EN 4533-001:2006

(Main)Aerospace series - Fibre optic systems - Handbook - Part 001: Termination methods and tools

Aerospace series - Fibre optic systems - Handbook - Part 001: Termination methods and tools

1.1 General

This Part of EN 4533 examines the termination aspects of fibre optic design for avionic installations. By termination is meant the mechanism used to interface from one component (usually a fibre) to another. This is normally performed by a connector, which aligns the fibre with another component (usually another connector) to a sufficient accuracy to allow continued transmission of an optical signal throughout the operational envelope.

This Part will explain the need for high integrity terminations, provide an insight into component selection issues and suggests best practice when terminating fibres into connectors for high integrity applications. A detailed review of the termination process can be found in Clause 4 of this part and is organised broadly in line with the sequence of a typical termination procedure.

The vast number of cable constructions and connectors available make defining a single termination instruction that is applicable to all combinations almost impossible. Because of the problems of defining a generic termination instruction, this handbook has concentrated on defining best practice for current to near future applications of fibre optics on aircraft.

This has limited the studies within this part to currently available ‘avionic’ silica fibre cables and adhesive filled butt-coupled type connectors. Many of the principles described however would still be applicable for other termination techniques. Other types of termination are considered further in the repair part of this handbook.

1.2 Need for high integrity terminations

In order to implement a fibre optic based system on an aircraft it is vital to ensure that the constituent elements of the system will continue to operate, to specification, over the life of the system. An important aspect of this requirement is the need for reliable interconnection components. (continued)

Luft- und Raumfahrt - Faseroptische Systemtechnik - Handbuch - Teil 001: Verarbeitungsmethoden und Werkzeuge

1.1 Allgemeines

Dieser Teil von EN 4533 untersucht die Anschlussaspekte bei der Gestaltung von Lichtwellenleitertechnik für die Installation in Luftfahrzeugen. Der Begriff Anschluss bezieht sich auf den Mechanismus, mit dem die Schnittstelle zwischen einem Bauteil (gewöhnlich einer Faser) zu einem anderen hergestellt wird. Dies erfolgt üblicherweise durch einen Steckverbinder, der die Faser mit einem anderen Bauteil (gewöhnlich einem anderen Steckverbinder) mit einer Genauigkeit ausrichtet, die ausreichend ist, um durchgehende Übertragung eines optischen Signals durch die gesamte Betriebshülle zu ermöglichen.

Dieser Teil erläutert die Notwendigkeit von hochintegrierten Anschlüssen, bietet Einblick in die Problematik der Bauteilauswahl, und enthält Vorschläge für die beste Verfahrensweise für das Anschließen von Fasern in Steckverbindern bei hochintegrierten Anwendungen. Ein detaillierter Überblick über die Anschlussprozesse ist in Abschnitt 4 dieses Teils enthalten und wird weitestgehend in Übereinstimmung mit der Abfolge eines typischen Anschlussverfahrens vorgenommen.

Die große Vielfalt an erhältlichen Kabelkonstruktionen und Steckverbindern macht es beinahe unmöglich, eine einzelne, auf alle Kombinationen zutreffende Anschlussvorschrift festzulegen. Aufgrund der Probleme bei der Festlegung einer allgemeinen Anschlussvorschrift liegt das Hauptaugenmerk dieses Handbuchs auf der Festlegung der besten Verfahrensweise für derzeitige und in naher Zukunft vorhandene Lichtwellen¬leiteranwendungen in Luftfahrzeugen.

Dadurch waren die Studien im Rahmen dieses Teils auf derzeit erhältliche Kabel mit Quarzglasfasern für die Luft- und Raumfahrt sowie mit Klebstoff gefüllte Steckverbinder mit Stirnflächenkopplung begrenzt. Viele der beschriebenen Grundsätze wären jedoch ebenfalls auf andere Anschlusstechniken anwendbar. Andere Anschlussarten werden ausführlicher im Reparatur-Teil dieses Handbuchs berücksichtigt.

Série aérospatiale - Systèmes des fibres optiques - Manuel d'utilisation - Partie 001 : Méthodes des terminaisons et outils

Aeronavtika - Sistemi iz optičnih vlaken - Priročnik - 001. del: Metode določanja in orodja

General Information

- Status

- Withdrawn

- Publication Date

- 11-Jul-2006

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- ASD-STAN - Aerospace

- Drafting Committee

- ASD-STAN/D 2 - Electrical

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-Feb-2020

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 04-Mar-2020

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 4533-001:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aerospace series - Fibre optic systems - Handbook - Part 001: Termination methods and tools". This standard covers: 1.1 General This Part of EN 4533 examines the termination aspects of fibre optic design for avionic installations. By termination is meant the mechanism used to interface from one component (usually a fibre) to another. This is normally performed by a connector, which aligns the fibre with another component (usually another connector) to a sufficient accuracy to allow continued transmission of an optical signal throughout the operational envelope. This Part will explain the need for high integrity terminations, provide an insight into component selection issues and suggests best practice when terminating fibres into connectors for high integrity applications. A detailed review of the termination process can be found in Clause 4 of this part and is organised broadly in line with the sequence of a typical termination procedure. The vast number of cable constructions and connectors available make defining a single termination instruction that is applicable to all combinations almost impossible. Because of the problems of defining a generic termination instruction, this handbook has concentrated on defining best practice for current to near future applications of fibre optics on aircraft. This has limited the studies within this part to currently available ‘avionic’ silica fibre cables and adhesive filled butt-coupled type connectors. Many of the principles described however would still be applicable for other termination techniques. Other types of termination are considered further in the repair part of this handbook. 1.2 Need for high integrity terminations In order to implement a fibre optic based system on an aircraft it is vital to ensure that the constituent elements of the system will continue to operate, to specification, over the life of the system. An important aspect of this requirement is the need for reliable interconnection components. (continued)

1.1 General This Part of EN 4533 examines the termination aspects of fibre optic design for avionic installations. By termination is meant the mechanism used to interface from one component (usually a fibre) to another. This is normally performed by a connector, which aligns the fibre with another component (usually another connector) to a sufficient accuracy to allow continued transmission of an optical signal throughout the operational envelope. This Part will explain the need for high integrity terminations, provide an insight into component selection issues and suggests best practice when terminating fibres into connectors for high integrity applications. A detailed review of the termination process can be found in Clause 4 of this part and is organised broadly in line with the sequence of a typical termination procedure. The vast number of cable constructions and connectors available make defining a single termination instruction that is applicable to all combinations almost impossible. Because of the problems of defining a generic termination instruction, this handbook has concentrated on defining best practice for current to near future applications of fibre optics on aircraft. This has limited the studies within this part to currently available ‘avionic’ silica fibre cables and adhesive filled butt-coupled type connectors. Many of the principles described however would still be applicable for other termination techniques. Other types of termination are considered further in the repair part of this handbook. 1.2 Need for high integrity terminations In order to implement a fibre optic based system on an aircraft it is vital to ensure that the constituent elements of the system will continue to operate, to specification, over the life of the system. An important aspect of this requirement is the need for reliable interconnection components. (continued)

EN 4533-001:2006 is classified under the following ICS (International Classification for Standards) categories: 49.060 - Aerospace electric equipment and systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 4533-001:2006 has the following relationships with other standards: It is inter standard links to EN 4533-001:2020, EN 4533-002:2017, EN ISO 8224-1:2003, EN 4531-001:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 4533-001:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.RURGMDLuft- und Raumfahrt - Faseroptische Systemtechnik - Handbuch - Teil 001: Verarbeitungsmethoden und WerkzeugeSérie aérospatiale - Systèmes des fibres optiques - Manuel d'utilisation - Partie 001 : Méthodes des terminaisons et outilsAerospace series - Fibre optic systems - Handbook - Part 001: Termination methods and tools49.060Aerospace electric equipment and systemsICS:Ta slovenski standard je istoveten z:EN 4533-001:2006SIST EN 4533-001:2009en,de01-junij-2009SIST EN 4533-001:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 4533-001July 2006ICS 49.060 English VersionAerospace series - Fibre optic systems - Handbook - Part 001:Termination methods and toolsSérie aérospatiale - Systèmes des fibres optiques - Manueld'utilisation - Partie 001 : Méthodes des terminaisons etoutilsLuft- und Raumfahrt - Faseroptische Systemtechnik -Handbuch - Teil 001: Verarbeitungsmethoden undWerkzeugeThis European Standard was approved by CEN on 28 April 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 4533-001:2006: ESIST EN 4533-001:2009

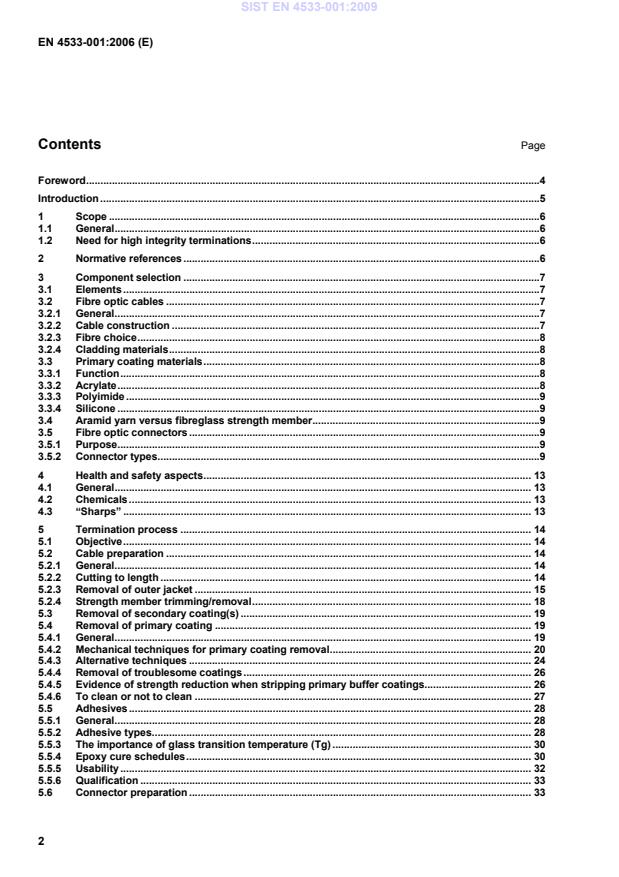

It is arranged in 4 parts, which reflect key aspects of an optical harness life cycle, namely: Part 001: Termination methods and tools Part 002: Test and measurement

Part 003: Looming and installation practices Part 004: Repair, maintenance and inspection b) Background It is widely accepted in the aerospace industry that photonic technology offers a number of significant advantages over conventional electrical hardware. These include massive signal bandwidth capacity, electrical safety, and immunity of passive fibre-optic components to the problems associated with electromagnetic interference (EMI). To date, the latter has been the critical driver for airborne fibre-optic communications systems because of the growing use of non-metallic aerostructures. However, future avionic requirements are driving bandwidth specifications from 10’s of Mbits/s into the multi-Gbits/s regime in some cases, i.e. beyond the limits of electrical interconnect technology. The properties of photonic technology can potentially be exploited to advantage in many avionic applications, such as video/sensor multiplexing, flight control signalling, electronic warfare, and entertainment systems, as well as in sensing many of the physical phenomena on-board aircraft. The basic optical interconnect fabric or `optical harness’ is the key enabler for the successful introduction of optical technology onto commercial and military aircraft. Compared to the mature telecommunications applications, an aircraft fibre-optic system needs to operate in a hostile environment (e.g. temperature extremes, humidity, vibrations, and contamination) and accommodate additional physical restrictions imposed by the airframe (e.g. harness attachments, tight bend radii requirements, and bulkhead connections). Until recently, optical harnessing technology and associated practices were insufficiently developed to be applied without large safety margins. In addition, the international standards did not adequately cover many aspects of the life cycle. The lack of accepted standards thus lead to airframe specific hardware and support. These factors collectively carried a significant cost penalty (procurement and through-life costs), that often made an optical harness less competitive than an electrical equivalent.

c) The fibre-optic harness study The Fibre-Optic Harness Study concentrated on developing techniques, guidelines, and standards associated with the through-life support of current generation fibre-optic harnesses applied in civil and military airframes (fixed and rotary wing). Some aspects of optical system design were also investigated. This programme has been largely successful. Guidelines and standards based primarily on harness study work are beginning to emerge through a number of standards bodies. Because of the aspects covered in the handbook, European prime contractors are in a much better position to utilise and support available fibre optic technology. SIST EN 4533-001:2009

This has limited the studies within this part to currently available ‘avionic’ silica fibre cables and adhesive filled butt-coupled type connectors. Many of the principles described however would still be applicable for other termination techniques. Other types of termination are considered further in the repair part of this handbook. 1.2 Need for high integrity terminations

In order to implement a fibre optic based system on an aircraft it is vital to ensure that the constituent elements of the system will continue to operate, to specification, over the life of the system. An important aspect of this requirement is the need for reliable interconnection components. This is often expressed as the need for reliable connectors, but in reality it is the need for a reliable cable to connector termination process. The essence of this requirement is the need to assure reliable light transmission through each optical connector throughout the operational envelope. This needs to be achieved through a robust process that enables a high level of optical performance over the lifetime of the terminations. Many factors can contribute to an optical connector’s in-service performance, such as basic connector design, choice of optical fibre, cable, operating and maintenance environment etc. However, one of the main factors governing in-service connector performance is the quality of the cable to connector termination. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 4533-002, Aerospace series – Fibre optic systems – Handbook – Part 002: Test and measurement.

There are various types of fibre optic cable on the market ranging from loose tube to tight jacket construction, containing a single fibre or an array of many fibres; however, at the time of publication of this handbook the range of options available to aerospace users is somewhat limited. Most of the possible cable types are only suitable for telecommunication applications due to environmental capability limitations, with avionic solutions being generally limited to single fibre, tight jacket constructions. 3.2.2 Cable construction Although the design of fibre optic cable for use on aircraft is fairly similar from one manufacturer to another there are important differences between cables. The two main areas of difference are fibre coatings and cable strength member materials. Each has its own positive and negative attributes in the context of termination procedures. Avionic fibre optic cables are typically constructed as follows, see Figures 1 and 2.

Key 1 Outer jacket 2 Buffer 3 Cladding 4 Core 5 Primary coating 6 Strength member Figure 1 — Typical avionic fibre optic cable construction 1 2 6 5 4 3 SIST EN 4533-001:2009

Figure 2 — Examples of typical avionic fibre optic cables 3.2.3 Fibre choice From the perspective of termination there is little difference between small and larger core optical fibres. The main fibre issues that impact upon the termination process relate to cladding and primary coating materials. Current generation of avionic fibre sizes tend to be larger than the standard high volume fibres such as those used in the datacomm/telecomm market and so have an associated cost and availability penalty. 3.2.4 Cladding materials Most avionic fibres employ an “all silica” fibre, i.e. both the core and the cladding are made from glass and may be treated as a single glass filament. Some designs use non-glass materials for the cladding e.g. plastic (acrylate) or epoxy. These fibres are referred to as Plastic Clad-Silica (PCS) and Hard Clad-Silica (HCS) respectively. Although these fibres have been used in a number of aircraft applications they are somewhat limited in thermal endurance capabilities and thus tend to be confined to the more benign environmental applications. The termination processes described in this handbook refer to all-silica fibres. 3.3 Primary coating materials 3.3.1 Function The major function of the fibre buffer coating [1] is to protect the fibre from abrasive and environmental damage. Many materials have been used for the primary coating of optical fibres but the most widely known and used of these are, acrylate, polyimide and silicone. The pros and cons of each are briefly described below. It should be noted that most fibres use an acrylate type material for the primary coating. Other materials can be encountered however, such as silicone, proprietary polymers and even metal, such as Gold or Aluminium (although these are somewhat specialised and will not be considered here). 3.3.2 Acrylate This is perhaps the most common of optical fibre primary coating materials and is relatively easy to remove with hand tools. The coating is usually a UV cured acrylate that is translucent and typically is the same thickness as the fibre. Acrylate’s have a limited temperature performance of up to approximately 100 °C therefore, for high temperature applications other additional coatings are also applied.

Key 1 Ferrules 2 Optical fibre 3 Spit alignment sleeve 4 Optical fibre Figure 3 — Butt-coupled fibre optic connector interface This is the simplest of the two in terms of the number of elements in the optical path. However, the performance of this interface is highly dependent upon the quality of the fibre end-face. This implies stringent requirements in terms of cleanliness and polishing (or cleaving).

An alternative to the butt-coupled interface is to place lenses between the two fibre ends (see Figure 4). Connectors employing such lenses are referred to as ‘Expanded Beam’ connectors. The purpose of the lens is to take the small diameter, diverging output of the fibre and convert it into a larger diameter, collimated (parallel) beam of light. This has advantages in terms of enhanced tolerance to particulate contamination.

The inclusion of lenses however, will increase connector insertion loss compared to butt-coupled interfaces as well as adding cost and complexity to the termination process.

1 2 3 4 SIST EN 4533-001:2009

Key 1 Ball lens 2 GRIN lens Figure 4 — Expanded beam fibre optic connector interfaces 3.5.2.3 Fibre attachment method There are two main types of fibre to connector attachment processes. The first is “pot and polish”, where a fibre is bonded into a ferrule using adhesive and subsequently polished. This process generally uses adhesive, a source of heat for curing the adhesive and various grades of polishing film and polishing tools to achieve a good fibre end finish. Although the pot and polish process is achievable in an aircraft environment it has notable differences to a conventional electrical wire termination process. This has led to significant effort being invested into the search for a mechanical based, dry, termination process that doesn’t require a heat source for attaching fibres to connectors. Some adhesive terminations can be performed with specialist adhesives e.g. anaerobic adhesives, without the need for a heat source. However the performance of these adhesives is inferior over temperature to that of heat cured epoxies. The second process, referred to as “crimp and cleave” is an attempt to satisfy the need for an electrical wire equivalent process. This is where a connector ferrule is crimped down onto the fibre or some other element of the fibre’s jacketing layers, with the fibre end being prepared by cleaving rather than polishing.

There are of course other connector termination processes; however, they tend to be variants or hybrids of the above two techniques. The one notable exception is a variation on fusion splicing (a fibre repair process designed to permanently join two fibres). In this technique a cleaved fibre is inserted into a connector and fused by an electric arc to a pre-installed, pre-polished fibre. This is not a widely used technique and has significant safety implications for on-aircraft use.

Fibre attachment is predominantly achieved by use of adhesive in the aerospace community, while crimping is more widespread in the telecommunications community. No aerospace suitable mechanical based termination process is presently available for silica fibres. Terminations using adhesive are thus the only ones considered in detail in this document. This is not to say that all-mechanical crimp and cleave terminations will not become available in the future. 3.5.2.4 Number of fibre channels The fibre optic system designer has a single choice when deciding how to join multiple optical fibres to equipment and to other optical fibres: whether to use multiple single-way connectors or a multi-way connector. 1 2 SIST EN 4533-001:2009

Figure 5 — Typical multi-way fibre optic connector (with backshell fitted) 3.5.2.7 Choice of tooling The development of fibre optic termination processes has lead to a broad range of tools becoming available for the attachment of optical fibres to optical connectors. Because silica has vastly different properties to copper, the following points should be noted: Most tools for cable preparation are similar to those for electrical connectors/cables; Appropriate choice of tools generally reduces the skill level requirements; Optical termination differs from wire termination because final termination quality is not a simple function of tool quality, but is also dependent upon operator skill and judgement; The optical termination process generally requires access to a power source (for epoxy curing processes); Care has to be taken when selecting tooling, particularly for any operation that will expose the silica fibre. Small changes to a tool or the way the tool is used can make resolvable differences to the strength of the fibre. SIST EN 4533-001:2009

Figure 6 — Hardened steel tool damage after cutting through silica optical fibre SIST EN 4533-001:2009

Figure 7 — Splayed out polyimide fibre end 5.2.3 Removal of outer jacket 5.2.3.1 Objectives The objectives for this activity are to consistently remove a controlled, pre-defined length of cable jacketing material, without damaging cable sub-layers, while also ensuring that the remaining cut face of the jacket is perpendicular to the fibre and free from rough edges (e.g. "ears"). This should also be achieved with both long tool life and ease of use. The range of possible tools for performing this activity is vast and as with many manual processes, the choice of outer jacket stripping tool will depend upon personal preference as well as functional performance. However, several important aspects concerning striping tool choice should be noted. 5.2.3.2 Blade type and wear characteristics Butting knife type blades have a very small, sharp contact area at blade closure, which will tend to wear quite quickly. In this situation, as the tool wears, the stripping hole will become smaller and more oval, with the possibility of eventually touching and damaging the sub-layers. It should be noted however, that these tools produce some of the best strip results when new. See Figure 8.

Figure 8 — Butting knife type blades

Butting die-type blades have a relatively large contact area on blade closure. This contact surface hardly wears at all. Consequently, the only area to wear will be the precision ground cutting blades, which become larger in diameter with use. Thus, as the tool wears, the stripping performance drops off to the point where the tool will no longer strip the cable's outer jacket. This is a relatively safe tool failure mode. See Figure 9.

Figure 9 — Die-type blades

Shearing (or scissor like) knife type blades often have sharpened V-shaped apertures to cut through the outer jacket. These operate in the same way as domestic electrical wire strippers with rather variable results. See Figure 10. SIST EN 4533-001:2009

Figure 10 — Shearing knife type blades

Precision wire strippers have properties common to both the butting die type blades and the shearing knife type blades. The control point of contact at tool closure is generally located at the tip of the tool and hardly wears. In this respect, the precision stripping hole will tend to get larger as the tool wears. However, the precision hole is formed at the junction of two shearing knife blade edges. It has been found that these very fine unsupported edges tend to break, giving rise to the creation of “ears” on the stripped cable end. This is due to small gaps at the point of contact between the blades. Similar wear characteristics have been observed for primary coating removal tools also. It should be noted that these tools often have the aperture size specified in terms of SWG or AWG. These numbers cannot be relied upon to give a consistent aperture size; i.e. 22 AWG on one tool will not necessarily have the same size stripping hole as a 22 AWG on a different tool. See Figure 11.

Figure 11 — Precision electrical wire strippers SIST EN 4533-001:2009

Any tool that permits the blade cutting depth to be manually adjusted to compensate for wear should be avoided unless sufficient control can be made on the adjustment, as this can lead to incorrectly set blades and the possibility of damaging cable sub-layers. 5.2.3.4 Cable handling tools (Gripping the cable) Cable guiding and support can be achieved in a number of ways: by hand, by integration into the stripping tool or by an entirely separate tool. Some tools have small v-groove sections that help to align the cable to the cutte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...