ASTM E2281-08

(Practice)Standard Practice for Process and Measurement Capability Indices

Standard Practice for Process and Measurement Capability Indices

SIGNIFICANCE AND USE

Process Capability—Process capability can be defined as the natural or inherent behavior of a stable process that is in a state of statistical control (1). A “state of statistical control” is achieved when the process exhibits no detectable patterns or trends, such that the variation seen in the data is believed to be random and inherent to the process. Process capability is linked to the use of control charts and the state of statistical control. A process must be studied to evaluate its state of control before evaluating process capability.

Process Control—There are many ways to implement control charts, but the most popular choice is to achieve a state of statistical control for the process under study. Special causes are identified by a set of rules based on probability theory. The process is investigated whenever the chart signals the occurrence of special causes. Taking appropriate actions to eliminate identified special causes and preventing their reappearance will ultimately obtain a state of statistical control. In this state, a minimum level of variation may be reached, which is referred to as common cause or inherent variation. For the purpose of this standard, this variation is a measure of the uniformity of process output, typically a product characteristic.

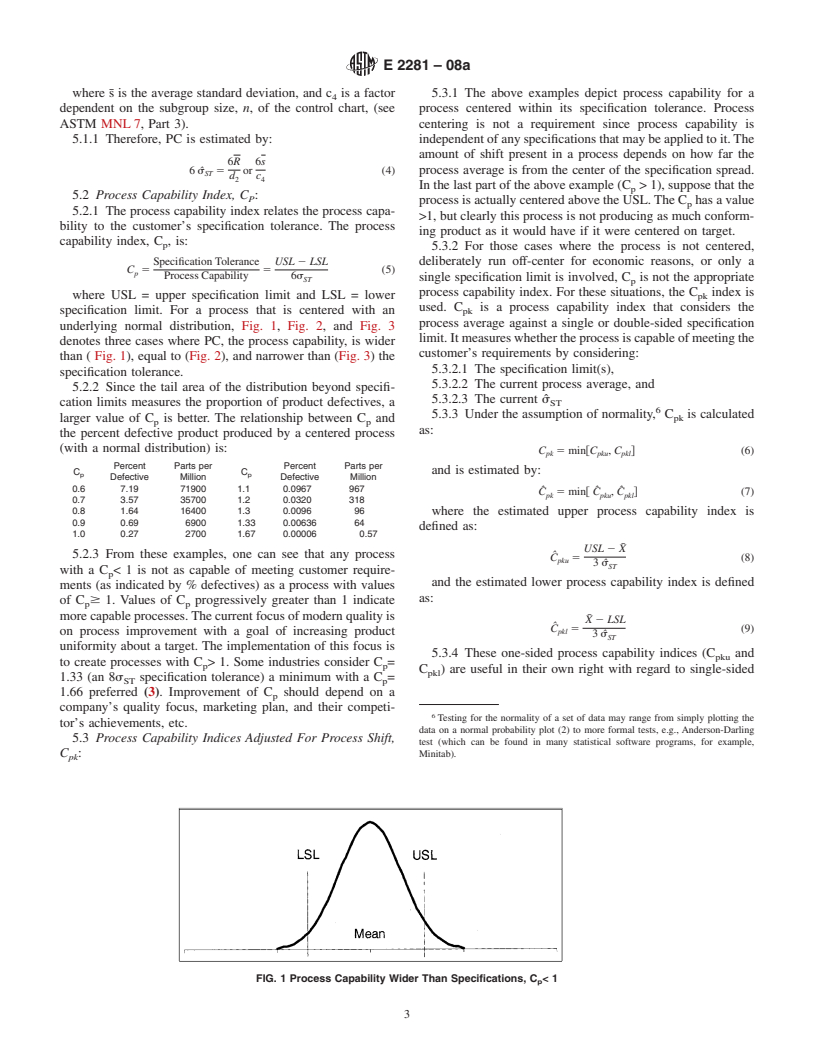

Process Capability Indices—The behavior of a process (as related to inherent variability) in the state of statistical control is used to describe its capability. To compare a process with customer requirements (or specifications), it is common practice to think of capability in terms of the proportion of the process output that is within product specifications or tolerances. The metric of this proportion is the percentage of the process spread used up by the specification. This comparison becomes the essence of all process capability measures. The manner in which these measures are calculated defines the different types of capability indices and their use. Two process capability indices are defi...

SCOPE

1.1 This practice provides guidance for the use of capability indices for evaluating process capability and performance. Process capability indices compare the variability of a process quality measure against product specifications or tolerances and assume the process is in a state of statistical control. Process performance indices are useful in situations when the process is not in a state of statistical control.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2281 – 08a

Standard Practice for

1

Process and Measurement Capability Indices

This standard is issued under the fixed designation E2281; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2.1 Discussion—A long period of time may be defined

as shifts, weeks, or months, etc.

1.1 Thispracticeprovidesguidancefortheuseofcapability

3.2.3 lower process capability index, C , n—index de-

pkl

indices for evaluating process capability and performance.

scribingprocesscapabilityinrelationtothelowerspecification

Process capability indices compare the variability of a process

limit.

quality measure against product specifications or tolerances

3.2.4 lower process performance index, P , n—index de-

and assume the process is in a state of statistical control. pkl

scribing process performance in relation to the lower specifi-

Process performance indices are useful in situations when the

cation limit.

process is not in a state of statistical control.

3.2.5 minimum process capability index, C , n—smaller of

pk

2. Referenced Documents the upper process capability index and the lower process

2

capability index.

2.1 ASTM Standards:

3.2.6 minimum process performance index, P , n—smaller

pk

E456 Terminology Relating to Quality and Statistics

of the upper process performance index and the lower process

E2586 Practice for Calculating and Using Basic Statistics

performance index.

2.2 ISO Standard:

3.2.7 process capability, PC, n—statistical estimate of the

ISO 3534-2 Statistics—Vocabulary and Symbols-Statistical

3

outcome of a characteristic from a process that has been

Quality Control

demonstrated to be in a state of statistical control.

2.3 Other Document:

3.2.8 process capability index, C , n—an index describing

p

MNL 7 Manual on Presentation of Data and Control Chart

4

process capability in relation to specified tolerance.

Analysis

3.2.9 process performance, PP, n—statistical measure of

3. Terminology

the outcome of a characteristic from a process that may not

have been demonstrated to be in a state of statistical control.

3.1 Definitions—Unless otherwise noted, all statistical

3.2.10 process performance index, P , n—index describing

terms are defined in Terminology E456.

p

process performance in relation to specified tolerance.

3.2 Definitions of Terms Specific to This Standard:

3.2.11 range, R, n—maximum value minus the minimum

3.2.1 average standard deviation, s¯, n—arithmetic average

value in a sample. E 2586

of sample standard deviations.

3.2.12 short term standard deviation, s , n—the inherent

3.2.2 long term standard deviation, s , n—sample stan-

ST

LT

variation present when a process is operating in a state of

dard deviation of all individual (observed) values taken over a

statistical control, expressed in terms of standard deviation.

long period of time.

3.2.12.1 Discussion—This may also be stated as the inher-

ent process variation.

3.2.13 special cause, n—source of intermittent variation in

1

ThispracticeisunderthejurisdictionofASTMCommitteeE11onQualityand

a process. ISO 3534-2

Statistics and is the direct responsibility of Subcommittee E11.30 on Statistical

3.2.13.1 Discussion—Sometimes“specialcause”istakento

Quality Control.

Current edition approved Oct. 1, 2008. Published October 2008. Originally besynonymouswith“assignablecause.”Howeveradistinction

approved in 2003. Last previous edition approved in 2008 as E2281–08.

should be recognized.Aspecial cause is assignable only when

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

it is specifically identified. Also a common cause may be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

assignable.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3.2.13.2 Discussion—A special cause arises because of

3

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

specific circumstances which are not always present.As such,

4th Floor, New York, NY 10036, http://www.ansi.org.

4 in a process subject to special causes, the magnitude of the

Available from ASTM Headquarters, 100 Barr Harbor Drive, W. Consho-

hocken, PA 19428. variation from time to time is unpredictable.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 2281 – 08a

3.2.14 stable process, n—process in a state of statistical manner in which these measures are calculated defines the

control; process condition when all special causes of variation different types of

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately,ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:E2281–03 Designation: E 2281 – 08

Standard Practice for

1

Process and Measurement Capability Indices

This standard is issued under the fixed designation E2281; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Section 3 was corrected editorially in May 2007.

1. Scope

1.1 Thispracticeprovidesguidancefortheuseofcapabilityindicesforevaluatingprocesscapabilityandperformance.Process

capabilityindicescomparethevariabilityofaprocessqualitymeasureagainstproductspecificationsortolerancesandassumethe

process is in a state of statistical control. Process performance indices are useful in situations when the process is not in a state

of statistical control.

2. Referenced Documents

2

2.1 ASTM Standards:

E456 Terminology Relating to Quality and Statistics

2.2 ISO Standard:

3

ISO 3534-2 Statistics—Vocabulary and Symbols-Statistical Quality Control

2.3 Other Document:

4

MNL 7 Manual on Presentation of Data and Control Chart Analysis

3. Terminology

3.1 DefinitionsDefinitions: Unless—Unless otherwise noted, all statistical terms are defined in Terminology E 456.

3.1.1

3.2 Definitions of Terms Specific to This Standard:

3.2.1 average standard deviation, s¯, n—arithmetic average of sample standard deviations.

3.1.2

3.2.2 long term standard deviation, s , n—sample standard deviation of all individual (observed) values taken over a long

LT

period of time.

3.1.2.1

3.2.2.1 Discussion—A long period of time may be defined as shifts, weeks, or months, etc.

3.1.3

3.2.3 lower process capability index, C , n—index describing process capability in relation to the lower specification limit.

pkl

3.1.4

3.2.4 lower process performance index, P , n—index describing process performance in relation to the lower specification

pkl

limit.

3.1.5

3.2.5 minimum process capability index, C , n—smalleroftheupperprocesscapabilityindexandthelowerprocesscapability

pk

index.

3.1.6

3.2.6 minimum process performance index, P , n—smaller of the upper process performance index and the lower process

pk

performance index.

3.1.7

1

This practice is under the jurisdiction of ASTM Committee E11 on Quality and Statistics and is the direct responsibility of Subcommittee E11.30 on Data Analysis.

Current edition approved June 10, 2003. Published July 2003.

1

This practice is under the jurisdiction ofASTM Committee E11 on Quality and Statistics and is the direct responsibility of Subcommittee E11.30 on Statistical Quality

Control.

e1

Current edition approved April 1, 2008. Published June 2008. Originally approved in 2003. Last previous edition approved in 2003 as E2281–03 .

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute, 11 W. 42nd St., 13th Floor, New York, NY 10036.

4

Available from ASTM Headquarters, 100 Barr Harbor Drive, W. Conshohocken, PA 19428.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2281–08

3.2.7 process capability, PC, n—statisticalestimateoftheoutcomeofacharacteristicfromaprocessthathasbeendemonstrated

to be in a state of statistical control.

3.1.8

3.2.8 process capability index, C , n—an index describing process capability in relation to specified tolerance.

p

3.1.9

3.2.9 process performance, PP, n—statisticalmeasureoftheoutcomeofacharacteristicfromaprocessthatmaynothavebeen

demonstrated to be in a state of statistical control.

3.1.10

3.2.10 process performance index, P , n—index describing process performance in relation to specified tolerance.

p

3.1.11

3.2.11 range, R, n—the largest observation minus the smallest observation in a set of values or observations.

3.1.12

3.2.12 short term standard deviation, s , n—the inherent variation present when a process is operating in a state of statistical

ST

control, expressed in terms of standard deviation.

3.1.12.1

3.2.12.1 Discussion—This may also be stated as the inherent process variation.

3.1.13

3.2.13 special cause, n—source of intermittent variation in a process. ISO3534-2

3.1.13.1 ISO 3534-2

3.2.13.1 Discussion—Sometimes “special cause” is taken to be sy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.