ASTM D6251/D6251M-00

(Specification)Standard Specification for Wood-Cleated Panelboard Shipping Boxes

Standard Specification for Wood-Cleated Panelboard Shipping Boxes

SCOPE

1.1 This specification covers the fabrication and closure of empty and full wood-cleated, hereafter referred to as wood-cleated, panelboard boxes. These boxes are intended for use as containers for domestic and overseas shipment of general materials and supplies, not exceeding 1000 lb [454 kg] depending on box type (see 10.1).

1.2 Wood-cleated panelboard shipping box performance is dependent on its fabricated components and subsequent assembly; therefore, a variety of types, classes, styles, and treatments reflecting varied performance are specified. This specification, however, does not cover wood-cleated panelboard box performance under all atmospheric, handling, shipping, and storage conditions.

1.3 If the use of other construction methods or techniques is acceptable and permitted (see 5.1.17), the resulting packaging systems shall be of equal or better performance than would result from the use of these specified materials and procedures. The appropriate distribution cycle, specified in Practice D4169, can be used to develop comparative procedures and criteria.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard. See IEEE/ASTM SI 10 for conversion of units.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of the standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6251/D 6251M – 00

Standard Specification for

Wood-Cleated Panelboard Shipping Boxes

This standard is issued under the fixed designation D 6251/D 6251M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Visual-Graded Dimension Lumber from In-Grade Tests of

Full-Size Specimens

1.1 This specification covers the fabrication and closure of

D 3951 Practice for Commercial Packaging

empty and full wood-cleated, hereafter referred to as wood-

D 3953 Specification for Strapping, Flat Steel and Seals

cleated, panelboard boxes. These boxes are intended for use as

D 4169 Practice for Performance Testing of Shipping Con-

containers for domestic and overseas shipment of general

tainers and Systems

materials and supplies, not exceeding 1000 lb [454 kg]

D 4727/D 4727M Specification for Corrugated and Solid

depending on box type (see 10.1).

Fiberboard Sheet Stock (Container Grade) and Cut

1.2 Wood-cleated panelboard shipping box performance is

Shapes

dependent on its fabricated components and subsequent assem-

D 6199 Practice for Quality of Wood Members Pallets and

bly; therefore, a variety of types, classes, styles, and treatments

Crates

reflecting varied performance are specified. This specification,

F 1667 Specification for Driven Fasteners, Nails, Spikes,

however, does not cover wood-cleated panelboard box perfor-

and Staples

mance under all atmospheric, handling, shipping, and storage

IEEE/ASTM SI 10 Standard for Use of the International

conditions.

System of Units (SI): The Modern Metric System

1.3 If the use of other construction methods or techniques is

2.2 Federal Specifications:

acceptable and permitted (see 5.1.17), the resulting packaging

A-A-58078 Plastic Board (For Packaging Applications)

systems shall be of equal or better performance than would

FF-F-133 Fasteners, Wood Joint, Corrugated – (Saw Edge)

result from the use of these specified materials and procedures.

2.3 Code of Federal Regulations:

The appropriate distribution cycle, specified in Practice

CFR Parts 107-180 Title 49, Hazardous Materials Regula-

D 4169, can be used to develop comparative procedures and

tions

criteria.

2.4 APA—The Engineered Wood Association:

1.4 The values stated in either inch-pound units or SI units

PRP-108 Performance Standards and Policies for

are to be regarded separately as standard. Within the text, the

Structural-Use Panels

SI units are shown in brackets. The values stated in each

PS1-95 Construction and Industrial Plywood

system are not exact equivalents; therefore, each system must

PS2-92 Performance Standard for Wood-Based Structural-

be used independently of the other. Combining values from the

Use Panels

two systems may result in nonconformance with the standard.

2.5 American Wood-Preservers’ Association (AWPA):

See IEEE/ASTM SI 10 for conversion of units.

P8-99 Standard for Oil-Borne Preservatives

1.5 This standard does not purport to address all of the

P9-98 Standards for Solvents and Formulations for Organic

safety concerns, if any, associated with its use. It is the

Preservative Systems

responsibility of the user of the standard to establish appro-

2.6 Hardwood Plywood and Veneer Association:

priate safety and health practices and determine the applica-

HPVA HP-1-1994 Hardwood and Decorative Plywood

bility of regulatory limitations prior to use.

2.7 National Lumber Grades Authority (NLGA):

2. Referenced Documents

2.1 ASTM Standards: 3

Annual Book of ASTM Standards, Vol 04.10.

D 996 Terminology of Packaging and Distribution Environ-

Annual Book of ASTM Standards, Vol 15.08.

Annual Book of ASTM Standards, Vol 14.02.

ments

Available from the Federal Supply Service Bureau, Specification Section, Suite

D 1990 Practice for Establishing Allowable Properties for

8100, 480 L’Enfant Plaza, SW, Washington, DC 20408.

Available from the Superintendent of Documents, US Government Printing

Office, Mail Stop: SSOP, Washington, DC 20402-9328.

1 8

This specification is under the jurisdiction of ASTM Committee D10 on Available from APA—The Engineered Wood Association, 7011 South 19th

Packaging and is the direct responsibility of Subcommittee D10.26 on Wooden Street, P.O. Box 11700, Tacoma, WA 98411-0700.

Crates, Pallets and Skids. Available from American Wood-Preservers’ Association, P.O. Box 5690,

Current edition approved Oct. 10, 2000. Published January 2001. Originally Granbury, TX 76049.

published as D 6251/D 6251M – 98. Last previous edition D 6251/D 6251M – 99. Available from Hardwood Plywood and Veneer Association, P.O. Box 2789,

Annual Book of ASTM Standards, Vol 15.09. Reston, VA 22090-0789, American National Standards Institute (ANSI) adopted.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 6251/D 6251M

Standard Grading Rules for Canadian Lumber, 1996 Edi-

tion, Printed Dec. 1, 1997

2.8 National Motor Freight Traffıc Association:

National Motor Freight Classification

2.9 Northeastern Lumber Manufacturers’ Association

(NELMA):

Standard Grading Rules: NELMA

2.10 Northern Softwood Lumber Bureau (NSLB):

Standard Grading Rules: NSLB

2.11 Southern Pine Inspection Bureau (SPIB):

1994 Grading Rules for Southern Yellow Pine

2.12 Uniform Classification Committee Standard:

Uniform Freight Classification

2.13 West Coast Lumber Inspection Bureau (WCLIB):

Standard Grading Rules Number 17 - WCLIB

2.14 Western Wood Products Association (WWPA):

Western Lumber Grading Rules - 98

3. Terminology

3.1 General definitions for packaging and distribution envi-

ronments are found in Terminology D 996.

4. Classification

4.1 Type (see 4.3):

4.1.1 Type I—Corrugated plastic.

4.1.2 Type II—Corrugated and solid fiberboard.

4.1.3 Type III—Plywood and oriented strand board (OSB)

FIG. 1 Styles of Cleated Panel Boxes

(only Style A, B, I, and J).

4.2 Class:

4.4.2 Treatment B—With water-repellent wood preserva-

4.2.1 Class 1—Domestic (see 10.1.1).

tive.

4.2.2 Class 2—Overseas (see 10.1.2).

4.5 Load Type (see 5.1.19 and 10.2):

4.3 Style (see Fig. 1 and 10.1):

4.5.1 Type 1—Easy.

4.3.1 Style A—Standard box corner (see Fig. 2).

4.5.2 Type 2—Average.

4.3.2 Style A1—Type I and II, Style A, modified with skids

4.5.3 Type 3—Difficult.

and when specified (see 5.1.3) unnailed top panel closure (see

4.6 Unnailed Top Panel Closure Option—When specified

4.6 and Fig. 3).

(see 4.3.2 and 5.1.3), Type I and II, Style A1, or Type III, Style

4.3.3 Style B—Interlocking three-way corners (see Fig. 4).

A or B shall have the top panel modified (see 7.1.8) and closed

4.3.4 Style C through K—Limited only to Type II, Class 1

with flat steel strapping as specified in the Supplemental

(see 5.1.2 and Fig. 1).

Requirements. Securing the top panel to the box with other

4.3.5 Style A, B, I, and J—Type III limited only to these

than flat steel strapping shall be prohibited.

styles (see 5.1.2 and Fig. 1)

4.7 Part Number—If required, a specification part number

4.4 Water-Repellent Wood Preservative (see 5.1.13):

for boxes described in this specification can be formulated (see

4.4.1 Treatment A—Without water-repellent wood preserva-

S3.3).

tive.

5. Ordering Information

11 5.1 Purchasers shall select the preferred permitted options

Available from National Lumber Grades Authority, #406-960 Quayside Drive,

New Westminster, B.C., Canada, V3M6G2. and include the following information in procurement docu-

Available from National Motor Freight Traffic Association, American Truck-

ments:

ing Associations, 2200 Mill Road, Alexandria, VA 22314.

5.1.1 Specification title, number, and date.

Available from Northeastern Lumber Manufacturers Association (NELMA),

5.1.2 Box type, class, style, preservative treatment, load

272 Tuttle Road, P.O. Box 87A, Cumberland, ME 04021.

Available from Northern Softwood Lumber Bureau (NSLB), 272 Tuttle Road, type, and closure required (see 4.1-4.6, and 6.5).

P.O. Box 87A, Cumberland, ME 04021.

5.1.3 When Type I and II, Style A1; or Type III, Style A or

Available from Southern Pine Inspection Bureau, 4709 Scenic Highway,

B, unnailed top panel closure is required (see 4.3, 4.6, and

Pensacola, FL 32504-9094.

7.1.8).

Available from the Uniform Classification Committee, Tariff Publishing

Officer, 151 Ellis St. N.E., Suite 200, Atlanta, GA 30335-6021.

5.1.4 Contents weight (see Tables 2-9).

Available from West Coast Lumber Inspection Bureau (WCLIB), 6980 SW

5.1.5 Cleat lumber quality classification required (see 6.3).

Varns Street, Tigard, OR 97223.

18 5.1.6 Lumber quality used for skid fabrication (see 6.3).

Available from Western Wood Products Association, 522 SW Fifth Avenue,

Suite 500, Portland, OR 97204-2122. 5.1.7 Intermediate cleat requirements for Type III, Class 1

D 6251/D 6251M

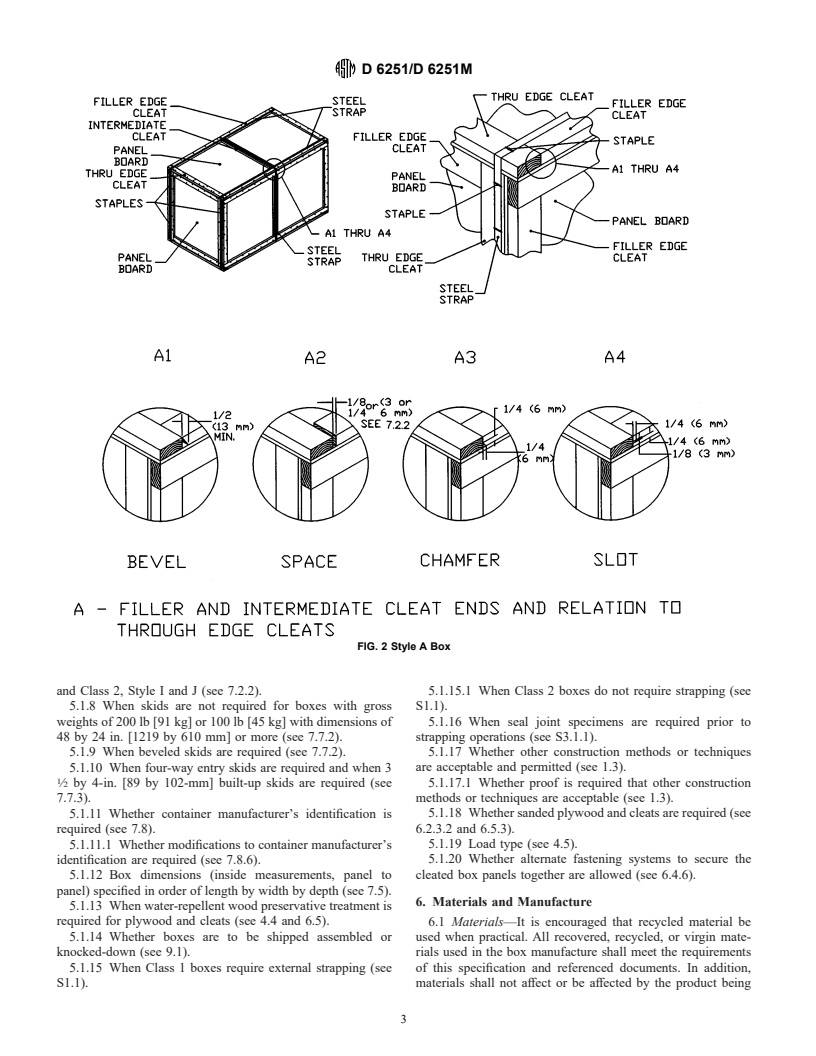

FIG. 2 Style A Box

and Class 2, Style I and J (see 7.2.2). 5.1.15.1 When Class 2 boxes do not require strapping (see

5.1.8 When skids are not required for boxes with gross S1.1).

weights of 200 lb [91 kg] or 100 lb [45 kg] with dimensions of 5.1.16 When seal joint specimens are required prior to

48 by 24 in. [1219 by 610 mm] or more (see 7.7.2). strapping operations (see S3.1.1).

5.1.9 When beveled skids are required (see 7.7.2). 5.1.17 Whether other construction methods or techniques

5.1.10 When four-way entry skids are required and when 3 are acceptable and permitted (see 1.3).

⁄2 by 4-in. [89 by 102-mm] built-up skids are required (see 5.1.17.1 Whether proof is required that other construction

7.7.3). methods or techniques are acceptable (see 1.3).

5.1.11 Whether container manufacturer’s identification is 5.1.18 Whether sanded plywood and cleats are required (see

required (see 7.8). 6.2.3.2 and 6.5.3).

5.1.19 Load type (see 4.5).

5.1.11.1 Whether modifications to container manufacturer’s

identification are required (see 7.8.6). 5.1.20 Whether alternate fastening systems to secure the

cleated box panels together are allowed (see 6.4.6).

5.1.12 Box dimensions (inside measurements, panel to

panel) specified in order of length by width by depth (see 7.5).

6. Materials and Manufacture

5.1.13 When water-repellent wood preservative treatment is

required for plywood and cleats (see 4.4 and 6.5). 6.1 Materials—It is encouraged that recycled material be

5.1.14 Whether boxes are to be shipped assembled or used when practical. All recovered, recycled, or virgin mate-

knocked-down (see 9.1). rials used in the box manufacture shall meet the requirements

5.1.15 When Class 1 boxes require external strapping (see of this specification and referenced documents. In addition,

S1.1). materials shall not affect or be affected by the product being

D 6251/D 6251M

FIG. 4 Style B Box

TABLE 1 Lumber Commercial Standards

A,B

Rules Grade

C

NLGA

D

NELMA

E

FIG. 3 Unnailed Top Panel Closure

SPIB Construction Light Framing

F

WCLIB

G

WWPA

H

NSLB

packed. Type II panelboard shall have no more than 40 % post

A

Structural design values greater (12.5 %) than Structural No. 3, but slightly

consumer recovered material.

(10 %) less than Structural No. 2.

6.2 Panelboard—Panelboard shall be as specified (5.1.2).

B

Wood shall be completely bark free to prevent spread of Oak Wilt disease.

C

6.2.1 Type I—Panelboard shall be polyethylene, containing

Standard Grading Rules for National Lumber Grades Authority.

D

Standard Grading Rules for Northeastern Lumber Manufacturers Association.

⁄2 % ultraviolet (UV) inhibitor and shall conform to A-A-

E

Standard Grading Rules for Southern Pine Inspection Bureau.

58078, Type II, or commercial equivalent. The plastic panel

F

Standard Grading Rules for West Coast Lumber Inspection Bureau.

G

basis weight shall be 245 to 255 lb/1000 ft [1195 to 1245 Standard Grading Rules for Western Wood Products Association.

H

Standard Grading Rules for Northern Softwood Lumber Bureau.

g/m ].

6.2.2 Type II—Panelboard shall be fiberboard conforming to

Specification D 4727/D 4727M. Class 1 and Class 2 boxes, layers in each panel. The strands shall be bonded together with

singlewall (SW), solid (SF), and V board shall conform to the a liquid exterior phenolic or an exterior isocyanate resin. The

requirements of 7.1.1. density of ⁄8-in. [10 mm] thick OSB panels shall be approxi-

3 3

6.2.3 Type III—Panelboard for Class 1 boxes shall conform mately 39 lb/ft [624.7 kg/m ].

to HPVA HP-1-1994, Type III, Grade 3-4; or PS1-95, Interior 6.2.3.2 The plywood thickness shall be specified in Tables 3

with Exterior Glue, Grade C-D. Panelboard for Class 2 boxes and 4. Plywood shall have no defects (knot holes, worm holes,

shall conform to HPVA HP-1-1994, Type I, Grade 3-4 or etc.) extending through more than two panel plies. Unless

PS1-95, Exterior, Grade C-D. otherwise specified, plywood shall be unsanded. If smooth

6.2.3.1 As an alternative, panelboard for Class 1 boxes can finish or sanded panels are required, appropriate sanded grades

also conform to PRP-108, Oriented Strand Board (OSB), should be specified in the contract (see 5.1.18). End grain joints

Structural 1 rated sheathing with Exposure 1 designation. The shall be prohibited for Grade 4 veneers. When the plywood is

strands shall have a ratio of length to width of approximately specified to be surface treated with water-repellent wood

3:1. The strands shall be oriented in one direction in each layer preservative, the treatment shall be as specified in 6.5.

and the strands of one layer shall be perpendicular to the 6.3 Lumber—Lumber for cleats shall conform to Practice

strands in adjacent layers. There shall not be less than three D 6199, Class 2 (see 7.2) or Table 1, as specified (see 5.1.5).

D 6251/D 6251M

TABLE 2 Type II Corrugated and Solid Fiberboard Requirements

carbon steel (stiff-stock) minimum 0.072 in. (15-gage) [1.83

Contents Weight mm] diameter) wire may also be used. Fasteners are driven

Lb [kg] Class 1 Class 2

subsequently by a special machine at a rapid rate, with

Not CF D SW SF D SF

sheared-bevel or sheared-square point. For Type I and II boxes,

A A A,B

Exceeding Exceeding Grades Grades Grades

the nail length, before driving, shall be a minimum of ⁄8-in. [3

0 75 200 200 V3S or V4S

mm] longer than the thickness of the material being joined. For

[0] [34]

Type III boxes, the nail length, before driving, shall be a

75 150 275 275 V3S or V4S

[34] [68] minimum of ⁄2-in. [13 mm] longer than the thickness of the

150 200 350 350 V3S or V4S

material being joined. The automatic machine for driving shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.