prEN 10370

(Main)Steel for the reinforcement of concrete - Stainless steel

Steel for the reinforcement of concrete - Stainless steel

This document specifies product characteristic test/assessment method and the way of expressing test results for stainless steel as defined in EN 10088-1:2014 and designated as in EN 10088-1:2014 for the use of the reinforcement of concrete.

It applies to stainless steel products with ribbed or indented surfaces, which are in the form of:

- bars and coils (rod, wire);

- sheets of factory-made machine-welded fabric;

- lattice girders and hybrid lattice girders composed by stainless steel and by weldable reinforcing steel according to prEN 10080:2023.

Steels according to this document have a ribbed, indented or smooth surface.

NOTE The protrusions between indentations of indented reinforcing steel have the same function as transverse ribs of ribbed reinforcing steel. There is no definition, which specifies the difference between ribbed and indented surface geometry. Therefore, in this document, the same bond parameters are used for ribbed and indented steel.

This document does not apply to:

- pre-stressed stainless steels;

- indented strip;

- stainless steel tube filled with carbon steel swarf, which is then hot or cold reduced;

- stainless steel smooth bar with weld material deposited on it;

- galvanized reinforcing steel;

- epoxy-coated reinforcing steel.

Stahl für die Bewehrung von Beton - Nichtrostender Stahl

Diese Europäische Norm legt Leistungsmerkmale, Prüfung/Bewertung von Prüfergebnissen von nichtrostendem Stahl definiert und bezeichnet nach EN 10088-1:2014 fest, der für die Bewehrung von Betonbauwerken verwendet wird.

Die Stahlerzeugnisse haben eine gerippte oder profilierte Oberfläche und werden geliefert in Form von:

- Stäben, Ringen (Walzdraht, Draht);

- werkmäßig gefertigten maschinell geschweißten Matten;

- Gitterträgern und hybriden Gitterträgern, hergestellt aus nichtrostendem Stahl und Schweißgeeignetem Betonstahl nach prEN 10080:2023.

Stähle nach dieser Europäischen Norm haben eine gerippte, profilierte oder glatte Oberfläche.

ANMERKUNG Die Erhebungen zwischen zwei Vertiefungen bei profiliertem Betonstahl haben die gleichen Funktionen wie die Schrägrippen bei geripptem Betonstahl. Daher gibt es keine Sonderdefinition mit dem Unterschied der geometrischen Merkmale zwischen dem gerippten und profilierten Betonstahl. Die in dieser Norm enthaltenen Festlegungen für den Verbund gelten für gerippten und profilierten Betonstahl.

Diese Europäische Norm gilt nicht für:

- nichtrostende Stähle für Vorspannen;

- profiliertes Band;

- nichtrostende Stahlrohre gefüllt mit unlegiertem Stahl, anschließend warm- oder kalt abgelängt;

- geschweißte nichtrostende Stäbe aus Stahl mit glatter Oberfläche;

- verzinkten Betonstahl;

- epoxidbeschichteten Betonstahl.

Aciers pour béton armé - Aciers inoxydables

Le présent document spécifie les caractéristiques des produits, la méthode d’essai et d’évaluation ainsi que le mode d’expression des résultats de l’essai, pour les aciers inoxydables tels que définis dans l’EN 10088-1:2014 et désignés comme indiqué dans l’EN 10088-1:2014 pour l’utilisation du béton armé.

Il s’applique aux produits en acier inoxydable présentant une surface avec des verrous ou des empreintes sous la forme de :

- barres et couronnes (fil machine, fil) ;

- panneaux de treillis soudés sur machine, fabriqués en usine ;

- treillis raidisseurs et treillis raidisseurs hybrides composés d’aciers inoxydables et d’aciers soudables pour béton armé conformément au prEN 10080:2023.

Les aciers conformes au présent document ont une surface à verrous, à empreintes ou lisse.

NOTE Les reliefs entre les empreintes d’un acier pour béton armé à empreintes ont la même fonction que les verrous d’un acier pour béton armé à verrous. Il n’existe pas de définition qui précise la différence entre une géométrie de surface à verrous et une géométrie de surface à empreintes. Par conséquent, dans le présent document, les mêmes paramètres de liaison sont utilisés pour un acier à verrous et un acier à empreintes.

Le présent document ne s’applique pas :

- aux armatures de précontrainte en acier ;

- aux feuillards crantés ;

- aux tubes d’acier inoxydable remplis de copeaux d’acier au carbone, qui sont ensuite réduits à chaud ou à froid ;

- aux barres d’acier inoxydable lisses avec matériau soudé déposé dessus ;

- aux aciers pour béton armé galvanisés ;

- aux aciers pour béton armé avec revêtement époxy.

Jeklo za armiranje betona - Nerjavno jeklo

General Information

- Status

- Not Published

- Publication Date

- 13-May-2024

- Technical Committee

- ECISS/TC 104 - Concrete reinforcing and prestressing steels

- Drafting Committee

- CEN/TC 459/SC 4/WG 3 - Corrosion resistant reinforcing steels

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 20-Jul-2023

- Due Date

- 21-Mar-2023

- Completion Date

- 20-Jul-2023

Overview

prEN 10370 - Steel for the reinforcement of concrete - Stainless steel (CEN draft) defines how stainless steels specified in EN 10088‑1:2014 are tested, assessed and declared when used as reinforcement in concrete. The standard covers stainless bars and coils (rod, wire), factory‑made machine‑welded fabric, lattice girders, and hybrid lattice girders combining stainless and weldable reinforcing steel (per prEN 10080:2023). Surface types include ribbed, indented or smooth profiles; ribbed and indented geometries use the same bond parameters. The document also sets out exclusions (for example, pre‑stressed stainless steels, indented strip, certain composite tubes, galvanized or epoxy‑coated reinforcing steel).

Key Topics and Requirements

- Product scope and definitions linked to EN 10088‑1:2014 designations.

- Essential characteristics: mechanical properties (tensile strength, Rp0.2 / 0.2% proof strength, elongation), weldability, bendability, bond strength to concrete, shear performance of welded fabric and lattice girders, cyclic load and fatigue behaviour, strength at elevated temperature, and durability.

- Bonding: parameters based on surface geometry and bond test methods for ribbed/indented/smooth steel.

- Test methods: procedures for tensile tests, bend/weldability checks, bond and shear tests, fatigue/cyclic tests, corrosion/durability assessments (informative annexes provide corrosion test and durability guidance).

- Assessment and Verification of Constancy of Performance (AVCP): product type testing, factory production control (FPC), initial inspection, continuous surveillance and audit testing.

- Classification, designation and identification requirements for bars, coils, welded fabric and lattice girders, plus delivery and manufacturing conditions.

- Informative annexes include lattice girder test methods, corrosion tests, welding guidance, non‑magnetic/thermal properties, and design guidance (links to EN 1992/Eurocode 2).

Applications and Who Uses It

prEN 10370 is intended for:

- Structural and geotechnical engineers specifying stainless steel reinforcement for high‑durability or corrosive environments (marine, chemical plants, tunnels, bridges, coastal and infrastructure works).

- Steel manufacturers, fabricators and suppliers producing stainless reinforcing bars, welded fabric and lattice systems.

- Construction contractors, precast manufacturers and reinforcement installers who require standardized identification, testing and quality control.

- Testing laboratories and conformity assessment bodies implementing AVCP, FPC and product‑type testing.

- Standards committees and procurement officials referencing harmonized test/assessment methods.

Related Standards

- EN 10088‑1:2014 - stainless steel definitions and designations (referenced).

- prEN 10080:2023 - weldable reinforcing steel (for hybrid lattice girders).

- EN 1992 (Eurocode 2) - referenced in annexes for symbols and design integration.

Keywords: prEN 10370, stainless steel reinforcement, ribbed reinforcing steel, bond strength, welded fabric, lattice girders, AVCP, FPC, corrosion resistance, EN 10088‑1.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

prEN 10370 is a draft published by the European Committee for Standardization (CEN). Its full title is "Steel for the reinforcement of concrete - Stainless steel". This standard covers: This document specifies product characteristic test/assessment method and the way of expressing test results for stainless steel as defined in EN 10088-1:2014 and designated as in EN 10088-1:2014 for the use of the reinforcement of concrete. It applies to stainless steel products with ribbed or indented surfaces, which are in the form of: - bars and coils (rod, wire); - sheets of factory-made machine-welded fabric; - lattice girders and hybrid lattice girders composed by stainless steel and by weldable reinforcing steel according to prEN 10080:2023. Steels according to this document have a ribbed, indented or smooth surface. NOTE The protrusions between indentations of indented reinforcing steel have the same function as transverse ribs of ribbed reinforcing steel. There is no definition, which specifies the difference between ribbed and indented surface geometry. Therefore, in this document, the same bond parameters are used for ribbed and indented steel. This document does not apply to: - pre-stressed stainless steels; - indented strip; - stainless steel tube filled with carbon steel swarf, which is then hot or cold reduced; - stainless steel smooth bar with weld material deposited on it; - galvanized reinforcing steel; - epoxy-coated reinforcing steel.

This document specifies product characteristic test/assessment method and the way of expressing test results for stainless steel as defined in EN 10088-1:2014 and designated as in EN 10088-1:2014 for the use of the reinforcement of concrete. It applies to stainless steel products with ribbed or indented surfaces, which are in the form of: - bars and coils (rod, wire); - sheets of factory-made machine-welded fabric; - lattice girders and hybrid lattice girders composed by stainless steel and by weldable reinforcing steel according to prEN 10080:2023. Steels according to this document have a ribbed, indented or smooth surface. NOTE The protrusions between indentations of indented reinforcing steel have the same function as transverse ribs of ribbed reinforcing steel. There is no definition, which specifies the difference between ribbed and indented surface geometry. Therefore, in this document, the same bond parameters are used for ribbed and indented steel. This document does not apply to: - pre-stressed stainless steels; - indented strip; - stainless steel tube filled with carbon steel swarf, which is then hot or cold reduced; - stainless steel smooth bar with weld material deposited on it; - galvanized reinforcing steel; - epoxy-coated reinforcing steel.

prEN 10370 is classified under the following ICS (International Classification for Standards) categories: 77.140.15 - Steels for reinforcement of concrete. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 10370 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/115 REV. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 10370 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2023

Jeklo za armiranje betona - Nerjavno jeklo

Steel for the reinforcement of concrete - Stainless steel

Stahl für die Bewehrung von Beton - Nichtrostender Stahl

Aciers pour béton armé - Aciers inoxydables

Ta slovenski standard je istoveten z: prEN 10370

ICS:

77.140.15 Jekla za armiranje betona Steels for reinforcement of

concrete

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2023

ICS 77.140.15

English Version

Steel for the reinforcement of concrete - Stainless steel

Aciers pour l'armature du béton - Aciers inoxydables Stahl für die Bewehrung von Beton - Nichtrostender

Stahl

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 459/SC 4.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 10370:2023 E

worldwide for CEN national Members.

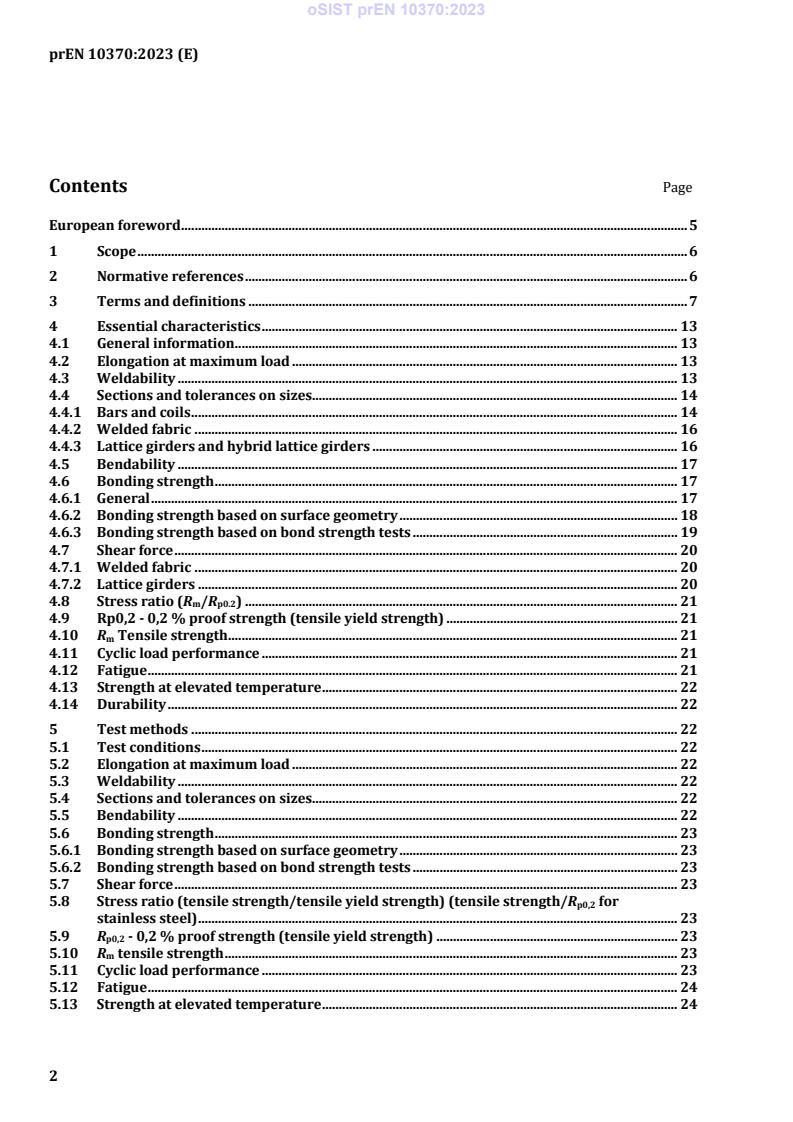

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Essential characteristics . 13

4.1 General information . 13

4.2 Elongation at maximum load . 13

4.3 Weldability . 13

4.4 Sections and tolerances on sizes. 14

4.4.1 Bars and coils . 14

4.4.2 Welded fabric . 16

4.4.3 Lattice girders and hybrid lattice girders . 16

4.5 Bendability . 17

4.6 Bonding strength . 17

4.6.1 General . 17

4.6.2 Bonding strength based on surface geometry . 18

4.6.3 Bonding strength based on bond strength tests . 19

4.7 Shear force . 20

4.7.1 Welded fabric . 20

4.7.2 Lattice girders . 20

4.8 Stress ratio (R /R ) . 21

m p0.2

4.9 Rp0,2 - 0,2 % proof strength (tensile yield strength) . 21

4.10 R Tensile strength . 21

m

4.11 Cyclic load performance . 21

4.12 Fatigue . 21

4.13 Strength at elevated temperature . 22

4.14 Durability . 22

5 Test methods . 22

5.1 Test conditions . 22

5.2 Elongation at maximum load . 22

5.3 Weldability . 22

5.4 Sections and tolerances on sizes. 22

5.5 Bendability . 22

5.6 Bonding strength . 23

5.6.1 Bonding strength based on surface geometry . 23

5.6.2 Bonding strength based on bond strength tests . 23

5.7 Shear force . 23

5.8 Stress ratio (tensile strength/tensile yield strength) (tensile strength/R for

p0,2

stainless steel) . 23

5.9 R - 0,2 % proof strength (tensile yield strength) . 23

p0,2

5.10 R tensile strength . 23

m

5.11 Cyclic load performance . 23

5.12 Fatigue . 24

5.13 Strength at elevated temperature . 24

5.14 Durability. 24

6 Assessment and verification of constancy of performance (AVCP) . 24

6.1 General . 24

6.2 Product type testing . 24

6.2.1 General . 24

6.2.2 Test samples, testing and compliance criteria . 25

6.2.3 Compliance criteria . 32

6.2.4 Re-testing . 33

6.2.5 Test report . 34

6.3 Factory production control (FPC) . 34

6.3.1 General . 34

6.3.2 Requirements . 34

6.4 Initial inspection of factory and of factory production control (FPC) . 42

6.5 Continuous surveillance of FPC . 42

6.5.1 General . 42

6.5.2 Audit testing of samples taken from the factory . 43

6.5.3 Evaluation, reporting and action . 47

6.6 Procedure for modifications . 49

7 Classification and designation . 49

7.1 Bars and coils . 49

7.2 Welded fabric . 49

7.3 Lattice girders and hybrid lattice girders . 50

8 Identification of the manufacturer and the product . 53

8.1 General . 53

8.2 Bar . 54

8.2.1 Identification of the manufacturer . 54

8.2.2 Identification of the product . 56

8.3 Coil . 57

8.4 Welded fabric . 58

8.5 Lattice girders . 58

9 Manufacturing process and delivery conditions . 58

9.1 Steelmaking and manufacturing processes . 58

9.2 Delivery conditions . 58

9.2.1 Chemically and/or mechanically descaled . 58

9.2.2 Not descaled . 59

Annex A (informative) Examples of weld points in lattice girder joints . 60

Annex B (normative) Test methods for lattice girders . 61

B.1 General . 61

B.2 Measurement of the dimensions of the lattice girder . 61

B.3 Shear test . 61

B.4 Test apparatus . 64

Annex C (informative) Guidance on durability . 66

C.1 General . 66

C.2 Terminology . 67

C.3 Prescriptive guidance . 67

C.4 Performance guidance . 68

Annex D (informative) Corrosion Test Method . 72

D.1 Scope . 72

D.2 Materials . 72

D.3 Specimens . 72

D.4 Testing procedure . 74

D.5 Test results . 74

D.6 Final evaluation criteria . 74

D.7 Test report . 75

Annex E (informative) Guidance on welding procedures, non-magnetic properties and

thermal expansion . 76

E.1 Welding procedures . 76

E.2 Guidance on non-magnetic properties . 77

E.3 Guidance on thermal expansion and other physical properties . 77

Annex F (informative) Comparison of symbols used in this European Standard with those

used in EN 1992-1-1 and EN 1992-1-2 . 78

Annex G (informative) Design guidance: constitutive relationship . 79

G.1 Background . 79

G.2 Recommendations . 80

Annex H (normative) Bond test for ribbed and indented reinforcing steel – Beam test . 81

H.1 Scope . 81

H.2 Principle of the test . 81

H.3 Samples and specimens . 81

H.4 Test equipment . 82

H.5 Preparation of samples . 83

H.6 Execution of the tests . 84

H.7 Test results . 84

H.8 Test report . 85

H.9 Determination of declared values for τ and τ and rib geometry requirements for

bm bu

FPC and continuous surveillance . 86

Annex ZA (informative) Relationship of this European Standard with Regulation (EU) No

305/2011 . 91

ZA.1 Scope and relevant characteristics . 91

ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) of

reinforcing steels . 92

ZA.3 Assignment of AVCP tasks . 92

Bibliography . 94

European foreword

This document (prEN 10370:2023) has been prepared by Technical Committee CEN/TC 459 “ECISS -

European Committee for Iron and Steel Standardization” , the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

Through its sub-committee SC 4 “Concrete reinforcing and prestressing steels” (secretariat: DIN)

1 Scope

This document specifies product characteristic test/assessment method and the way of expressing test

results for stainless steel as defined in EN 10088-1:2014 and designated as in EN 10088-1:2014 for the

use of the reinforcement of concrete.

It applies to stainless steel products with ribbed or indented surfaces, which are in the form of:

— bars and coils (rod, wire);

— sheets of factory-made machine-welded fabric;

— lattice girders and hybrid lattice girders composed by stainless steel and by weldable reinforcing

steel according to prEN 10080:2023.

Steels according to this document have a ribbed, indented or smooth surface.

NOTE The protrusions between indentations of indented reinforcing steel have the same function as

transverse ribs of ribbed reinforcing steel. There is no definition, which specifies the difference between ribbed and

indented surface geometry. Therefore, in this document, the same bond parameters are used for ribbed and

indented steel.

This document does not apply to:

— pre-stressed stainless steels;

— indented strip;

— stainless steel tube filled with carbon steel swarf, which is then hot or cold reduced;

— stainless steel smooth bar with weld material deposited on it;

— galvanized reinforcing steel;

— epoxy-coated reinforcing steel.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1766:2017, Products and systems for the protection and repair of concrete structures — Test methods

— Reference concretes for testing

EN 10020:2000, Definition and classification of grades of steel

EN 10079:2007, Definition of steel products

EN 10088-1:2014, Stainless steels — Part 1: List of stainless steels

EN 12390-3:2019, Testing hardened concrete — Part 3: Compressive strength of test specimens

EN ISO 377:2017, Steel and steel products — Location and preparation of samples and test pieces for

mechanical testing (ISO 377:2017)

EN ISO 6892-2:2018, Metallic materials — Tensile testing — Part 2: Method of test at elevated temperature

(ISO 6892-2:2018)

EN ISO 7500-1:2018, Metallic materials — Calibration and verification of static uniaxial testing machines

— Part 1: Tension/compression testing machines — Calibration and verification of the force-measuring

system (ISO 7500-1:2018)

EN ISO 15630-1:2019, Steel for the reinforcement and prestressing of concrete — Test methods — Part 1:

Reinforcing bars, rods and wire (ISO 15630-1:2019)

EN ISO 15630-2:2019, Steel for the reinforcement and prestressing of concrete — Test methods — Part 2:

Welded fabric and lattice girders (ISO 15630-2:2019)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 10020:2000, EN 10079:2007

and the following apply.

3.1

7% strength

strength at 7% total elongation, R

7.0

3.2

angle of inclination of diagonals, ϑ

angle between the axis of a diagonal and the longitudinal axis of a lattice girder in the plane of the diagonal

in the middle of the height of a lattice girder

3.3

angle of transverse rib or indentation inclination, ß

angle between the axis of the transverse rib and the longitudinal axis of the bar, rod or wire

3.4

batch

quantity of rebars, processed from an identical heat or cast, size or alloy, processed in the same

production lot, in the same process conditions or any quantity of welded fabric or lattice girders of one

type produced by one manufacturer and presented for examination at any one time

3.5

characteristic value C

v

value of a material or product property having a prescribed probability of not being attained in a

hypothetical unlimited test series

Note 1 to entry: This value generally corresponds to a specific fractile of the assumed statistical distribution of

the particular property of the material or product.

3.6

coil

single length of reinforcing steel wound in concentric rings, including coils welded together to produce a

single coiled length

3.7

design height of a lattice girder, H

distance between the lowest point of the lower chord and the highest point of the upper chord

3.8

design width of a lattice girder, B

distance between the outlying points of the lower chords

3.9

hybrid lattice girder

lattice girder where the metallic structure is composed of both stainless steel used for the reinforcement

of concrete and weldable reinforcing steel.

Note 1 to entry: For hybrid lattice girders, the same definitions apply as for lattice girders.

3.10

indented reinforcing steel

reinforcing steel with defined indentations uniformly distributed over the entire length

3.11

indentation depth, t

distance between the surface of the wire and the deepest point of the indentation

3.12

indentation width, b

width of the indention to be measured parallel to the axis of the bar, rod or wire

3.13

lattice girder

two or three-dimensional metallic structure comprising an upper chord, one or more lower chords and

continuous or discontinuous diagonals which are welded or mechanically assembled to the chords

3.14

lattice girder length, L

lg

overall length of a lattice girder

3.15

lattice girder overhang, u ,u

1 2

length of the diagonals beyond either the upper chord (u1) or the lower chord (u2)

3.16

length of a welded fabric sheet, L

wf

dimension of the longest side of a sheet of welded fabric, irrespective of the manufacturing direction

3.17

longitudinal rib

uniform continuous protrusion parallel to the axis of the bar, rod or wire

3.18

longitudinal wire

reinforcing steel in the manufacturing direction of the welded fabric

3.19

lower chord

set of longitudinal reinforcing steels placed in the lower part of a lattice girder

Note 1 to entry: They form harmonic curves in the case of continuous diagonals or are independent elements in

the case of discontinuous diagonals.

3.20

minimum value

value below which no test result shall fall

3.21

maximum value

value which no test result shall exceed

3.22

nominal cross-sectional area, A

n

cross-sectional area equivalent to the area of a circular plain bar of the same nominal diameter,

nd

nom

d ie. .

nom

3.23

overall height of a lattice girder, H

distance between the lowest point and the highest point of a lattice girder

3.24

overall width of a lattice girder, B

distance between the outlying points of a lattice girder

3.25

overhang of welded fabric, u1, u2, u3, u4

length of longitudinal or transverse wires projecting beyond the centre of the outer crossing wire in a

sheet of welded fabric

3.26

pitch of diagonals, P

s

distance between equivalent consecutive junction points of the diagonals with the chords

3.27

pitch of welded fabric

centre-to-centre distance of wires in a sheet of welded fabric

3.28

production lot

an uninterrupted period of production

3.29

purpose made lattice girder

lattice girder manufactured according to user's specific requirements

3.30

purpose made welded fabric

welded fabric manufactured according to user's specific requirements

3.31

reinforcing steel

steel product with a circular or practically circular cross-section which is suitable for the reinforcement

of concrete

3.32

relative indentation area f

P

area of the projection of all indentations on a plane perpendicular to the longitudinal axis of the bar, rod

or wire, divided by the indentation spacing and the nominal circumference

3.33

relative rib area, f

R

area of the projection of all ribs on a plane perpendicular to the longitudinal axis of the bar, rod or wire,

divided by the rib spacing and the nominal circumference

3.34

ribbed reinforcing steel

reinforcing steel with at least two rows of transverse ribs, which are uniformly distributed over the entire

length

3.35

rib height h

distance from the highest point of the rib (transverse or longitudinal) to the surface of the core, to be

measured normal to the axis of the bar, rod or wire

3.36

rib or indentation spacing, c

distance between the centres of two consecutive transverse ribs measured parallel to the axis of the bar,

rod or wire

3.37

semi-finished product

ribbed or indented product which requires further processing in order to achieve the standard and

special properties specified in this document for reinforcing steels

3.38

special property

property contained in this document which is not determined as part of the factory production control

requirements for every test unit

3.39

standard lattice girder

lattice girder manufactured according to specified delivery conditions and available from stock

3.40

standard property

property which is contained in this document as part of the factory production control requirements for

every test unit

3.41

standard welded fabric

welded fabric manufactured according to specified delivery conditions and available from stock

3.42

transverse rib

any rib on the surface of the bar, rod or wire other than a longitudinal rib

3.43

transverse rib flank inclination, α

angle of the rib flank measured perpendicular to the longitudinal axis of the rib

3.44

transverse wire

reinforcing steel perpendicular to the manufacturing direction of the welded fabric

3.45

welded fabric

arrangement of longitudinal and transverse bars, rods or wires of the same or different nominal diameter

and length that are arranged substantially at right angles to each other and factory electrical resistance

welded together by automatic machines at all points of intersection

3.46

width of a welded fabric sheet, B

dimension of the shortest side of the sheet of welded fabric, irrespective of the manufacturing direction

3.47

bar

product of plain round or ribbed cross-section

Note 1 to entry: Symbols, unit and abbreviated terms used in this European Standard are listed in Table 1.

Note 2 to entry: For comparison of symbols used in this European Standard with those used in EN 1992-1-1 and

EN 1992-1-2 see Annex F.

Table 1 — Symbols, unit and abbreviated terms

Symbol Description Unit

a

x Average value of test results

α Transverse rib flank inclination °

ϑ Inclination of the diagonals in lattice girder or in hybrid lattice girder °

a

a1, a2, a3, a4 Increment (specified in the product specification)

ACh Cross-sectional area of chord mm

A Cross-sectional area of diagonal mm

Di

Agt Percentage total elongation at maximum force %

A Nominal cross-sectional area mm

n

b Width of indentation mm

B Length of transverse wire in welded fabric mm

B Design width of lattice girder or hybrid lattice girder mm

B2 Overall width of lattice girder or hybrid lattice girder mm

c Transverse rib or indentation spacing mm

Cv Specified characteristic value

d Nominal diameter of the reinforcing steel mm

nom

dC Diameter of transverse wires in welded fabric mm

Symbol Description Unit

d Diameter of longitudinal wires in welded fabric mm

L

e Gap between rib or indentation rows mm

b

E Young’s modulus MPa

Fd Shear force of a clamped joint in lattice girder or hybrid lattice girder kN

f Relative indentation area -

P

fR Relative rib area -

F Shear force of a single weld in lattice girder or hybrid lattice girder kN

w

h Rib height mm

H Design height of lattice girder or hybrid lattice girder mm

H2 Overall height of lattice girder or hybrid lattice girder mm

k Coefficient as a function of the number of test results -

Llg Length of lattice girder or hybrid lattice girder mm

L Length of longitudinal wire in welded fabric mm

wf

NC Number of transverse wires in welded fabric -

N Number of longitudinal wires in welded fabric -

L

PC Pitch of transverse wires in welded fabric mm

P Pitch of longitudinal wires in welded fabric mm

L

Ps Pitch of diagonals of lattice girder or hybrid lattice girder mm

b

R7.0 strength at 7 % total elongation MPa

b

R Tensile strength MPa

m

Rm/Rp0.2 Ratio tensile strength/0,2 % proof strength -

b

R 0,2 % proof strength (tensile yield strength) MPa

p0,2

b

Rp0.2act Actual value of 0,2 % proof strength MPa

R /R Ratio actual value of 0,2 % proof strength/specified value of 0,2 % proof strength -

p0.2act p0.2nom

b

Rp0.2Ch 0,2 % proof strength of the chord in lattice girder or in hybrid lattice grider MPa

b

R 0,2 % proof strength of the diagonal in lattice girder or in hybrid lattice girder MPa

p0.2Di

b

Rp0.2nom Specified value of 0,2 % proof strength MPa

a

s Estimate of the standard deviation

ß Angle of transverse rib or indentation inclination °

t Depth of indentation mm

Overhang of the longitudinal wires in welded fabric or length of the diagonals beyond

u1, u2 mm

the upper or lower chord of a lattice girder or hybrid lattice girder

u3, u4 Overhang of the transverse wires in welded fabric mm

a

The unit depends on the property.

b 2

1 MPa = 1 N/mm .

4 Essential characteristics

4.1 General information

Table 2, for information only, summarizes the tensile product characteristics of the voluntary standards,

national regulations and Eurocodes in force in the European countries.

Table 2 — Tensile properties (informative)

Properties Ductility Classes

A B C

Characteristic value of

a, b

0,2 % Proof Strength R 400 to 750

p0,2

[MPa]

Characteristic values of

Ratio tensile strength ≥ 1,15

≥ 1,05 ≥ 1,08

c

0,2 % Proof Strength ˂1,35

Rm/Rp0,2

Characteristic values of

Elongation at maximum ≥ 2,5 ≥ 5,0 ≥ 7,5

load A (%)

gt

a

In EN 1992-1-1 the minimum prof strength range is 400 ÷ 700 [MPa]

b

In EN 1992-1-1 the maximum actual proof stress Rp0.2, shall not exceed (1,3 x Rp0.2), where Rp0.2 is the

characteristic value.

c

In the case of austenitic and duplex stainless steels, because of their specific stress-strain constitutive

relationship, the ratio is calculated by using the value of R7.0 instead of Rm.

In this standard, the specified values for the tensile properties (R , R , R / R , A ,) shall be the

m p0.2 m p0.2 gt

corresponding specified characteristic value with p = 95 % for R and R , and p = 90 % for A , R / R .

m p0.2 gt m p0.2

The values R and R shall be calculated using the nominal cross-sectional area of the product.

p0.2 m

For stainless steel the 0,2 % proof strength (R ) shall be assumed as the tensile yield strength

p0.2

4.2 Elongation at maximum load

The elongation at maximum load (A %) is determined according to 5.2. The determined characteristic

gt

value for elongation at maximum load shall be the lower limit (fractile p) of the confidence interval at

which there is a 90 % probability (1 - α = 0, 90) that 90 % (p = 0,90) of the individual measured values

are at or above this lower limit with at least A (%) ≥ 2,5 %. This definition refers to the long-term quality

gt

level of production. The declared performance is the corresponding specified characteristic value.

4.3 Weldability

The weldability of stainless steel for the reinforcement of concrete is a function of the chemical

composition and determined according to 5.3. The list of the stainless steel designations is given in

EN 10088-1:2014 (see examples in Table 3). For each designated chemical composition according to

EN 10088-1:2014 each individual element shall comply with the specified maximum values. The declared

performance is the steel class designated according to EN 10088-1:2014.

The chemical compositions of the stainless steel used for the reinforcement of concrete are listed in the

relevant Tables of EN 10088-1:2014.

Table 3 — List of the stainless steels mostly used for the reinforcement of concrete

Steel Designation

Steel number Steel name

1.4003 X2CrNi12

1.4062 X2CrNi22-2

1.4162 X2CrMnNiN21-5-1

1.4301 X5CrNi18-10

1.4311 X2CrNiN18-10

1.4315 X5CrNiN19-9

1.4401 X5CrNiMo17-12-2

1.4406 X2CrNiMoN17-11-2

1.4362 X2CrNiN23-4

1.4429 X2CrNiMoN17-13-3

1.4436 X3CrNiMo17-13-3

1.4462 X2CrNiMoN22-5-3

1.4482 X2CrMnNiMoN21-5-3

1.4571 X6CrNiMoTi17-12-2

NOTE 1 Stainless steel selection for suitability to the application involved by agreement between the

manufacturer and the purchaser is an important consideration in achieving the desired corrosion resistance or

controlled magnetic permeability, or both, because these properties are not provided by all stainless steels.

NOTE 2 Annex E contains guidance on welding procedures.

4.4 Sections and tolerances on sizes

4.4.1 Bars and coils

The nominal diameters, the cross-sectional area and the deviation Δm (%) of the measured mass per

meter from nominal mass per meter shall be determined according to 5.4. The declared performance is

the minimum and maximum value for the deviation of measured mass per meter Δm [%] from nominal

mass per meter complying at least with the ranges specified in Table 4.

The nominal length of bars shall be agreed at the time of enquiry and order. The permissible deviation

from the nominal length shall be agreed at the time of enquiry and order.

The nominal coil mass shall be agreed at the time of enquiry and order. The permissible deviation from

the nominal coil mass shall be agreed at the time of enquiry and order.

Table 4 — Nominal diameters and the cross-sectional area and tolerances on mass per meter

run

Tolerances on mass per

a

Nominal diameter Nominal cross-sectional area

metre run

(mm) (mm )

Δm %

3 7,1

4 12,6

4,5 15,9

5 19,6 ±9,0

5,5 23,8

6 28,3

6,5 33,2

7 38,5

7,5 44,2

8 50,3

8,5 56,7

9 63,6 ±6,0

9,5 70,9

10 78,5

11 95,0

12 113,1

14 153,9

16 201,1

20 314,2

22 380,0

24 452,4

25 490,9

26 530,7

28 615,8

±4,5

30 706,9

32 804,2

34 907,9

35 962,1

40 1256,6

43 1452,2

50 1963,5

63,5 3166,9

Tolerances on mass per

a

Nominal diameter Nominal cross-sectional area

metre run

(mm) (mm )

Δm %

a

On the base of the nominal diameter the nominal mass per meter (Mpm) can be calculated with the

following formula:

d

ρ

nom

M ×π×

pm

2 1000

where:

M is the mass per meter in kg

pm

dnom is the nominal diameter in mm

ρ is the material density in kg/dm as reported in EN 10088-1:2014.

4.4.2 Welded fabric

The declared performance is the range of maximum deviation from the nominal values:

— Maximum deviation from nominal length Δl [mm or %]. The permitted deviation is ±25 mm

or ±0,5 % whichever is greater;

— Maximum deviation from nominal width Δw [mm or %]. The permitted deviation is ±25 mm

or ±0,5 % whichever is greater;

— Maximum deviation from nominal pitch Δp [mm or %]. The permitted deviation is ±15 mm or ±7,5 %

whichever is greater. The pitch of longitudinal wires and transverse wires shall not be less than

50 mm. The centre-to-centre distance for double bars shall be at least 100 mm;

— Maximum deviation from nominal overhang Δo [mm or %]. The overhang should not be less than

25 mm.

Tolerances in the separation of wires/bars should not under any circumstances lead to a reduction in the

number of wires/bars in the specified welded fabric.

4.4.3 Lattice girders and hybrid lattice girders

The declared performance is the range of maximum deviation from the nominal values:

— Maximum deviation from nominal length ΔL [mm or %]. The permitted deviations for the lattice

girders are ±40 mm if L ≤ 5,0 m and ±0,8 %, if L > 5,0 m;

— Maximum deviation from nominal height ΔH1 and ΔH2 [mm]. The permitted deviations for the lattice

girders are 〖_(−3)^(+1)〗 mm;

— Maximum deviation from nominal width ΔB1 and ΔB2 [mm]. The permitted deviations for the lattice

girders are ±7,5 mm;

— Maximum deviation from nominal pitch ΔPs [mm]. The permitted deviations for the lattice girders

are ±2,5 mm;

— Maximum overhang: may be agreed at the time of enquiry and order.

=

4.5 Bendability

Bendability is determined by bend tests according to 5.5 with mandrel diameters no greater than those

specified in Table 5.

The declared performance is the maximum mandrel diameter d fulfilled for the specified number of

m,max

individual tests not exceeding the maximum values specified in Table 5.

Table 5 — Mandrel diameter for the bend test

Nominal diameter o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...