EN 13170:2008

(Main)Thermal insulation products for buildings - Factory made products of expanded cork (ICB) - Specification

Thermal insulation products for buildings - Factory made products of expanded cork (ICB) - Specification

This European Standard specifies the requirements for factory made products of expanded cork, which are used for the thermal insulation of buildings. The products are made with granulated cork agglomerated without additional binders and are delivered as boards without facings.

This European Standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking, labelling and packaging.

Products covered by this European Standard are also used in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered.

This European Standard does not specify the required level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application are to be found in regulations or non conflicting standards.

Products with a declared thermal resistance lower than 0,25 m2K/W, at 10 °C, or a declared thermal conductivity greater than 0,060 W/(mK), at 10 °C, are not covered by this European Standard.

Wärmedämmstoffe für Gebäude - Werkmäßig hergestellte Produkte aus expandiertem Kork (ICB) - Spezifikation

Diese Europäische Norm legt die Anforderungen für werkmäßig hergestellte Produkte aus expandiertem,

ohne zusätzliche Bindemittel gebundenem Kork fest, die für die Wärmedämmung von Gebäuden benutzt

werden. Die Produkte werden in der Form von Platten geliefert, mit und ohne Kaschierungen.

Diese Europäische Norm beschreibt die Stoffeigenschaften und enthält die Prüfverfahren und Festlegungen

für die Konformitätsbewertung, die Kennzeichnung, die Etikettierung und die Verpackung.

In dieser Europäischen Norm beschriebene Produkte werden auch in vorgefertigten Wärmedämmsystemen

und Mehrschicht-Verbundplatten angewendet; die Eigenschaften von Systemen, in die diese Produkte

integriert sind, werden nicht behandelt.

Diese Europäische Norm legt keine Anforderungsniveaus für eine vorgegebene Eigenschaft fest, die ein

Produkt erreichen muss, um für einen bestimmten Anwendungsfall tauglich zu sein. Für bestimmte

Anwendungen benötigte Anforderungen können Regelwerken oder übereinstimmenden Normen entnommen

werden.

Diese Europäische Norm gilt nicht für Produkte, deren Nennwert des Wärmedurchlasswiderstandes niedriger

als 0,25 m2 ⋅ K/W ist oder deren Nennwert der Wärmeleitfähigkeit größer als 0,060 W/(m ⋅ K) bei 10 °C ist.

Produits isolants thermiques pour le bâtiment - Produits manufacturés en liège expansé (ICB) - Spécification

La présente Norme européenne spécifie les exigences auxquelles doivent satisfaire les produits manufacturés en liège expansé utilisés pour l’isolation thermique des bâtiments. Les produits sont agglomérés sans addition de liants et sont livrés sous forme de panneaux, avec ou sans parements.

La présente Norme européenne décrit les caractéristiques du produit et inclut les procédures d’essai, d’évaluation de la conformité, de marquage, d’étiquetage et d’emballage.

Les produits couverts par la présente norme européenne sont également utilisés dans des systèmes d’isolation thermique et dans des panneaux composites préfabriqués ; la performance des systèmes incorporant ces produits n’y est pas définie.

La présente norme européenne ne spécifie pas, pour une propriété donnée, le niveau exigé que doit atteindre un produit pour démontrer son aptitude à l’emploi dans une application particulière. Les niveaux requis pour une application donnée figurent dans les réglementations ou normes non conflictuelles.

Les produits dont la résistance thermique déclarée, à la température de 10 °C, est inférieure à 0,25 m².K/W ou dont la conductivité thermique déclarée, à la température de 10 °C, est supérieure à 0,060 W/(m.K) ne sont pas du domaine d’application de la présente norme européenne.

Toplotnoizolacijski proizvodi za stavbe - Proizvodi iz ekspandirane plute (ICB) - Specifikacija

General Information

- Status

- Withdrawn

- Publication Date

- 25-Nov-2008

- Withdrawal Date

- 27-Nov-2012

- Technical Committee

- CEN/TC 88 - Thermal insulating materials and products

- Drafting Committee

- CEN/TC 88 - Thermal insulating materials and products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Nov-2012

- Completion Date

- 28-Nov-2012

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13170:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal insulation products for buildings - Factory made products of expanded cork (ICB) - Specification". This standard covers: This European Standard specifies the requirements for factory made products of expanded cork, which are used for the thermal insulation of buildings. The products are made with granulated cork agglomerated without additional binders and are delivered as boards without facings. This European Standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking, labelling and packaging. Products covered by this European Standard are also used in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered. This European Standard does not specify the required level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application are to be found in regulations or non conflicting standards. Products with a declared thermal resistance lower than 0,25 m2K/W, at 10 °C, or a declared thermal conductivity greater than 0,060 W/(mK), at 10 °C, are not covered by this European Standard.

This European Standard specifies the requirements for factory made products of expanded cork, which are used for the thermal insulation of buildings. The products are made with granulated cork agglomerated without additional binders and are delivered as boards without facings. This European Standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking, labelling and packaging. Products covered by this European Standard are also used in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered. This European Standard does not specify the required level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application are to be found in regulations or non conflicting standards. Products with a declared thermal resistance lower than 0,25 m2K/W, at 10 °C, or a declared thermal conductivity greater than 0,060 W/(mK), at 10 °C, are not covered by this European Standard.

EN 13170:2008 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13170:2008 has the following relationships with other standards: It is inter standard links to EN 13170:2001/AC:2005, EN 13170:2001, EN 13170:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13170:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13170:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Toplotnoizolacijski proizvodi za stavbe - Proizvodi iz ekspandirane plute (ICB) - SpecifikacijaWärmedämmstoffe für Gebäude - Werkmäßig hergestellte Produkte aus expandiertem Kork (ICB) - SpezifikationProduits isolants thermiques pour le bâtiment - Produits manufacturés en liège expansé (ICB) - SpécificationThermal insulation products for buildings - Factory made products of expanded cork (ICB) - Specification91.100.60Thermal and sound insulating materialsICS:Ta slovenski standard je istoveten z:EN 13170:2008SIST EN 13170:2009en,de01-februar-2009SIST EN 13170:2009SLOVENSKI

STANDARDSIST EN 13170:2002/AC:2006SIST EN 13170:20021DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13170November 2008ICS 91.100.60Supersedes EN 13170:2001

English VersionThermal insulation products for buildings - Factory madeproducts of expanded cork (ICB) - SpecificationProduits isolants thermiques pour le bâtiment - Produitsmanufacturés en liège expansé (ICB) - SpécificationWärmedämmstoffe für Gebäude - Werkmäßig hergestellteProdukte aus expandiertem Kork (ICB) - SpezifikationThis European Standard was approved by CEN on 25 October 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13170:2008: ESIST EN 13170:2009

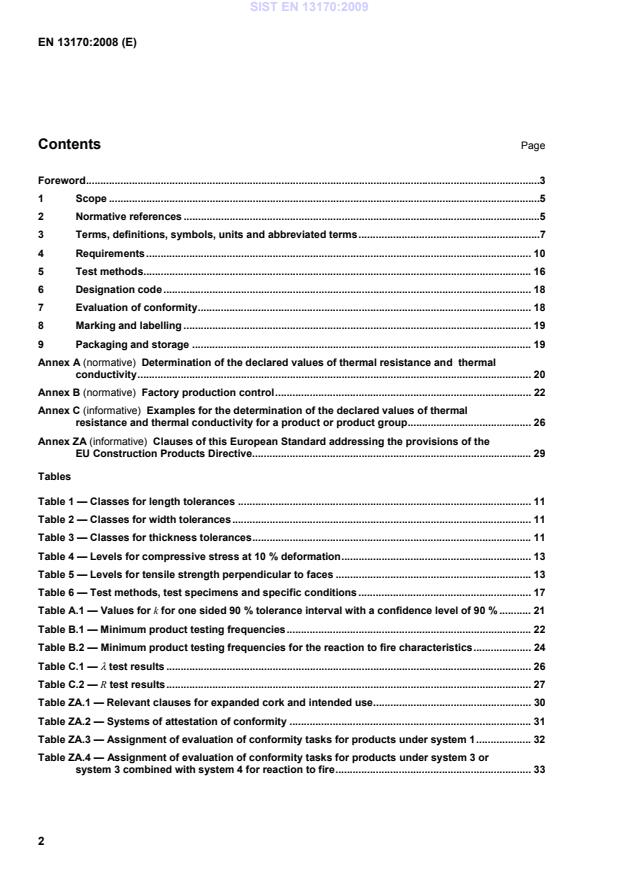

Determination of the declared values of thermal resistance and

thermal conductivity . 20 Annex B (normative)

Factory production control . 22 Annex C (informative)

Examples for the determination of the declared values of thermal resistance and thermal conductivity for a product or product group . 26 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive. 29

Tables Table 1 — Classes for length tolerances . 11 Table 2 — Classes for width tolerances . 11 Table 3 — Classes for thickness tolerances . 11 Table 4 — Levels for compressive stress at 10 % deformation . 13 Table 5 — Levels for tensile strength perpendicular to faces . 13 Table 6 — Test methods, test specimens and specific conditions . 17 Table A.1 — Values for k for one sided 90 % tolerance interval with a confidence level of 90 % . 21 Table B.1 — Minimum product testing frequencies . 22 Table B.2 — Minimum product testing frequencies for the reaction to fire characteristics . 24 Table C.1 — λ test results . 26 Table C.2 — R test results . 27 Table ZA.1 — Relevant clauses for expanded cork and intended use . 30 Table ZA.2 — Systems of attestation of conformity . 31 Table ZA.3 — Assignment of evaluation of conformity tasks for products under system 1 . 32 Table ZA.4 — Assignment of evaluation of conformity tasks for products under system 3 or system 3 combined with system 4 for reaction to fire . 33

1 Scope This European Standard specifies the requirements for factory made products of expanded cork, which are used for the thermal insulation of buildings. The products are made with granulated cork agglomerated without additional binders and are delivered as boards without facings. This European Standard specifies product characteristics and includes procedures for testing, evaluation of conformity, marking, labelling and packaging. Products covered by this European Standard are also used in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered. This European Standard does not specify the required level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application are to be found in regulations or non-conflicting standards. Products with a declared thermal resistance lower than 0,25 m2⋅K/W, at 10 °C, or a declared thermal conductivity greater than 0,060 W/(m⋅K), at 10 °C, are not covered by this European Standard. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 822, Thermal insulating products for building applications — Determination of length and width EN 823, Thermal insulating products for building applications — Determination of thickness EN 824, Thermal insulating products for building applications — Determination of squareness EN 825, Thermal insulating products for building applications — Determination of flatness EN 826, Thermal insulating products for building applications — Determination of compression behaviour EN 1602, Thermal insulating products for building applications — Determination of the apparent density EN 1603, Thermal insulating products for building applications — Determination of dimensional stability under constant normal laboratory conditions (23 °C/50 % relative humidity) EN 1604, Thermal insulating products for building applications — Determination of dimensional stability under specified temperature and humidity conditions EN 1605, Thermal insulating products for building applications — Determination of deformation under specified compressive and temperature conditions EN 1606, Thermal insulating products for building applications — Determination of compressive creep EN 1607, Thermal insulating products for building applications — Determination of tensile strength perpendicular to faces EN 1609, Thermal insulating products for building applications — Determination of short term water absorption by partial immersion SIST EN 13170:2009

EN 29053, Acoustics — Materials for acoustical applications - Determination of air flow resistance (ISO 9053:1991) EN ISO 354, Acoustics — Measurement of sound absorption in a reverberation room (ISO 354:2003) EN ISO 1182, Reaction to fire tests for building products — Non-combustibility test (ISO 1182:2002) EN ISO 1716, Reaction to fire tests for building products — Determination of the heat of combustion (ISO 1716:2002)

EN ISO 9229:2007, Thermal insulation — Vocabulary (ISO 9229:2007)

EN ISO 11654, Acoustics — Sound absorbers for use in buildings — Rating of sound absorption (ISO 11654:1997) EN ISO 11925-2, Reaction to fire tests — Ignitability of building products subjected to direct impingement of flame – Part 2: Single-flame source test (ISO 11925-2:2002) ISO 12491, Statistical methods for quality control of building materials and components

1 Under review SIST EN 13170:2009

NOTE The level is given by the declared value of the characteristic concerned. 3.1.2.2 class combination of two levels of the same property between which the performance shall fall 3.2 Symbols, units and abbreviated terms 3.2.1 Symbols and units used in this standard: αp is the practical sound absorption coefficient – αw is the weighted sound absorption coefficient – b is the width mm c is the compressibility mm d is the thickness under a load of (2,5 ± 0,5) kPa mm SIST EN 13170:2009

W/(m⋅K) λmean is the mean thermal conductivity

W/(m⋅K) n is the number of test results

– R90/90 is the 90 % fractile with a confidence level of 90 % for the thermal resistance m2⋅K/W RD is the declared thermal resistance m2⋅K/W Ri is one test result of thermal resistance

m2⋅K/W Rmean is the mean thermal resistance

m2⋅K/W ρa is the apparent density kg/m3 Sb is the deviation from squareness on length and width mm/m Sd is the deviation from squareness on thickness mm Smax is the deviation from flatness mm sR is the estimate of the standard deviation of the thermal resistance m2⋅K/W sλ is the estimate of the standard deviation of the thermal conductivity W/(m⋅K) s′ is the dynamic stiffness MN/m3 σ10 is the compressive stress at 10 % deformation kPa σb is the bending strength kPa σc is the declared compressive stress (for compressive creep) kPa SIST EN 13170:2009

Table 2 — Classes for width tolerances Class Tolerances mm W1 ± 2 W2 ± 3

NOTE The commonly linear dimensions of ICB boards are: Length:

1000 mm Width:

500 mm 4.2.3 Thickness Thickness, d, shall be determined in accordance with EN 823, method B.2, under a pressure of (2,5 ± 0,5) kPa. No test result shall deviate from the nominal thickness, dN, by more than the tolerances given in Table 3 for the declared class. Table 3 — Classes for thickness tolerances Class Thickness Tolerances T1 20 mm ≤ d ≤ 50 mm ± 1 mm T2 d > 50 mm ± 2 %, maximum ± 2 mm

4.2.4 Squareness Squareness shall be determined in accordance with EN 824. The deviation from squareness on length and width, Sb, shall not exceed 4 mm/m. The deviation from squareness on thickness, Sd, shall not exceed 2 mm. 4.2.5 Flatness Flatness shall be measured according to EN 825. The deviation from flatness, Smax, shall not exceed 2 mm. 4.2.6 Dimensional stability 4.2.6.1 Dimensional stability under constant normal laboratory conditions Dimensional stability under constant normal laboratory conditions (23 °C/50 % relative humidity) shall be determined in accordance with EN 1603 after storage for 48 h. The relative changes in length, ∆εl, and width, ∆εb, shall not exceed 0,5 %; the relative deviation in flatness, ∆εs, shall not exceed 1 mm/m. SIST EN 13170:2009

4.3.5 Tensile strength perpendicular to faces Tensile strength perpendicular to the faces, σmt, shall be determined in accordance with EN 1607. The value of tensile strength shall be declared in steps of 10 kPa. No test result shall be lower than the value given in Table 5 for the declared level. Table 5 — Levels for tensile strength perpendicular to faces Level Requirement kPa TR40 ≥ 40 TR50 ≥ 50 TR60 ≥ 60

NOTE 2 Referring to the designation code CC(i1/i2/y)σc, Clause 6, a declared level CC(2,5/2/10)50, as for example, indicates a value not exceeding 2 % for compressive creep and 2,5 % for total relative thickness reduction after extrapolation at 10 years (i.e. 30 times one hundred twenty two days of testing) under a declared stress of 50 kPa. 4.3.8 Shear strength Shear strength, τ, shall be determined in accordance with EN 12090. No test result shall be lower than 50 kPa. 4.3.9 Water absorption Short-term water absorption by partial immersion, Wp, shall be determined in accordance with EN 1609, method A. No test result shall exceed 0,5 kg/m2. 4.3.10 Water vapour transmission Water vapour transmission properties shall be determined in accordance with EN 12086 and declared as the water vapour resistance, Z. No test result shall be less than the declared value, Z. 4.3.11 Dynamic stiffness Dynamic stiffness, s′, shall be determined in accordance with EN 29052-1, without pre-loading. The value of dynamic stiffness shall be declared in levels with steps of 1 MN/m3. No test result shall exceed the declared level, SD. For products having a declared level of compressibility (see 4.3.12.3) lower or equal to 2 mm, if the imposed load exceeds 5,0 kPa, the dynamic stiffness shall be determined under the imposed load plus the self-weight of the screed. SIST EN 13170:2009

6 Designation code A designation code for the product shall be given by the manufacturer. The following shall be included except when there is no requirement for a property described in 4.3: The expanded cork abbreviated term ICB This standard number EN 13170 Thickness tolerances Ti Dimensional stability at specified temperature DS(T+) Dimensional stability under specified temperature and humidity conditions DS(TH) Compressive stress at 10 % deformation CS(10)i Tensile strength perpendicular to faces TRi Point load PL(P)i Compressive creep CC(i1/i2/y)σc Short term water absorption WS Water vapour transmission Zi Dynamic stiffness SDi Compressibility CPi Practical sound absorption coefficient APi Weighted sound absorption coefficient AWi Air flow resistivity AFri The designation code for products of expanded cork is illustrated by the following example: ICB — EN 13170 — T2 — DS(T+) — CS(10)100 — TR50 — PL(P)200 — WS — Z1 — SD15 NOTE The characteristics determined in 4.2 are not included in the designation code if a limit value (threshold value) is given for the product. 7 Evaluation of conformity The manufacturer or his authorised representative shall be responsible for the conformity of his product with the requirements of this European Standard. The evaluation of conformity shall be carried out in accordance with EN 13172 and shall be based on initial type testing (ITT), factory production control (FPC) by the manufacturer, including product assessment and tests on samples taken at the factory. The compliance of the product with the requirements of this standard and with the stated values (including classes) shall be demonstrated by: SIST EN 13170:2009

For the EC certificate and declaration of conformity, as appropriate, see ZA.2.2. 8 Marking and labelling Products conforming to this standard shall be clearly marked, either on the product or on a label or on the packaging, with the following information: product name or other identifying characteristic; name or identifying mark and address of the manufacturer or his authorised representative; shift or time of production and manufacturing plant or traceability code; reaction to fire class; declared thermal resistance; declared thermal conductivity; nominal thickness; designation code as given in Clause 6; type of facing, if any; nominal length, nominal width; number of boards and area in the package, as appropriate. NOTE For CE marking and labelling, see ZA.3. 9 Packaging and storage The packaging shall ensure that the product will be stored, transported and delivered protected from rain and atmospheric humidity. SIST EN 13170:2009

Determination of the declared values of thermal resistance and

thermal conductivity A.1 General It is the responsibility of the manufacturer to determine the declared values of thermal resistance and thermal conductivity. He will have to demonstrate conformity of the product to its declared values. The declared values of thermal resistance and thermal conductivity of a product are the expected values of these properties during an economically reasonable working life under normal conditions, assessed through measured data at reference conditions. A.2 Input data In order to calculate the declared values, the manufacturer shall have at least ten test results for thermal resistance or thermal conductivity, obtained from internal or external direct measurements. These measurements shall be carried out, at regular intervals, spread over a period of the last twelve months. If less than ten test results are available, that period may be extended until ten results are obtained but in a maximum period of three years, within which the product and production conditions have not changed significantly. For new products, the ten thermal resistance or thermal conductivity test results shall be obtained spread over a minimum period of ten days. The declared values shall be calculated according to the method given in A.3 and shall be recalculated at intervals not exceeding three months of production. A.3 Declared values A.3.1 General The derivation of the declared values RD and λD from the calculated values R90/90 and λ90/90 shall use the rules given in 4.2.1 which include the rounding conditions. A.3.2 Case where both thermal resistance and thermal conductivity are declared The declared values RD and λD shall be derived from the calculated values R90/90 and λ90/90 which are determined using the equations A.1, A.2 and A.3. λ90/90 = λmean + k × sλ (A.1) 1)(12meani−−=∑=nsniλλλ (A.2) R90/90 = dN/λ90/90 (A.3) SIST EN 13170:2009

Factory production control Table B.1 — Minimum product testing frequencies Clause Minimum testing frequenciesa No Title Direct testing Indirect testing Test method Frequency 4.2.1 Thermal resistance – Thermal conductivity 1 per 3 months and indirect testing Apparent density 1 per 2 hours 4.2.2 Length and width 1 per 2 hours - - 4.2.3 Thickness 1 per 2 hours - - 4.2.4 Squareness 1 per 4 hours - - 4.2.5 Flatness 1 per 8 hours - - 4.2.6 Dimensional stability at normal laboratory conditions 1 per 6 months - -

Dimensional stability under specified temper

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...