EN 18035:2025

(Main)Prestressing steels - Waxed and sheathed strands for construction applications

Prestressing steels - Waxed and sheathed strands for construction applications

This document specifies the requirements for uncoated high strength steel strands of zinc or zinc alloy coated high strength steel strands, encapsulated with wax and a sheath for construction applications.

The document applies only to products as supplied by the manufacturer.

Spannstähle - Gewachste und gehüllte Litze für Bauanwendungen

Dieses Dokument legt die allgemeinen Anforderungen für unbeschichtete oder zink- oder zinklegierungsbeschichtete hochfeste Stahllitzen für Bauanwendungen fest, die mit Wachs und Hülle ummantelt sind.

Dieses Dokument gilt nur für diejenigen Produkte, die vom Hersteller geliefert werden.

Aciers de précontrainte - Torons gainés cirés pour applications dans la construction

Le présent document spécifie les exigences relatives aux torons en acier à haute résistance non revêtus ou aux torons en acier à haute résistance revêtus de zinc ou d’un alliage de zinc, encapsulés dans de la cire et une gaine pour les applications dans la construction.

Le présent document ne s’applique qu’aux produits tels que fournis par le fabricant.

Prednapeta jekla - Povoskane in oplaščene niti za uporabo v gradbeništvu

General Information

- Status

- Published

- Publication Date

- 18-Nov-2025

- Technical Committee

- ECISS/TC 104 - Concrete reinforcing and prestressing steels

- Drafting Committee

- CEN/TC 459/SC 4/WG 5 - Protected and sheathed strands for pre-stressing

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 19-Nov-2025

- Due Date

- 14-May-2024

- Completion Date

- 19-Nov-2025

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 18035:2025 - "Prestressing steels - Waxed and sheathed strands for construction applications" (CEN) specifies requirements for high‑strength steel strands (uncoated or zinc/zinc‑alloy coated) that are encapsulated with wax and a continuous sheath for use in construction. The standard applies to products as supplied by the manufacturer and covers manufacturing, material properties, performance requirements, conformity assessment and delivery conditions.

Key topics and technical requirements

- Product scope and designation: Defines how waxed and sheathed strands are designated (base strand, +W for wax, thickness class, sheath colour and strength class). Strength class is used for designation purposes only.

- Manufacturing requirements:

- Base strands produced from wire rod in accordance with EN ISO 16120 series.

- For zinc/zinc‑alloy coated strands, coating of individual wires must be completed before stranding.

- The sheath is applied by direct extrusion over the waxed strand.

- Wax specifications (examples from Table 1):

- Congealing point ≥ 65 °C; drop melting point ≥ 60 °C.

- Cone penetration ≤ 125 (1/10 mm at 25 °C).

- Bleeding at 40 °C ≤ 1.0 %.

- Oxidation stability (ASTM D942) ≤ 0.03 MPa (100 h at 100 °C).

- Performance and dimensional properties:

- Geometrical properties of base strands and overall diameter.

- Straightness, mass of wax per unit length, sheath thickness and mass.

- Functional tests: water tightness, initial resistance to friction, retention of adherence under thermal variations, impact resistance, deflected tensile and fatigue/relaxation characteristics.

- Conformity and testing:

- Clauses on sampling, acceptance units and frequency of inspection.

- Annex A provides normative testing procedures and test methods.

- Delivery conditions: Conditioning, transport/storage, labelling and documentation (e.g., EN 10204 inspection documents, force/extension diagrams).

Applications and users

EN 18035 is intended for:

- Manufacturers of prestressing strands and bonded strand systems.

- Structural and geotechnical engineers specifying prestressing elements for bridges, buildings, ground anchors and other concrete or prestressed structures.

- Procurement/specification authors, testing laboratories and certification bodies verifying compliance.

- Contractors and asset owners managing transport, storage and installation of prestressing materials.

Practical value: using EN 18035 ensures consistent material quality, predictable performance under thermal and mechanical loads, improved corrosion protection for prestressing tendons and clear requirements for supply, testing and documentation.

Related standards

Key referenced documents include: EN ISO 16120 (wire rod), EN 10244‑2 (zinc coatings), EN ISO 15630‑3 (prestressing steel test methods), EN 1179 (primary zinc), EN 10020 (steel classification), EN ISO 9227 (salt spray) and EN 10204 (inspection documents). These should be consulted together with EN 18035 when specifying or testing waxed and sheathed prestressing strands.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 18035:2025 is a standard published by the European Committee for Standardization (CEN). Its full title is "Prestressing steels - Waxed and sheathed strands for construction applications". This standard covers: This document specifies the requirements for uncoated high strength steel strands of zinc or zinc alloy coated high strength steel strands, encapsulated with wax and a sheath for construction applications. The document applies only to products as supplied by the manufacturer.

This document specifies the requirements for uncoated high strength steel strands of zinc or zinc alloy coated high strength steel strands, encapsulated with wax and a sheath for construction applications. The document applies only to products as supplied by the manufacturer.

EN 18035:2025 is classified under the following ICS (International Classification for Standards) categories: 77.140.15 - Steels for reinforcement of concrete. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 18035:2025 has the following relationships with other standards: It is inter standard links to ISO 22285:2018, ISO 1817:2024, ISO 11357-6:2025, ISO 18553:2025, ISO 1183-1:2025, EN 12518:2000, EN ISO 15630-3:2025, EN 10204:2004, EN 15534-1:2014/prA1, EN ISO 10304-4:2022, EN ISO 175:2010, EN ISO 16120-4:2017, EN 13078:2003, EN ISO 4892-2:2013, EN ISO 10304-1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 18035:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2026

Prednapeta jekla - Povoskane in oplaščene niti za uporabo v gradbeništvu

Prestressing steels - Waxed and sheathed strands for construction applications

Spannstähle - Gewachste und gehüllte Litzen für Bauanwendungen

Aciers de précontrainte - Torons gainés cirés pour applications dans la construction

Ta slovenski standard je istoveten z: EN 18035:2025

ICS:

77.140.15 Jekla za armiranje betona Steels for reinforcement of

concrete

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 18035

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2025

EUROPÄISCHE NORM

ICS 77.140.15

English Version

Prestressing steels - Waxed and sheathed strands for

construction applications

Aciers de précontrainte - Torons gainés cirés pour Spannstähle - Gewachste und gehüllte Litze für

applications dans la construction Bauanwendungen

This European Standard was approved by CEN on 25 September 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 18035:2025 E

worldwide for CEN national Members.

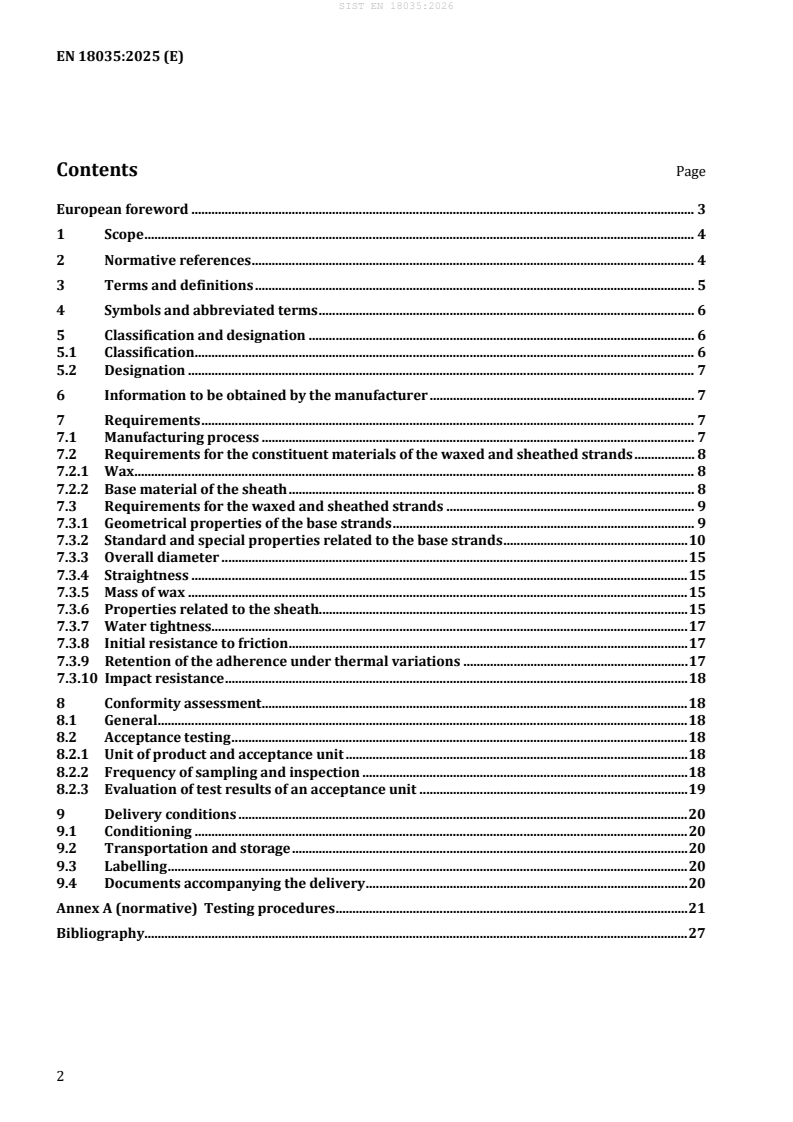

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 5

4 Symbols and abbreviated terms . 6

5 Classification and designation . 6

5.1 Classification . 6

5.2 Designation . 7

6 Information to be obtained by the manufacturer . 7

7 Requirements . 7

7.1 Manufacturing process . 7

7.2 Requirements for the constituent materials of the waxed and sheathed strands . 8

7.2.1 Wax . 8

7.2.2 Base material of the sheath . 8

7.3 Requirements for the waxed and sheathed strands . 9

7.3.1 Geometrical properties of the base strands . 9

7.3.2 Standard and special properties related to the base strands . 10

7.3.3 Overall diameter . 15

7.3.4 Straightness . 15

7.3.5 Mass of wax . 15

7.3.6 Properties related to the sheath. 15

7.3.7 Water tightness . 17

7.3.8 Initial resistance to friction . 17

7.3.9 Retention of the adherence under thermal variations . 17

7.3.10 Impact resistance . 18

8 Conformity assessment . 18

8.1 General . 18

8.2 Acceptance testing . 18

8.2.1 Unit of product and acceptance unit . 18

8.2.2 Frequency of sampling and inspection . 18

8.2.3 Evaluation of test results of an acceptance unit . 19

9 Delivery conditions . 20

9.1 Conditioning . 20

9.2 Transportation and storage . 20

9.3 Labelling . 20

9.4 Documents accompanying the delivery . 20

Annex A (normative) Testing procedures . 21

Bibliography. 27

European foreword

This document (EN 18035:2025) has been prepared by Technical Committee CEN/TC 459/SC 4

“Concrete reinforcing and prestressing steels”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2026, and conflicting national standards shall be

withdrawn at the latest by May 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies the requirements for uncoated high strength steel strands of zinc or zinc alloy

coated high strength steel strands, encapsulated with wax and a sheath for construction applications.

The document applies only to products as supplied by the manufacturer.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1179:2003, Zinc and zinc alloys — Primary zinc

EN 10020, Definition and classification of grades of steel

EN 10204, Metallic products — Types of inspection documents

EN 10244-1, Steel wire and wire products — Non-ferrous metallic coatings on steel wire — Part 1: General

principles

EN 10244-2, Steel wire and wire products — Non-ferrous metallic coatings on steel wire — Part 2: Zinc or

zinc alloy coatings

EN ISO 175, Plastics — Methods of test for the determination of the effects of immersion in liquid chemicals

(ISO 175)

EN ISO 527-1, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-1)

EN ISO 527-2, Plastics — Determination of tensile properties — Part 2: Test conditions for moulding and

extrusion plastics (ISO 527-2)

EN ISO 4892-2, Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps

(ISO 4892-2)

EN ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227)

EN ISO 10304-1, Water quality — Determination of dissolved anions by liquid chromatography of ions —

Part 1: Determination of bromide, chloride, fluoride, nitrate, nitrite, phosphate and sulfate (ISO 10304-1)

EN ISO 10304-4, Water quality — Determination of dissolved anions by liquid chromatography of ions —

Part 4: Determination of chlorate, chloride and chlorite in water with low contamination (ISO 10304-4)

EN ISO 15630-3, Steel for the reinforcement and prestressing of concrete — Test methods — Part 3:

Prestressing steel (ISO 15630-3)

EN ISO 16120-1, Non-alloy steel wire rod for conversion to wire — Part 1: General requirements

(ISO 16120-1)

EN ISO 16120-2, Non-alloy steel wire rod for conversion to wire — Part 2: Specific requirements for general

purpose wire rod (ISO 16120-2)

EN ISO 16120-4, Non-alloy steel wire rod for conversion to wire — Part 4: Specific requirements for wire

rod for special applications (ISO 16120-4)

ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1: Immersion

method, liquid pyknometer method and titration method

ISO 1817, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO 2137, Petroleum products and lubricants — Determination of cone penetration of lubricating greases

and petrolatum

ISO 2176, Petroleum products — Lubricating grease — Determination of dropping point

ISO 2207, Petroleum waxes — Determination of congealing point

ISO 6964, Polyolefin pipes and fittings — Determination of carbon black content by calcination and

pyrolysis — Test method

ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation

induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT)

ISO 18553, Method for the assessment of the degree of pigment or carbon black dispersion in polyolefin

pipes, fittings and compounds

ISO 22285, Petroleum products and lubricants — Determination of oil separation from grease — Pressure

filtration method

NF M 07-023, Liquid fuels — Determination of chlorides in crude petroleum and petroleum products

ASTM D942, Standard Test Method for Oxidation Stability of Lubricating Greases by the Oxygen Pressure

Vessel Method

ASTM B997, Standard Specification for Zinc-Aluminum Alloys in Ingot Form for Hot-Dip Coatings

ASTM D1693, Standard Test Method for Environmental Stress-Cracking of Ethylene Plastics

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

uncoated strand

strand consisting of seven uncoated plain cold drawn high strength steel wires

3.2

zinc or zinc alloy coated strand

strand consisting of seven zinc or zinc alloy continuous hot-dip coated cold drawn high strength steel

wires

3.3

waxed and sheathed strand

uncoated or zinc alloy coated strand encapsulated with wax and a sheath

3.4

sheath

continuous envelope surrounding the strand

3.5

batch of wax

quantity of wax produced in one manufacturing operation

4 Symbols and abbreviated terms

For the purposes of this document, the following symbols and abbreviations apply:

A (%) Percentage total extension at maximum force

gt

D (%) Average coefficient of reduction of the maximum force in the deflected tensile test

D (mm) Minimum diameter of the coil of waxed and sheathed strand

i

E (MPa) Modulus of elasticity of the strand

F (kN) Initial force in the isothermal stress relaxation test and the stress corrosion test

F (kN) Maximum force

m

F (kN) Mean maximum force of the two test pieces adjacent to the test piece submitted to

m,a

the relaxation test, fatigue test or corrosion test

F (kN) 0,1 % proof force

p0,1

F (N) Force range in the axial force fatigue test

r

ΔF (N) Force loss in the test piece at time t in the isothermal stress relaxation test

rt

F (N) Upper force in the axial force fatigue test

up

L (mm) Length of the test piece

M (g) Nominal mass per meter of the strand

M (g) Total mass of the test piece

t

M (g) Mass of the sheath

s

M (g) Total mass of wires

w

M (g/m) Mass of wax per unit length

wl

N Number of force cycles in the axial force fatigue test

S (mm ) Nominal cross-sectional area of the strand

n

t (h) Minimum lifetime to fracture in the stress corrosion test

a

t (h) Median lifetime to fracture in the stress corrosion test

f,m

t (mm) Minimum thickness of the sheath

n

Δm (%) Deviation from the nominal mass per meter

5 Classification and designation

5.1 Classification

The steels of the constituent strands of waxed and sheathed strands covered by this document shall be

classified as special steels according to EN 10020.

5.2 Designation

The designation of the products covered by this document comprises in the order:

— description of the product (i.e. waxed and sheathed strand);

— designation of the strand from which the waxed and sheathed strand is produced in square brackets;

— symbol + W for wax;

— thickness class;

— colour of the sheath when other than black, when applicable.

EXAMPLE

Waxed and sheathed strand [Y1860S7+ZA-15,7-R1-F3-D2]+W–Tn2 white designates a waxed and sheathed

strand with a thickness class Tn2, made from a strand coated with a zinc-aluminium alloy of nominal diameter

15,7 mm, strength class 1 860 MPa, relaxation class R1, fatigue class F3 and class D2 of deflected tensile properties,

of white colour.

NOTE The strength class is only used for designation purposes (see EN 10027-1). The strength class

corresponds to the tensile strength obtained by dividing the maximum force (F ) by the nominal cross-sectional

m

area (S ).

n

6 Information to be obtained by the manufacturer

The following information shall be obtained at the time of enquiry and order:

a) designation of the product in accordance with 5.2;

b) packaging and protection requirements;

c) requirements concerning information to accompany the delivery (e.g. date of manufacture, delivery

note, type of inspection document (see EN 10204), copies of force/extension diagrams);

d) special requirements for labelling.

7 Requirements

7.1 Manufacturing process

The manufacturing method of the waxed and sheathed strands is at the discretion of the manufacturer

and shall be in accordance with the following:

— The base strands are manufactured from wire produced with wire rod in accordance with

EN ISO 16120-1 and EN ISO 16120-2 or EN ISO 16120-1 and EN ISO 16120-4. Strands with normal

production lengths may contain welds made in the individual wires before cold working but shall not

contain welds made during or after cold working.

— In the case of zinc or zinc alloy coated strands, the coating of the constituent wires of the strand shall

be completed before stranding.

— The sheath shall be applied to the waxed strand by direct extrusion.

7.2 Requirements for the constituent materials of the waxed and sheathed strands

7.2.1 Wax

The wax shall meet the requirements given in Table 1.

Table 1 — Requirements for waxes

Specified property Reference of the test Specified values

method

Aggressive elements: NF M 07–023 for the

extraction method

Measurement methods:

- -

Cl EN ISO 10304-4 for Cl ≤ 50 ppm

2-

-

S

EN ISO 10304-1 for NO

≤ 50 ppm

2-

-

and SO

NO 4

Common ion

2-

SO ≤ 100 ppm

2-

chromatography for S

Congealing point ISO 2207 ≥ 65 °C

Drop melting point ISO 2176 ≥ 60 °C

Cone penetration

ISO 2137 ≤ 125

(1/10 mm; at 25 °C)

a

ISO 22285

Bleeding at 40 °C ≤ 1,0 %

(without the 100 g mass)

Oxidation stability ASTM D942 ≤ 0,03 MPa (100 h at 100 °C)

Pass a test of

Red rust protection with a wax

layer of 125 μm ± 5 μm - Saline EN ISO 9227 168 h ± 2 h at 35 °C ± 1 °C

fog at 5 % NaCl

(no corrosion)

a

After 7 days, without the 100 g mass.

7.2.2 Base material of the sheath

The base material used for black sheaths shall be a high-density polyethylene (HDPE) and use carbon

black as a filler. The base material of the sheath shall meet the requirements given in Tables 2 and 3.

Table 2 — Requirements for the base material of sheath with additives

Specified property Reference of the Specified values

test method

Density ISO 1183-1 ≥ 0,940 g/cm

Tensile stress at yield at 23 °C EN ISO 527-1 and ≥ 22 MPa

a

EN ISO 527-2

Tensile strain at break at 23 °C EN ISO 527-1 and ≥ 600 %

a

EN ISO 527-2

Tensile strain at break at - 20 °C EN ISO 527-1 and ≥ 150 %

a

EN ISO 527-2

Thermal stability (OIT) ISO 11357-6 ≥ 30 min at 210 °C under O2

a

The tensile testing speed shall be 50 mm/min ± 10 %. The test pieces shall be preferably be of 1BA or 1BB shape

according to EN ISO 527-1 and EN ISO 527-2.

Table 3 — Requirements for the base material of the sheath concerning the carbon black

Specified property Reference of the test method Specified values

Content ISO 6964 (2,3 ± 0,3) %

Dispersion ISO 18553 Maximum index 3

Distribution ISO 18553 Maximum index C2

NOTE The requirements in Tables 2 and 3 could be met by products of Type III, Class C, Category 4 and Grade

W8 or of Type IV, Class D, Category 5 and Grade W9 as defined by ASTM D1248.

The base material for sheaths other than black shall be an uncoloured high-density polyethylene (HDPE)

to which additives are added (colorant, anti-oxydizer, anti-UV). The density of the uncoloured high-

. The high-density

density polyethylene (HDPE) shall be greater than or equal to 0,940 g/cm

polyethylene (HDPE) with its additives shall meet the requirements of Table 2.

The additives shall allow ensuring a sufficient colorimetric stability under UV action in time. The

colorimetric stability may be determined according to a method agreed at the time of enquiry and order

(see 7.3.6.8).

7.3 Requirements for the waxed and sheathed strands

7.3.1 Geometrical properties of the base strands

The nominal diameters, cross-sectional areas and masses per meter of the base strand used for the waxed

and sheathed strands shall be as given in Table 4.

The base 7-wire strand shall include a straight central wire, called a core wire around which are spun six

wires in one layer. The outer wires shall be tightly spun around the central wire with a lay length between

14 and 18 times the nominal strand diameter. The diameter of the central wire shall be at least 3,0 %

greater than the diameter of the outer helical wires.

a a

Table 4 — Nominal diameters, cross-sectional areas and masses per meter

Nominal diameter Nominal cross-sectional area Nominal mass per meter

d S M

n

mm mm g/m

12,5 93,0 726,3

12,9 100 781,0

13,0 102 796,6

15,2 139 1 086

15,3 140 1 093

15,7 150 1 172

a

The nominal mass per metre is calculated from the nominal cross-sectional area and a density of

7,81 kg/dm

The permissible deviation from the nominal mass per meter Δm shall not be more than ± 2 %.

Measurements of mass per meter and Δm shall be performed according to EN ISO 15630-3.

7.3.2 Standard and special properties related to the base strands

7.3.2.1 Mechanical characteristics

a) The maximum force (F ), the proof force (F ), the modulus of elasticity (E), the percentage total

m p0,1

extension at maximum force (Agt) of the waxed and sheathed strands are specified as minimum

and/or maximum values.

b) The maximum force (F ), the proof force (F ), the modulus of elasticity (E), the percentage total

m p0,1

extension at maximum force (Agt) of the waxed and sheathed strands shall be determined in

accordance with EN ISO 15630-3.

7.3.2.2 Deflected tensile strength

The deflected tensile strength is the strand capacity to resist to an applied force with a 20 ° deviation. The

average coefficient of reduction of the maximum force in the deflected tensile test, D, shall be determined

in accordance with EN ISO 15630-3.

7.3.2.3 Relaxation

The relaxation, specified as the percentage loss ΔF of initial force F shall be determined in an isothermal

rt 0

relaxation test in accordance with EN ISO 15630-3.

7.3.2.4 Fatigue strength

The fatigue strength, specified as a number of force cycles N at a force range F and a maximum force F ,

r up

shall be determined by an axial force-controlled fatigue test in accordance with EN ISO 15630-3.

Different fatigue classes are defined in Table 5 and Table 6.

NOTE Other classes and S/N curves can be agreed at the time of enquiry and order.

7.3.2.5 Durability of the base uncoated strand

The durability in the case of base uncoated strand is specified as the resistance of the base uncoated

strand against hydrogen induced stress corrosion cracking in thiocyanate solutions A and/or B and shall

be determined in accordance with EN ISO 15630-3.

The performance is expressed as the minimum time in hours t without fracture and/or, where

a

applicable, the median time in hours t until fracture in the used test solution (A and/or B according to

f,m

EN ISO 15630-3) at an initial force F = 0,80 𝐹𝐹 (mean value according to EN ISO 15630-3) for the

0 m,a

specified number of individual tests.

7.3.2.6 Durability of the base zinc or zinc alloy coated strand

The durability in the case of base zinc or zinc alloy coated strand is specified as the coating properties of

the base strand.

Coating properties and tests for zinc and zinc alloy coated strands are defined in Table 7.

7.3.2.7 Summary of the requirements for the standard and special properties of the waxed and

sheathed strands manufactured from uncoated strands

The requirements for the standard and special properti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...