ASTM D5534-94(2018)

(Test Method)Standard Test Method for Vapor-Phase Rust-Preventing Characteristics of Hydraulic Fluids

Standard Test Method for Vapor-Phase Rust-Preventing Characteristics of Hydraulic Fluids

SIGNIFICANCE AND USE

4.1 Procedures such as Test Methods D665 and D3603 assess the ability of new or unused hydraulic fluid to prevent rusting on wetted steel surfaces but do not address the prevention of rusting in the vapor space above the fluid. This procedure addresses the latter question under one set of test conditions and need not be applicable to some service conditions. Since used fluids have not been cooperatively tested in this procedure, its utility for in-service monitoring has not been established.

SCOPE

1.1 This test method covers the ability of hydraulic fluids to prevent the rusting of steel in the vapor phase over the hydraulic fluid and water.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5534 − 94 (Reapproved 2018)

Standard Test Method for

Vapor-Phase Rust-Preventing Characteristics of Hydraulic

Fluids

This standard is issued under the fixed designation D5534; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A108 Specification for Steel Bar, Carbon and Alloy, Cold-

Finished

1.1 This test method covers the ability of hydraulic fluids to

A240/A240M Specification for Chromium and Chromium-

prevent the rusting of steel in the vapor phase over the

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

hydraulic fluid and water.

Vessels and for General Applications

1.2 The values stated in SI units are to be regarded as

D91 Test Method for Precipitation Number of Lubricating

standard. The values given in parentheses after SI units are

Oils

provided for information only and are not considered standard.

D665 Test Method for Rust-Preventing Characteristics of

1.3 WARNING—Mercury has been designated by many Inhibited Mineral Oil in the Presence of Water

D1193 Specification for Reagent Water

regulatory agencies as a hazardous material that can cause

central nervous system, kidney and liver damage. Mercury, or D3603 Test Method for Rust-Preventing Characteristics of

Steam Turbine Oil in the Presence of Water (Horizontal

its vapor, may be hazardous to health and corrosive to

materials. Caution should be taken when handling mercury and Disk Method)

E1 Specification for ASTM Liquid-in-Glass Thermometers

mercury containing products. See the applicable product Ma-

terial Safety Data Sheet (MSDS) for details and EPA’s

2.2 Other Standards:

website—http://www.epa.gov/mercury/faq.htm—for addi-

IP 60/80 Specification for Petroleum Spirit

tional information. Users should be aware that selling mercury

BS 970: 1955–EN3B Specification for wrought steels

and/or mercury containing products into your state or country

may be prohibited by law.

3. Summary of Test Method

1.4 This standard does not purport to address all of the

3.1 This test method is divided into two parts:

safety concerns, if any, associated with its use. It is the

3.1.1 Part A—Used only for fluids where water is the

responsibility of the user of this standard to establish appro-

continuous phase. Examples of such fluids include water-

priate safety, health, and environmental practices and deter-

glycol hydraulic fluids and high-water-content hydraulic fluids.

mine the applicability of regulatory limitations prior to use.

Do not use PartAto evaluate invert emulsion hydraulic fluids.

1.5 This international standard was developed in accor-

3.1.2 Part B—Used for both water-containing fluids and

dance with internationally recognized principles on standard-

completely water-free fluids such as petroleum based hydraulic

ization established in the Decision on Principles for the

fluids, except phosphate esters. In Part B a small beaker of

Development of International Standards, Guides and Recom-

water is present to provide water vapor to cause corrosion in

mendations issued by the World Trade Organization Technical

the absence of a vapor-phase inhibitor in the fluid. Part B is the

Barriers to Trade (TBT) Committee.

appropriate procedure for evaluating invert emulsion hydraulic

fluids.

2. Referenced Documents

3.2 In both Part A and Part B, a steel specimen is attached

2.1 ASTM Standards:

to the underside of the cover of a beaker containing the fluid

undertest.Theapparatusandspecimenareidenticaltothoseof

This test method is under the jurisdiction of ASTM Committee D02 on

Test Method D3603. The fluid is brought to a test temperature

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

of 60 °C (140 °F).

Subcommittee D02.N0 on Hydraulic Fluids.

Current edition approved April 1, 2018. Published June 2018. Originally

ɛ1

approved in 1994. Last previous edition approved in 2011 as D5534 – 94 (2011) .

DOI: 10.1520/D5534-94R18.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM U.K., http://www.energyinst.org.

Standards volume information, refer to the standard’s Document Summary page on Available from IHS, 15 Inverness Way East, Englewood, CO 80112, http://

the ASTM website. www.global.ihs.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5534 − 94 (2018)

3.3 InPartB,thetestspecimenisexposedtothevaporfrom

the fluid for 30 min prior to the introduction of water.Abeaker

of water is then placed in the undercarriage of the cover.

3.4 After 6 h, the apparatus is disassembled and the speci-

men is rated visually for the presence of rust.

3.5 Since the apparatus and test conditions are identical,

Part A can be completed simultaneously with Test Method

D3603 by adding the vapor-phase specimen to that procedure.

4. Significance and Use

4.1 Procedures such as Test Methods D665 and D3603

assess the ability of new or unused hydraulic fluid to prevent

rusting on wetted steel surfaces but do not address the

prevention of rusting in the vapor space above the fluid. This

procedure addresses the latter question under one set of test

conditions and need not be applicable to some service condi-

tions. Since used fluids have not been cooperatively tested in

thisprocedure,itsutilityforin-servicemonitoringhasnotbeen

established.

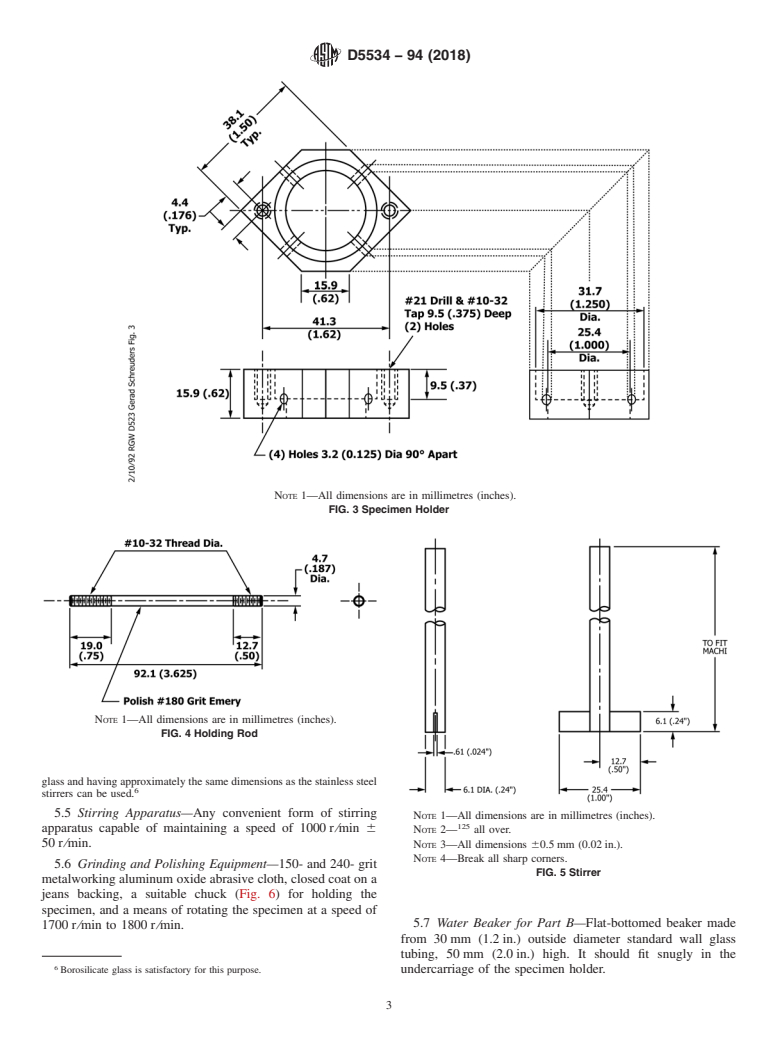

5. Apparatus

5.1 Oil Bath—Thermostatically controlled liquid bath ca-

NOTE 1—All dimensions are in millimetres (inches).

pable of maintaining a temperature in the oil sample of 60 °C

FIG. 1 Rusting Test Apparatus

6 1 °C (140 °F 6 2 °F). The bath shall have holes to

accommodate the test beakers.

NOTE 1—The bath used forTest Method D665 can be used with a slight

modification, that is, the centers of the beaker holes are moved from

1 23

6.4 mm to 18.3 mm ( ⁄4 in. to ⁄32 in.) from the axis of the stirrers.

NOTE 2—To indicate the temperature, a thermometric device such as,

resistance temperature detectors (RTDs), thermistors, or liquid-in-glass

thermometers with equivalent or better requirements ofASTM Thermom-

eter 9C or 9F, or IP Thermometer 21C, as prescribed in Specification E1

may be used.

5.2 Beaker—400 mL, Berzelius-type, tall-form heat resis-

tant glass beaker, approximately 127 mm (5 in.) in height

measured from the inside bottom center and approximately

70 mm (2 ⁄4 in.) in inside diameter measured at the middle, and

without pourout (see Fig. 1).

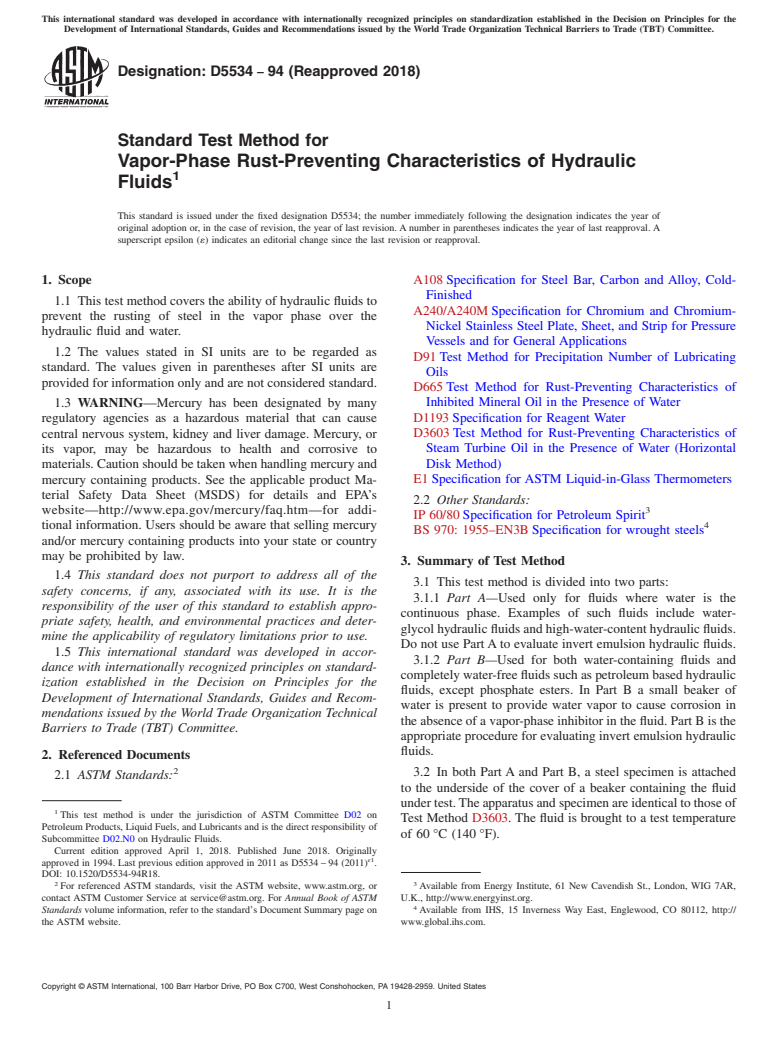

5.3 Beaker Cover (Fig. 2) and Specimen Holder (Fig.

3)—Flat beaker cover of 4.8 mm ( ⁄16 in.) methyl methacrylate

resin or other fluid-resistant material, kept in position by a

suitablegroove.Threeholes,7.9 mm( ⁄16 in.)indiameter,shall

NOTE 1—All dimensions are in millimetres (inches).

be provided.Two are located on any diameter of the cover, one

FIG. 2 Beaker Cover

for a stirrer 18.3 mm ( ⁄32 in.) from the cover’s center, and the

other for the vapor-phase test specimen 7.9 mm ( ⁄16 in.) from

the center on the opposite side. The third hole, for a NOTE 3—Other holders suitable for supporting the specimen in Test

MethodD3603arealsosuitableforsupportingthewaterbeakerinthistest

thermometer, is located 27 mm (1 ⁄16 in.) from the center on a

method. The undercarriage design is not considered to be critical.

diameter perpendicular to that of the other two holes. The

undercarriage is a Test Method D3603 specimen holder suit- 5.4 Stirrer—Constructed entirely from stainless steel in the

form of an invertedT(Fig. 5).Aflat blade 25.4 mm by 6.1 mm

ably attached to the beaker cover, used here to support the

water beaker (see 5.7) used in Part B. One suitable undercar- by 0.6 mm (1 in. by 0.24 in. by 0.024 in.) shall be attached to

riage (the one used in the round-robin) is shown in Fig. 1.An a 6.1 mm (0.24 in.) rod in such a way that the blade is

undercarriage must be present even for Part A, to prevent symmetrical with the rod and has its flat surface in the vertical

vortexing. The holding rod, appropriate for this apparatus, is pane.

depicted in Fig. 4.

NOTE 4—A suitable material is an 18 % chromium, 8 % nickel alloy

steel conforming to Type 304 of Specification A240/A240M, or SAE No.

30304, or BS 970: Part 1: 1983: 302531.

British Standard 2, 1965 Section 5, or equivalent, may be used. NOTE5—Ifstainlesssteelisnotavailable,stirrersmadeofheatresistant

D5534 − 94 (2018)

NOTE 1—All dimensions are in millimetres (inches).

FIG. 3 Specimen Holder

NOTE 1—All dimensions are in millimetres (inches).

FIG. 4 Holding Rod

glass and having approximately the same dimensions as the stainless steel

stirrers can be used.

5.5 Stirring Apparatus—Any convenient form of stirring

NOTE 1—All dimensions are in millimetres (inches).

apparatus capable of maintaining a speed of 1000 r⁄min 6

NOTE 2— all over.

50 r⁄min. NOTE 3—All dimensions 60.5 mm (0.02 in.).

NOTE 4—Break all sharp corners.

5.6 Grinding and Polishing Equipment—150- and 240- grit

FIG. 5 Stirrer

metalworking aluminum oxide abrasive cloth, closed coat on a

jeans backing, a suitable chuck (Fig. 6) for holding the

specimen, and a means of rotating the specimen at a speed of

5.7 Water Beaker for Part B—Flat-bottomed beaker made

1700 r⁄min to 1800 r⁄min.

from 30 mm (1.2 in.) outside diameter standard wall glass

tubing, 50 mm (2.0 in.) high. It should

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.