ASTM D6804-24

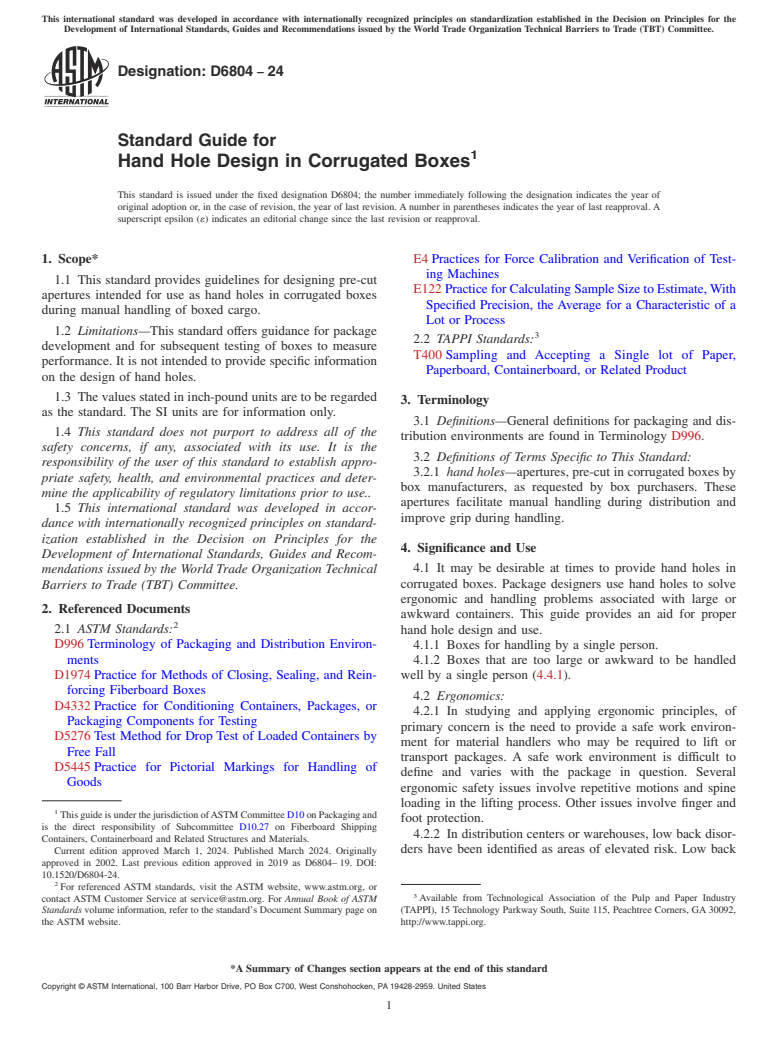

(Guide)Standard Guide for Hand Hole Design in Corrugated Boxes

Standard Guide for Hand Hole Design in Corrugated Boxes

SIGNIFICANCE AND USE

4.1 It may be desirable at times to provide hand holes in corrugated boxes. Package designers use hand holes to solve ergonomic and handling problems associated with large or awkward containers. This guide provides an aid for proper hand hole design and use.

4.1.1 Boxes for handling by a single person.

4.1.2 Boxes that are too large or awkward to be handled well by a single person (4.4.1).

4.2 Ergonomics:

4.2.1 In studying and applying ergonomic principles, of primary concern is the need to provide a safe work environment for material handlers who may be required to lift or transport packages. A safe work environment is difficult to define and varies with the package in question. Several ergonomic safety issues involve repetitive motions and spine loading in the lifting process. Other issues involve finger and foot protection.

4.2.2 In distribution centers or warehouses, low back disorders have been identified as areas of elevated risk. Low back problems continue to represent the most common and costly musculoskeletal disorders in the work place.4

4.2.3 One method used to reduce the concern of distance of lift (spinal loading) is to bring the reach of the material handler's hands closer to the body. With large or awkward boxes, placing hand holes in a more advantageous position can solve this problem.

4.2.4 Maximum weight for lifting is not generally specified by safety organizations. However, when considerations of repetition, movement, and other ergonomics are taken into account, a typical maximum load per single person is often limited to 40 to 50 lb per package.

4.3 NIOSH:

4.3.1 The National Institute for Occupational Safety and Health (NIOSH) has published Work Practices Guide for Manual Lifting.5 This document may be of assistance in developing proper hand holes and their placement for a specific package.

4.3.2 Hand holes for single person box handling are generally intended for vertical symmetric lifting with some rotation and ...

SCOPE

1.1 This standard provides guidelines for designing pre-cut apertures intended for use as hand holes in corrugated boxes during manual handling of boxed cargo.

1.2 Limitations—This standard offers guidance for package development and for subsequent testing of boxes to measure performance. It is not intended to provide specific information on the design of hand holes.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use..

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6804 − 24

Standard Guide for

1

Hand Hole Design in Corrugated Boxes

This standard is issued under the fixed designation D6804; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E4 Practices for Force Calibration and Verification of Test-

ing Machines

1.1 This standard provides guidelines for designing pre-cut

E122 Practice for Calculating Sample Size to Estimate, With

apertures intended for use as hand holes in corrugated boxes

Specified Precision, the Average for a Characteristic of a

during manual handling of boxed cargo.

Lot or Process

1.2 Limitations—This standard offers guidance for package

3

2.2 TAPPI Standards:

development and for subsequent testing of boxes to measure

T400 Sampling and Accepting a Single lot of Paper,

performance. It is not intended to provide specific information

Paperboard, Containerboard, or Related Product

on the design of hand holes.

1.3 The values stated in inch-pound units are to be regarded

3. Terminology

as the standard. The SI units are for information only.

3.1 Definitions—General definitions for packaging and dis-

1.4 This standard does not purport to address all of the

tribution environments are found in Terminology D996.

safety concerns, if any, associated with its use. It is the

3.2 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

3.2.1 hand holes—apertures, pre-cut in corrugated boxes by

priate safety, health, and environmental practices and deter-

box manufacturers, as requested by box purchasers. These

mine the applicability of regulatory limitations prior to use.

apertures facilitate manual handling during distribution and

1.5 This international standard was developed in accor-

improve grip during handling.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4. Significance and Use

Development of International Standards, Guides and Recom-

4.1 It may be desirable at times to provide hand holes in

mendations issued by the World Trade Organization Technical

corrugated boxes. Package designers use hand holes to solve

Barriers to Trade (TBT) Committee.

ergonomic and handling problems associated with large or

2. Referenced Documents

awkward containers. This guide provides an aid for proper

2

2.1 ASTM Standards: hand hole design and use.

D996 Terminology of Packaging and Distribution Environ-

4.1.1 Boxes for handling by a single person.

ments 4.1.2 Boxes that are too large or awkward to be handled

D1974 Practice for Methods of Closing, Sealing, and Rein-

well by a single person (4.4.1).

forcing Fiberboard Boxes

4.2 Ergonomics:

D4332 Practice for Conditioning Containers, Packages, or

4.2.1 In studying and applying ergonomic principles, of

Packaging Components for Testing

primary concern is the need to provide a safe work environ-

D5276 Test Method for Drop Test of Loaded Containers by

ment for material handlers who may be required to lift or

Free Fall

transport packages. A safe work environment is difficult to

D5445 Practice for Pictorial Markings for Handling of

define and varies with the package in question. Several

Goods

ergonomic safety issues involve repetitive motions and spine

loading in the lifting process. Other issues involve finger and

1

This guide is under the jurisdiction of ASTM Committee D10 on Packaging and

foot protection.

is the direct responsibility of Subcommittee D10.27 on Fiberboard Shipping

4.2.2 In distribution centers or warehouses, low back disor-

Containers, Containerboard and Related Structures and Materials.

Current edition approved March 1, 2024. Published March 2024. Originally ders have been identified as areas of elevated risk. Low back

approved in 2002. Last previous edition approved in 2019 as D6804– 19. DOI:

10.1520/D6804-24.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Technological Association of the Pulp and Paper Industry

Standards volume information, refer to the standard’s Document Summary page on (TAPPI), 15 Technology Parkway South, Suite 115, Peachtree Corners, GA 30092,

the ASTM website. http://www.tappi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6804 − 19 D6804 − 24

Standard Guide for

1

Hand Hole Design in Corrugated Boxes

This standard is issued under the fixed designation D6804; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This standard provides guidelines for designing pre-cut apertures intended for use as hand holes in corrugated boxes during

manual handling of boxed cargo.

1.2 Limitations—This standard offers guidance for package development and for subsequent testing of boxes to measure

performance. It is not intended to provide specific information on the design of hand holes.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D996 Terminology of Packaging and Distribution Environments

D1974 Practice for Methods of Closing, Sealing, and Reinforcing Fiberboard Boxes

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

D5276 Test Method for Drop Test of Loaded Containers by Free Fall

D5445 Practice for Pictorial Markings for Handling of Goods

E4 Practices for Force Calibration and Verification of Testing Machines

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

3

2.2 TAPPI Standards:

T400 Sampling and Accepting a Single lot of Paper, Paperboard, Containerboard, or Related Product

1

This guide is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.27 on Fiberboard Shipping Containers,

Containerboard and Related Structures and Materials.

Current edition approved Oct. 1, 2019March 1, 2024. Published November 2019March 2024. Originally approved in 2002. Last previous edition approved in 20152019

as D6804– 02(2015). DOI: 10.1520/D6804-19.– 19. DOI: 10.1520/D6804-24.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Technological Association of the Pulp and Paper Industry (TAPPI), 15 Technology Parkway South, Suite 115, Peachtree Corners, GA 30092,

http://www.tappi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6804 − 24

3. Terminology

3.1 Definitions—General definitions for packaging and distribution environments are found in Terminology D996.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 hand holes—apertures, pre-cut in corrugated boxes by box manufacturers, as requested by box purchasers. These apertures

facilitate manual handling during distribution and improve grip during handling.

4. Significance and Use

4.1 It may be desirable at times to provide hand holes in corrugated boxes. Package designers use hand holes to solve ergonomic

and handling problems associated with large or awkward containers. This guide provides an aid for proper hand hole design and

use.

4.1.1 Boxes for handling by a single person.

4.1.2 Boxes that are too large or awkward to be handled well by a single person (4.4.1).

4.2 Ergonomics:

4.2.1 In studying and applying ergonomic principles, of primary concern is the need to provide a safe work environment for

material handlers who may be required to lift or transport packages. A safe work environment is difficult to define and varies with

the package in question. Several ergonomic safety issues inv

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.