall be no more than the measured deflection in the reference test. The deflection of this frame must either be known from previously existing test data or by theoretical calculation. If this data is not available or it is not possible to accurately calculate the deflection, then exchange is not allowed. d) Alternative frame has successful test evidence, which demonstrates that all the necessary design features (e.g. junctions, fixings) of the fire resistant glazed element under consideration can be constructed with the alternative frame without impairing the required fire performance in a test of the fire resistant glazed element. Previously existing test data may be used. e) In particular, the test report shall include information on expansion joints if these are to be covered by the extended application. f) Frame section may be changed provided that it can be demonstrated that: axial stress levels in the vertical elements and the bending stress in horizontal elements are not increased in the cold state; HP/A factor for the frame and bead is not increased (see also Figure B.5); depth of the section is not reduced (see also Figure B.3); wall thickness and number of chambers in the frame are not be reduced. 7.3 Frame surface coverings Decorative surface coverings of the framing members may be exchanged, or added where one does not exist, provided it can be demonstrated that the covering material achieves at least Class A2 when classified according to EN 13501-1. In addition it must be shown that they do not adversely affect the SIST EN 15254-4:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...