ASTM D4821-03

(Guide)Standard Guide for Carbon Black—Validation of Test Method Precision and Bias

Standard Guide for Carbon Black—Validation of Test Method Precision and Bias

SCOPE

1.1 This guide covers a procedure for using ASTM Standard Reference Blacks (SRBs) to continuously monitor the precision of those carbon black test methods for which standard values have been established. It also offers guidelines for troubleshooting various test methods.

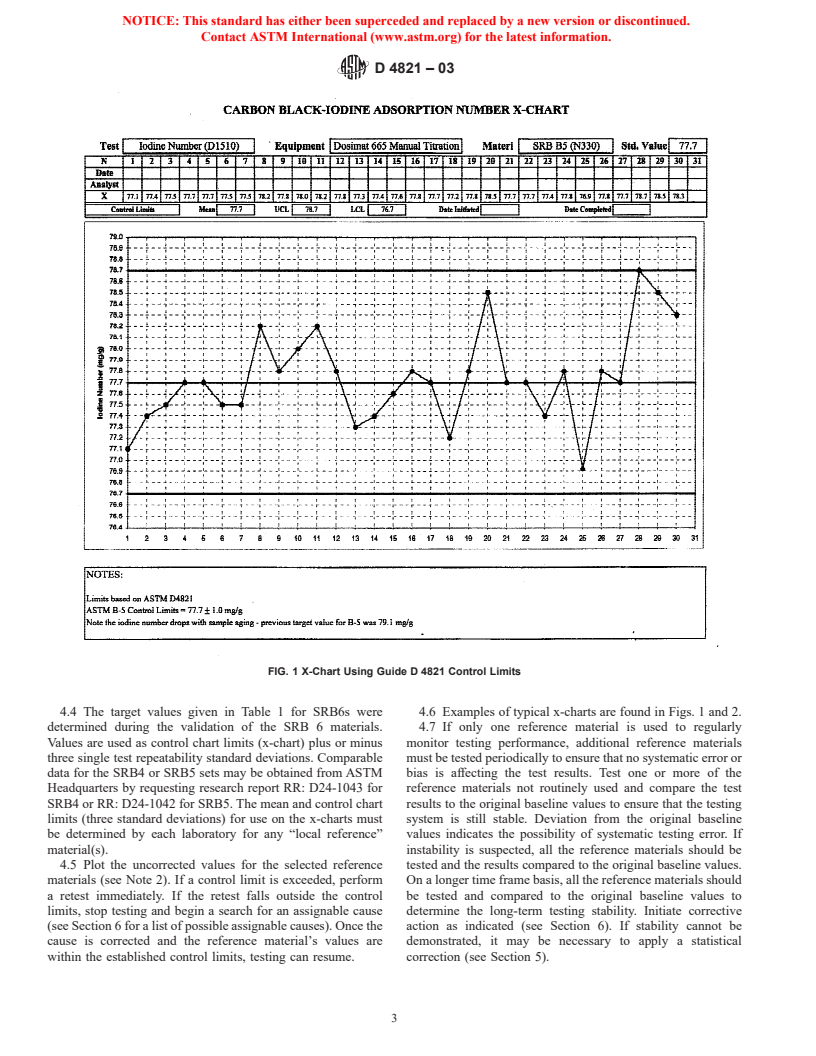

1.2 This guide establishes the x-chart control limits to be used when continuously monitoring those tests listed in Section . Alternatively, these control limits may be used as a basis for comparison to testing precision computed within a laboratory.

1.3 This guide uses statistical control chart methodology as discussed in STP-15-D to determine if a laboratory's test results differ significantly from the accepted values of the SRBs.

1.4 This guide provides a statistical procedure for improving test reproducibility when a laboratory cannot physically calibrate its apparatus to obtain the standard values of the ASTM SRBs, within the ranges given in the precision statement of the test method.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4821 – 03

Standard Guide for

Carbon Black—Validation of Test Method Precision and

1

Bias

This standard is issued under the fixed designation D 4821; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1765 Classification System for Carbon Blacks Used in

4

Rubber Products

1.1 This guide covers a procedure for using ASTM Standard

2

D 2414 Test Method for Carbon Black—Oil Absorption

Reference Blacks (SRBs) to continuously monitor the preci-

4

Number

sion of those carbon black test methods for which standard

4

D 3265 Test Method for Carbon Black—Tint Strength

values have been established. It also offers guidelines for

D 3493 Test Method for Carbon Black—Oil Absorption

troubleshooting various test methods.

4

Number of Compressed Sample

1.2 This guide establishes the x-chart control limits to be

D 6556 Test Methods for Carbon Black—Total and Exter-

used when continuously monitoring those tests listed in Section

4

nal Surface Area by Nitrogen Adsorption

2. Alternatively, these control limits may be used as a basis for

comparison to testing precision computed within a laboratory.

3. Significance and Use

1.3 This guide uses statistical control chart methodology as

3 3.1 One of the major causes of poor test precision is the lack

discussed in STP-15-D to determine if a laboratory’s test

of calibration or standardization of instruments, apparatus,

results differ significantly from the accepted values of the

reagents, and technique among laboratories. The sum of all

SRBs.

sources of testing error is unique for an individual laboratory.

1.4 This guide provides a statistical procedure for improv-

A least-squares regression of a laboratory’s actual test values

ing test reproducibility when a laboratory cannot physically

for reference materials to the established mean values will

calibrate its apparatus to obtain the standard values of the

result in a unique least-squares regression line (and equation)

ASTM SRBs, within the ranges given in the precision state-

for that laboratory. Generally, there are two reasons for using

ment of the test method.

the SRBs in testing: (1) to monitor testing performance (see

1.5 The values stated in SI units are to be regarded as the

Section 4) to ensure that no systematic error or bias is affecting

standard. The values given in parentheses are for information

the test results, or (2) to establish a statistical calibration (see

only.

Section 5) when the correction of assignable causes (see

1.6 This standard does not purport to address all of the

Section 6) does not yield in-control test results.

safety concerns, if any, associated with its use. It is the

3.2 In addition to the calibration of a test method by

responsibility of the user of this standard to establish appro-

physicochemical means, a statistical method for achieving

priate safety and health practices and determine the applica-

calibration of a test method is presented.

bility of regulatory limitations prior to use.

3.3 This guide outlines the use of control charts to graphi-

2. Referenced Documents cally present calibration test data determined for the ASTM

SRBs for those test methods given in Section 2. All laborato-

2.1 ASTM Standards:

ries are encouraged to utilize statistical control charts and the

D 1510 Test Method for Carbon Black—Iodine Adsorption

4

SRBs because this allows a comparison of testing precision

Number

within a laboratory to the “industry average” values found in

Table 1.

1

This guide is under the jurisdiction of ASTM Committee D24 on Carbon Black 3.4 The techniques of this guide can be used to continuously

and is the direct responsibility of Subcommittee D24.61 on Carbon Black Sampling

monitor testing execution and precision for other tests that are

and Statistical Analysis.

not listed in Section 2 or for materials that fall outside the range

Current edition approved Jan. 10, 2003. Published February 2003. Originally

of the SRBs for those tests listed in Section 2. In these cases,

approved in 1988. Last previous edition approved in 2001 D 4821 – 01a.

2

Standard Reference Blacks are available from Laboratory Standards & Tech-

each laboratory will have to establish the applicable mean and

nologies, Inc., 227 Somerset St., Borger, TX 79007. Phone/fax: (806) 273-3006.

control limit values for the “local reference.” The monitoring

E-mail: jwbal@infinitytx.net.

3 will then consist of a comparison of present test results for the

Symposium on Manual on Presentation of Data and Control Chart Analysis,

ASTM STP 15D, ASTM, 1976.

4

Annual Book of ASTM Standards, Vol 09.01.

Copyright © AST

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.