EN 12697-1:2020

(Main)Bituminous mixtures - Test methods - Part 1: Soluble binder content

Bituminous mixtures - Test methods - Part 1: Soluble binder content

This document describes test methods for the determination of the soluble binder content of samples of bituminous mixtures.

The test methods described are suitable for quality control purposes during the production of plant mix and for checking compliance with a product specification.

For the analysis of mixtures containing modified binders, the guidance of Annex D should be followed.

Asphalt - Prüfverfahren - Teil 1: Löslicher Bindemittelgehalt

Dieses Dokument beschreibt Prüfverfahren zur Bestimmung des löslichen Bindemittelgehaltes in Proben aus Asphalt.

Die beschriebenen Prüfverfahren sind zur Qualitätskontrolle während der Herstellung des Mischgutes sowie zur Überprüfung der Übereinstimmung mit einer Produktspezifikation geeignet.

Zur Untersuchung von Gemischen, welche modifizierte Bindemittel enthalten, sollten die Hinweise in Anhang D beachtet werden.

Mélanges bitumineux - Méthodes d'essai - Partie 1 : Teneur en liant soluble

Le présent document décrit des méthodes d’essai pour déterminer la teneur en liant soluble d’échantillons de matériaux enrobés.

Les méthodes d’essai décrites sont applicables pour la maîtrise de la qualité de production en usine et pour les vérifications de conformité aux spécifications des produits.

Pour l'analyse des mélanges contenant des liants modifiés, il convient de suivre les recommandations données en Annexe D.

Bitumenske zmesi - Preskusne metode - 1. del: Topni delež veziva

General Information

- Status

- Published

- Publication Date

- 10-Mar-2020

- Withdrawal Date

- 29-Sep-2020

- Technical Committee

- CEN/TC 227 - Road materials

- Drafting Committee

- CEN/TC 227/WG 1 - Bituminous mixtures

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Sep-2025

- Completion Date

- 02-Sep-2025

Relations

- Effective Date

- 24-Mar-2020

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 13108-8:2016 - Bituminous mixtures - Material specifications - Part 8: Reclaimed asphalt - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 12697-39:2020 - Bituminous mixtures - Test methods - Part 39: Binder content by ignition - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12697-1:2020 - "Bituminous mixtures - Test methods - Part 1: Soluble binder content" (CEN) specifies procedures for determining the soluble binder content of samples of bituminous mixtures. The standard is intended for routine laboratory analysis used in production quality control and for checking compliance with product specifications. For mixtures containing polymer‑modified binders, Annex D provides specific guidance.

Key topics and technical requirements

- Scope and purpose: Methods suitable for plant mix quality control and specification checks; supersedes EN 12697-1:2012.

- Sample preparation: Requirements for preparing laboratory samples, including guidance for mixtures with high mineral-matter content.

- Binder extraction methods: Describes solvent‑based extraction techniques and acceptable solvents. Annex B details extraction apparatus and procedures, including:

- Hot extractor (paper or wire‑mesh filter)

- Soxhlet extractor

- Bottle rotation and centrifuge extractors

- Cold dissolution and automatic extractor methods

- Separation of mineral matter: Procedures and apparatus (pressure filters, centrifuges, etc.) to separate aggregate from dissolved binder.

- Binder quantity measurement: Procedures for gravimetric recovery, volume and mass calculations, and expression of results (including calculation methods by difference or total recovery).

- Drying to constant mass: Requirements for drying aggregates/extracts to constant mass before weighing.

- Precision and reporting: Precision data from interlaboratory experiments, required reporting elements and test report content.

- Safety: Explicit warning on hazardous solvents (e.g., dichloromethane, toluene, xylene, perchloroethylene) - occupational exposure limits, ventilation and training requirements.

Practical applications and users

Who uses EN 12697-1:2020:

- Road materials testing laboratories and in‑plant QC labs

- Asphalt and bitumen producers monitoring binder content during production

- Pavement engineers and contractors verifying compliance with contract specifications

- Material auditors and regulatory bodies performing acceptance testing

- Research and development teams assessing new mix designs, including polymer‑modified binders

Typical applications:

- Routine QC of plant‑produced asphalt mixtures

- Acceptance testing against specification binder content limits

- Investigations of field cores and production disputes

- Validation of mix designs and binder modification effects

Related standards

- Other parts of the EN 12697 series cover additional test methods for bituminous mixtures (e.g., particle size, compaction, stiffness).

- EN 12697-1:2020 replaces EN 12697-1:2012; check national implementations via CEN members for adoption details.

Keywords: EN 12697-1:2020, soluble binder content, bituminous mixtures test methods, binder extraction, asphalt testing, plant mix quality control, polymer‑modified binders, CEN standard.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12697-1:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Bituminous mixtures - Test methods - Part 1: Soluble binder content". This standard covers: This document describes test methods for the determination of the soluble binder content of samples of bituminous mixtures. The test methods described are suitable for quality control purposes during the production of plant mix and for checking compliance with a product specification. For the analysis of mixtures containing modified binders, the guidance of Annex D should be followed.

This document describes test methods for the determination of the soluble binder content of samples of bituminous mixtures. The test methods described are suitable for quality control purposes during the production of plant mix and for checking compliance with a product specification. For the analysis of mixtures containing modified binders, the guidance of Annex D should be followed.

EN 12697-1:2020 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12697-1:2020 has the following relationships with other standards: It is inter standard links to EN 12697-1:2012, ISO 3310-1:2016, EN 12697-3:2013+A1:2018, CEN ISO/TR 18486:2017, EN 12697-4:2023, EN 12697-14:2020, EN 12697-28:2020, EN 12697-2:2024, EN 13108-8:2016, EN 12697-5:2009, EN 12697-15:2022, EN 12594:2007, EN 13108-9:2016, EN 12697-39:2020, EN 12697-39:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12697-1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2020

Nadomešča:

SIST EN 12697-1:2012

Bitumenske zmesi - Preskusne metode - 1. del: Topni delež veziva

Bituminous mixtures - Test methods - Part 1: Soluble binder content

Asphalt - Prüfverfahren - Teil 1: Löslicher Bindemittelgehalt

Mélanges bitumineux - Méthodes d'essai - Partie 1 : Teneur en liant soluble

Ta slovenski standard je istoveten z: EN 12697-1:2020

ICS:

93.080.20 Materiali za gradnjo cest Road construction materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12697-1

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2020

EUROPÄISCHE NORM

ICS 93.080.20 Supersedes EN 12697-1:2012

English Version

Bituminous mixtures - Test methods - Part 1: Soluble

binder content

Mélanges bitumineux - Méthodes d'essai - Partie 1 : Asphalt - Prüfverfahren - Teil 1: Löslicher

Teneur en liant soluble Bindemittelgehalt

This European Standard was approved by CEN on 18 November 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12697-1:2020 E

worldwide for CEN national Members.

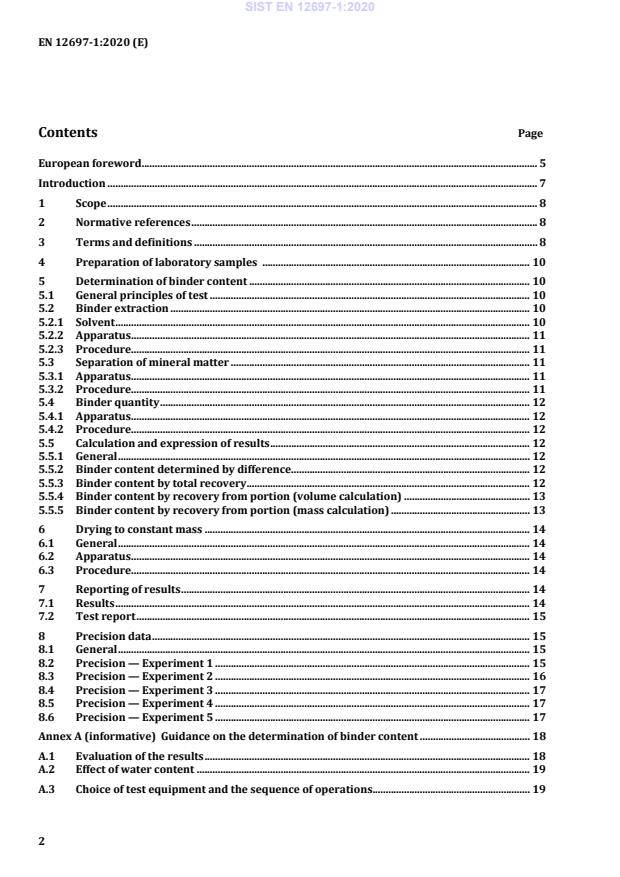

Contents Page

European foreword . 5

Introduction . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Preparation of laboratory samples . 10

5 Determination of binder content . 10

5.1 General principles of test . 10

5.2 Binder extraction . 10

5.2.1 Solvent . 10

5.2.2 Apparatus . 11

5.2.3 Procedure. 11

5.3 Separation of mineral matter . 11

5.3.1 Apparatus . 11

5.3.2 Procedure. 11

5.4 Binder quantity . 12

5.4.1 Apparatus . 12

5.4.2 Procedure. 12

5.5 Calculation and expression of results . 12

5.5.1 General . 12

5.5.2 Binder content determined by difference . 12

5.5.3 Binder content by total recovery . 12

5.5.4 Binder content by recovery from portion (volume calculation) . 13

5.5.5 Binder content by recovery from portion (mass calculation) . 13

6 Drying to constant mass . 14

6.1 General . 14

6.2 Apparatus . 14

6.3 Procedure. 14

7 Reporting of results . 14

7.1 Results . 14

7.2 Test report . 15

8 Precision data . 15

8.1 General . 15

8.2 Precision — Experiment 1 . 15

8.3 Precision — Experiment 2 . 16

8.4 Precision — Experiment 3 . 17

8.5 Precision — Experiment 4 . 17

8.6 Precision — Experiment 5 . 17

Annex A (informative) Guidance on the determination of binder content . 18

A.1 Evaluation of the results . 18

A.2 Effect of water content . 19

A.3 Choice of test equipment and the sequence of operations . 19

A.4 Determination of total binder content . 19

Annex B (normative) Use of equipment for the determination of binder content . 21

B.1 Binder extraction . 21

B.1.1 Hot extractor (paper filter) method . 21

B.1.2 Hot extractor (wire mesh filter) method . 26

B.1.3 Soxhlet extractor method . 27

B.1.4 Bottle rotation machine method . 29

B.1.5 Centrifuge extractor method . 32

B.1.6 Cold mix dissolution of bitumen by agitation . 34

B.1.7 Automatic extractor method . 35

B.2 Separation of mineral matter . 36

B.2.1 Continuous flow centrifuge . 36

B.2.2 Pressure filter . 38

B.2.3 Bucket type centrifuge — Type 1 . 39

B.2.4 Bucket type centrifuge — Type 2 . 41

B.3 Soluble binder content . 41

B.3.1 Method by recovery from a portion using a volume calculation . 41

B.3.2 Method by recovery from a portion using a mass calculation. 44

Annex C (normative) Determination of residual mineral matter in the binder extract by

incineration . 45

C.1 General . 45

C.2 Method 1 . 45

C.2.1 Apparatus . 45

C.2.2 Reagent . 45

C.2.3 Procedure . 45

C.3 Method 2 . 46

C.3.1 Apparatus . 46

C.3.2 Procedure . 46

Annex D (informative) Guidance on determination of soluble binder content of mixtures

with polymer-modified binders . 48

D.1 General . 48

D.2 Preparatory treatment of laboratory samples of bituminous mixtures . 48

D.3 Determination of binder content . 48

D.3.1 General principles of test . 48

D.3.2 Binder extraction . 48

D.3.3 Separation of mineral matter . 50

D.3.4 Binder quantity . 51

D.3.5 Calculation and expression of results . 51

D.4 Drying to constant mass . 51

D.5 Reporting of results . 51

D.6 Precision data . 51

Bibliography . 52

European foreword

This document (EN 12697-1:2020) has been prepared by Technical Committee CEN/TC 227 “Road

materials”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2020, and conflicting national standards

shall be withdrawn at the latest by September 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12697-1:2012.

The following is a list of significant technical changes since the previous edition:

— the title no longer makes the method exclusively for hot mix asphalt;

— [ge] editorial update according to current standard template;

— [ge] NOTES modified or adjusted to normal text where appropriate according to ISO/IEC Directives

– Part 2:2016, 24.5;

— [ge] the wording “accuracy of” has been altered to “to the nearest” in relevant procedures;

3 3 3 3

— [ge] The unit mm x 10 mm corrected to cm ;

— [Clause 2 and 5.3.2.4] EN 933-1 replaced by EN 12697-2;

— [Clause 4] Title amended to read: Preparation of laboratory samples. Completed with description

for mixtures with high mineral matter content;

— [5.2.2.1], [6.2.2] and [B.1.7.1.6] accuracy for balance of 0,05 % amended to ± 0,1 g;

— [5.2.3.1] clause deleted (superfluous). Following clauses renumbered accordingly;

— [5.5.2 to 5.5.5] Titles amended for clarification;

— [6.1] completed with observation about influence of water for the result of binder content;

— [8.2.2 and 8.2.3] dated reference deleted for EN 12697-28:2000;

— [8.6] new clause about precision of automatic devices:

— [Figure A.1] new figure introduced. Completed with Automatic extractor method. Minor editorial

corrections;

— [B.1.5.1.5] table with dimensions related to Figure B.7 has been corrected in accordance with

figure;

— [B.1.7] procedure for automatic extractor method included;

— [B.2.1.1.1] acceleration amended to 25 000 m/s for consistency with EN 12697-3;

— [C.2.1.1.1] accuracy of balance amended to read ± 1 mg;

— [C.2.1.5] capacity of ignitions dishes clarified: Ignition dish, of at least 125 cm capacity;

— [C.3.1.1] accuracy of balance, amended to read ± 10 mg;

— [Bibliography] updated.

A list of all parts in the EN 12697 series can be found on the CEN website

WARNING — The method described in this document may require the use of dichloromethane

(methylene chloride), 1,1,1-trichloroethane, benzene, trichloroethylene, xylene, toluene,

perchloroethylene (tetracloroethylene) or other solvents capable of dissolving bitumen. These solvents

are hazardous to health and are subject to occupational exposure limits as detailed in relevant

legislation and regulations.

Exposure levels are related to both handling procedures and ventilation provision and it is emphasized

that adequate training should be given to staff employed in the usage of these substances.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

This document describes a unified approach to the examination of bituminous mixtures that allows

some divergence in the detail of procedures followed by individual laboratories. In Clause 5 of this

document, a description is given of the basic operations that together form the test method for the

proper determination of the binder content of bituminous mixtures. Guidance on the test method is

given in Annex A and Figure A.1, while the use of alternative items of equipment that are equally

suitable for carrying out particular parts of the test method are described in Annex B. Although the

apparatus specified for the separation of mineral filler from the binder solution obtained after

extraction is of a suitably efficient level not to affect the precision of the test described in Clause 8, a

method for determining the amount of residual mineral matter in the extract is given in Annex C for use

in those particular cases where some doubt may exist.

Methods and equipment other than those described in Annex B and Annex C, including automated

equipment, are permissible provided that they have been demonstrated to provide the same results as

one of the methods in Annex B or Annex C within the limits of the precision given in this document.

Guidance on determination of soluble binder content of mixtures with polymer-modified binders is

given in Annex D.

1 Scope

This document describes test methods for the determination of the soluble binder content of samples of

bituminous mixtures.

The test methods described are suitable for quality control purposes during the production of plant mix

and for checking compliance with a product specification.

For the analysis of mixtures containing modified binders, the guidance of Annex D should be followed.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12697-2, Bituminous mixtures — Test methods — Part 2: Determination of particle size distribution

EN 12697-3, Bituminous mixtures — Test methods — Part 3: Bitumen recovery: Rotary evaporator

EN 12697-4, Bituminous mixtures — Test methods — Part 4: Bitumen recovery: Fractionating column

EN 12697-14, Bituminous mixtures — Test methods — Part 14: Water content

EN 12697-28, Bituminous mixtures — Test methods — Part 28: Preparation of samples for determining

binder content, water content and grading

ISO 3310-1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth

ISO 3310-2, Test sieves — Technical requirements and testing — Part 2: Test sieves of perforated metal

plate

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

soluble binder content

percentage by mass of extractable binder in an anhydrous sample, determined by extracting the binder

from the sample

3.2

insoluble binder content

percentage by mass of binder that adheres to the aggregate particles after extraction

3.3

precision

closeness of agreement between independent test results obtained under stipulated conditions

Note 1 to entry: Precision depends only on the distribution of random errors and does not relate to the true

value or the specified value.

Note 2 to entry: The measure of precision is usually expressed in terms of imprecision and computed as a

standard deviation of the test results. Less precision is indicated by a larger standard deviation.

Note 3 to entry: “Independent test results” means results obtained in a manner not influenced by any previous

result on the same or similar test sample. Quantitative measures of precision depend critically on the stipulated

conditions. Repeatability and reproducibility conditions are particular sets of extreme conditions.

3.4

repeatability

precision under repeatability conditions

3.5

repeatability conditions

conditions in which independent test results are obtained with the same method on identical test items

in the same laboratory by the same operator using the same equipment within short intervals of time

3.6

repeatability limit

maximum absolute difference between two test results obtained under repeatability conditions that

may be expected with a probability of 95 %

Note 1 to entry: The symbol used for repeatability limit is r.

3.7

reproducibility

precision under reproducibility conditions

3.8

reproducibility conditions

conditions in which test results are obtained with the same method on identical test items in different

laboratories with different operators using different equipment

3.9

reproducibility limit

maximum absolute difference between two test results obtained under reproducibility conditions that

may be expected with a probability of 95 %

Note 1 to entry: The symbol used for reproducibility limit is R.

3.10

single test result

value obtained by applying the standard test method once, fully, on a single specimen

Note 1 to entry: The single test result can also be the mean of two or more observations or the result of a

calculation from a set of observations as specified by the standard test method.

4 Preparation of laboratory samples

Prepare laboratory samples in accordance with EN 12697-28 to obtain suitable test portions.

In the case of bituminous mixtures with high mineral matter content, take into account the capacity of

the apparatus described in B.2 to determine the mass of the material.

5 Determination of binder content

5.1 General principles of test

The test method for determining the binder content of a test portion of bituminous mixture, prepared in

accordance with Clause 4, normally comprises the following basic operations:

a) binder extraction by dissolving in a hot or cold solvent;

b) separation of mineral matter from the binder solution;

c) determination of binder quantity by difference or binder recovery;

d) calculation of soluble binder content.

NOTE 1 The sequence of operations and choice of test procedures to be followed are illustrated in Figure A.1.

If it is suspected that water is present in the laboratory sample, the sample should either be dried to

constant mass (see Clause 6), or the water content determined by the method described in EN 12697-

14, or the sample treated as in EN 12697-28.

NOTE 2 All test procedures and associated equipment relating to each basic operation shown in Figure A.1 are

equally acceptable. Other equipment and procedures, including non-extraction methods, can also be used. There

are documented data to show that the method and equipment will provide results with an accuracy and a

precision no worse than that of one of the procedures explicitly shown in Figure A.1.

5.2 Binder extraction

5.2.1 Solvent

The tests in this document require the use of solvents capable of dissolving bitumen and in some cases

involve distilling the solution to recover all or some of the bitumen.

NOTE Currently all hydrocarbon solvents are regarded as “hazardous” and “environmentally unfriendly” to

varying degrees.

Until such time as there is an agreed CEN policy with regard to the usage of hydrocarbon solvents, each

member state should specify its preferred solvent, taking into account the Montreal Protocol and the

views of its own Regulatory Bodies (see also “Warning” in the Foreword).

Trichloroethylene should be stored in sealed bottles or canisters, which are protected against UV

radiation.

When trichloroethylene is recovered by distillation for further use, care should be taken to ensure that

the solvent still complies with the appropriate requirements. In particular, acidity may develop; a useful

precaution is to store the solvent over calcium oxide in coloured glass or suitable metal containers.

5.2.2 Apparatus

The apparatus should be calibrated and traceable.

5.2.2.1 Balance, capable of weighing a test portion to an accuracy of ± 0,1 g.

5.2.2.2 Binder extraction apparatus, conforming to the requirements of the method selected from

B.1, as appropriate.

5.2.3 Procedure

5.2.3.1 Weigh the test portion to the nearest 0,1 g, and place it in the binder extraction apparatus in

accordance with the requirements of the method selected from B.1, as appropriate.

5.2.3.2 The binder extraction procedure shall ensure that no soluble binder is left adhering to the

aggregate particles after extraction.

NOTE In limited cases, it can be difficult to dissolve every trace of binder adhering to the aggregate (see A.4).

5.3 Separation of mineral matter

5.3.1 Apparatus

5.3.1.1 Trays, that can be heated without damage or change in mass and which are used to dry

recovered aggregate.

5.3.1.2 Apparatus for the separation of mineral filler from the binder solution, conforming to

the requirements of the method selected from B.2, as appropriate.

5.3.2 Procedure

5.3.2.1 Collect the binder solution obtained in accordance with 5.2 and proceed in accordance with

the method selected from B.2, as appropriate.

5.3.2.2 The procedure used to separate the mineral filler from the binder solution shall ensure that

the residue on ignition of the recovered binder does not exceed 0,5 %, if the nominal filler content is

less than 6 % of the mass of aggregate, or 1 % if the nominal filler content is 6 % or greater, when

determined in accordance with Annex C.

NOTE 1 This check is not necessary for all samples but rather serves to prove the effectiveness of the method.

NOTE 2 The residue depends on the solvent and the equipment used.

5.3.2.3 Transfer, where necessary, the clean recovered aggregate to a tray. Evaporate the solvent

from the aggregate and the binder extraction apparatus. Transfer any remaining fine mineral matter

from the binder extraction apparatus to the tray with the rest of the recovered aggregate, ensuring that

all mineral matter has been removed from the binder extraction apparatus. Weigh and record the mass

of the aggregate in the tray.

5.3.2.4 If required, determine the particle size distribution of the recovered aggregate in

accordance with EN 12697-2, making due allowance for any mineral filler collected by the filter paper,

where appropriate.

5.4 Binder quantity

5.4.1 Apparatus

5.4.1.1 Recovery apparatus, conforming to the requirements of the method selected from B.3.

The apparatus should be calibrated and traceable.

5.4.2 Procedure

Difference method

Where the binder quantity is determined by difference, add the mass of recovered aggregate to the

mass of any mineral filler collected by filter paper.

Recovery method

Where the binder quantity is determined by recovering the binder of the binder solution, follow the

procedures described in B.3.

5.5 Calculation and expression of results

5.5.1 General

The soluble binder content, S, as a percentage of the mass of the original dry test portion, shall be

calculated in accordance with 5.5.2, 5.5.3, 5.5.4 or 5.5.5, as appropriate.

Formulae are given for un-dried test portions. Where test portions have been dried to constant mass, M

becomes the mass of the dried test portion and M is deleted.

W

NOTE For mixtures with a binder having a significant proportion of insolubles, the total binder content can

be calculated by taking account of the insoluble binder content in accordance with A.4.

5.5.2 Binder content determined by difference

Calculate the soluble binder content, S, in percentage by mass, using Formula (1):

100× MM− + M

( )

1 W

S=

MM−

W

(1)

where

S is the soluble binder content, expressed in percent (%);

M is the mass of un-dried test portion, expressed in grams (g);

M is the mass of recovered mineral matter, expressed in grams (g);

M is the mass of water in the un-dried test portion, expressed in grams (g).

W

5.5.3 Binder content by total recovery

Calculate the soluble binder content, S, in percentage by mass, using Formula (2):

100× M

b

S=

MM−

W

(2)

where

S is the soluble binder content, expressed in percent (%);

M is the mass of un-dried test portion, expressed in grams (g);

M is the mass of recovered binder, expressed in grams (g);

b

M is the mass of water in the un-dried test portion, expressed in grams (g).

W

5.5.4 Binder content by recovery from portion (volume calculation)

Calculate the soluble binder content, S, in percentage by mass, using Formula (3):

100× zV× × d

S=

(M− M )(× dv×− z)

w

(3)

where

S is the soluble binder content, expressed in percent (%);

M is the mass of un-dried test portion, expressed in grams (g);

z is the average mass of binder recovered from each aliquot portion of binder solution,

expressed in grams (g);

V is the total volume of solvent, expressed in cubic millimetres (mm );

v is the volume of each aliquot solution portion, expressed in cubic millimetres (mm );

d is the density of the binder at 25 °C, expressed in grams per cubic millimetres (g/mm );

M is the mass of water in the un-dried test portion, expressed in grams (g).

W

5.5.5 Binder content by recovery from portion (mass calculation)

Calculate the soluble binder content, S, in percentage by mass, using Formula (4):

100× M

B

S= (4)

MM−

W

where

S is the soluble binder content, expressed in percent (%);

M is the mass of un-dried test portion, expressed in grams (g);

M is the mass of the water in the un-dried test portion, expressed in grams (g);

W

M is the mass of soluble binder in the test portion, expressed in grams (g).

B

MM−

MM=

(5)

BP

MM−

3 2

where

M is the mass of solvent in the test portion, expressed in grams (g);

P

M , M , M are as defined in B.3.2.

1 2 3

6 Drying to constant mass

6.1 General

In all the test procedures in this document it is necessary, at some stage, to ensure that materials or

equipment are dried to constant mass. On all such occasions, the method in 6.2 to 6.3 shall be used. In

case of a method by difference, the potential present water will be considered as binder.

6.2 Apparatus

6.2.1 Oven or drying cabinet, of suitable capacity and capable of holding the required temperatures.

6.2.2 Balance, with an accuracy of ± 0,1 g.

6.2.3 Desiccator, of suitable capacity (optional).

6.3 Procedure

6.3.1 Place the material or equipment in the oven or drying cabinet and dry to constant mass.

NOTE 1 In case of an oven, a temperature of (110 ± 5) °C is usually suitable. Where it is necessary to dry a test

portion before analysis a temperature of (80 ± 5) °C can be more suitable to avoid binder drainage, but a longer

time will be necessary.

NOTE 2 In case of a drying cabinet lower temperatures are used. The lower the temperature, the longer it will

take to dry to constant mass.

NOTE 3 Constant mass is defined as successive weighings after drying at least 1 h apart not differing by more

than 0,1 %.

For convenience, it is recommended that the successive weighings to determine constant mass should

be carried out whilst the material is hot. It may be advisable to protect the balance from heat.

6.3.2 When constant mass has been achieved, cool in a moisture-free atmosphere and weigh.

NOTE A moisture-free atmosphere can be obtained by cooling in a desiccator.

7 Reporting of results

7.1 Results

Report the soluble binder content, and, where appropriate:

a) the water content to the nearest 0,1 % by mass in accordance with EN 12697-14;

b) and/or the insoluble binder content in accordance with A.4.

7.2 Test report

The report shall contain at least the following information in addition to that in 7.1:

a) name and address of the testing laboratory;

b) unique serial number for the test report;

c) name of the client;

d) description and an identification of the sample, and the date of receipt;

e) identification of the test method by reference to the Annex B apparatus used;

f) any deviations, additions to or exclusions from the test method;

g) whether or not the sample was accompanied by a sampling certificate;

h) signature of officer accepting the technical responsibility for the test report;

i) date of issue.

8 Precision data

8.1 General

NOTE 1 Criteria for judging the acceptability of the binder content of bituminous mixtures determined by this

document are limited. The data that are tabulated herein were obtained from four separate precision experiments

on materials from different geographical regions within the European Union. An indication of the precision of this

method of test can be obtained from the data presented in 8.2, 8.3, 8.4 and 8.5.

Differences in the results obtained by two laboratories on test samples taken from the same bulk

sample might be due to errors in the sample reduction and/or the procedures adopted by the analysis.

Any systematic differences in the comparison of a group of test results should be investigated to detect

the cause or causes of the bias.

NOTE 2 This bias will generally be due to non-adherence to the detail of the method of analysis if the same test

procedures are being followed or, in isolated cases, small differences might be due to the particular test procedure

selected.

If differences arise when the same test procedures are being followed it will normally be possible, with

co-operation between the laboratories, to eliminate the cause. If small differences occur due to the test

procedures being different, it is recommended that the two laboratories concerned, at the earliest

opportunity, examine the interpretation of the test results.

8.2 Precision — Experiment 1

NOTE The limits for the differences between the analysis results of two test samples obtained from the same

bulk sample are as given in 8.2.4.

8.2.1 Obtain two test samples in accordance with sampling procedures in 8.2.2 to 8.2.3, as

appropriate.

8.2.2 Obtain the test material for repeatability tests by dividing a sample twice the size required for a

single test in accordance with the sample reduction procedure in EN 12697-28.

8.2.3 Obtain the test material for reproducibility tests by first dividing a sample eight times the size

required for analysis into two approximately equal portions (one for each laboratory). Each laboratory

shall then reduce its portion to the size required for a single test in accordance with the sample

reduction procedure in EN 12697-28.

8.2.4 The repeatability, r, for binder content is 0,3 %. The reproducibility, R, for binder content is

0,5 %.

NOTE The above figures are based on a precision exercise carried out several years ago on coated macadams.

The precision was found to be the same for mixtures containing aggregates of nominal sizes larger and smaller

than 20 mm.

8.3 Precision — Experiment 2

The permissible range, a , in percent, is given by Formula (6):

zul

a = 2,77 (0,10 + 0,002 A) (6)

zul

where

a is the permissible range, expressed in percent (%);

zul

A is the oversize of the aggregate on a 11,2 mm test sieve, expressed in percent (%).

If the individual values for two specimens do not differ by more than the permissible range, a , the

zul

arithmetic mean should be considered to be the test result.

The repeatability standard deviation, s , in percent, is given by Formula (7):

r

s = (0,10 + 0,002 A) (7)

r

where

s is the repeatability standard deviation, expressed in percent (%);

r

A is the oversize of the aggregate on a 11,2 mm test sieve, expressed in percent (%).

If several values of A have been determined for a particular specimen, the arithmetic mean from these

should be taken as A.

The repeatability, r, is 2,77 s .

r

The reproducibility standard deviation, s , in percent, is given by Formula (8):

R

s = (0,15 + 0,002 A) (8)

R

where

s is the reproducible standard deviation, expressed in percent (%);

R

A is the oversize of the aggregate on a 11,2 mm sieve, expressed in percent (%).

If several values of A have been determined for a particular specimen, the arithmetic mean from these

should be taken as A.

The reproducibility, R, is 2,77 s .

R

8.4 Precision — Experiment 3

A precision experiment in accordance with ISO 5725-1 and ISO 5725-2 on the evaporation method by a

fraction of the solution, a mass method, was carried out in 1994/95 with 14 participating laboratories.

The precision is:

— repeatability, r = 0,23;

— reproducibility, R = 0,34 for an AC10.

8.5 Precision — Experiment 4

A precision experiment in accordance with ISO 5725-1 and ISO 5725-2 was coordinated by EAPIC in

January 2008. The results of 41 participants were statistically analysed, after which the results of 6

laboratories were rejected. All methods of EN 12697-1 were allowed and the following methods were

used: hot extraction, cold extraction and continuous centrifugation (also including automated

apparatus). The following precision values were obtained:

— repeatability, r = 0,23;

— reproducibility, R = 0,31;

— average difference from real value: − 0,03 %.

8.6 Precision — Experiment 5

EAPIC tests carried out in 2015-2016 have given r and R values for a population of 67 laboratories, with

a majority of automatic devices:

— corrected average value of binder contain = 5,47 %;

— r = 0,188;

— R = 0,269.

Annex A

(informative)

Guidance on the determination of binder content

A.1 Evaluation of the results

A.1.1 The advantages and disadvantages of the various analysis methods are a matter of individual

assessment which will depend on the circumstances that exist in any particular case. Nevertheless, the

methods, when carried out by a skilled operator, will produce comparable test results on all materials,

provided:

a) strict attention is paid to the details of the test procedures specified in this document;

b) the operator has shown that the repeatability requirements specified in Clause 8 of this document

have been achieved.

Comparable does not mean identical, as small systematic differences in results can arise when different

techniques of analysis are used except in the case of mixtures containing volatile diluents e.g. cutback

bitumens. These differences will be smaller than the reproducibility limits given in Clause 8. Where

volatile diluents are present in the bituminous mixture, significant differences in analysis results could

occur, depending on whether the binder is determined directly or by difference.

A.1.2 In reporting the results, the method employed should be stated. Clause 7 gives requirements for

the information which is to be given.

A.1.3 If the results obtained by different laboratories are to be compared over a period of time, it is

advisable to examine them for bias, which may inadvertently arise due to:

a) sampling point and method of sampling;

b) differences in method and systematic deviations from recommended technique;

c) differences in technique caused by a lack of full understanding of the test method;

d) in isolated cases, a small effect due to particular properties of the material being tested.

Where possible such differences should be reconciled before attempts are made to make direct

comparison between the results of tests.

A.1.4 It should be appreciated that, compared to the bitumen in the freshly mixed material, changes

can take place in the nature of bitumen in the road pavement which affect its solubility in the solvents

used in these methods of analysis. This factor, together with binder loss due to trafficking, increase in

aggregate content due to the ingress of uncoated detritus and changes in aggregate grading resulting

from compaction or the c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...