ASTM F366-04

(Specification)Standard Specification for Fixation Pins and Wires

Standard Specification for Fixation Pins and Wires

ABSTRACT

This specification covers the material requirements and functional dimensions for fixation pins and wires. Factors such as bending strength, fatigue strength, break strength (Knowles type only), torsion strength, and ductility are considered important but the values and associated test methods for which have not been established yet.

SCOPE

1.1 This specification covers functional dimensions for fixation pins and wires.

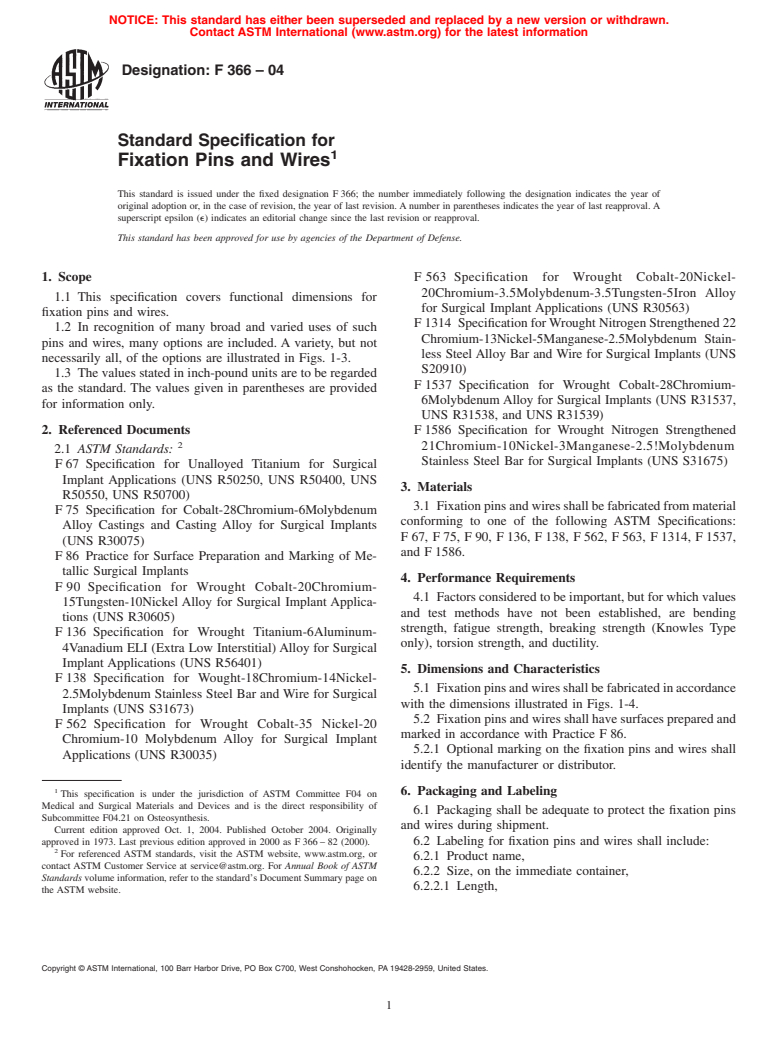

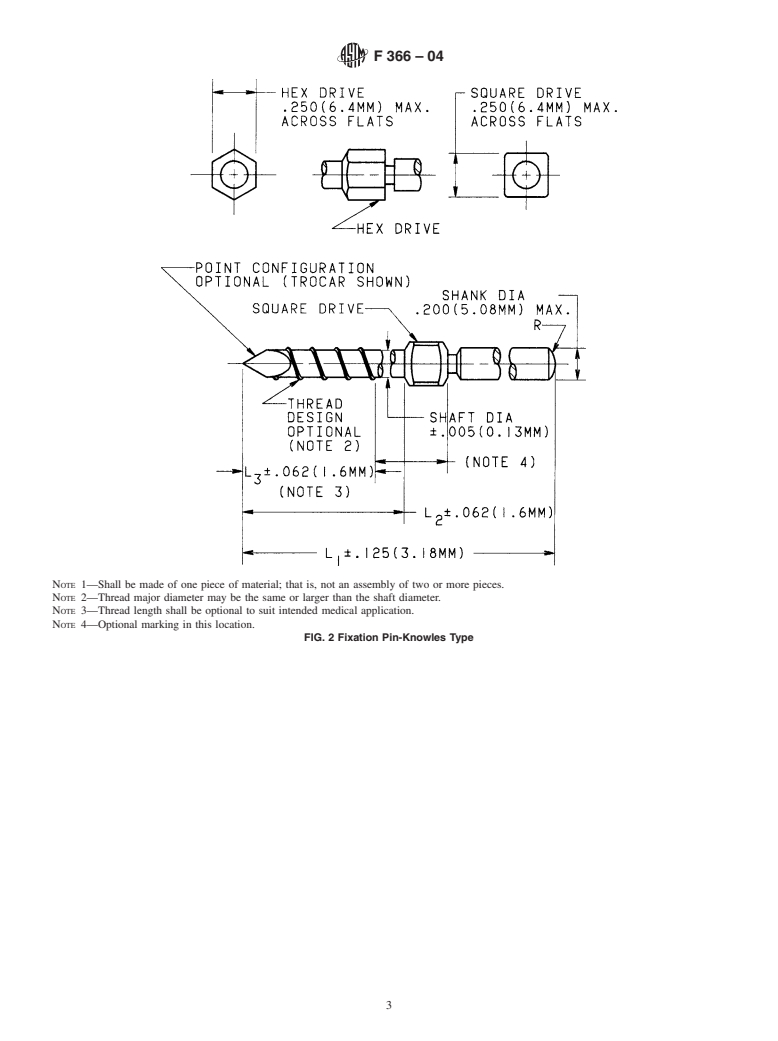

1.2 In recognition of many broad and varied uses of such pins and wires, many options are included. A variety, but not necessarily all, of the options are illustrated in 1-3.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 366 – 04

Standard Specification for

1

Fixation Pins and Wires

This standard is issued under the fixed designation F 366; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope F 563 Specification for Wrought Cobalt-20Nickel-

20Chromium-3.5Molybdenum-3.5Tungsten-5Iron Alloy

1.1 This specification covers functional dimensions for

for Surgical Implant Applications (UNS R30563)

fixation pins and wires.

F 1314 Specification forWrought Nitrogen Strengthened 22

1.2 In recognition of many broad and varied uses of such

Chromium-13Nickel-5Manganese-2.5Molybdenum Stain-

pins and wires, many options are included. A variety, but not

less Steel Alloy Bar and Wire for Surgical Implants (UNS

necessarily all, of the options are illustrated in Figs. 1-3.

S20910)

1.3 The values stated in inch-pound units are to be regarded

F 1537 Specification for Wrought Cobalt-28Chromium-

as the standard. The values given in parentheses are provided

6Molybdenum Alloy for Surgical Implants (UNS R31537,

for information only.

UNS R31538, and UNS R31539)

2. Referenced Documents

F 1586 Specification for Wrought Nitrogen Strengthened

2

21Chromium-10Nickel-3Manganese-2.5!Molybdenum

2.1 ASTM Standards:

Stainless Steel Bar for Surgical Implants (UNS S31675)

F 67 Specification for Unalloyed Titanium for Surgical

Implant Applications (UNS R50250, UNS R50400, UNS

3. Materials

R50550, UNS R50700)

3.1 Fixationpinsandwiresshallbefabricatedfrommaterial

F 75 Specification for Cobalt-28Chromium-6Molybdenum

conforming to one of the following ASTM Specifications:

Alloy Castings and Casting Alloy for Surgical Implants

F 67, F 75, F 90, F 136, F 138, F 562, F 563, F 1314, F 1537,

(UNS R30075)

and F 1586.

F 86 Practice for Surface Preparation and Marking of Me-

tallic Surgical Implants

4. Performance Requirements

F 90 Specification for Wrought Cobalt-20Chromium-

4.1 Factors considered to be important, but for which values

15Tungsten-10Nickel Alloy for Surgical Implant Applica-

and test methods have not been established, are bending

tions (UNS R30605)

strength, fatigue strength, breaking strength (Knowles Type

F 136 Specification for Wrought Titanium-6Aluminum-

only), torsion strength, and ductility.

4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical

Implant Applications (UNS R56401)

5. Dimensions and Characteristics

F 138 Specification for Wought-18Chromium-14Nickel-

5.1 Fixationpinsandwiresshallbefabricatedinaccordance

2.5Molybdenum Stainless Steel Bar and Wire for Surgical

with the dimensions illustrated in Figs. 1-4.

Implants (UNS S31673)

5.2 Fixation pins and wires shall have surfaces prepared and

F 562 Specification for Wrought Cobalt-35 Nickel-20

marked in accordance with Practice F 86.

Chromium-10 Molybdenum Alloy for Surgical Implant

5.2.1 Optional marking on the fixation pins and wires shall

Applications (UNS R30035)

identify the manufacturer or distributor.

1

6. Packaging and Labeling

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

6.1 Packaging shall be adequate to protect the fixation pins

Subcommittee F04.21 on Osteosynthesis.

and wires during shipment.

Current edition approved Oct. 1, 2004. Published October 2004. Originally

approved in 1973. Last previous edition approved in 2000 as F 366 – 82 (2000). 6.2 Labeling for fixation pins and wires shall include:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.2.1 Product name,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2.2 Size, on the immediate container,

Standards volume information, refer to the standard’s Document Summary page on

6.2.2.1 Length,

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F366–04

NOTE 1—Pins and wires may be smooth shank or threaded.

NOTE 2—Point angle and helix angle, where applicable, is as specified by manufacturer.

NOTE 3—On square or triangular shanks, flats are equal and corners are on the same circumference as the pin diameter. Shank diameters on pins larger

1

than ⁄8 in. (3.2 mm) may be reduced.

NOTE 4—Optional designs, both ends pointed or point with suture hole.

FIG. 1 Fixation Pins and Wires

6.2.2.2 Diameter (if round) or cross-sectional size (if square 7. Keywords

1

of hexagonal), that is, ⁄4 in. (6.4 mm) square, and

7.1 fixation materials; flexible surgical wire; orthopae

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.