ASTM E2963-22

(Test Method)Standard Test Method for Laboratory Measurement of Acoustical Effectiveness of Ship Noise Treatments Laboratory Measurement of Acoustical Effectiveness for Marine Bulkhead and Deck Treatments

Standard Test Method for Laboratory Measurement of Acoustical Effectiveness of Ship Noise Treatments Laboratory Measurement of Acoustical Effectiveness for Marine Bulkhead and Deck Treatments

SIGNIFICANCE AND USE

5.1 To fully understand the effects of a given treatment, five acoustical factors (transmission loss, acceptance, radiation efficiency, absorption, and damping) must be characterized. For example, only knowing the effect of a given treatment on transmission loss will not allow the acoustical designer or engineer to assess its impacts on propagation of vibration (among other effects), which is an important path to consider for large machinery items and propeller excitation.

5.2 It is necessary to have a common definition of acoustical performance and test procedure to determine all five acoustical factors for ship’s treatments so that the performance of different treatment types, as well as the same treatment type from different manufacturers, can be compared.

5.3 In some cases, particularly for damping treatments, the effect of the treatment will be dependent on the non-treated structure’s material and geometry and other non-acoustic factors such as environmental conditions (that is, temperature). To fully characterize a treatment it may be necessary to test a range of base constructions. For reasons of practicality, convenience, or economy, it may be sufficient to test only one to three constructions to achieve an understanding of the material performance in a range of practical situations. Additional discussion is provided in Annex A1.

SCOPE

1.1 This test method covers the laboratory measurement of the acoustical effectiveness of treatments installed on ship bulkheads, decks, and side shells. Measurements are focused on assessing changes in transmission loss, radiation efficiency, and acceptance that occur when treatments are applied. Measurements of changes to absorption and damping are addressed in Appendix X1 and Appendix X2, respectively.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 Any material that is to be installed on a marine division must meet appropriate fire, combustibility, and other applicable SOLAS, USCG, IMO, Navy, or other required non-acoustical standards and specifications. See Appendix X3 for additional information.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2963 − 22

Standard Test Method for

Laboratory Measurement of Acoustical Effectiveness of

Ship Noise Treatments Laboratory Measurement of

Acoustical Effectiveness for Marine Bulkhead and Deck

1

Treatments

This standard is issued under the fixed designation E2963; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method is designed to measure the acoustical effectiveness of treatments that are intended

to reduce airborne noise on ships. Such treatments would be applied to compartment structural

partitions such as bulkheads, decks, and side shells. To fully characterize the acoustical performance

of a treatment, five parameters must be assessed: transmission loss, radiation efficiency, acceptance,

absorption, and damping. This test method focuses on the assessment of the first three of these

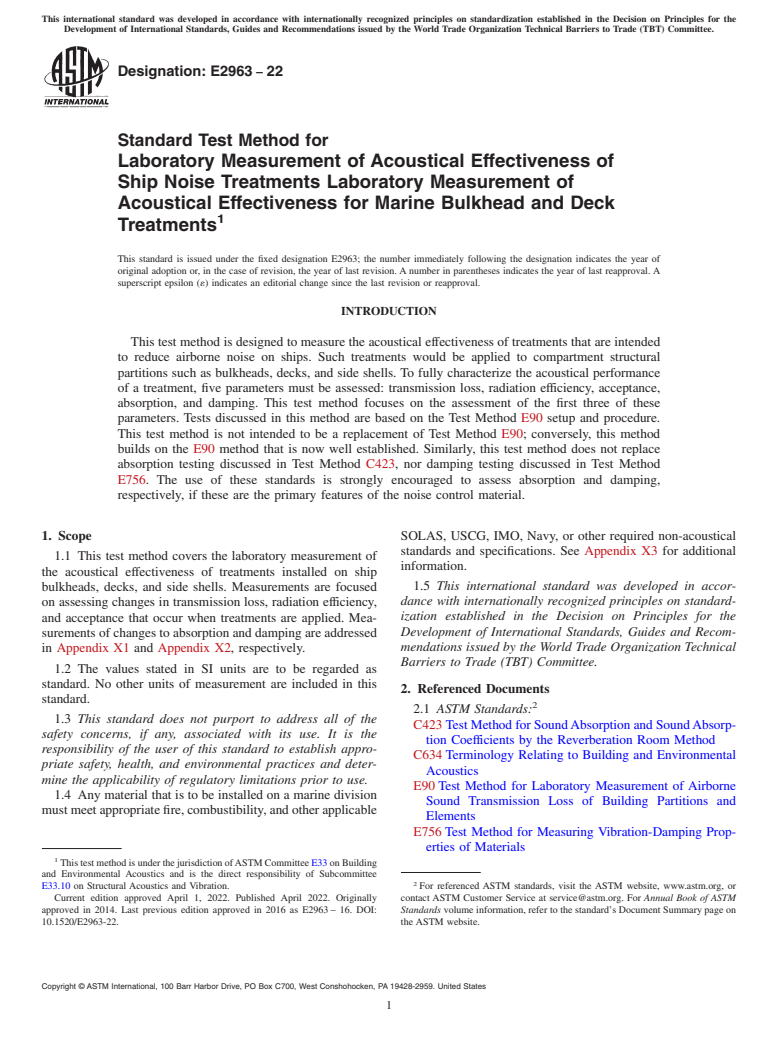

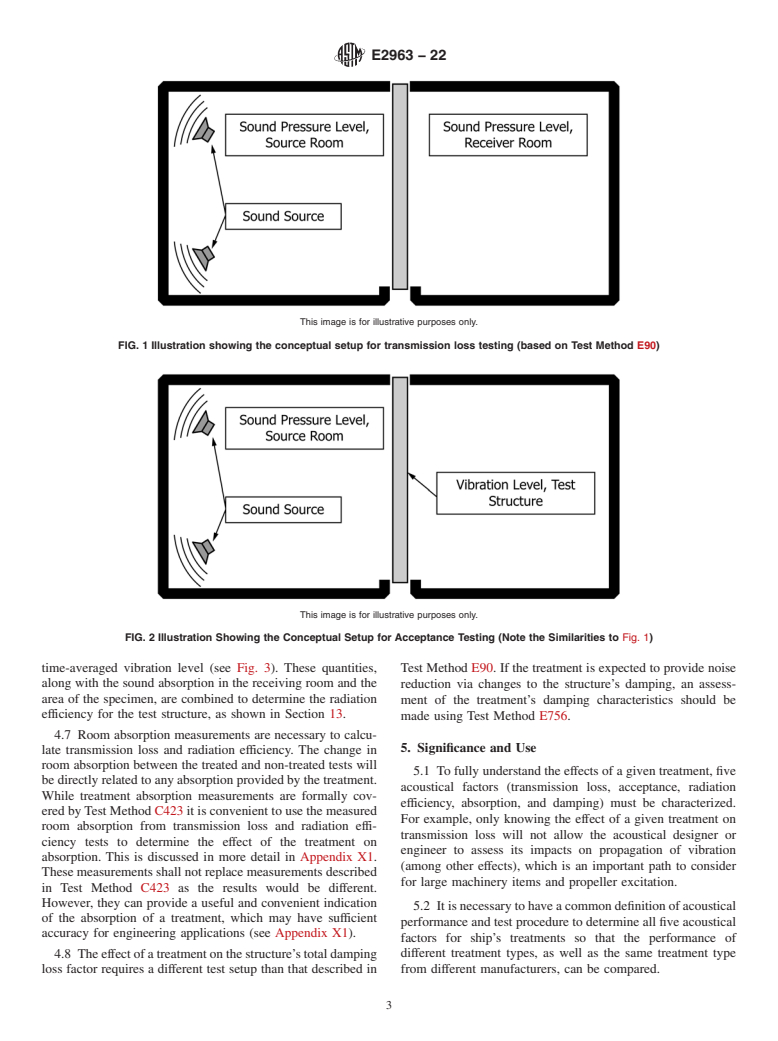

parameters. Tests discussed in this method are based on the Test Method E90 setup and procedure.

This test method is not intended to be a replacement of Test Method E90; conversely, this method

builds on the E90 method that is now well established. Similarly, this test method does not replace

absorption testing discussed in Test Method C423, nor damping testing discussed in Test Method

E756. The use of these standards is strongly encouraged to assess absorption and damping,

respectively, if these are the primary features of the noise control material.

1. Scope SOLAS, USCG, IMO, Navy, or other required non-acoustical

standards and specifications. See Appendix X3 for additional

1.1 This test method covers the laboratory measurement of

information.

the acoustical effectiveness of treatments installed on ship

1.5 This international standard was developed in accor-

bulkheads, decks, and side shells. Measurements are focused

dance with internationally recognized principles on standard-

on assessing changes in transmission loss, radiation efficiency,

ization established in the Decision on Principles for the

and acceptance that occur when treatments are applied. Mea-

Development of International Standards, Guides and Recom-

surements of changes to absorption and damping are addressed

mendations issued by the World Trade Organization Technical

in Appendix X1 and Appendix X2, respectively.

Barriers to Trade (TBT) Committee.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

2. Referenced Documents

standard.

2

2.1 ASTM Standards:

1.3 This standard does not purport to address all of the

C423 Test Method for SoundAbsorption and SoundAbsorp-

safety concerns, if any, associated with its use. It is the

tion Coefficients by the Reverberation Room Method

responsibility of the user of this standard to establish appro-

C634 Terminology Relating to Building and Environmental

priate safety, health, and environmental practices and deter-

Acoustics

mine the applicability of regulatory limitations prior to use.

E90 Test Method for Laboratory Measurement of Airborne

1.4 Any material that is to be installed on a marine division

Sound Transmission Loss of Building Partitions and

mustmeetappropriatefire,combustibility,andotherapplicable

Elements

E756 Test Method for Measuring Vibration-Damping Prop-

erties of Materials

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE33onBuilding

and Environmental Acoustics and is the direct responsibility of Subcommittee

2

E33.10 on Structural Acoustics and Vibration. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2022. Published April 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2014. Last previous edition approved in 2016 as E2963 – 16. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2963-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2963 − 22

3

2.2 ANSI Standards:

L = sound pressure level, dB re: 20 µPa. Lv – velocity

p

-8

ANSI S1.4-1983 (R2006) Specification for Sound Level

level, dB re: 10 nm/s (that is, 10 m/s)

Meters

L = acceptance in decibels referenced to 20 µPa/10 nm/s

Λ

ANSI S1.6-1984 (R2011) Preferred Frequencies, Frequency L = radiation efficiency in decibels

σ

Levels, and Band Number for Acoustical Measurements TL = transmission lo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2963 − 16 E2963 − 22

Standard Test Method for

Laboratory Measurement of Acoustical Effectiveness of

Ship Noise Treatments Laboratory Measurement of

Acoustical Effectiveness for Marine Bulkhead and Deck

1

Treatments

This standard is issued under the fixed designation E2963; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method is designed to measure the acoustical effectiveness of treatments that are intended

to reduce airborne noise on ships. Such treatments would be applied to compartment structural

partitions such as bulkheads, decks, and side shells. To fully characterize the acoustical performance

of a treatment, five parameters must be assessed: transmission loss, radiation efficiency, acceptance,

absorption, and damping. This test method focuses on the assessment of the first three, and provides

for convenient assessments of absorption and damping. three of these parameters. Tests discussed in

this method are based on the Test Method E90 setup and procedure. This test method is not intended

to be a replacement of Test Method E90; conversely, this method builds on the E90 method that is now

well established. Similarly, this test method does not replace absorption testing discussed in Test

Method C423, nor damping testing discussed in Test Method E756, though for reasons of convenience

this method can be used to make approximate assessments of how different treatments may impact

these parameters. The use of these standards is strongly encouraged to assess absorption and damping,

respectively, if these are the primary features of the noise control material.

1. Scope

1.1 This test method covers the laboratory measurement of the acoustical effectiveness of treatments installed on ship bulkheads,

decks, and side shells. Measurements are focused on assessing changes in transmission loss, radiation efficiency, and acceptance

that occur when treatments are applied. Measurements of changes to absorption and damping are addressed in Appendix X1 and

Appendix X2, respectively.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 Any material that is to be installed on a marine division must meet appropriate fire, combustibility, and other applicable

SOLAS, USCG, IMO, Navy, or other required non-acoustical standards and specifications. See Appendix X3 for additional

information.

1

This test method is under the jurisdiction of ASTM Committee E33 on Building and Environmental Acoustics and is the direct responsibility of Subcommittee E33.10

on Structural Acoustics and Vibration.

Current edition approved April 1, 2016April 1, 2022. Published April 2016April 2022. Originally approved in 2014. Last previous edition approved in 20152016 as

E2963 – 15.16. DOI: 10.1520/E2963-16.10.1520/E2963-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2963 − 22

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C423 Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method

E634C634 Practice for Sampling of Zinc and Zinc Alloys for Analysis by Spark Atomic Emission SpectrometryTerminology

Relating to Building and Environmental Acoustics

E90 Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements

E756 Test Method for Measuring Vibration-Damping Properties of Materials

3

2.2 ANSI Standards:

ANSI S1.4-1983 (R2006) Specification for Sound Level Meters

ANSI S1.6-1984 (R2011) Preferred Frequencies, Frequ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.