ASTM F1836M-09

(Specification)Standard Specification for Stuffing Tubes, Nylon, and Packing Assemblies (Metric)

Standard Specification for Stuffing Tubes, Nylon, and Packing Assemblies (Metric)

ABSTRACT

This specification covers the general requirements for nylon stuffing tubes and packing assemblies. Nylon stuffing tubes are intended for making electric cable penetrations in marine shipboard enclosures for electrical equipment. The following types are suitable for thin-wall enclosures up to a certain thickness and thick-wall enclosures, bulkheads, and decks of also of a certain thickness. Nylon stuffing tubes shall be classified into four types: Type 1 with straight, unified form thread, Type 2 with 90°, unified form thread, Type 3 with NPT, American standard pipe thread and Type 4 with Y, unified form thread. Materials used for the manufacture of these stuffing tubes and packing assemblies shall include polyamide or nylon and synthetic rubber or neoprene. The sizes and dimensions of stuffing tubes and packing assemblies are completely described. In order determine properties such as vibration resistance, ruggedness, and seal effectiveness of stuffing tubes, the following tests shall be performed: vibration test, mechanical abuse test, and level of effectiveness test. In terms of physical appearance, stuffing tubes shall be free from warp, cracks, chipped edges or surfaces, blisters, uneven surfaces, scratches, dents, and heat marks. They shall be free from fins, burrs, and unsightly finish caused by chipping, filing, or grinding without subsequent buffing or polishing. All molded nylon parts shall be cleaned thoroughly of annealing mediums. Packing assemblies shall be free of voids, pin holes, flash, or other imperfections, that may impair their serviceability.

SCOPE

1.1 This specification covers the general requirements for nylon stuffing tubes and packing assemblies. Nylon stuffing tubes are intended for making electric cable penetrations in marine shipboard enclosures for electrical equipment. The following types are suitable for both thin-wall enclosures up to 5 mm (3/16 in.) thick and thick-wall enclosures, bulkheads, and decks of 5 to 19 mm (3/16 to ¾ in.) thick.

1.2 This specification does not cover metal stuffing tubes.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1836M −09 AnAmerican National Standard

Standard Specification for

1

Stuffing Tubes, Nylon, and Packing Assemblies (Metric)

This standard is issued under the fixed designation F1836M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.4 IEC Standard

Standard 68-2-6 Environmental Testing–Part 2: Tests–Test

1.1 This specification covers the general requirements for

5

FC: Vibration (Sinusoidal) Sixth Edition

nylon stuffing tubes and packing assemblies. Nylon stuffing

tubes are intended for making electric cable penetrations in

3. Terminology

marine shipboard enclosures for electrical equipment. The

following types are suitable for both thin-wall enclosures up to

3.1 Definitions of Terms Specific to This Standard:

3

5mm( ⁄16 in.) thick and thick-wall enclosures, bulkheads, and 3.1.1 nylon stuffıng tube, n—a marine electrical fitting used

3 3

decks of 5 to 19 mm ( ⁄16 to ⁄4 in.) thick. for the sealing of cable penetration into shipboard enclosures

while maintaining or exceeding the degree of protection for

1.2 This specification does not cover metal stuffing tubes.

which the enclosure is rated.

1.3 This standard does not purport to address all of the

3.1.2 packing assembly, n—the compressible insert for the

safety concerns, if any, associated with its use. It is the

nylon stuffing tube. It consists of one neoprene bushing and

responsibility of the user of this standard to establish appro-

three nylon washers.

priate safety and health practices and determine the applica-

3.1.3 enclosure, n—an electrical panel, cabinet, junction

bility of regulatory limitations prior to its use.

box, light fixture, electrical equipment, control box, or panel.

2. Referenced Documents

2

4. Classification

2.1 ASTM Standards:

D2000 Classification System for Rubber Products in Auto-

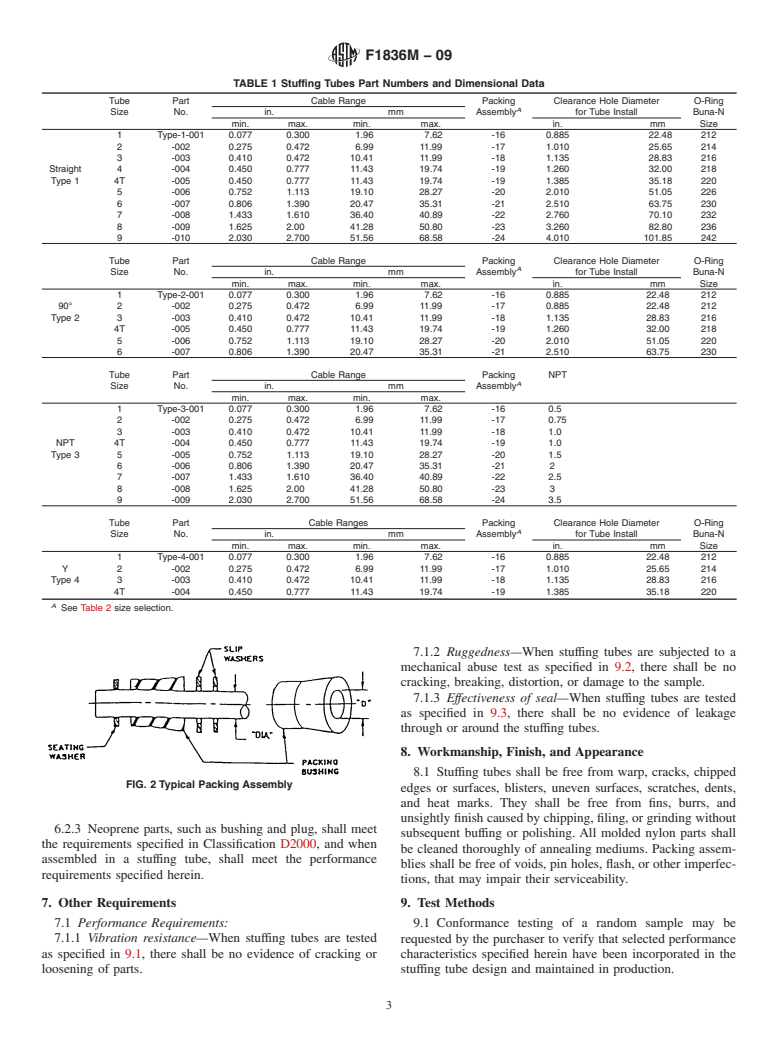

4.1 Nylon stuffing tubes shall be of the following types (see

motive Applications

Fig. 1):

D4066 Classification System for Nylon Injection and Extru-

4.1.1 Type 1—straight—Unified Form Thread.

sion Materials (PA)

4.1.2 Type 2—90°—Unified Form Thread.

2.2 NEMA Standards:

4.1.3 Type 3—NPT—American Standard Pipe Thread.

Standard 250 Enclosures for Electrical Equipment (1000 V

4.1.4 Type 4—Y—Unified Form Thread.

3

Max)

2.3 ASME Standard:

5. Ordering Information

ASME B1.1 Unified Inch Screw Threads (UN and UNR

5.1 Orders for stuffing tubes under this specification shall

4

Thread Form)

include the following:

5.1.1 Type (see 4.1).

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships

5.1.2 Part number (see Table 1).

and Marine Technology and is the direct responsibility of Subcommittee F25.10 on

5.1.3 Packing assembly size (see Fig. 2 and Table 2).

Electrical.

5.1.4 The O-ring included in the stuffing tube assembly has

Current edition approved March 1, 2009. Published March 2009. Originally

approved in 1997. Last previous edition approved in 2007 as F1836M - 97(2007).

a finite shelf life. If the stuffing tube assembly is used after the

DOI: 10.1520/F1836M-09.

shelf life has expired, the O-ring should be replaced, using the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

appropriate size listed in Table 1.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from National Electrical Manufacturers Association (NEMA), 1300

5

N. 17th St., Suite 1752, Rosslyn, VA 22209, http://www.nema.org. Available from American Society of Mechanical Engineers (ASME), ASME

4

Available from the International Electrotechnical Commission, 3 rue de International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

Varembe, Case postale 131, CH-1211, Geneva 20, Switzerland. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1836M−09

FIG. 1Stuffing Tube Types

5.1.5 ASTM Part Number. The part number comprises the 6.1.1 Polyamide (nylon) molding plastic material shall be

ASTM specification number, type designator and assigned Group 1, Class 8, Grade 1 in accordance with Specification

dash number as shown in the following example: D4066.

6.1.2 Synthetic rubber (neoprene) shall be in accordance

F1836M Type-3 -002

ASTM Part Type Size

with Classification D2000, M2, BC, 410, A14, B14, C12, and

Designator Designator Designator

F19.

Example: F1836M Type-3-002: Size 2 NPT stuffing tub

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F1836M–97 (Reapproved 2007) Designation: F 1836M – 09

Standard Specification for

1

Stuffing Tubes, Nylon, and Packing Assemblies (Metric)

This standard is issued under the fixed designation F 1836M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers the general requirements for nylon stuffing tubes and packing assemblies. Nylon stuffing tubes are

intended for making electric cable penetrations in marine shipboard enclosures for electrical equipment. The following types are

3

suitable for both thin-wall enclosures up to 5 mm ( ⁄16 in.) thick and thick-wall enclosures, bulkheads, and decks of 5 to 19 mm

3 3

( ⁄16 to ⁄4 in.) thick.

1.2 This specification does not cover metal stuffing tubes.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to its use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 2000 Classification System for Rubber Products in Automotive Applications

D 4066 Classification System for Nylon Injection and Extrusion Materials (PA)

2.2 NEMA Standards:

3

Standard 250 Enclosures for Electrical Equipment (1000 V Max)

2.3 ASME Standard:

4

ASME B1.1 Unified Inch Screw Threads (UN and UNR Thread Form)

2.4 IEC Standard

5

Standard 68-2-6 Environmental Testing–Part 2: Tests–Test FC: Vibration (Sinusoidal) Sixth Edition

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 nylon stuffıng tube, n—a marine electrical fitting used for the sealing of cable penetration into shipboard enclosures while

maintaining or exceeding the degree of protection for which the enclosure is rated.

3.1.2 packing assembly, n—the compressible insert for the nylon stuffing tube. It consists of one neoprene bushing and three

nylon washers.

3.1.3 enclosure, n—an electrical panel, cabinet, junction box, light fixture, electrical equipment, control box, or panel.

4. Classification

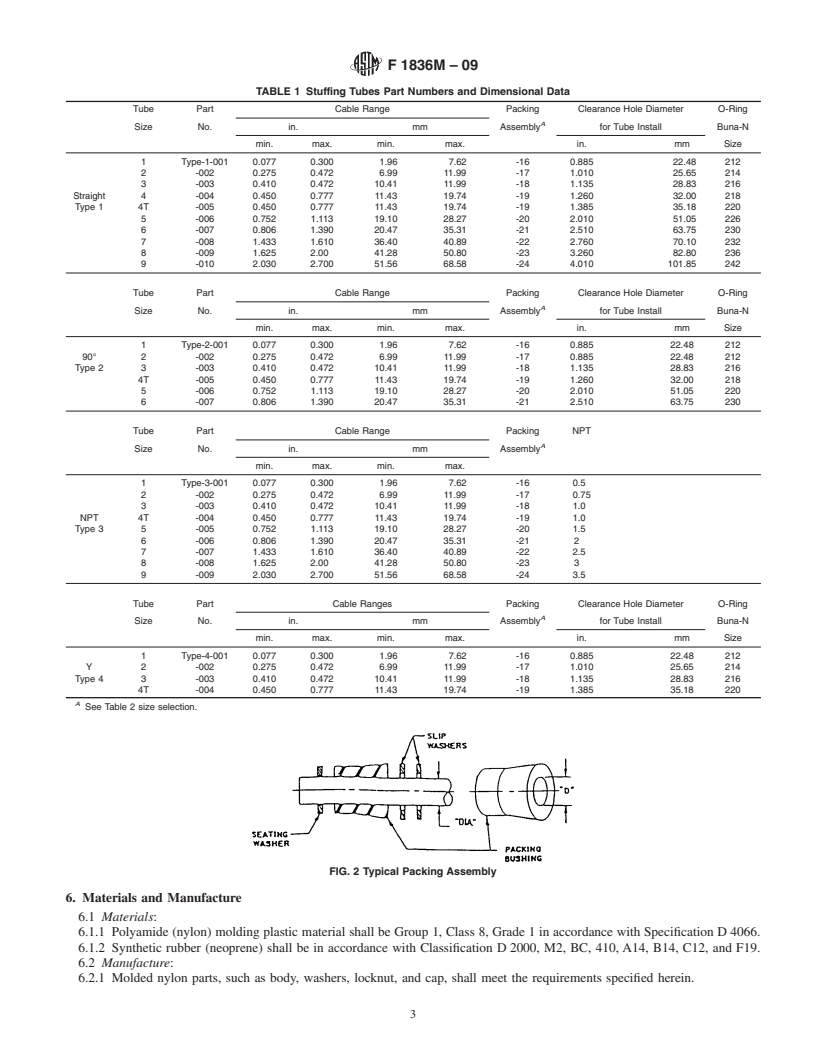

4.1 Nylon stuffing tubes shall be of the following types (see Fig. 1):

4.1.1 Type 1—straight—Unified Form Thread.

4.1.2 Type 2—90°—Unified Form Thread.

4.1.3 Type 3—NPT—American Standard Pipe Thread.

4.1.4 Type 4—Y—Unified Form Thread.

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.10 on

Electrical.

Current edition approved MayMarch 1, 2007.2009. Published June 2007.March 2009. Originally approved in 1997. Last previous edition approved in 20022007 as

F 1836M - 97(20027).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from National Electrical Manufacturers Association (NEMA), 1300 N. 17th St., Suite 1752, Rosslyn, VA 22209, http://www.nema.org.

4

Available from the International Electrotechnical Commission, 3 rue de Varembe, Case postale 131, CH-1211, Geneva 20, Switzerland.

5

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1836M – 09

FIG. 1 Stuffing Tube Types

5. Ordering Information

5.1 Orders for stuffing tubes under this specification shall include the following:

5.1.1 Type (see 4.1).

5.1.2 Part number (see Table 1).

5.1.3 Packing assembly size (see Fig. 2 and Table 2).

5.1.4 The O-ring included in the stuffing tube assembly has a finite shelf life. If the stuffing tube assembly is used after the shelf

life has expired, the O-ring should be replaced, using the appropriate size listed in Table 1.

5.1.5 ASTM Part Number. The part number comprises the ASTM specification number, type designator and assigned dash

number as shown in the following example:

F 1836M Type-3 -002

ASTM Part Type Size

Desi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.