ASTM G194-08

(Test Method)Standard Test Method for Measuring Rolling Friction Characteristics of a Spherical Shape on a Flat Horizontal Plane

Standard Test Method for Measuring Rolling Friction Characteristics of a Spherical Shape on a Flat Horizontal Plane

SIGNIFICANCE AND USE

Rolling friction like sliding friction depends upon many factors. It is a system effect that involves the nature of the rolling surface and the counterface. The sliding friction force (F) is usually considered to be the sum of forces arising from deformations of surface features (Fs), from attractive forces (atomic, molecular, etc.) at contact points (Fa) and force from interaction of films and particulates on the rubbing surfaces (Ff):

The rolling friction force includes these force contributions plus effects from the relative stiffness of the contacting surfaces, the diameter (curvature) of the spherical shape (ball, orange, etc.) and other factors. Because there are so many factors involved in a rolling tribosystem, rolling resistance can best be quantified by an actual test of the sphere of interest on the intended counterface, as in this test method.

There are countless applications where it is important to quantify the rolling characteristics of a particular spherical shape on a particular surface. The interlaboratory tests conducted for this test method were performed on hardened steel balls like those used in ball bearings. This test method could be used to assess the effect of different counterface surfaces on the rolling characteristics of balls for ball bearings. Conversely, it could be used as a quality control test on balls. Surface imperfections/defects/films, etc. on the balls can affect how they roll: the distance traveled on a common counterface.

5.3 Industrial applications of this test method can include assessing conveying surfaces for spherical or nearly special parts: check valve balls, cabinet knobs, Christmas ornaments, toilet floats, etc. Many medical devices use special shapes where rolling characteristics are a consideration. Similarly, many pharmaceutical products (pills) are spherical or nearly spherical in shape, and this test method can be used to assess rolling characteristics for conveying or other reasons such as size (mass) c...

SCOPE

1.1 This test method covers the use of an angled launch ramp to initiate rolling of a sphere or nearly spherical shape on a flat horizontal surface to determine the rolling friction characteristics of a given spherical shape on a given surface.

1.1.1 Steel balls on a surface plate were used in interlaboratory tests (see Appendix X1). Golf balls on a green, soccer and lacrosse balls on playing surfaces, bowling balls on an a lane, basketballs on hardwood, and marbles on composite surface were tested in the development of this test method, but the test applies to any sphere rolling on any flat horizontal surface.

1.1.2 The rolling friction of spheres on horizontal surfaces is affected by the spherical shape’s stiffness, radius of curvature, surface texture, films on the surface, the nature of the counterface surface; there are many factors to consider. This test method takes all of these factors into consideration. The spherical shape of interest is rolled on the surface of interest using a standard ramp to initiate rolling and standard techniques to measure and treat the rolled distance after leaving the ramp.

1.1.3 This test method produces a rolling resistance number on a specific spherical shape on a specific surface. It is intended for comparing similar tribosystems. For example, the rolling resistances of marbles on a particular surface are not to be compared with the rolling resistance of soccer balls on grass, because their masses and diameters are very different as are the counterface surfaces on which they roll.

1.1.4 Different launch ramps for are appropriate for different types of spherical shapes. If a sphere of interest cannot be accommodated with using one of the launch ramps discussed in Appendix X1 and Appendix X2, a different launch ramp can be developed and added with future revisions to this test method.

1.2 The values stated in SI units are to be regarded as standard. No other units of measur...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G194 − 08

StandardTest Method for

Measuring Rolling Friction Characteristics of a Spherical

1

Shape on a Flat Horizontal Plane

This standard is issued under the fixed designation G194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the use of an angled launch

responsibility of the user of this standard to establish appro-

ramptoinitiaterollingofasphereornearlysphericalshapeon

priate safety and health practices and determine the applica-

a flat horizontal surface to determine the rolling friction

bility of regulatory limitations prior to use.

characteristics of a given spherical shape on a given surface.

1.1.1 Steel balls on a surface plate were used in interlabo-

2. Referenced Documents

ratory tests (see Appendix X1). Golf balls on a green, soccer

2

2.1 ASTM Standards:

and lacrosse balls on playing surfaces, bowling balls on an a

G40Terminology Relating to Wear and Erosion

lane, basketballs on hardwood, and marbles on composite

G115Guide for Measuring and Reporting Friction Coeffi-

surface were tested in the development of this test method, but

cients

the test applies to any sphere rolling on any flat horizontal

G143Test Method for Measurement of Web/Roller Friction

surface.

Characteristics

1.1.2 Therollingfrictionofspheresonhorizontalsurfacesis

affected by the spherical shape’s stiffness, radius of curvature,

3. Terminology

surface texture, films on the surface, the nature of the counter-

3.1 Definitions:

face surface; there are many factors to consider. This test

3.1.1 rolling friction force, n—in tribology,aforce,opposite

method takes all of these factors into consideration. The

tothedirectionofrolling,resistingrollingofasphericalshape,

spherical shape of interest is rolled on the surface of interest

ball, roller, wheel, etc. forced against and rolling in a direction

using a standard ramp to initiate rolling and standard tech-

on another surface. G40

niquestomeasureandtreattherolleddistanceafterleavingthe

ramp. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 coeffıcient of rolling resistance (CORR)— dimension-

1.1.3 This test method produces a rolling resistance number

less measure of rolling retardation experienced by a spherical

onaspecificsphericalshapeonaspecificsurface.Itisintended

shape(sphereandthelike)onaflathorizontalplaneofinterest;

for comparing similar tribosystems. For example, the rolling

itistheratiooftheverticaldistancebetweenthesphere’spoint

resistances of marbles on a particular surface are not to be

of contact with the launch ramp and the horizontal plane

compared with the rolling resistance of soccer balls on grass,

divided by the distance rolled on the horizontal plane after

becausetheirmassesanddiametersareverydifferentasarethe

leaving the launch ramp.

counterface surfaces on which they roll.

1.1.4 Differentlaunchrampsforareappropriatefordifferent

3.2.2 rolling resistance number (RR), n— dimensionless

types of spherical shapes. If a sphere of interest cannot be

measure of the retardation produced on a spherical shape

accommodatedwithusingoneofthelaunchrampsdiscussedin

rolling on a flat horizontal surface: the higher the number, the

AppendixX1andAppendixX2,adifferentlaunchrampcanbe

higher the retardation. This number is obtained by multiplying

developed and added with future revisions to this test method.

the CORR by 100.

1.2 The values stated in SI units are to be regarded as

4. Summary of Test Method

standard. No other units of measurement are included in this

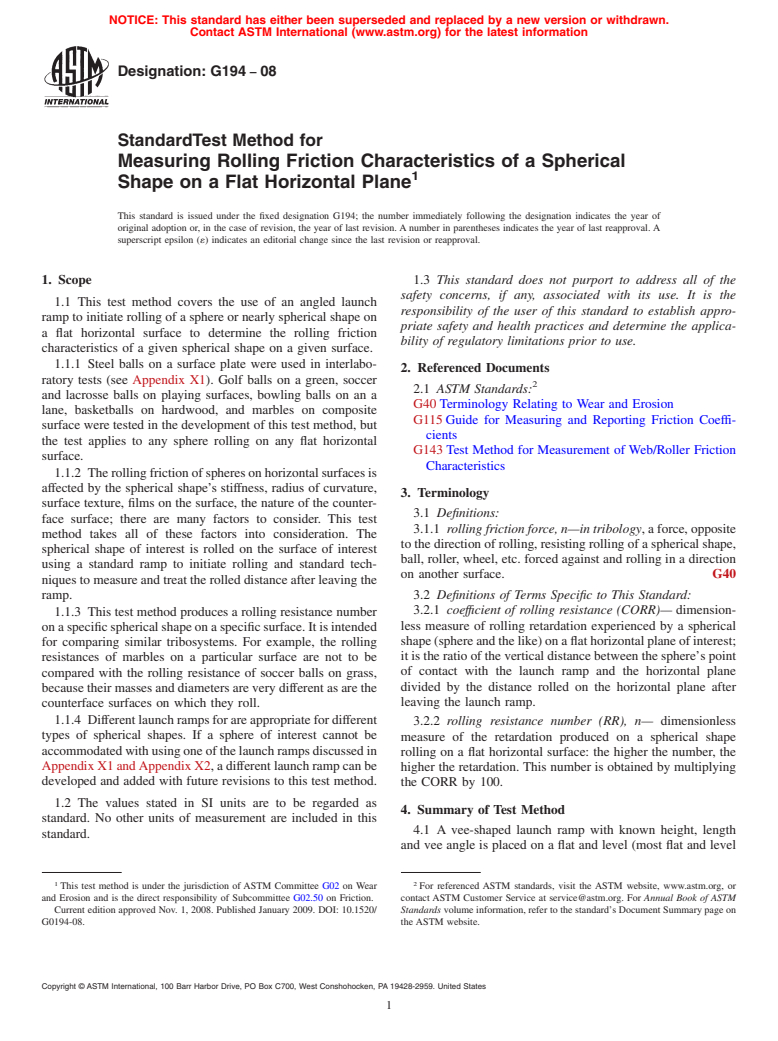

4.1 A vee-shaped launch ramp with known height, length

standard.

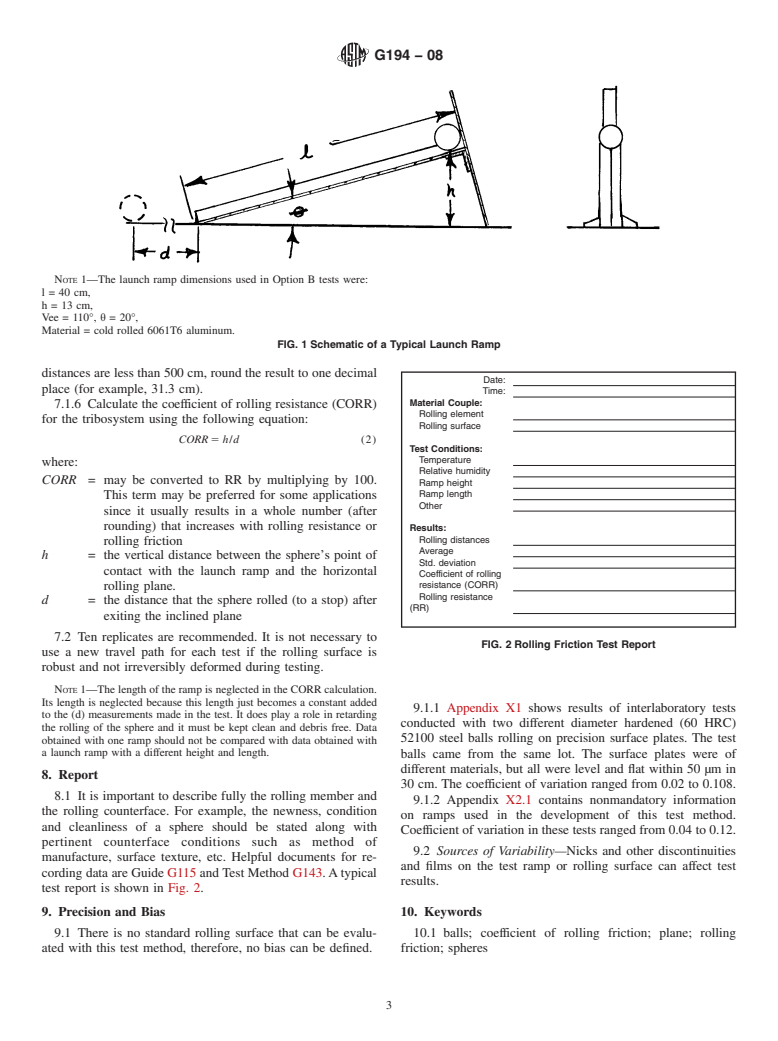

and vee angle is placed on a flat and level (most flat and level

1 2

This test method is under the jurisdiction of ASTM Committee G02 on Wear For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2008. Published January 2009. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

G0194-08. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G194 − 08

portion) of a surface of interest and a sphere (ball bearing, 5.4 Rolling friction of spherical shapes can be a consider-

orange, golf ball, etc.) is rolled down the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.