EN ISO 14620-1:2002

(Main)Space systems - Safety requirements - Part 1: System safety (ISO 14620-1:2002)

Space systems - Safety requirements - Part 1: System safety (ISO 14620-1:2002)

ISO 14620-1:2002 defines the safety programme and the technical safety requirements that are implemented in order to comply with the safety policy as defined in ISO 14300-2. It is intended to protect flight and ground personnel, the launch vehicle, associated payloads, ground support equipment, the general public, public and private property, and the environment from hazards associated with space systems. Launch site operations are described by ISO 14620-2.

The safety policy is applied by implementing a system safety programme, supported by risk assessment, which can be summarized as follows: hazardous characteristics (system and environmental hazards) and functions with potentially hazardous failure effects are identified and progressively evaluated by iteratively performing systematic safety analyses; the potential hazardous consequences associated with the system characteristics and functional failures are subjected to a hazard reduction sequence whereby hazards are eliminated from the system design and operations, hazards are minimized, and hazard controls are applied and verified; the risks that remain after the application of a hazard elimination and reduction process are progressively assessed and subjected to risk assessment, in order to show compliance with safety targets, support design trades, identify and rank risk contributors, support apportionment of project resources for risk reduction, assess risk reduction progress, and support the safety and project decision-making process (e.g. waiver approval, residual risk acceptance); the adequacy of the hazard and risk control measures applied are formally verified in order to support safety validation and risk acceptance; safety compliance is assessed by the project and safety approval obtained from the relevant authorities.

ISO 14620-1:2002 is applicable to all space projects where during any project phase there exists the potential for hazards to personnel or the general public, space flight systems, ground support equipment, facilities, public or private property, or the environment.

The imposition of these requirements on the project suppliers' activities requires that the customer's project product assurance and safety organization also respond to these requirements in a manner which is commensurate with the project's safety criticality.

When viewed from the perspective of a specific programme or project context, the requirements defined in ISO 14620-1:2002 should be tailored to match the genuine requirements of a particular profile and circumstances of a programme or project.

Raumfahrtsysteme - Sicherheitsanforderungen - Teil 1: Systemsicherheit (ISO 14620-1:2002)

1.1 Allgemein

Diese Europäische Norm legt das Sicherheitsprogramm und die sicherheitstechnischen Anforderungen fest, die in Übereinstimmung mit der in ISO 14300 2 festgelegten Sicherheitsleitlinien umzusetzen sind, um Flug- und Bodenpersonal, Träger, zugehörige Nutzlasten, Bodendienstgeräte, die allgemeine Öffentlichkeit, öffentliches und privates Eigentum sowie die Umwelt vor Gefährdungen im Zusammenhang mit europäischen Raumfahrtsystemen zu schützen. Abschussbasisoperationen sind in ISO 14620 2 beschrieben.

Die Sicherheitsleitlinien werden durch Umsetzung eines Sicherheitsprogramms, unterstützt durch eine Risikobewertung, verwirklicht, das sich wie folgt zusammenfassen lässt:

a) Gefährdungsmerkmale (System- und Umweltgefährdungen) und Funktionen mit potentiell gefährdenden Ausfall-/Fehlerauswirkungen werden identifiziert und schrittweise durch iterative Durchführung systematischer, deterministischer Sicherheitsanalysen bewertet;

b) potentielle Gefährdungsfolgen im Zusammenhang mit den Merkmalen und Funktionsausfällen/-fehlern des Systems werden einer Gefährdungsreduzierungssequenz unterzogen, wobei:

1) Gefährdungen aus dem Systemdesign und -betrieb beseitigt;

2) Gefährdungen minimiert;

3) Gefährdungskontrollmaßnahmen angewandt und verifiziert werden.

c) Die nach Durchführung des Gefährdungsbeseitigungs- und -reduzierungsprozesses verbleibenden Risiken werden schrittweise bewertet und einer Risikobewertung unterzogen, um:

1) die Übereinstimmung mit den Sicherheitszielen aufzuzeigen;

2) vergleichende Designbewertungen zu unterstützen;

3) Risikoverursacher festzustellen und einzustufen;

4) die Zuteilung von Projektmitteln zur Risikoreduzierung zu unterstützen;

5) den Fortschritt der Risikoreduzierung zu beurteilen;

6) den Prozess von Sicherheits- und Projektentscheidungsfindungen (z. B. Sonderfreigaben, Restrisikobilligung) zu unterstützen.

d) Die Angemessenheit der Gefährdungs- und Risikokontrollmaßnahmen wird formal verifiziert, um die Beglaubigung d

Systèmes spatiaux - Exigences de sécurité - Partie 1: Sécurité système (ISO 14620-1:2002)

1.1 Généralités

La présente Norme européenne définit le programme de sécurité et les exigences techniques de sécurité mises en �uvre pour se conformer à la politique de sécurité définie dans la norme ISO 14300-2. Elle vise à protéger le personnel de vol et le personnel au sol, le lanceur, les charges utiles associées, les équipements de support au sol, le grand public, les biens publics et privés et l'environnement contre les dangers associés aux systèmes spatiaux. Les opérations sur la base de lancement sont décrites dans la norme ISO 14620-2.

La politique de sécurité est appliquée par la mise en �uvre d'un programme de sécurité système, reposant sur une évaluation des risques, qui peut être résumé comme suit :

a) les caractéristiques dangereuses (dangers liés au système et à l'environnement) et les fonctions présentant des effets potentiellement dangereux liés à des défaillances sont identifiées et progressivement évaluées en effectuant de manière itérative des analyses systématiques de sécurité ;

b) les conséquences potentiellement dangereuses associées aux caractéristiques du système et aux défaillances fonctionnelles sont soumises à une séquence de réduction des dangers aux termes de laquelle :

1) des dangers sont supprimés par la conception du système et par sa mise en �uvre opérationnelle ;

2) des dangers sont minimisés ;

3) des opérations de maîtrise des dangers sont appliquées et vérifiées.

c) les risques qui subsistent après application du processus d'élimination et de réduction des dangers sont soumis à une évaluation progressive des risques, dans le but :

1) d'assurer la conformité avec les objectifs de sécurité ;

2) de prendre en compte des comparaisons de conception ;

3) d'identifier et de classer les facteurs contribuant aux risques ;

4) de considérer une répartition des ressources du projet pour réduire les risques ;

5) d'évaluer l'état d'avancement de la réduction des risques ;

6) de consolider le processus de prise de décision du pr

Space systems - Safety requirements - Part 1: System safety (ISO 14620-1:2002)

General Information

- Status

- Withdrawn

- Publication Date

- 30-Nov-2002

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/SS T02 - Aerospace

- Drafting Committee

- CEN/SS T02 - Aerospace

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Apr-2018

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 21-Mar-2018

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 12-Feb-2026

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN ISO 14620-1:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space systems - Safety requirements - Part 1: System safety (ISO 14620-1:2002)". This standard covers: ISO 14620-1:2002 defines the safety programme and the technical safety requirements that are implemented in order to comply with the safety policy as defined in ISO 14300-2. It is intended to protect flight and ground personnel, the launch vehicle, associated payloads, ground support equipment, the general public, public and private property, and the environment from hazards associated with space systems. Launch site operations are described by ISO 14620-2. The safety policy is applied by implementing a system safety programme, supported by risk assessment, which can be summarized as follows: hazardous characteristics (system and environmental hazards) and functions with potentially hazardous failure effects are identified and progressively evaluated by iteratively performing systematic safety analyses; the potential hazardous consequences associated with the system characteristics and functional failures are subjected to a hazard reduction sequence whereby hazards are eliminated from the system design and operations, hazards are minimized, and hazard controls are applied and verified; the risks that remain after the application of a hazard elimination and reduction process are progressively assessed and subjected to risk assessment, in order to show compliance with safety targets, support design trades, identify and rank risk contributors, support apportionment of project resources for risk reduction, assess risk reduction progress, and support the safety and project decision-making process (e.g. waiver approval, residual risk acceptance); the adequacy of the hazard and risk control measures applied are formally verified in order to support safety validation and risk acceptance; safety compliance is assessed by the project and safety approval obtained from the relevant authorities. ISO 14620-1:2002 is applicable to all space projects where during any project phase there exists the potential for hazards to personnel or the general public, space flight systems, ground support equipment, facilities, public or private property, or the environment. The imposition of these requirements on the project suppliers' activities requires that the customer's project product assurance and safety organization also respond to these requirements in a manner which is commensurate with the project's safety criticality. When viewed from the perspective of a specific programme or project context, the requirements defined in ISO 14620-1:2002 should be tailored to match the genuine requirements of a particular profile and circumstances of a programme or project.

ISO 14620-1:2002 defines the safety programme and the technical safety requirements that are implemented in order to comply with the safety policy as defined in ISO 14300-2. It is intended to protect flight and ground personnel, the launch vehicle, associated payloads, ground support equipment, the general public, public and private property, and the environment from hazards associated with space systems. Launch site operations are described by ISO 14620-2. The safety policy is applied by implementing a system safety programme, supported by risk assessment, which can be summarized as follows: hazardous characteristics (system and environmental hazards) and functions with potentially hazardous failure effects are identified and progressively evaluated by iteratively performing systematic safety analyses; the potential hazardous consequences associated with the system characteristics and functional failures are subjected to a hazard reduction sequence whereby hazards are eliminated from the system design and operations, hazards are minimized, and hazard controls are applied and verified; the risks that remain after the application of a hazard elimination and reduction process are progressively assessed and subjected to risk assessment, in order to show compliance with safety targets, support design trades, identify and rank risk contributors, support apportionment of project resources for risk reduction, assess risk reduction progress, and support the safety and project decision-making process (e.g. waiver approval, residual risk acceptance); the adequacy of the hazard and risk control measures applied are formally verified in order to support safety validation and risk acceptance; safety compliance is assessed by the project and safety approval obtained from the relevant authorities. ISO 14620-1:2002 is applicable to all space projects where during any project phase there exists the potential for hazards to personnel or the general public, space flight systems, ground support equipment, facilities, public or private property, or the environment. The imposition of these requirements on the project suppliers' activities requires that the customer's project product assurance and safety organization also respond to these requirements in a manner which is commensurate with the project's safety criticality. When viewed from the perspective of a specific programme or project context, the requirements defined in ISO 14620-1:2002 should be tailored to match the genuine requirements of a particular profile and circumstances of a programme or project.

EN ISO 14620-1:2002 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN ISO 14620-1:2002 has the following relationships with other standards: It is inter standard links to EN 16602-40:2018, EN ISO 3450:2008, EN 1807:1999/prA1, CEN/TS 15477:2006, EN 14738:2004, EN 14607-6:2004, EN 14607-1:2004, ISO 14620-1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN ISO 14620-1:2002 is associated with the following European legislation: Standardization Mandates: M/237. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN ISO 14620-1:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2004

Space systems - Safety requirements - Part 1: System safety (ISO 14620-1:2002)

Space systems - Safety requirements - Part 1: System safety (ISO 14620-1:2002)

Raumfahrtsysteme - Sicherheitsanforderungen - Teil 1: Systemsicherheit (ISO 14620-

1:2002)

Systemes spatiaux - Exigences de sécurité - Partie 1: Sécurité systeme (ISO 14620-

1:2002)

Ta slovenski standard je istoveten z: EN ISO 14620-1:2002

ICS:

49.140 Vesoljski sistemi in operacije Space systems and

operations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN ISO 14620-1

NORME EUROPÉENNE

EUROPÄISCHE NORM

December 2002

ICS 49.140

English version

Space systems - Safety requirements - Part 1: System safety

(ISO 14620-1:2002)

Systèmes spatiaux - Exigences de sécurité - Partie 1: Raumfahrtsysteme - Sicherheitsanforderungen - Teil 1:

Sécurité système (ISO 14620-1:2002) Systemsicherheit (ISO 14620-1:2002)

This European Standard was approved by CEN on 24 June 2002.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,

Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2002 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN ISO 14620-1:2002 E

worldwide for CEN national Members.

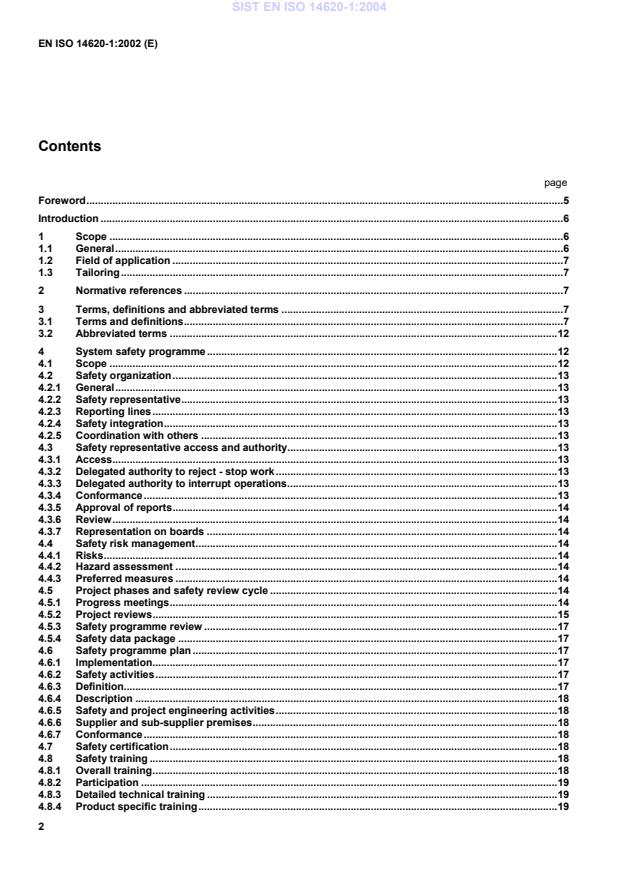

Contents

page

Foreword.5

Introduction .6

1 Scope .6

1.1 General.6

1.2 Field of application .7

1.3 Tailoring.7

2 Normative references .7

3 Terms, definitions and abbreviated terms .7

3.1 Terms and definitions.7

3.2 Abbreviated terms .12

4 System safety programme.12

4.1 Scope .12

4.2 Safety organization.13

4.2.1 General.13

4.2.2 Safety representative.13

4.2.3 Reporting lines.13

4.2.4 Safety integration.13

4.2.5 Coordination with others .13

4.3 Safety representative access and authority.13

4.3.1 Access.13

4.3.2 Delegated authority to reject - stop work.13

4.3.3 Delegated authority to interrupt operations.13

4.3.4 Conformance.13

4.3.5 Approval of reports.14

4.3.6 Review.14

4.3.7 Representation on boards .14

4.4 Safety risk management.14

4.4.1 Risks.14

4.4.2 Hazard assessment .14

4.4.3 Preferred measures .14

4.5 Project phases and safety review cycle .14

4.5.1 Progress meetings.14

4.5.2 Project reviews.15

4.5.3 Safety programme review .17

4.5.4 Safety data package .17

4.6 Safety programme plan .17

4.6.1 Implementation.17

4.6.2 Safety activities.17

4.6.3 Definition.17

4.6.4 Description .18

4.6.5 Safety and project engineering activities.18

4.6.6 Supplier and sub-supplier premises.18

4.6.7 Conformance.18

4.7 Safety certification.18

4.8 Safety training .18

4.8.1 Overall training.18

4.8.2 Participation .19

4.8.3 Detailed technical training .19

4.8.4 Product specific training.19

4.8.5 Records.19

4.8.6 Identification.19

4.9 Accident/incident reporting and investigation .19

4.10 Safety documentation .19

4.10.1 General.19

4.10.2 Customer access .19

4.10.3 Supplier review .19

4.10.4 Documentation.20

4.10.5 Safety data package .20

4.10.6 Safety deviations and waivers.20

4.10.7 Verification tracking log.21

4.10.8 Lessons-learned file .21

5 Safety engineering.21

5.1 Safety engineering policy .21

5.1.1 General.21

5.1.2 Elements.21

5.1.3 Lessons learned.22

5.2 Safety design principles .22

5.2.1 Human life consideration.22

5.2.2 Design selection .22

5.2.3 System safety order of precedence.22

5.2.4 Environmental compatibility.23

5.2.5 Safe without services .23

5.2.6 Fail safe design.23

5.2.7 Hazard detection - Signalling and safing .23

5.2.8 Access .24

5.3 Safety risk reduction and control.24

5.3.1 Severity .24

5.3.2 Failure tolerance requirements .26

5.3.3 Design for minimum risk.27

5.3.4 Probabilistic safety targets.27

5.4 Identification and control of safety critical functions.28

5.4.1 Identification.28

5.4.2 Inadvertent operation .28

5.4.3 Provisions.28

5.4.4 Safe shutdown and failure tolerance requirements.28

5.4.5 Electronic, electrical, electromechanical .28

6 Safety analysis requirements and techniques .29

6.1 General.29

6.2 Assessment and allocation of requirements .29

6.2.1 Safety requirements .29

6.2.2 Additional safety requirements.29

6.2.3 Define safety requirements - functions .29

6.2.4 Define safety requirements - subsystems .29

6.2.5 Justification.29

6.2.6 Functional and subsystem specification .30

6.3 Safety analysis.30

6.3.1 General.30

6.3.2 Mission analysis .30

6.3.3 Feasibility .30

6.3.4 Preliminary definition .30

6.3.5 Detailed definition, production and qualification .30

6.3.6 Utilization.30

6.3.7 Disposal .30

6.4 Specific safety analysis .30

6.4.1 General.30

6.4.2 Hazard analysis.31

6.4.3 Safety risk assessment .31

6.4.4 Safety analysis for hardware-software systems .32

6.5 Supporting assessment and analysis .32

6.5.1 General.32

6.5.2 Warning time analysis .32

6.5.3 Caution and warning analysis .33

6.5.4 Common cause and common mode failure analysis.33

6.5.5 Fault tree analysis.34

6.5.6 Human dependability analysis .34

6.5.7 Failure modes, effects and criticality analysis .34

6.5.8 Sneak analysis .34

6.5.9 Zonal analysis .35

6.5.10 Energy trace analysis .35

7 Safety verification .35

7.1 General.35

7.2 Tracking of hazards .36

7.2.1 Hazard reporting system.36

7.2.2 Status .36

7.2.3 Safety progress meeting.36

7.2.4 Review and disposition.36

7.2.5 Documentation.36

7.2.6 Mandatory inspection points.36

7.3 Safety verification methods.36

7.3.1 Verification engineering and planning .36

7.3.2 Methods and reports .36

7.3.3 Verification requirements.37

7.3.4 Analysis .37

7.3.5 Inspections .37

7.3.6 Tests.37

7.3.7 Verification and approval.37

7.4 Qualification of safety critical functions .37

7.4.1 Validation.37

7.4.2 Qualification .37

7.4.3 Failure tests.38

7.4.4 Verification of design or operational characteristics.38

7.4.5 Safety verification testing .38

7.5 Hazard close-out .38

7.5.1 Safety assurance verification .38

7.5.2 Safety approval authority.38

7.6 Residual risk reduction .38

8 Operational safety.39

8.1 Basic requirements.39

8.2 Flight operations and mission control .39

8.2.1 Launcher operations .39

8.2.2 Contamination.39

8.2.3 Flight rules.39

8.2.4 Hazardous commanding control.39

8.2.5 Mission operation change control .40

8.2.6 Safety surveillance and anomaly control .40

8.3 Ground operations.40

8.3.1 Applicability.40

8.3.2 Initiation .40

8.3.3 Review and inspection .40

8.3.4 Hazardous operations .40

8.3.5 Launch and landing site requirements.41

8.3.6 GSE requirements.41

Bibliography .42

Foreword

This document EN ISO 14620-1:2002 has been prepared by Technical Committee CEN/SS T02 "Aerospace", the

secretariat of which is held by CMC, in collaboration with Technical Committee ISO/TC 20 "Aircraft and space

vehicles".

This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at the latest by June 2003, and conflicting national standards shall be withdrawn at the latest by

June 2003.

The European Standard EN ISO 14620-1 was prepared by the European Cooperation for Space Standardization

(ECSS) Product Assurance Working Group for CEN in close collaboration with ISO Technical Committee

ISO/TC 20, Aircraft and space vehicles, Subcommittee SC 14, Space systems and operations, WG 5, Program

management.

EN ISO 14620 consists of the following parts, under the general title Space systems — Safety requirements:

Part 1: System safety

Part 2: Launch site operations

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,

France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain,

Sweden, Switzerland and the United Kingdom.

Introduction

This European Standard is one of the series of space standards intended to be applied together for the

management, engineering and product assurance in space projects and applications.

1 Scope

1.1 General

This European Standard defines the safety programme and the technical safety requirements that are implemented

in order to comply with the safety policy as defined in ISO 14300-2. It is intended to protect flight and ground

personnel, the launch vehicle, associated payloads, ground support equipment, the general public, public and

private property, and the environment from hazards associated with space systems. Launch site operations are

described by ISO 14620-2.

The safety policy is applied by implementing a system safety programme, supported by risk assessment, which can

be summarized as follows:

a) hazardous characteristics (system and environmental hazards) and functions with potentially hazardous failure

effects are identified and progressively evaluated by iteratively performing systematic safety analyses;

b) the potential hazardous consequences associated with the system characteristics and functional failures are

subjected to a hazard reduction sequence whereby:

1) hazards are eliminated from the system design and operations;

2) hazards are minimized;

3) hazard controls are applied and verified.

c) the risks that remain after the application of a hazard elimination and reduction process are progressively

assessed and subjected to risk assessment, in order to:

1) show compliance with safety targets;

2) support design trades;

3) identify and rank risk contributors;

4) support apportionment of project resources for risk reduction;

5) assess risk reduction progress;

6) support the safety and project decision-making process (e.g. waiver approval, residual risk

acceptance).

d) the adequacy of the hazard and risk control measures applied are formally verified in order to support safety

validation and risk acceptance;

e) safety compliance is assessed by the project and safety approval obtained from the relevant authorities.

1.2 Field of application

This European Standard is applicable to all space projects where during any project phase there exists the

potential for hazards to personnel or the general public, space flight systems, ground support equipment, facilities,

public or private property, or the environment.

The imposition of these requirements on the project suppliers’ activities requires that the customer’s project product

assurance and safety organization also respond to these requirements in a manner which is commensurate with

the project’s safety criticality.

1.3 Tailoring

When viewed from the perspective of a specific programme or project context, the requirements defined in this

European Standard should be tailored to match the genuine requirements of a particular profile and circumstances

of a programme or project.

NOTE Tailoring is the process by which individual requirements of specifications, standards and related documents are

evaluated, and made applicable to a specific programme or project by selection, and in some exceptional cases, modification of

existing or addition of new requirements.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of any of these publications apply to this European

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

ISO 14300-1, Space systems – Programme management – Part 1: Structuring of a programme.

ISO 14300-2, Space systems – Programme management – Part 2: Product assurance.

ISO 14620-2, Space systems – Safety requirements – Part 2: Launch site operations.

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this European Standard, the following terms and definitions apply.

3.1.1

accident

undesired event arising from operation of any project-specific items which results in:

a) human death or injury;

b) loss of, or damage to, hardware, software or facilities which could then affect the accomplishment of the

mission;

c) loss of, or damage to, public or private property; or

d) detrimental effects on the environment

[EN 13701:2001]

NOTE Accident and mishap are synonymous.

3.1.2

cause

that which produces an effect; that which gives rise to any action, phenomenon or condition

NOTE 1 Cause and effect are correlative terms (Oxford English Dictionary).

NOTE 2 Specific to this European Standard, cause, when used in the context of hazard analysis, is the action or condition by

which a hazardous event is initiated (an initiating event). The cause can arise as the result of failure, human error, design

inadequacy, induced or natural environment, system configuration or operational mode(s).

NOTE 3 Adapted from EN 13701:2001.

3.1.3

caution condition

condition which has the potential to degrade into a warning condition, and which might require specific action,

including the implementation of special procedures or restrictions on the operation of the system

[EN 13701:2001]

3.1.4

common cause failure

failure of multiple items occurring from a single cause which is common to all of them

[NUREG/CR-2300 PRA:1982]

3.1.5

common mode failure

failure of multiple identical items that fail in the same mode

NOTE 1 Common mode failures are a particular case of common cause failures.

NOTE 2 Adapted from NUREG/CR-2300 PRA:1982.

3.1.6

contingency procedure

pre-planned procedure to be executed in response to a departure from specified behaviour

[EN 13701:2001]

3.1.7

critical fault

fault which is assessed as likely to result in injury to persons, significant material damage, or other unacceptable

consequences

[IEC 60050:1992]

3.1.8

emergency

condition when potentially catastrophic or critical hazardous events have occurred, where immediate and pre-

planned safing action is possible and is mandatory in order to protect personnel

NOTE Adapted from EN 13701:2001.

3.1.9

fail safe

design property of an item which prevents its failures from resulting in critical faults

[IEC 60050:1992]

3.1.10

failure

termination of the ability of an item to perform a required function

[IEC 60050:1992]

3.1.11

fault, noun

the state of an item characterized by inability to perform as required, excluding the inability during

preventative maintenance or other planned actions, or due to lack of external resources

NOTE 1 A fault is often the result of a failure of the item itself, but can exist without prior failure.

NOTE 2 Adapted from IEC 60050:1992.

3.1.12

fault, noun

an unplanned occurrence or defect in an item which may result in one or more failures of the item itself or

of other associated equipment

[IEC 60050:1992]

NOTE An item may contain a sub-element fault, which is a defect that can manifest itself only under certain circumstances.

When those circumstances occur, the defect in the sub-element will cause the item to fail, resulting in an error. This error can

propagate to other items causing them, in turn, to fail. After the failure occurs, the item as a whole is said to have a fault or to be

in a faulty state [definition 3.1.11 above].

[EN 13701:2001]

3.1.13

hazard

existing or potential condition of an item that can result in a mishap

NOTE This condition can be associated with the design, fabrication, operation or environment of the item, and has the

potential for mishaps.

[ISO 14620-2]

3.1.14

hazardous event

occurrence leading to undesired consequences and arising from the triggering by one (or more) initiator events of

one (or more) hazards

NOTE Adapted from EN 13701:2001.

3.1.15

incident

unplanned event that could have been an accident but was not

[EN 13701:2001]

3.1.16

inhibit

a design feature that provides a physical interruption between an energy source and a function actuator

EXAMPLE A relay or transistor between a battery and a pyrotechnic initiator, a latch valve between a propellant tank and

thruster.

NOTE 1 Two inhibits are independent if no single failure can eliminate more than one inhibit.

NOTE 2 Adapted from EN 13701:2001.

3.1.17

operator error

failure of an operator to perform an action as required or trained or the inadvertent or incorrect action of an operator

3.1.18

organization

group of people and facilities with an arrangement of responsibilities, authorities and relationships

EXAMPLE Company, corporation, firm, enterprise, institution, charity, sole trader, association, or parts or

combination thereof.

NOTE 1 The arrangement is generally orderly.

NOTE 2 An organization can be public or private.

NOTE 3 This definition is valid for the purposes of quality management system standards. The term "organization" is defined

differently in ISO/IEC Guide 2.

[EN ISO 9000:2000]

3.1.19

programme

coordinated set of activities, not necessarily interdependent, that continue over a period of time and are designed

to accomplish broad scientific or technical goals or increased knowledge in a specific subject

EXAMPLE The defence programme; The Apollo programme; Earth observation programme; Manned space and

mirogravity programme.

NOTE 1 A programme can comprise several projects.

NOTE 2 A programme can last several years.

NOTE 3 "program" is American Standard English spelling for "programme".

NOTE 4 "program" is British Standard English for 'a series of coded instructions to control the operation of a computer or

other machine' – Oxford English Dictionary.

3.1.20

project

unique set of coordinated activities, with definite starting and finishing points, undertaken by an individual or

organization to meet specific objectives within defined schedule, cost and performance parameters

[BS 6079:1996]

3.1.21

purchaser

customer in a contractual situation

NOTE The purchaser is sometimes referred to as the "business second party".

3.1.22

residual risk

risk remaining in a system after completion of the hazard reduction and control process

[EN 13701:2001]

3.1.23

risk

quantitative measure of the magnitude of a potential loss and the probability of incurring that loss

[EN 13701:2001]

3.1.24

safe state

state that does not lead to critical or catastrophic consequences

3.1.25

safety critical function

function that, if lost or degraded, or as a result of incorrect or inadvertent operation, would result in catastrophic or

critical consequences

NOTE Adapted from EN 13701:2001.

3.1.26

safing

action of containment or control of emergency and warning situations or placing a system (or part thereof) in a

predetermined safe condition

NOTE Adapted from EN 13701:2001.

3.1.27

supplier

organization or person that provides a product

EXAMPLE Producer, distributor, retailer or vendor of a product, or provider of a service or information.

NOTE 1 A supplier can be internal or external to the organization.

NOTE 2 In a contractual situation a supplier is sometimes called "contractor".

[EN ISO 9000:2000]

3.1.28

system

set of interdependent elements constituted to achieve a given objective by performing a specified function

NOTE The system is considered to be separated from the environment and other external systems by an imaginary

surface which cuts the links between them and the considered system. Through these links, the system is affected by the

environment, is acted upon by the external systems, or acts itself on the environment or the external systems.

[IEC 60050:1992]

3.1.29

system safety

application of engineering and management principles, criteria, and techniques to optimize all aspects of safety

within the constraints of operational effectiveness, time, and cost throughout all phases of the system life cycle

3.1.30

warning condition

condition where potentially catastrophic or critical hazardous events are imminent and where pre-planned safing

action is required within a limited time

NOTE Adapted from EN 13701:2001.

3.1.31

zonal analysis

systematic inspection of the geographical locations of the components and interactions of a system, evaluation of

potential subsystem-to-subsystem interactions with and without failure, and assessment of the severity of potential

hazards inherent in the system installation.

3.2 Abbreviated terms

The following abbreviated terms are used within this European Standard.

Abbreviation Meaning

CCB configuration control board

ECSS European Cooperation for Space Standardization

EEE electronic, electrical, electromechanical

FMECA failure modes, effects and criticality analysis

FTA fault free analysis

GEO geostationary orbit

GSE ground support equipment

IEC International Electrotechnical Commission

LEO low Earth orbit

MIL STD military standard (US Department of Defense)

MIP mandatory inspection point

NRB nonconformance review board

NUREG-CR US Nuclear Regulatory Commission contractor report

TRB test review board

VTL verification tracking log

4 System safety programme

4.1 Scope

a) The scope and content of the safety programme is to establish a safety management system to implement

provisions of this European Standard commensurate with the programme requirements.

b) The system safety programme should be tailored by the customer in accordance with the type of project, safety

criticality, complexity, and phase of development in accordance with the requirements of ISO 14300-1 and ISO

14300-2.

1) The supplier shall establish and maintain a system safety programme.

2) The supplier shall apply launch site and launch vehicle safety requirements regulations as defined in

the project requirements to support efficient and effective achievement of system safety objectives.

3) The appropriate system safety programme requirements of this European Standard shall be applied for

the implementation of the applicable launch site and launch vehicle requirements and regulations.

c) Compli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...