EN 12101-6:2005

(Main)Smoke and heat control systems - Part 6: Specification for pressure differential systems - Kits

Smoke and heat control systems - Part 6: Specification for pressure differential systems - Kits

This document specifies pressure differential systems designed to hold back smoke at a leaky physical barrier in a building, such as a door (either open or closed) or other similarly restricted openings. It covers methods for calculating the parameters of pressure differential smoke control systems as part of the design procedure. It gives test procedures for the systems used, as well as describing relevant, and critical, features of the installation and commissioning procedures needed to implement the calculated design in a building. It covers systems intended to protect means of escape such as stairwells, corridors and lobbies, as well as systems intended to provide a protected firefighting bridgehead for the Fire Services.

The systems incorporate smoke control components in accordance with the relevant Parts of EN 12101 and kits comprising these and possibly other components (see 3.1.18). This document gives requirements and methods for the evaluation of conformity for such kits.

Rauch- und Wärmefreihaltung - Teil 6: Festlegungen für Differenzdrucksysteme - Bausätze

Anwendungsbereich

Diese Europäische Norm beschreibt Differenzdrucksysteme, die ausgelegt sind, um Rauch an einer undichten Barriere, z. B. an einer Tür (entweder geöffnet oder geschlossen) oder ähnlich eingeschränkte Öffnungen, innerhalb des Gebäudes zurückzuhalten. Es wird davon ausgegangen, dass die Verfahren zur Berechnung der Parameter einer Rauchschutzanlage im Zuge der konstruktiven Auslegung behandelt werden. Diese Europäische Norm führt die angewandten Prüfverfahren für das System auf und beschreibt gleichzeitig die maßgebenden und kritischen Eigenschaften der Installations- und Inbetriebnahmeverfahren, die benötigt werden, um die berechnete Auslegung in einem Gebäude zu erfüllen. Diese Norm behandelt sowohl Systeme, die zur Sicherung von Rettungsmaßnahmen gedacht sind wie z. B. Treppenschächte, Korridore und Vorräume als auch Systeme, die dazu dienen, einen geschützten Brückenkopf für die Brandbekämpfungsmaßnahmen der Feuerwehr zu schaffen.

Systèmes pour le contrôle des fumées et de la chaleur - Partie 6: Spécifications relatives aux systèmes à différentiel de pression - Kits

La présente norme décrit les systèmes à différentiel de pression destinés à retenir les fumées derrière une barrière physique présentant des débits de fuites dans un bâtiment telle qu'une porte (ouverte ou fermée) ou autre ouverture réduite de ce type. Elle couvre les différentes méthodes de calcul des paramètres des systèmes de contrôle des fumées à différentiel de pression comme partie intégrante du mode opératoire de conception. Elle fournit des modes opératoires d'essai pour les systèmes utilisés, et décrit également les caractéristiques pertinentes et essentielles des Modes opératoires d'installation et de mise en service nécessaires pour mettre en �uvre les calculs de conception dans un bâtiment. Elle couvre les systèmes destinés à protéger les moyens d'évacuation tels que les cages d'escaliers, les couloirs et les paliers ainsi que les systèmes destinés à créer un PC avancé protégé pour les pompiers.

Le système comprend des composants de contrôle de la fumée conformément aux parties concernées de l'EN 12101 et des kits intégrant ces composants et éventuellement d'autres composants (voir 3.1.18). Ce document fournit des exigences et des méthodes pour évaluer la conformité de ces kits.

Sistemi za nadzor dima in toplote – 6. del: Sistemi za zagotovitev tlačnih razlik – Oprema

General Information

- Status

- Withdrawn

- Publication Date

- 07-Jun-2005

- Withdrawal Date

- 03-Feb-2026

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/SC 1 - Smoke and heat control systems and components

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Apr-2022

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12101-6:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Smoke and heat control systems - Part 6: Specification for pressure differential systems - Kits". This standard covers: This document specifies pressure differential systems designed to hold back smoke at a leaky physical barrier in a building, such as a door (either open or closed) or other similarly restricted openings. It covers methods for calculating the parameters of pressure differential smoke control systems as part of the design procedure. It gives test procedures for the systems used, as well as describing relevant, and critical, features of the installation and commissioning procedures needed to implement the calculated design in a building. It covers systems intended to protect means of escape such as stairwells, corridors and lobbies, as well as systems intended to provide a protected firefighting bridgehead for the Fire Services. The systems incorporate smoke control components in accordance with the relevant Parts of EN 12101 and kits comprising these and possibly other components (see 3.1.18). This document gives requirements and methods for the evaluation of conformity for such kits.

This document specifies pressure differential systems designed to hold back smoke at a leaky physical barrier in a building, such as a door (either open or closed) or other similarly restricted openings. It covers methods for calculating the parameters of pressure differential smoke control systems as part of the design procedure. It gives test procedures for the systems used, as well as describing relevant, and critical, features of the installation and commissioning procedures needed to implement the calculated design in a building. It covers systems intended to protect means of escape such as stairwells, corridors and lobbies, as well as systems intended to provide a protected firefighting bridgehead for the Fire Services. The systems incorporate smoke control components in accordance with the relevant Parts of EN 12101 and kits comprising these and possibly other components (see 3.1.18). This document gives requirements and methods for the evaluation of conformity for such kits.

EN 12101-6:2005 is classified under the following ICS (International Classification for Standards) categories: 13.220.99 - Other standards related to protection against fire. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12101-6:2005 has the following relationships with other standards: It is inter standard links to EN 12101-6:2022, EN 1505:1997, EN ISO 13943:2000, prEN 12101-9, EN 12101-10:2005, EN 13501-4:2016, EN 13501-3:2025, EN 1506:2007, EN ISO 9001:2000, EN ISO 9974-3:2000, EN ISO 13691:2002, EN ISO 19879:2021, EN ISO 9974-2:2000, CEN/TR 14489:2005, EN ISO 6743-4:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12101-6:2005 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/109. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12101-6:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Smoke and heat control systems - Part 6: Specification for pressure differential systems - Kits2SUHPDSystemes pour le contrôle des fumées et de la chaleur - Partie 6: Spécifications relatives aux systemes a différentiel de pression - KitsRauch- und Wärmefreihaltung - Teil 6: Festlegungen für Differenzdrucksysteme - BausätzeTa slovenski standard je istoveten z:EN 12101-6:2005SIST EN 12101-6:2005en13.220.20ICS:SLOVENSKI

STANDARDSIST EN 12101-6:200501-september-2005

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12101-6June 2005ICS 13.220.99English versionSmoke and heat control systems - Part 6: Specification forpressure differential systems - KitsSystèmes pour le contrôle des fumées et de la chaleur -Partie 6: Spécifications pour les systèmes à différentiel depression - KitsAnlagen zur Kontrolle von Rauch- und Wärmesströmungen- Teil 6: Anforderung an Differenzdrucksysteme - BausätzeThis European Standard was approved by CEN on 17 January 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12101-6:2005: E

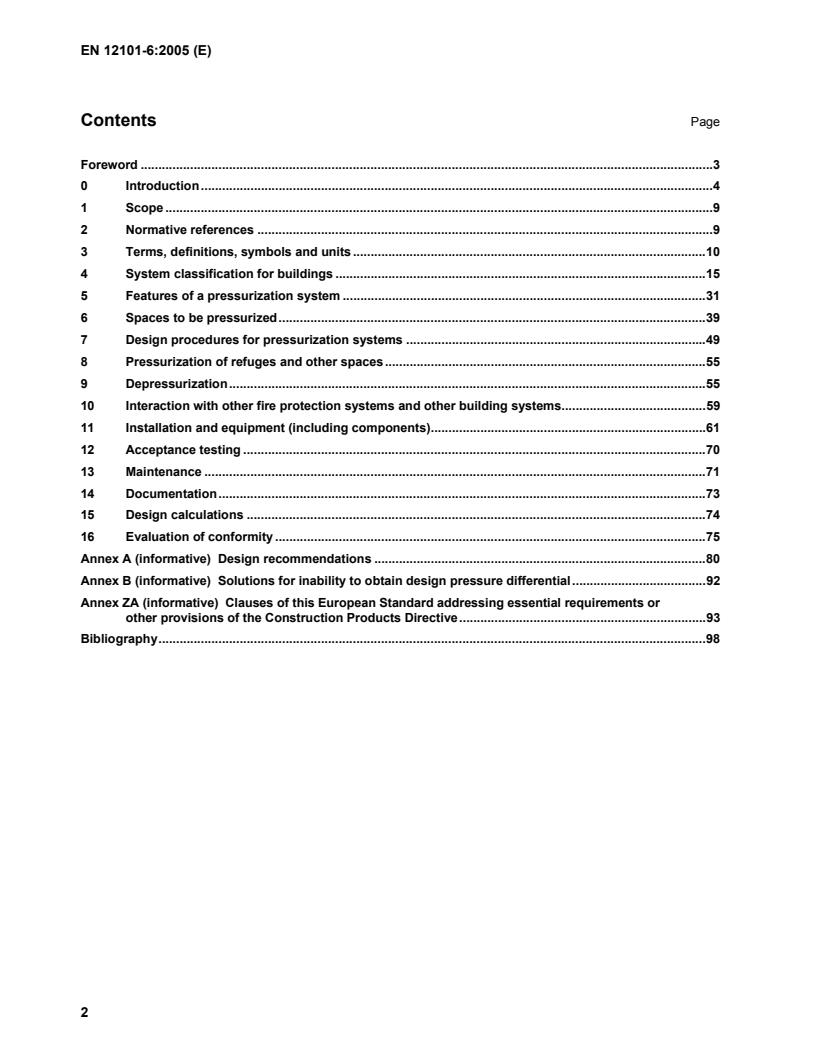

Design recommendations.80 Annex B (informative)

Solutions for inability to obtain design pressure differential.92 Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of the Construction Products Directive.93 Bibliography.98

0 Introduction 0.1 Smoke movement in the building This document covers information and requirements on the design, calculation methods, installation and testing of systems intended to limit the spread of smoke by means of pressure differentials. Pressure differential systems can be achieved by two methods: i) pressurization – maintaining a positive pressure within the protected spaces (see Figure 1a), or ii) depressurization – removing hot gases from the fire zone at a lower pressure than the adjacent protected space (see Figure 1b).

Key 1 Outside 2 Pressurized space 3 Overpressure relief 4 External leakage 5 Fire zone 6 Air release vents 7 Air intake 8 Supply fan 9 Supply ductwork Figure 1 a) — Examples of pressurization and depressurization systems

DP-5-5000613455625PaPaPaPa7

Key 1 Stair 2 Lobby 3 Accommodation (DP Depressurized space) 4 Exhaust (Depressurize) 5 Leakage path through doors etc. 6 Replacement air 7 Fire-resisting construction Figure 1 b) — Example of a depressurization system – basements or other spaces with no external windows In the event of fire, the smoke produced follows a pattern of movement arising from the following main driving forces. Buoyancy experienced by hot gases on the fire storey. Within the fire zone, smoke produced by the fire experiences a buoyancy force owing to its reduced density. In a building this can result in upwards smoke movement between storeys if leakage paths exist to the storey above. In addition, this buoyancy can cause smoke to spread through leakage paths in vertical barriers between rooms, e.g. doors, walls, partitions. The pressure differential typically causes smoke and hot gases to leak out of gaps at the top of a door and cool air to be drawn in through gaps at the bottom. Thermal expansion of hot gases in the fire zone. Fire induced expansion of gases can result in a build up of pressure, accompanied by a flow of hot gases out of the compartment. However, in most cases the initial expansion forces may dissipate quickly and may be ignored. Stack effect throughout the building. In cold ambient conditions, the air in a building is generally warmer and less dense than the external air. The buoyancy of the warm air causes it to rise within vertical shafts in the

building service installations: fire resisting ducts and fire dampers prEN 13501-4, Fire classification of construction products and building elements — Part 4: Classification using data from fire resistance tests on components of smoke control systems EN ISO 9001:2000, Quality management systems — Requirements (ISO 9001:2000) EN ISO 13943:2000, Fire safety — Vocabulary (ISO 13943:2000)

m2 total leakage area through the walls as defined in Table A.5; APV m2 area of the pressure operated relief vent; Arem m2 leakage area from the lobby other than through the open door; At m2 total leakage area between all lift doors and the lift well; AVA m2 air release vent area per storey; AVS m2 net vent area per storey maintained throughout the route to the outside of the building i.e. from the accommodation into a shaft, the shaft cross sectional area and the top vent area (shaft to atmosphere); AW m2 total effective leakage area of all windows out of the space; AWall

m2 area of the walls as defined in Table A.5;

Pa pressure in the lobby when the door is open into the unpressurized space; Q m3/s airflow into or out of a pressurized space; QD m3/s air leakage rate via gaps around closed doors; QDC m3/s total identified leakage rate from the pressurized space with the doors closed; QDO m3/s air leakage rate through open doors or large openings; Qfr m3/s air supply needed to provide the required airflow through the open door into the fire room; QLd m3/s air leakage rate via lift landing doors; QLob m3/s the air supply needed to provide the required air flow through the open door into the fire room; Qn m3/s door leakage rate at the design pressurization as calculated for a ventilated toilet or other areas that are directly connected to the pressurized space; QOther m3/s air leakage rate via other paths that may exist; Qp m3/s air supply to the stair or lobby needed to satisfy the pressure differential requirement; Qs m3/s total air supply rate required with all doors closed; QSDO m3/s total air supply rate including leakage from supply ducting; QTm m3/s air leakage rate via mechanical extraction from a toilet or other areas; QTn m3/s leakage by natural means into the toilet (or other) space; QWindow m3/s air leakage rate via cracks around windows; R – index that can vary between 1 and 2, depending on the type of leakage path being considered; Wd m door width.

4.7 and Figure 7

The system examples to be applied will depend on national provisions valid in the place of use of the system or the decision of appropriate authorities. 4.2 Class A pressurization system 4.2.1 General The design conditions are based on the assumption that a building will not be evacuated unless directly threatened by fire. The level of fire compartmentation is such that it is usually safe for occupants to remain within the building. Therefore, it is unlikely that more than one door onto the protected space (either that between the stair and the lobby/corridor, or the final exit door) will be open simultaneously. Class A system shall not be used in mixed use developments. 4.2.2 Class A requirements 4.2.2.1 Airflow criterion The airflow through the doorway between the pressurized stair and the lobby or corridor shall be not less than 0,75 m/s when: a) on any one storey the doors between the lobby/corridor and the pressurized stair are open; b) the air release from the lobby/corridor on that storey is open; c) on all other storeys all doors between the pressurized stair and the lobbies/corridors are closed;

Airflow criterion

Pressure difference criterion (all doors closed) Key 1 Door open 2 Door closed 3 Air release path NOTE The open door can indicate an open flow path through a simple lobby.

Figure 2 — Design conditions for Class A systems 4.2.2.2 Pressure difference criterion The pressure difference across a closed door between the pressurized stair and the lobby/corridor shall be not less than 50 Pa ± 10 % when: a) the air release from the lobby/corridor on that storey is open; b) on all other storeys the doors between the pressurized stair and the lobby/corridor are closed; c) all doors between the pressurized stair and the final exit are closed; d) the final exit door is closed. NOTE The ± 10 % is not for use in the calculation but for flexibility in the acceptance test results.

4.3.2.2 Airflow criterion The air supply shall be sufficient to maintain a minimum airflow of 2 m/s through the open door between the lobby and the accommodation at the fire affected storey with all of the following doors open between: a) the stair and the lobby on the fire affected storey; b) the stair and the lobby on an adjacent storey; c) the firefighting lift shaft and the lobby on the adjacent storey; d) the stair and the external air at the fire service access level; and the air release path on the fire floor is open. If a door that has two leaves is assumed to be open for calculation purposes, one leaf may be assumed to be in the closed position for these calculations. The number of open doors assumed for design shall depend upon the location and type of firefighting facilities installed in the building, and in particular rising main outlets. Where the hose passes through a door, that door shall be considered to be fully open.

Airflow criterion

Pressure difference criterion (all doors closed) Key 1 Firefighting stair

2 Firefighting lobbies 3 Door open 4 Door closed 5 Air release path 6 Door open (firefighting lobbies) 7 Door closed (firefighting lobbies) 8 Air flow from firefighting lift shaft Figure 3 — Design conditions for Class B systems 4.3.2.3 Air supply Any air supply serving a firefighting staircase or lift shaft, and their associated lobbies where present, shall be separate from any other ventilation or pressure differential system. 4.3.2.4 Firefighting shaft Firefighting shafts shall be constructed in accordance with the appropriate national provisions valid in the place of use of the system. 4.3.2.5 Door opening force The system shall be designed so that the force on the door handle shall not exceed 100 N. NOTE 1 The corresponding maximum pressure differential across the door can be determined using the procedure in Clause 15 and Annex A, as a function of the door configuration.

50 Pa v) Final exit door is open and items I) to iii) above are complied with 10 Pa NOTE For flexibility in the acceptance test results there is ± 10 % tolerance on the measurement allowed.

The design conditions for Class C systems are shown in Figure 4. 0,75 m/s10 Pa50 Pa3332112

Airflow criterion

Pressure difference criterion

Pressure difference criterion (all doors closed) Key 1 Door open 2 Door closed 3 Air release path NOTE Figure 4 can include lobbies. Figure 4 — Design conditions for Class C systems

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...