prEN 10369-1

(Main)Prestressing steels - Protected and sheathed strands for prestressing - Part 1: General requirements

Prestressing steels - Protected and sheathed strands for prestressing - Part 1: General requirements

This document specifies the requirements for uncoated high strength steel strands or zinc or zinc alloy coated high strength steel strands, encapsulated with a protection product and a sheath 1).

The intended use of these products is mainly the prestressing of concrete.

NOTE These products can also be used in other stress applications in the construction field (e.g. stay cables for bridges) where the protection of the products is not removed in use.

The standard applies only to products as supplied by the producer.

1) The word "sheath" used in the present document does not cover the sheaths as stated in mandate M/115 and specified in EN 523.

Spannstähle - Geschützte und gehüllte Litzen für Vorspannen - Teil 1: Allgemeine Anforderungen

Dieses Dokument legt die allgemeinen Anforderungen für unbeschichtete hochfeste Stahllitzen oder zink- oder zinklegierungsbeschichtete hochfeste Stahllitzen fest, die mit einem Schutzprodukt und Hülle ummantelt sind1).

Die beabsichtigte Verwendung dieser Produkte ist hauptsächlich die Vorspannung von Beton.

ANMERKUNG Diese Erzeugnisse dürfen auch bei anderen Anwendungen mit Beanspruchungen im Baubereich (z. B. Schrägseile für Brücken), bei denen der Schutz der Produkte bei der Verwendung nicht beseitigt wird.

Die Norm gilt nur für Produkte, welche vom Hersteller geliefert werden.

1) Das Wort "Hülle", das in der vorliegenden Norm verwendet wird, deckt nicht die Hüllen ab, wie in Mandat M/115 angegeben und in EN 523 spezifiziert.

Armatures de précontrainte - Torons protégés gainés pour précontrainte - Partie 1 : Prescriptions générales

Le présent document spécifie les prescriptions applicables aux torons en acier à haute résistance non revêtus ou aux torons en acier à haute résistance revêtus de zinc ou d’un alliage de zinc, enrobés d’un produit de protection et d’une gaine ).

L’usage prévu pour ces produits est principalement la précontrainte du béton.

NOTE Ces produits peuvent également être utilisés dans d’autres applications sous contrainte dans le domaine de la construction (haubans de ponts, par exemple) pour lesquelles la protection des produits n'est pas retirée lors de l’utilisation.

La norme s’applique uniquement aux produits tels qu’ils sont fournis par le producteur.

1) Le mot « gaine » utilisé dans le présent document ne couvre pas les gaines telles qu’elles ont été définies dans le Mandat M / 115 et spécifiées dans l’EN 523.

Prednapeta jekla - Zaščitena in obložena vlakna za prednapenjanje - 1. del: Splošno

General Information

- Status

- Not Published

- Publication Date

- 17-Aug-2021

- Withdrawal Date

- 17-Feb-2022

- Technical Committee

- ECISS/TC 104 - Concrete reinforcing and prestressing steels

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 21-Jan-2021

- Completion Date

- 21-Jan-2026

- Directive

- 89/106/EEC - Construction products

Overview

prEN 10369-1 - "Prestressing steels - Protected and sheathed strands for prestressing - Part 1: General requirements" (CEN, draft 2019) specifies general requirements for high‑strength steel strands (uncoated or zinc / zinc‑alloy coated) that are encapsulated with a protection product (grease or wax) and a continuous sheath. The standard targets products as supplied by the producer and is primarily intended for the prestressing of concrete, though it also covers other construction stress applications (for example, stay cables) where the protection remains in service. Note: the term “sheath” here excludes the sheaths defined under mandate M/115 / EN 523.

Key topics and requirements

- Scope and product definitions

- Defines protected and sheathed strand, plus variants: sliding (type S), adherent (type A) and double sheathed.

- Materials and protection products

- Requirements for grease and wax protection products (Annex A) and sheath base materials (Annex B).

- Designation and classification

- Product designation format (strand reference, protection symbol +G/+W, type S/A, sheath colour) and classification of constituent steels.

- Testing and performance

- Comprehensive test methods (Annex C) for:

- Mass per unit length of protection product

- Sheath thickness and initial resistance to friction

- Bond retention under thermal variations

- Water tightness (static and dynamic)

- Impact resistance and other durability checks

- Comprehensive test methods (Annex C) for:

- Quality assurance

- Assessment and Verification of Constancy of Performance (AVCP), including type testing and factory production control (FPC) requirements.

- Delivery and documentation

- Conditioning, transportation, storage, labelling and documents accompanying delivery (e.g., EN 10204 inspection documents, force/extension diagrams).

Applications and users

Who benefits from prEN 10369-1:

- Prestressing steel manufacturers specifying production, protection and sheathing processes.

- Structural and bridge engineers writing specifications for prestressed concrete components and stay cables.

- Contractors and fabricators responsible for procurement, handling, transport and installation.

- Quality managers and testing laboratories implementing AVCP, FPC and test regimes.

- Regulatory authorities and specifiers ensuring compliance with Construction Products Regulation (CPR) requirements.

Practical uses:

- Specifying durable, corrosion‑protected strands for pre‑tensioned or post‑tensioned concrete members.

- Selecting sliding vs. adherent systems depending on design requirements for movement and bond.

- Verifying long‑term watertightness and mechanical protection of prestressing systems.

Related standards

- prEN 10369-2 (Sliding strands) and prEN 10369-3 (Adherent strands)

- prEN 10138-1 / prEN 10138-3 (prestressing steel general and strand)

- prEN 10337 (zinc coated prestressing wires/strands)

- EN 10204 (inspection documents), EN ISO 15630-3 (test methods), EN ISO 9227 (salt spray) and other referenced ISO/EN test standards.

Keywords: prestressing steels, protected and sheathed strands, prEN 10369-1, CEN, prestressing of concrete, zinc coated strand, grease, wax, AVCP, factory production control, sliding strands, adherent strands.

Frequently Asked Questions

prEN 10369-1 is a draft published by the European Committee for Standardization (CEN). Its full title is "Prestressing steels - Protected and sheathed strands for prestressing - Part 1: General requirements". This standard covers: This document specifies the requirements for uncoated high strength steel strands or zinc or zinc alloy coated high strength steel strands, encapsulated with a protection product and a sheath 1). The intended use of these products is mainly the prestressing of concrete. NOTE These products can also be used in other stress applications in the construction field (e.g. stay cables for bridges) where the protection of the products is not removed in use. The standard applies only to products as supplied by the producer. 1) The word "sheath" used in the present document does not cover the sheaths as stated in mandate M/115 and specified in EN 523.

This document specifies the requirements for uncoated high strength steel strands or zinc or zinc alloy coated high strength steel strands, encapsulated with a protection product and a sheath 1). The intended use of these products is mainly the prestressing of concrete. NOTE These products can also be used in other stress applications in the construction field (e.g. stay cables for bridges) where the protection of the products is not removed in use. The standard applies only to products as supplied by the producer. 1) The word "sheath" used in the present document does not cover the sheaths as stated in mandate M/115 and specified in EN 523.

prEN 10369-1 is classified under the following ICS (International Classification for Standards) categories: 77.140.15 - Steels for reinforcement of concrete. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 10369-1 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/115. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 10369-1 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2019

Prednapeta jekla - Zaščitena in obložena vlakna za prednapenjanje - 1. del:

Splošno

Prestressing steels - Protected and sheathed strands for prestressing - Part 1: General

Spannstähle - Geschützte und gehüllte Litze zum Vorspannen - Teil 1: Allgemeine

Anforderungen

Aciers de précontrainte - Fils protégés et gainés de précontrainte - Partie 1 : Généralités

Ta slovenski standard je istoveten z: prEN 10369-1

ICS:

77.080.20 Jekla Steels

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2019

ICS 77.140.15

English Version

Prestressing steels - Protected and sheathed strands for

prestressing - Part 1: General requirements

Armatures de précontrainte - Torons protégés gainés Spannstähle - Geschützte und gehüllte Litzen für

pour précontrainte - Partie 1 : Prescriptions générales Vorspannen - Teil 1: Allgemeine Anforderungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 459/SC 4.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 10369-1:2019 E

worldwide for CEN national Members.

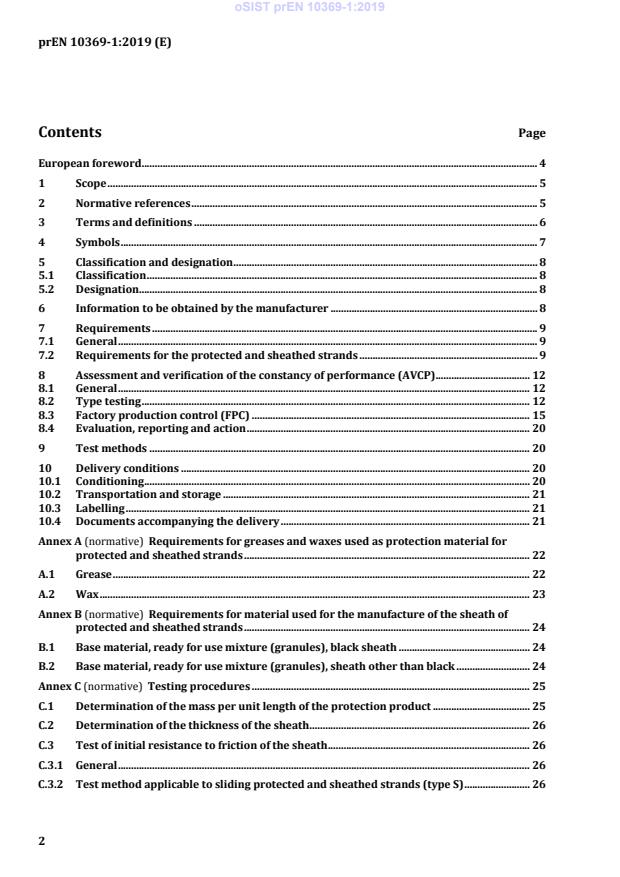

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols . 7

5 Classification and designation . 8

5.1 Classification . 8

5.2 Designation. 8

6 Information to be obtained by the manufacturer . 8

7 Requirements . 9

7.1 General . 9

7.2 Requirements for the protected and sheathed strands . 9

8 Assessment and verification of the constancy of performance (AVCP) . 12

8.1 General . 12

8.2 Type testing . 12

8.3 Factory production control (FPC) . 15

8.4 Evaluation, reporting and action . 20

9 Test methods . 20

10 Delivery conditions . 20

10.1 Conditioning . 20

10.2 Transportation and storage . 21

10.3 Labelling . 21

10.4 Documents accompanying the delivery . 21

Annex A (normative) Requirements for greases and waxes used as protection material for

protected and sheathed strands . 22

A.1 Grease . 22

A.2 Wax . 23

Annex B (normative) Requirements for material used for the manufacture of the sheath of

protected and sheathed strands . 24

B.1 Base material, ready for use mixture (granules), black sheath . 24

B.2 Base material, ready for use mixture (granules), sheath other than black . 24

Annex C (normative) Testing procedures . 25

C.1 Determination of the mass per unit length of the protection product . 25

C.2 Determination of the thickness of the sheath . 26

C.3 Test of initial resistance to friction of the sheath . 26

C.3.1 General . 26

C.3.2 Test method applicable to sliding protected and sheathed strands (type S) . 26

C.3.3 Test method applicable to adherent protected and sheathed strands (type A) . 26

C.4 Test of bond retention under thermal variations . 27

C.5 Water tightness test . 28

C.5.1 Static test . 28

C.5.2 Dynamic test . 28

C.6 Impact resistance of the sheath . 29

Annex ZA (informative) Relationship between this European Standard and the

requirements of Regulation (EU) No. 305/2011 aimed to be covered . 32

ZA.1 Scope and relevant characteristics . 32

ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 33

ZA.3 Assignment of AVCP tasks . 34

Bibliography . 35

European foreword

This document (prEN 10369-1:2019) has been prepared by Technical Committee CEN/TC 459/SC 4

“Concrete reinforcing and prestressing steels”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Construction Products Regulation (EU 305/2011).

For relationship with EU EU Construction Products Regulation (EU 305/2011), see informative

Annex ZA, which is an integral part of this document.

prEN 10369 consists of three parts under the general title “Prestressing steels — Protected and

sheathed strands for prestressing”:

— Part 1: General requirements

— Part 2: Sliding strands

— Part 3: Adherent strands

Whenever approved, the publication of this series of standards will wait until EN 10138-1 and

EN 10138-3 and EN 10337 are approved.

1 Scope

This document specifies the requirements for uncoated high strength steel strands or zinc or zinc alloy

1)

coated high strength steel strands, encapsulated with a protection product and a sheath .

The intended use of these products is mainly the prestressing of concrete.

NOTE These products can also be used in other stress applications in the construction field (e.g. stay cables

for bridges) where the protection of the products is not removed in use.

The standard applies only to products as supplied by the producer.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 728, Plastics piping and ducting systems — Polyolefin pipes and fittings — Determination of oxidation

induction time

EN 10020, Definition and classification of grades of steel

prEN 10138-1, Prestressing steels — Part 1: General requirements

prEN 10138-3, Prestressing steels — Part 3: Strand

EN 10204, Metallic products — Types of inspection documents

prEN 10337, Zinc and zinc alloy coated prestressing steel wires and strands

prEN 10369-2, Prestressing steels — Protected and sheathed strands for prestressing — Part 2: Sliding

strands

prEN 10369-3, Prestressing steels — Protected and sheathed strands for prestressing — Protected and

sheathed high strength steel strands — Part 3: Adherent strands

EN ISO 175, Plastics — Methods of test for the determination of the effects of immersion in liquid

chemicals (ISO 175:2010)

EN ISO 527-1, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-1)

EN ISO 527-2, Plastics — Determination of tensile properties — Part 2: Test conditions for moulding and

extrusion plastics (ISO 527-2)

EN ISO 4892-2, Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps

(ISO 4892-2)

EN ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227)

1)

The word "sheath" used in the present document does not cover the sheaths as stated in mandate M/115 and

specified in EN 523.

EN ISO 10304-1, Water quality — Determination of dissolved anions by liquid chromatography of ions —

Part 1: Determination of bromide, chloride, fluoride, nitrate, nitrite, phosphate and sulfate (ISO 10304-1)

EN ISO 10304-4, Water quality — Determination of dissolved anions by liquid chromatography of ions —

Part 4: Determination of chlorate, chloride and chlorite in water with low contamination (ISO 10304-4)

EN ISO 15630-3, Steel for the reinforcement and prestressing of concrete — Test methods — Part 3:

Prestressing steel (ISO 15630-3)

ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1: Immersion

method, liquid pyknometer method and titration method

ISO 2137, Petroleum products and lubricants — Determination of cone penetration of lubricating greases

and petrolatum

ISO 2176, Petroleum products — Lubricating grease — Determination of dropping point

ISO 2207, Petroleum waxes — Determination of congealing point

ISO 6964, Polyolefin pipes and fittings — Determination of carbon black content by calcination and

pyrolysis — Test method

ISO 18553, Method for the assessment of the degree of pigment or carbon black dispersion in polyolefin

pipes, fittings and compounds

BS 2000-121, Methods of test for petroleum and its products — Determination of oil separation from

lubricating grease — Pressure filtration method

DIN 51451, Testing of petroleum products and related products — Analysis by infrared spectrometry —

General working principles

NF M 07-023, Liquid fuels — Determination of chlorides in crude petroleum and petroleum products

NF T 60-191, Petroleum products and lubricating greases — Oil separation on storage of grease — Static

conditions under pressure

ASTM D95, Standard Test Method for Water in Petroleum Products and Bituminous Materials by

Distillation

ASTM D942, Standard Test Method for Oxidation Stability of Lubricating Greases by the Oxygen Pressure

Vessel Method

3 Terms and definitions

For the purposes of this document, the terms and definitions given in prEN 10138-1 and prEN 10337

and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

uncoated strand

strand consisting of uncoated high strength steel wires in accordance with prEN 10138-1 and

prEN 10138-3

3.2

zinc or zinc alloy coated prestressing strand

strand consisting of zinc or zinc alloy hot-dip coated high strength steel wires in accordance with prEN

3.3

protected and sheathed strand

uncoated or zinc or zinc alloy coated strand encapsulated with a protection product and a sheath

A distinction is made between:

3.3.1

sliding protected and sheathed strand (type S)

protected and sheathed strand for which the protection product allows a movement between the sheath

and strand by application of a specified force

3.3.2

adherent protected and sheathed strand (type A)

protected and sheathed strand for which an adherence between the sheath and strand restricts their

relative movement until a specified minimum force is reached

3.3.3

protected and double sheathed strand

protected and sheathed strand using double sheathing for both types (S and A)

3.4

protection product

product applied before sheathing to ensure full encapsulation

3.5

sheath

continuous envelope surrounding the strand

3.6

batch of protection material

quantity of grease or wax produced in one manufacturing operation

4 Symbols

The symbols used in this European Standard and the corresponding designations are given in Table 1.

Table 1 — Symbols and corresponding designations

Symbol Unit Designation

L mm Length of the test piece

M g Total mass of the test piece

t

M g Mass of the sheath

s

M g Total mass of wires

w

M g/m Mass per unit length of the protection product

pl

E MPa Modulus of elasticity of the strand

α ° Angle of bend of the test piece in the test for resistance to rotating

bending

D mm Diameter of the core wire

a

5 Classification and designation

5.1 Classification

The steels of the constituent strands of protected and sheathed strands covered by this document are

classified as special steels according to EN 10020.

5.2 Designation

The designation of the products covered by this standard comprises in the order:

— the description of the product (i.e. protected and sheathed strand);

— the designation of the strand from which the protected and sheathed strand is produced according

to the relevant standard in square brackets;

— the symbol of the protection product (+ G for grease; + W for wax);

— the symbol of the type of protected and sheathed strand (S or A, respectively see prEN 10369-2 and

prEN 10369-3);

— the colour of the sheath when other than black.

6 Information to be obtained by the manufacturer

The following information shall be obtained by the manufacturer at the time of enquiry and order:

a) designation of the product in accordance with 5.2;

b) the packaging and protection requirements;

c) the requirements concerning information to accompany the delivery (e.g. date of manufacture,

delivery note, type of inspection document, see EN 10204, copies of force/extension diagrams);

d) special requirements for labelling.

7 Requirements

7.1 General

7.1.1 Manufacturing process

The strands to be protected and sheathed shall be manufactured in accordance with prEN 10138-1 and

prEN 10138-3 or prEN 10337.

The manufacturing method of the protected and sheathed strands shall be at the discretion of the

manufacturer provided that the sheath is applied to the protected strand by direct extrusion and all the

requirements of this standard are fulfilled.

7.1.2 Requirements for the constituent materials of the protected and sheathed strands

7.1.2.1 Strand

The uncoated strands shall be in accordance with prEN 10138-1 and prEN 10138-3 and be free from

rust at the time of application of the protection and sheath.

The zinc or zinc alloy coated prestressing strands shall be in accordance with prEN 10337.

7.1.2.2 Protection product

7.1.2.2.1 General

The protection product is a mineral oil-based grease or a microcrystalline wax.

7.1.2.2.2 Grease

The grease shall meet the requirements given in Table A.1.

7.1.2.2.3 Wax

The wax shall meet the requirements given in Table A.2.

7.1.2.3 Base material of the sheath

The base material of the sheath shall meet the requirements given in Annex B.

7.2 Requirements for the protected and sheathed strands

7.2.1 Standard and special properties

The requirements for the standard and special properties as defined in prEN 10138-1 and

prEN 10138-3 or prEN 10337 respectively shall apply.

7.2.2 Overall diameter

The overall diameter of the protected and sheathed strands shall be within a specified range in

accordance with the requirements of:

— prEN 10369-2 for sliding protected and sheathed strands (type S), and

— prEN 10369-3 for adherent protected and sheathed strands (type A).

7.2.3 Straightness

The maximum bow height of the protected and sheathed strands from a reference line of 1 m long,

measured within the curvature, in its plane, according to EN ISO 15630-3, shall be less than or equal to

25 mm.

7.2.4 Mass of the protection product

The minimum specified value for the mass of grease or wax per metre of strand shall be as given in the

relevant requirements of prEN 10369-2 or prEN 10369-3.

The mass per unit length of grease or wax shall be determined according to the procedure described in

C.1.

7.2.5 Properties of the sheath

7.2.5.1 Thickness

The minimum thickness of the sheath shall meet the requirements specified in prEN 10369-2 or

prEN 10369-3 at any section.

The thickness of the sheath shall be determined according to the procedure described in C.2.

7.2.5.2 Surface conditions

There shall be no trace of protection product at the surface of the sheath.

The sheath shall not show continuous scratches, injuries or craters visible with a normal or corrected

vision. Local discontinuities shall not be of a length greater than the maximum overall diameter of the

protected and sheathed strand. The thickness of the sheath at a local discontinuity shall not fall below

the specified minimum.

7.2.5.3 Mechanical properties

The specified values of mechanical properties of the sheath shall be the minimum specified value of

tensile stress at yield, tensile strain at break at 23 °C, determined according to EN ISO 527-1 and

EN ISO 527-2 on a specimen 1B with a testing speed of 100 mm/min ± 10 %, and shall meet the

requirements specified in prEN 10369-2 or prEN 10369-3.

7.2.5.4 Stress cracking resistance

There shall be neither rupture nor cracking of the sheath, visible under a visual inspection by a person

with a normal or corrected vision when tested according to ASTM D1693 in an aqueous solution with

1 % of nonylphenol poly(ethylene-oxy)ethanol.

7.2.5.5 Resistance to aggressive media

The values of the tensile stress at yield and tensile strain at break of the sheath at 23 °C, determined

according to EN ISO 527-1 and EN ISO 527-2 on a specimen 1B with a testing speed of

100 mm/min ± 10 %, shall be greater than or equal to 75 % of those specified in prEN 10369-2 or

prEN 10369-3, after an exposure of 16 weeks to each of the aggressive media as listed in Table 2.

Table 2 — List of typical aggressive media and test agents

Exposure to Test agent

Mineral oil Oil No 3 according to ISO 1817

Acid 10 % sulphuric acid

Base Saturated calcium hydroxide 40 % sodium hydroxide

Solvents Blend of acetone: ethanol: n-heptane: toluol, 1:1:1:1 by mass

Salt water Saturated solution of demineralised tab water and NaCl

The change of the test piece volume after each test shall be lower than or equal to 5 %.

The tests shall be carried out according to EN ISO 175.

7.2.5.6 Resistance to ionising radiation

Where required or applicable, there shall not appear cracks visible under a visual inspection without

assistance by a person with a normal or corrected vision and the yield strength of the sheath shall

remain at a value greater than or equal to 75 % of that specified in prEN 10369-2 or prEN 10369-3,

after a 3 000 h-test.

The test shall be carried out according to EN ISO 4892-2.

7.2.5.7 Properties after exposure to temperature

The values of tensile stress at yield and tensile strain at break of the sheath shall be greater than or

equal to 75 % of those specified in prEN 10369-2 or prEN 10369-3, after exposure of the sheath for 72

h ± 1 h to temperatures of 100 °C ± 5 °C and - 20 °C ± 2 °C.

The tensile test shall be carried out at 23 °C ± 5 °C according to EN ISO 527-1 and 2 on a specimen 1B

with a testing speed of 100 mm/min ± 10 %.

7.2.5.8 Colour stability

Where required and for specific applications, the colour stability as well as the method of verification of

this property may be specified for colours other than black.

7.2.6 Water tightness

Water tightness of the product shall be specified as the maximum mass variation of the test piece and

the mass of water passing through the test piece during the test as specified in prEN 10369-2 or

prEN 10369-3.

The tests to characterize the water tightness shall be carried out according to the procedure described

in C.5.

NOTE These tests are intended to give the proof of a proper filling of the spaces between the wires of the

strand and between the sheath and the wires by the protection product.

7.2.7 Initial resistance to friction

Initial resistance to friction shall be a maximum or minimum specified force as given in prEN 10369-2

or prEN 10369-3.

It shall be determined according to the procedure described in C.3.

7.2.8 Retention of the adherence under thermal variations

The retention of the adherence under thermal variations is only specified for adherent protected and

sheathed strands (type A), see prEN 10369-3.

It shall be determined according to the procedure described in C.4.

7.2.9 Impact resistance

Impact resistance shall be as specified in prEN 10369-2 or prEN 10369-3.

The test shall be carried out according to the procedure described in C.6.

8 Assessment and verification of the constancy of performance (AVCP)

8.1 General

The compliance of the protected and sheathed strands for prestressing with the requirements of this

standard and with the performances declared by the manufacturer in the declaration of performance

(DoP) shall be demonstrated by:

— determination of the product type;

— factory production control by the manufacturer, including product assessment.

The manufacturer shall always retain the overall control and shall have the necessary means to take

responsibility for the conformity of the product with its declared performance(s).

8.2 Type testing

8.2.1 General

All performances related to characteristics included in this standard shall be determined when the

manufacturer intends to declare the respective performances.

Assessment previously performed in accordance with the provisions of this standard, may be taken into

account provided that they were made to the same or a more rigorous test method, under the same

AVCP system on the same product or products of similar design, construction and functionality, such

that the results are applicable to the product in question.

NOTE 1 Same AVCP system means testing by an independent third party, under the responsibility of a notified

product certification body.

For the purposes of assessment, the manufacturer's products may be grouped into families, where it is

considered that the results for one or more characteristics from any one product within the family are

representative for those same characteristics for all products within that same family.

NOTE 2 Products can be grouped in different families for different characteristics.

NOTE 3 Reference to the assessment method standards can be made to allow the selection of a suitable

representative sample.

In addition, the determination of the product type shall be performed for all characteristics included in

the standard for which the manufacturer declares the performance:

— at the beginning of the production of a new or modified protected and sheathed strands for

prestressing (unless a member of the same product range), or

— at the beginning of a new or modified method of production (where this may affect the stated

properties); or

they shall be repeated for the appropriate characteristic(s), whenever a change occurs in the protected

and sheathed strands for prestressing design, in the raw material or in the supplier of the components,

or in the method of production (subject to the definition of a family), which would affect significantly

one or more of the characteristics.

Where components are used whose characteristics have already been determined, by the component

manufacturer, on the basis of assessment methods of other product standards, these characteristics

need not be re-assessed. The specifications of these components shall be documented.

Products bearing regulatory marking in accordance with appropriate harmonized European

specifications may be presumed to have the performances declared in the DoP, although this does not

replace the responsibility on the protected and sheathed strands for prestressing manufacturer to

ensure that the protected and sheathed strands for prestressing as a whole is correctly manufactured

and its component products have the declared performance values.

8.2.2 Test samples, testing and compliance criteria

The type and number of initial tests on protected and sheathed strands for prestressing (defined by the

type i.e. S or A, the protection material i.e. grease or wax, the sheath thickness class i.e. T 1, T 2 or

n n

T 3), shall be as given in Table 2.

n

The samples to be taken per size shall permit the determination of geometrical properties, standard

mechanical properties and special properties, with retests on any invalid results due to inappropriate

testing procedure where necessary.

The samples shall be taken as random samples from the production material presented for testing. Care

should be taken to ensure that the samples genuinely reflect the properties of the products to be tested.

Any sample preparation shall be in accordance with EN ISO 377.

Tests previously performed in accordance with the provisions of this standard (the same or more

technically demanding and appropriate test method, sampling procedure and system of attestation of

conformity) may be taken into account.

Initial type tests shall be repeated for the appropriate characteristic(s), whenever a change occurs in

the design of protected and sheathed strand, in the raw material or in the supplier of the components,

or in the production process (subject to the definition of a family), which would affect significantly one

or more of the characteristics.

Products marked in accordance with appropriate harmonized European specifications may be

presumed to have the performances stated with that marking, although this does not replace the

responsibility on the protected and sheathed strand designer to ensure that the protected and sheathed

strand as a whole is correctly designed and its component products have the necessary performance

values to meet the design.

Table 3 — Type and number of tests for the type testing

Base strand Case 1 – Integrated manufacturers

Certificate of constancy of performance of the product

according to prEN 10138-1 and prEN 10138-3 or

prEN 10337

Visual control “free of rust”

Case 2 – Manufacturers buying their base strand

Control of CE marking according to prEN 10138-1 and

prEN 10138-3 or prEN 10337

Visual control “free of rust”

Verification of the mechanical properties of For each supplier of base strand:

the protected and sheathed strands

a

- 5 tensile tests

a

- 1 relaxation test

a

- 1 fatigue test

Protection material Declaration of conformity with the support of test reports

for all properties listed in either Table A.1 or Table A.2 by

the supplier

Material for sheathing Declaration of conformity with the support of test reports

for all properties listed in Tables B.1 and B.2 by the supplier

Protection and sheath regular tests 5 tests per each diameter of protected and sheathed strand

(defined by the type i.e. S or A, the protection material i.e.

Overall diameter

grease or wax, the sheath thickness class i.e. T 1, T 2 or

n n

Straightness

T 3)

n

Mass of the protection product

Thickness of the sheath

Surface conditions and homogeneity

Protection and sheath other tests 1 test per diameter of protected and sheathed strands

(defined by the type i.e. S or A, the protection material i.e.

Water tightness

grease or wax, the sheath thickness class i.e. T 1, T 2 or

n n

Initial resistance to friction

T 3)

n

Impact resistance

Protection and sheath special tests 1 test per supplier’s combination (protection material +

sheath) independently of the type of protected and sheathed

Stress cracking resistance of the sheath

strand and sheath thickness class

Resistance to aggressive media

Sheath’s mechanical properties

Retention of the adherence (only type A)

Resistance to ionising radiation

Colour stability (other than black), where

required

Properties after exposure to temperature

a

These tests may be carried out on samples specially produced in the same manufacturing conditions without the

incorporation of the protection product.

8.2.3 Test reports

The results of the determination of the product type shall be documented in test reports. All test reports

shall be retained by the manufacturer for at least 10 years after the last date of production of the

protected and sheathed strands for prestressing to which they relate.

8.2.4 Shared other party results

A manufacturer may use the results of the product type determination obtained by someone else (e.g.

by another manufacturer, as a common service to manufacturers, or by a product developer), to justify

his own declaration of performance regarding a product that is manufactured according to the same

design (e.g. dimensions) and with raw materials, constituents and manufacturing methods of the same

kind, provided that:

— the results are known to be valid for products with the same essential characteristics relevant for

the product performance;

— in addition to any information essential for confirming that the product has such same

performances related to specific essential characteristics, the other party who has carried out the

determination of the product type concerned or has had it carried out, has expressly accepted to

transmit to the manufacturer the results and the test report to be used for the latter’s product type

determination, as well as information regarding production facilities and the production control

process that can be taken into account for FPC;

— the manufacturer using other party results accepts to remain responsible for the product having

the declared performances and he also:

— ensures that the product has the same characteristics relevant for performance as the one that

has been subjected to the determination of the product type, and that there are no significant

differences with regard to production facilities and the production control process compared

to that used for the product that was subjected to the determination of the product type; and

— keeps available a copy of the determination of the product type report that also contains the

information needed for verifying that the product is manufactured according to the same

design and with raw materials, constituents and manufacturing methods of the same kind.

8.3 Factory production control (FPC)

8.3.1 General

The manufacturer shall establish, document and maintain an FPC system to ensure that the products

placed on the market comply with the declared performance of the essential characteristics.

The FPC system shall consist of procedures, regular inspections and tests and/or assessments and the

use of the results to control raw and other incoming materials or components, equipment, the

production process and the product.

All the elements, requirements and provisions adopted by the manufacturer shall be documented in a

systematic manner in the form of written policies and procedures.

This factory production control system documentation shall ensure a common understanding of the

evaluation of the constancy of performance and enable the achievement of the required product

performances and the effective operation of the production control system to be checked. Factory

production control therefore brings together operational techniques and all measures allowing

maintenance and control of the compliance of the product with the declared performances of the

essential characteristics.

In case the manufacturer has used shared product type results, the FPC shall also include the

appropriate documentation as foreseen in 8.2.4.

8.3.2 Requirements

8.3.2.1 General

The manufacturer is responsible for organizing the effective implementation of the FPC system in line

with the content of this product standard. Tasks and responsibilities in the production control

organization shall be documented and this documentation shall be kept up-to-date.

The responsibility, authority and the relationship between personnel that manages, performs or verifies

work affecting product constancy, shall be defined. This applies in particular to personnel that need to

initiate actions preventing product non-constancies from occurring, actions in case of non-constancies

and to identify and register product constancy problems.

Personnel performing work affecting the constancy of performance of the product shall be competent

on the basis of appropriate education, training, skills and experience for which records shall be

maintained.

In each factory the manufacturer may delegate the action to a person having the necessary authority to:

— identify procedures to demonstrate constancy of performance of the product at appropriate stages;

— identify and record any instance of non-constancy;

— identify procedures to correct instances of non-constancy.

The manufacturer shall draw up and keep up-to-date documents defining the factory production

control. The manufacturer's documentation and procedures should be appropriate to the product and

manufacturing process. The FPC system should achieve an appropriate level of confidence in the

constancy of performance of the product. This involves:

a) the preparation of documented procedures and instructions relating to factory production control

operations, in accordance with the requirements of the technical specification to which reference is

made;

b) the effective implementation of these procedures and instructions;

c) the recording of these operations and their results;

d) the use of these results to correct any deviations, repair the effects of such deviations, treat any

resulting instances of non-conformity and, if necessary, revise the FPC to rectify the cause of non-

constancy of performance.

Where subcontracting takes place, the manufacturer shall retain the overall control of the product and

ensure that he receives all the information that is necessary to fulfil his responsibilities according to this

European standard.

If the manufacturer has part of the product designed, manufactured, assembled, packed, processed

and/or labelled by subcontracting, the FPC of the subcontractor may be taken into account, where

appropriate for the product in question.

The manufacturer who subcontracts all of his activities may in no circumstances pass the above

responsibilities on to a subcontractor.

NOTE Manufacturers having an FPC system, which complies with EN ISO 9001 standard and which addresses

the provisions of the present European standard are considered as satisfying the FPC requirements of the

Regulation (EU) No 305/2011.

8.3.2.2 Equipment

8.3.2.2.1 Testing

All weighing, measuring and testing equipment shall be calibrated and regularly inspected according to

documented procedures, frequencies and criteria.

8.3.2.2.2 Manufacturing

All equipment used in the manufacturing process shall be regularly inspected and maintained to ensure

that use, wear or failure does not cause inconsistency in the manufacturing process. Inspections and

maintenance shall be carried out and recorded in accordance with the manufacturer’s written

procedures and the records retained for the period defined in the manufacturer's FPC procedures.

8.3.2.3 Raw materials and components

The specifications of all incoming raw materials and components shall be documented, as shall the

inspection scheme for ensuring their compliance. In case supplied kit components are used, the

constancy of performance system of the component shall be that given in the appropriate harmonized

technical specification for that component.

8.3.2.4 Traceability and marking

Individual coils of protected and sheathed strand shall be identifiable and traceable with regard to their

production origin. The manufacturer shall have written procedures ensuring that processes related to

affixing traceability codes and/or markings are inspected regularly.

8.3.2.5 Controls during manufacturing process

The manufacturer shall plan and carry out production under controlled conditions.

8.3.2.6 Product testing and evaluation

8.3.2.6.1 Unit of product and unit of inspection

The unit of product is the coil of strand as delivered to the customer.

The unit of inspection shall be composed of a maximum of 50 tonnes of protected and sheathed strands

of the same type (S or A) and diameter produced from the same constituent materials according to the

same manufacturing conditions in a period not exceeding 7 days.

8.3.2.6.2 Frequency of sampling and inspection for factory production control

The protected and sheathed strands shall be sampled and tested in accordance with Table 3.

Table 4 — Sampling and testing frequency for factory production control of protected

and sheathed strands

Base strand According to prEN 10138-1 and

prEN 10138-3 or prEN 10337

Mechanical and technological properties

(prestressing steel strand manufacturers

Surface conditions (free of rust)

holding a certificate of constancy of the

performance of the product) or CE

marking

Every unit of manufacture or unit of

inspection according to prEN 10138-1

and prEN 10138-3 or prEN 10337

Protection material Grease

Inspection certificate 3.1 including results

for the following properties: aspect, cone

penetration, dropping point, chemical

signature, by the supplier for each batch

Wax

Inspection certificate 3.1 including results

for the following properties: aspect, cone

penetration, dropping point, chemical

signature, by the supplier for each batch

Material for sheathing Declaration of conformity to the

properties specified in Tables B.1 and B.2

by the supplier for each batch

Protection and sheath regular tests One test per unit of product

Overall diameter

Straightness

Mass of the protection product

Thickness of the sheath

Surface conditions

Protection and sheath other tests One test per unit of inspection

Initial resistance to friction One test every 20 units of inspection with

a minimum of one test every 6 months

Water tightness and impact resistance

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...