ASTM C411-05

(Test Method)Standard Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

Standard Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

SIGNIFICANCE AND USE

Performance in service is the final measure of value for a thermal insulation, but simulative service tests give useful indications. One type involves application for a specified time to a surface heated at a temperature approximately that of intended service, and noting during the test and afterward, changes in the material and its properties. Measurement of these changes are used for predicting what occurs in service as a result of exposure to temperatures corresponding to those of the tests.

SCOPE

1.1 This test method covers the determination of the performance of commercial sizes of both block and pipe forms of thermal insulating materials when exposed to simulated hot-surface application conditions. The term "hot-surface performance" has reference to a simulated use-temperature test in which the heated testing surface is in a horizontal position.

1.2 This test method refers primarily to high-temperature insulations that are applicable to hot-side temperatures in excess of 200°F (93°C). It is used for materials such as preformed insulations, insulating cements, blankets, and the like, by proper laboratory preparation of the samples.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C411–05

Standard Test Method for

Hot-Surface Performance of High-Temperature Thermal

1

Insulation

This standard is issued under the fixed designation C411; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope indications. One type involves application for a specified time

to a surface heated at a temperature approximately that of

1.1 This test method covers the determination of the perfor-

intended service, and noting during the test and afterward,

mance of commercial sizes of both block and pipe forms of

changes in the material and its properties. Measurement of

thermal insulating materials when exposed to simulated hot-

these changes are used for predicting what occurs in service as

surface application conditions. The term “hot-surface perfor-

a result of exposure to temperatures corresponding to those of

mance” has reference to a simulated use-temperature test in

the tests.

which the heated testing surface is in a horizontal position.

1.2 This test method refers primarily to high-temperature

5. Apparatus

insulations that are applicable to hot-side temperatures in

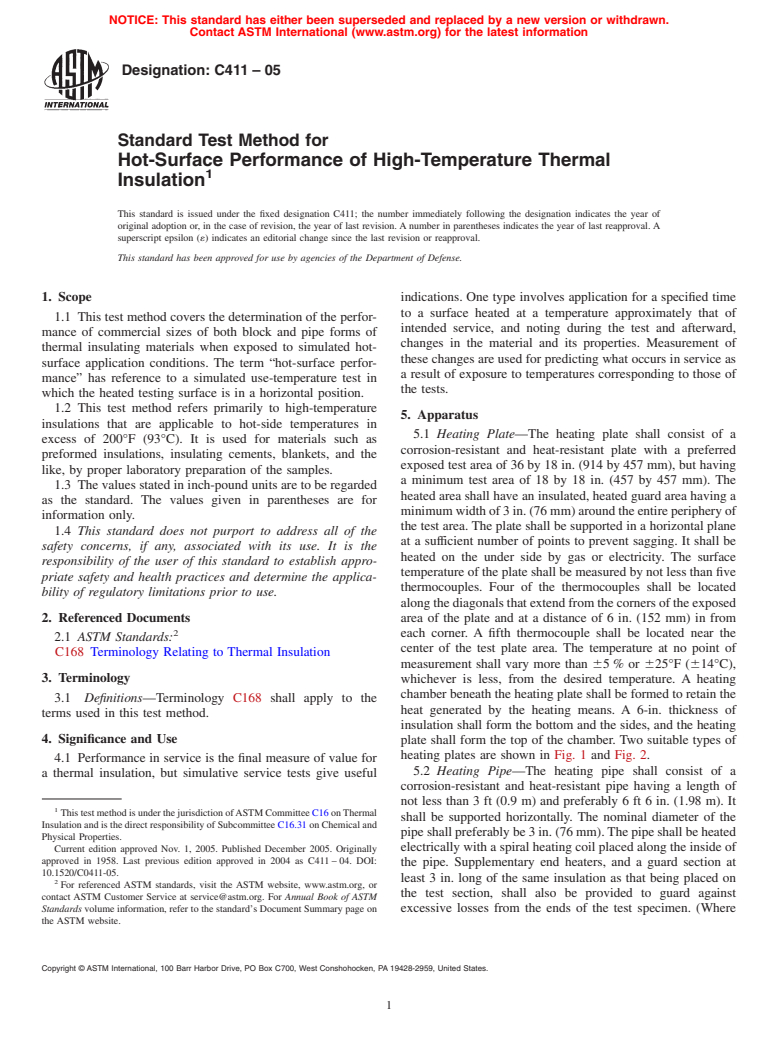

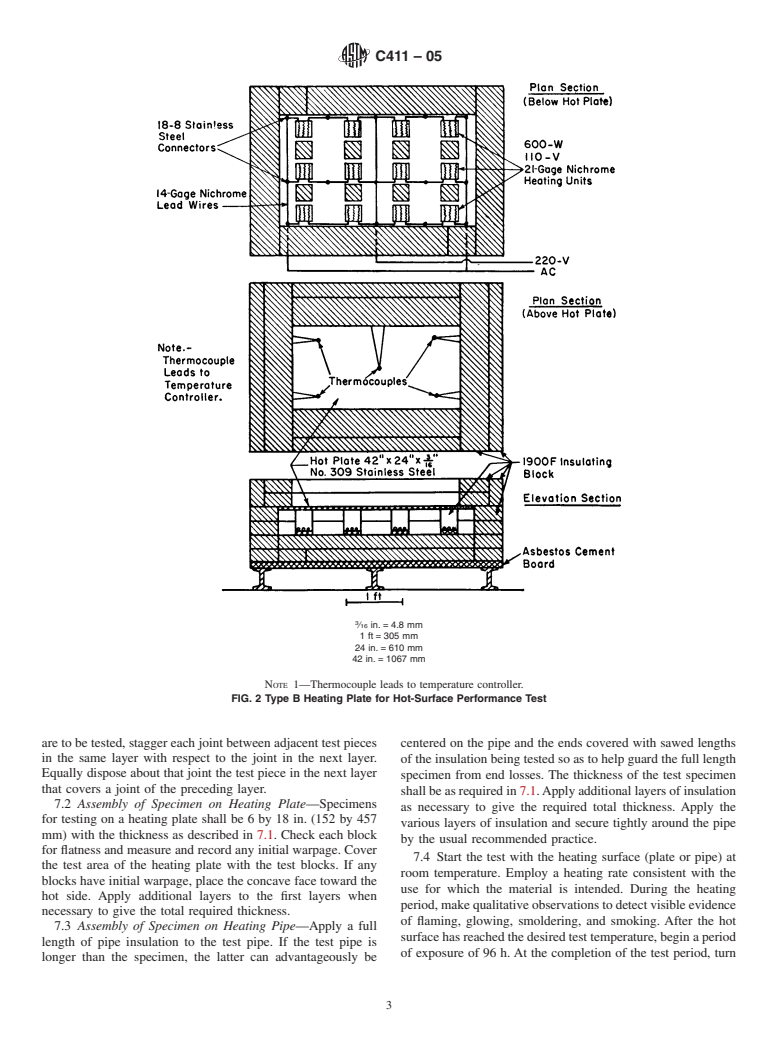

5.1 Heating Plate—The heating plate shall consist of a

excess of 200°F (93°C). It is used for materials such as

corrosion-resistant and heat-resistant plate with a preferred

preformed insulations, insulating cements, blankets, and the

exposed test area of 36 by 18 in. (914 by 457 mm), but having

like, by proper laboratory preparation of the samples.

a minimum test area of 18 by 18 in. (457 by 457 mm). The

1.3 The values stated in inch-pound units are to be regarded

heated area shall have an insulated, heated guard area having a

as the standard. The values given in parentheses are for

minimumwidthof3in.(76mm)aroundtheentireperipheryof

information only.

the test area. The plate shall be supported in a horizontal plane

1.4 This standard does not purport to address all of the

at a sufficient number of points to prevent sagging. It shall be

safety concerns, if any, associated with its use. It is the

heated on the under side by gas or electricity. The surface

responsibility of the user of this standard to establish appro-

temperature of the plate shall be measured by not less than five

priate safety and health practices and determine the applica-

thermocouples. Four of the thermocouples shall be located

bility of regulatory limitations prior to use.

alongthediagonalsthatextendfromthecornersoftheexposed

2. Referenced Documents area of the plate and at a distance of 6 in. (152 mm) in from

2

each corner. A fifth thermocouple shall be located near the

2.1 ASTM Standards:

center of the test plate area. The temperature at no point of

C168 Terminology Relating to Thermal Insulation

measurement shall vary more than 65%or 625°F (614°C),

3. Terminology whichever is less, from the desired temperature. A heating

chamber beneath the heating plate shall be formed to retain the

3.1 Definitions—Terminology C168 shall apply to the

heat generated by the heating means. A 6-in. thickness of

terms used in this test method.

insulation shall form the bottom and the sides, and the heating

4. Significance and Use

plate shall form the top of the chamber. Two suitable types of

heating plates are shown in Fig. 1 and Fig. 2.

4.1 Performance in service is the final measure of value for

5.2 Heating Pipe—The heating pipe shall consist of a

a thermal insulation, but simulative service tests give useful

corrosion-resistant and heat-resistant pipe having a length of

not less than 3 ft (0.9 m) and preferably 6 ft 6 in. (1.98 m). It

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

shall be supported horizontally. The nominal diameter of the

Insulation and is the direct responsibility of Subcommittee C16.31 on Chemical and

pipe shall preferably be 3 in. (76 mm).The pipe shall be heated

Physical Properties.

Current edition approved Nov. 1, 2005. Published December 2005. Originally electrically with a spiral heating coil placed along the inside of

approved in 1958. Last previous edition approved in 2004 as C411 – 04. DOI:

the pipe. Supplementary end heaters, and a guard section at

10.1520/C0411-05.

least 3 in. long of the same insulation as that being placed on

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the test section, shall also be provided to guard against

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on excessive losses from the ends of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.