ASTM D1264-03(2008)

(Test Method)Standard Test Method for Determining the Water Washout Characteristics of Lubricating Greases

Standard Test Method for Determining the Water Washout Characteristics of Lubricating Greases

SIGNIFICANCE AND USE

This test method estimates the resistance of greases to water washout from ball bearings under conditions of the test. No correlation with field service has been established.

SCOPE

1.1 This test method covers the evaluation of the resistance of a lubricating grease to washout by water from a bearing, when tested at 38 and 79°C (100 and 175°F) under the prescribed laboratory conditions. It is not to be considered the equivalent of service evaluation tests. This test method may not be suitable for some greases containing highly volatile components.

1.2 The values state in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1264–03 (Reapproved 2008)

Standard Test Method for

Determining the Water Washout Characteristics of

Lubricating Greases

This standard is issued under the fixed designation D1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Significance and Use

1.1 This test method covers the evaluation of the resistance 4.1 This test method estimates the resistance of greases to

of a lubricating grease to washout by water from a bearing, water washout from ball bearings under conditions of the test.

when tested at 38 and 79°C (100 and 175°F) under the No correlation with field service has been established.

prescribed laboratory conditions. It is not to be considered the

5. Apparatus

equivalentofserviceevaluationtests.Thistestmethodmaynot

5.1 Ball Bearing, ASTM test bearing size 6204 (see

be suitable for some greases containing highly volatile com-

ponents. ADJD3336).

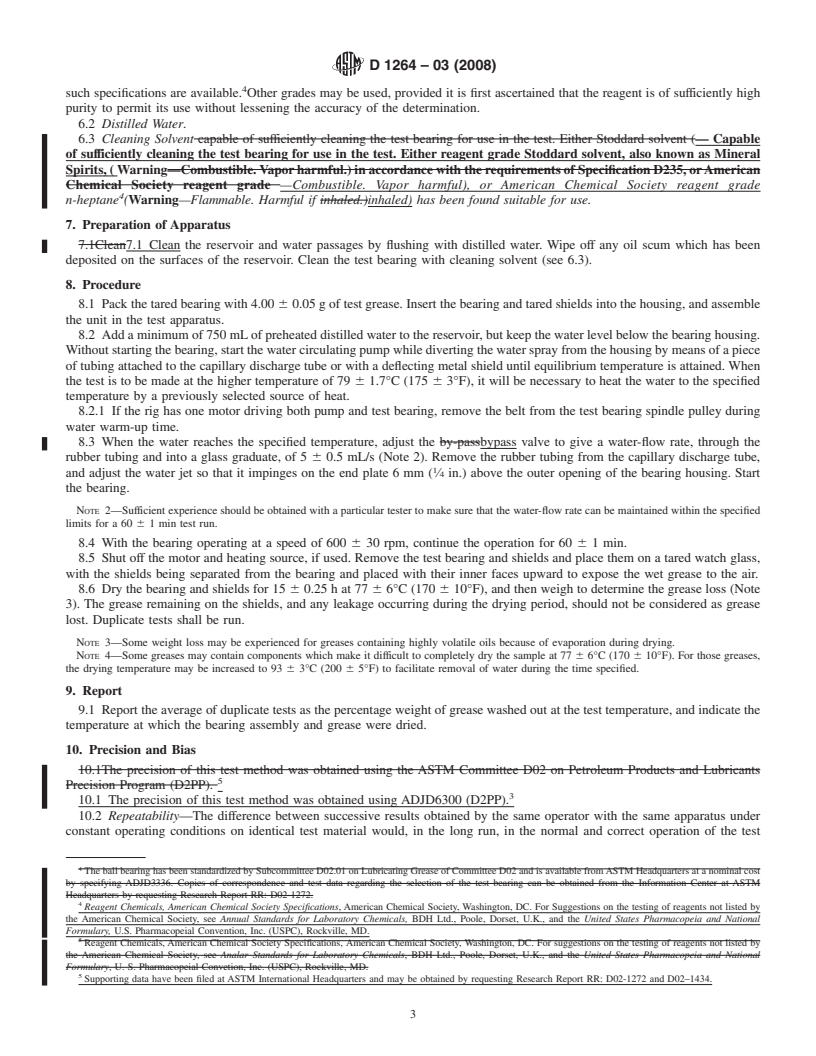

5.2 Bearing Housing and Shield with dimensions as shown

1.2 The values state in SI units are to be regarded as the

standard. The values given in parentheses are for information in Fig. 1.

5.3 Reservoir, Bearing-Housing Mount, Circulating Pump,

only.

1.3 This standard does not purport to address all of the and Drive Motor, similar or equivalent to those shown in Fig.

1.

safety concerns, if any, associated with its use. It is the

responsibility of the user this standard to establish appropriate 5.4 Heating Source, to maintain the water temperature at 79

6 1.7°C (175 6 3°F).

safety and health practices and determine the applicability of

regulatory limitations prior to use. For specific warning

NOTE 1—Suitable temperature control may be obtained by the use of

statements, see 6.3.

immersionheaters,steamcoils,orinfraredheatlamps,inconjunctionwith

transformers or thermostats.

2. Referenced Documents

5.5 Thermometer or Thermocouple, to determine the tem-

2.1 ASTM Adjuncts:

perature of the water reservoir.

Standard Ball Bearing

D2PP, Version 4.43, Determination of Precision and Bias

6. Materials and Reagents

Data for Use in Test Methods for Petroleum Products

6.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

3. Summary of Test Method

all reagents shall conform to the specifications of the commit-

3.1 The grease is packed into a ball bearing, the bearing is

tee onAnalytical Reagents of theAmerican Chemical Society,

then inserted in a housing with specified clearances, and

where such specifications are available. Other grades may be

rotated at 600 6 30 rpm. Water, controlled at the specified test

used, provided it is first ascertained that the reagent is of

temperature, impinges on the bearing housing at a rate of 5 6

sufficiently high purity to permit its use without lessening the

0.5 mL/s. The amount of grease washed out in 60 6 1 min is

accuracy of the determination.

a measure of the resistance of the grease to water washout.

6.2 Distilled Water.

6.3 Cleaning Solvent—Capable of sufficiently cleaning the

test bearing for use in the test. Either reagent grade Stoddard

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.G0.06 on Functional Tests - Contamination.

Current edition approved Dec. 1, 2008. Published February 2009. Originally Reagent Chemicals, American Chemical Society Specifications, American

´1

approved in 1953. Last previous edition approved in 2003 as D1264–03 . DOI: Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

10.1520/D1264-03R08. listed by the American Chemical Society, see Annual Standards for Laboratory

Available from ASTM International Headquarters. Order Adjunct No. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

ADJD3336. Original adjunct produced in 1984. and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

ADJD6300 is no longer available. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1264–03 (2008)

in. mm in. mm °F °C

0.010 0.25 0.875 22.22 100 6 5 37.8 6 3

0.015 0.38 0.938 23.81 175 6 3 79.4 6 2

0.031 0.79 2 ⁄4 57.1

⁄8 3.18 6 152

⁄32 3.97

⁄16 4.76

⁄4 6.35

FIG. 1 Water Washout Characteristics of Lubricating Grease Apparatus

solvent, also known as Mineral Spirits, (Warning— reagent grade n-heptane (Warning—Flammable. Harmful if

Combustible. Vapor harmful), or American Chemical Society inhaled) has been found suitable for use.

D1264–03 (2008)

7. Preparation of Apparatus occurringduringthedryingperiod,shouldnotbeconsideredas

grease lost. Duplicate tests shall be run.

7.1 Clean the reservoir a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:D1264–03 Designation:D1264–03 (Reapproved 2008)

Standard Test Method for

Determining the Water Washout Characteristics of

Lubricating Greases

This standard is issued under the fixed designation D 1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Updated adjunct information and deleted apparatus footnote editorially in November 2003.

1. Scope *

1.1 This test method covers the evaluation of the resistance of a lubricating grease to washout by water from a bearing, when

tested at 38 and 79°C (100 and 175°F) under the prescribed laboratory conditions. It is not to be considered the equivalent of

service evaluation tests. This test method may not be suitable for some greases containing highly volatile components.

1.2 The values state in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 6.3.

2. Referenced Documents

2.1 ASTM Adjuncts:

ADJD3336 Standard Ball Bearing

Standard Ball Bearing

ADJD6300 D2PP,D2PP, Version 4.43, Determination of Precision and Bias Data for Use in Test Methods for Petroleum

Products

3. Summary of Test Method

3.1 The grease is packed into a ball bearing, the bearing is then inserted in a housing with specified clearances, and rotated at

600 6 30 rpm. Water, controlled at the specified test temperature, impinges on the bearing housing at a rate of 5 6 0.5 mL/s. The

amount of grease washed out in 60 6 1 min is a measure of the resistance of the grease to water washout.

4. Significance and Use

4.1 This test method estimates the resistance of greases to water washout from ball bearings under conditions of the test. No

correlation with field service has been established.

5. Apparatus

5.1 Ball Bearing, ASTM test bearing size 6204 (see ADJD3336).

5.2 Bearing Housing and Shield with dimensions as shown in Fig. 1.

5.3 Reservoir, Bearing-Housing Mount, Circulating Pump, and Drive Motor, similar or equivalent to those shown in Fig. 1.

Table 1 provides the metric equivalents. .

5.4 Heating Source, to maintain the water temperature at 79 6 1.7°C (175 6 3°F).

NOTE 1—Suitable temperature control may be obtained by the use of immersion heaters, steam coils, or infrared heat lamps, in conjunction with

transformers or thermostats.

5.5 Thermometer or Thermocouple , to determine the temperature of the water reservoir.

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.G0.06

on Functional Tests - Contamination.

Current edition approved Nov. 4, 2003. Published July 2003. Originally approved in 1953. Last previous edition approved in 2000 as D1264–00.

´1

Current edition approved Dec. 1, 2008. Published February 2009. Originally approved in 1953. Last previous edition approved in 2003 as D 1264–03 .

The ball bearing has been standardized by Committee D02. Available from ASTM International Headquarters. Order Adjunct No. ADJD3336.

Available from ASTM International Headquarters. Order Adjunct No. ADJD3336. Original adjunct produced in 1984.

Available from ASTM International Headquarters. Order Adjunct No. ADJD6300.

ADJD6300 is no longer available.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1264–03 (2008)

FIG. 1 Water Washout Characteristics of Lubricating Grease Apparatus

in. mm in. mm °F °C

0.010 0.25 0.875 22.22 100 6 5 37.8 6 3

0.015 0.38 0.938 23.81 175 6 3 79.4 6 2

0.031 0.79 2 ⁄4 57.1

⁄8 3.18 6 152

⁄32 3.97

⁄16 4.76

⁄4 6.35

6. Materials and Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the committee on Analytical Reagents of the American Chemical Society, where

D1264–03 (2008)

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

6.2 Distilled Water.

6.3 Cleaning Solvent— Capable of sufficiently cleaning the test bearing for use in the test. Either reagent grade Stoddard

solvent, also known as Mineral Spirits, ( Warning—Combustible. Vapor harmful), or American Chemical Society reagent grade

n-heptane (Warning—Flammable. Harmful if inhaled) has been found suitable for use.

7. Preparation of Apparatus

7.1 Clean the reservoir and water passages by flushing with distilled water. Wipe off any oil scum which has been deposited

on the surfaces of the reservoir. Clean the test bearing with cleaning solvent (see 6.3).

8. Procedure

8.1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D1264–00 Designation:D1264–03 (Reapproved 2008)

Standard Test Method for

Determining the Water Washout Characteristics of

Lubricating Greases

This standard is issued under the fixed designation D 1264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval. This test method has been adopted for use by

government agencies to replace Method 3252 of Federal Test Method Standard No. 79 lb.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the evaluation of the resistance of a lubricating grease to washout by water from a bearing, when

tested at 38 and 79°C (100 and 175°F) under the prescribed laboratory conditions. It is not to be considered the equivalent of

service evaluation tests. This test method may not be suitable for some greases containing highly volatile components.

1.2 The values state in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazardwarning statements, see 6.3and 7.1.

2. Referenced Documents

2.1 ASTM Standards:

D235Specification for Mineral Spirits (Petroleum Spirits) Hydrocarbon Dry Cleaning Solvent ASTM Adjuncts:

Standard Ball Bearing

D2PP, Version 4.43, Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products

3. Summary of Test Method

3.1 The grease is packed into a ball bearing, the bearing is then inserted in a housing with specified clearances, and rotated at

600 6 30 rpm. Water, controlled at the specified test temperature, impinges on the bearing housing at a rate of 5 6 0.5 mL/s. The

amount of grease washed out in 60 6 1 min is a measure of the resistance of the grease to water washout.

4. Significance and Use

4.1 This test method estimates the resistance of greases to water washout from ball bearings under conditions of the test. No

correlation with field service has been established.

5. Apparatus

5.1 Ball Bearing, ASTM test bearing size 6204. , ASTM test bearing size 6204 (see ADJD3336).

5.2 Bearing Housing and Shield with dimensions as shown in Fig. 1.

5.3 Reservoir, Bearing-Housing Mount, Circulating Pump, and Drive Motor, similar or equivalent to those shown in Fig. 1.

Table 1 provides the metric equivalents. .

5.4 Heating Source, to maintain the water temperature at 79 6 1.7°C (175 6 3°F).

NOTE 1—Suitable temperature control may be obtained by the use of immersion heaters, steam coils, or infrared heat lamps, in conjunction with

transformers or thermostats.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.G on

Lubricating Grease.

Current edition approved Dec. 10, 2000. Published January 2001. Originally published as D1264–53T. Last previous edition D1264–96.

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.G0.06

on Functional Tests - Contamination.

´1

Current edition approved Dec. 1, 2008. Published February 2009. Originally approved in 1953. Last previous edition approved in 2003 as D 1264–03 .

Annual Book of ASTM Standards, Vol 06.04.

Available from ASTM International Headquarters. Order Adjunct No. ADJD3336. Original adjunct produced in 1984.

This apparatus is available from the Precision Scientific Co., 3737 Cortland St., Chicago, IL, Labline, Inc., 3072-82 W. Grant Ave., Chicago, IL, 60622 as Catalog No.

4165, and Stanhope-Seta Limited, Park Close, Englefield Green, Egham, Surrey, England, TW20 OXD. as Catalog No. 1961.

ADJD6300 is no longer available.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1264–03 (2008)

FIG. 1 Water Washout Characteristics of Lubricating Grease Apparatus

in. mm in. mm °F °C

0.010 0.25 0.875 22.22 100 6 5 37.8 6 3

0.015 0.38 0.938 23.81 175 6 3 79.4 6 2

0.031 0.79 2 ⁄4 57.1

⁄8 3.18 6 152

⁄32 3.97

⁄16 4.76

⁄4 6.35

5.5 Thermometer or Thermocouple , to determine the temperature of the water reservoir.

6. Materials and Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the committee on Analytical Reagents of the American Chemical Society, where

D1264–03 (2008)

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

6.2 Distilled Water.

6.3 Cleaning Solvent capable of sufficiently cleaning the test bearing for use in the test. Either Stoddard solvent (— Capable

of sufficiently cleaning the test bearing for use in the test. Either reagent grade Stoddard solvent, also known as Mineral

Spirits,(Warning—Combustible.Vaporharmful.)inaccordancewiththerequirementsofSpecificationD235,orAmerican

Chemical Society reagent grade —Combustible. Vapor harmful), or American Chemical Society reagent grade

n-heptane (Warning—Flammable. Harmful if inhaled.)inhaled) has been found suitable for use.

7. Preparation of Apparatus

7.1Clean7.1 Clean the reservoir and water passages by flushing with distilled water. Wipe off any oil scum which has been

deposited on the surfaces of the reservoir. Clean the test bearing with cleaning solvent (see 6.3).

8. Procedure

8.1 Pack the tared bearing with 4.00 6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.