ASTM D8304-19

(Test Method)Standard Test Method for Determination of Compounded Forms of Iron in In-service Fluids

Standard Test Method for Determination of Compounded Forms of Iron in In-service Fluids

SIGNIFICANCE AND USE

5.1 This test method is applicable for determining the level of iron contamination in lubricating oils from sources other than physical wear of the machinery or equipment, such as corrosion. It is particularly suited for oils from engines running on sulphur containing fuels where acidic combustion by-products can enter the lubrication system and cause corrosive damage. The test can be performed at the point of use as it does not require extensive laboratory equipment allowing timely intervention if necessary.

SCOPE

1.1 This method covers a procedure for determining the concentration of compounded forms of iron in in-service fluids. It is applicable over an iron concentration range of 20 mg/kg to 800 mg/kg (ppm by mass hereafter). The test is not sensitive to metallic iron and thus provides a means of discrimination between the two forms of iron. It is suitable for monitoring the condition of equipment where iron contamination in the lubricating oil or functional fluid may not originate solely from physical wear, for example from corrosion or other forms of undesirable chemical processes within the equipment.

1.2 Units—The values stated in SI units are to be regarded as standard. Concentrations are reported as parts per million by mass (ppm) equivalent to iron contents expressed in mg per kg of oil sample (mg/kg).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8304 − 19

Standard Test Method for

Determination of Compounded Forms of Iron in In-service

1

Fluids

This standard is issued under the fixed designation D8304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4177 Practice for Automatic Sampling of Petroleum and

Petroleum Products

1.1 This method covers a procedure for determining the

D6300 Practice for Determination of Precision and Bias

concentrationofcompoundedformsofironinin-servicefluids.

Data for Use in Test Methods for Petroleum Products and

Itisapplicableoveranironconcentrationrangeof20 mg⁄kgto

Lubricants

800 mg⁄kg (ppm by mass hereafter).The test is not sensitive to

E177 Practice for Use of the Terms Precision and Bias in

metallic iron and thus provides a means of discrimination

ASTM Test Methods

between the two forms of iron. It is suitable for monitoring the

condition of equipment where iron contamination in the

3. Terminology

lubricating oil or functional fluid may not originate solely from

3.1 Definitions:

physical wear, for example from corrosion or other forms of

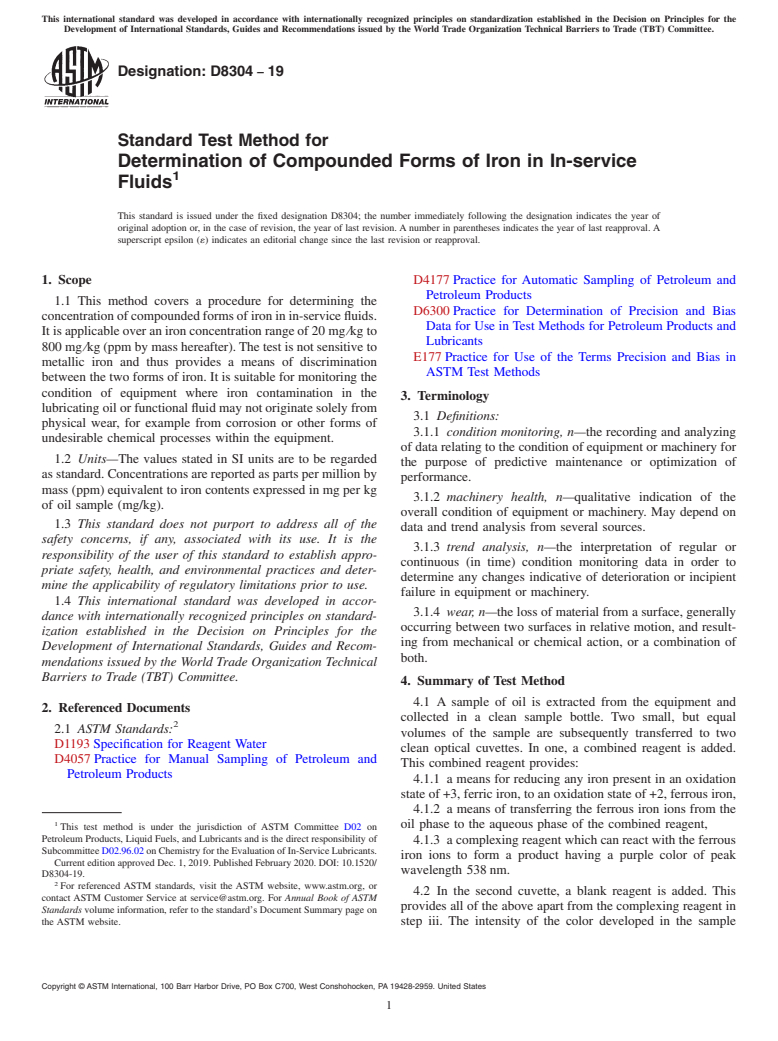

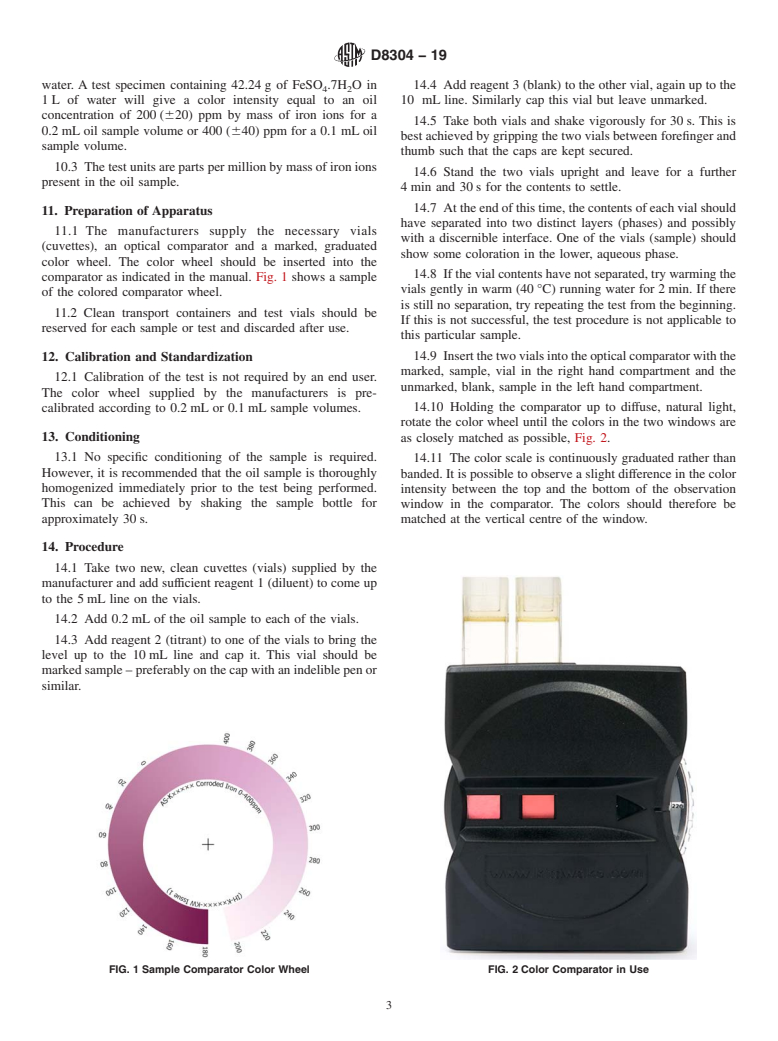

3.1.1 condition monitoring, n—the recording and analyzing

undesirable chemical processes within the equipment.

of data relating to the condition of equipment or machinery for

1.2 Units—The values stated in SI units are to be regarded

the purpose of predictive maintenance or optimization of

as standard. Concentrations are reported as parts per million by

performance.

mass (ppm) equivalent to iron contents expressed in mg per kg

3.1.2 machinery health, n—qualitative indication of the

of oil sample (mg/kg).

overall condition of equipment or machinery. May depend on

1.3 This standard does not purport to address all of the

data and trend analysis from several sources.

safety concerns, if any, associated with its use. It is the

3.1.3 trend analysis, n—the interpretation of regular or

responsibility of the user of this standard to establish appro-

continuous (in time) condition monitoring data in order to

priate safety, health, and environmental practices and deter-

determine any changes indicative of deterioration or incipient

mine the applicability of regulatory limitations prior to use.

failure in equipment or machinery.

1.4 This international standard was developed in accor-

3.1.4 wear, n—the loss of material from a surface, generally

dance with internationally recognized principles on standard-

occurring between two surfaces in relative motion, and result-

ization established in the Decision on Principles for the

ing from mechanical or chemical action, or a combination of

Development of International Standards, Guides and Recom-

both.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

4.1 A sample of oil is extracted from the equipment and

2. Referenced Documents

collected in a clean sample bottle. Two small, but equal

2

2.1 ASTM Standards:

volumes of the sample are subsequently transferred to two

D1193 Specification for Reagent Water

clean optical cuvettes. In one, a combined reagent is added.

D4057 Practice for Manual Sampling of Petroleum and

This combined reagent provides:

Petroleum Products

4.1.1 a means for reducing any iron present in an oxidation

state of +3, ferric iron, to an oxidation state of +2, ferrous iron,

4.1.2 a means of transferring the ferrous iron ions from the

1

oil phase to the aqueous phase of the combined reagent,

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

4.1.3 a complexing reagent which can react with the ferrous

Subcommittee D02.96.02 on Chemistry for the Evaluation of In-Service Lubricants.

iron ions to form a product having a purple color of peak

Current edition approved Dec. 1, 2019. Published February 2020. DOI: 10.1520/

wavelength 538 nm.

D8304-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 In the second cuvette, a blank reagent is added. This

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

provides all of the above apart from the complexing reagent in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. step iii. The intensity of the color developed in the sample

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.