ASTM D6379-21

(Test Method)Standard Test Method for Determination of Aromatic Hydrocarbon Types in Aviation Fuels and Petroleum Distillates-High Performance Liquid Chromatography Method with Refractive Index Detection

Standard Test Method for Determination of Aromatic Hydrocarbon Types in Aviation Fuels and Petroleum Distillates-High Performance Liquid Chromatography Method with Refractive Index Detection

SIGNIFICANCE AND USE

5.1 Accurate quantitative information on aromatic hydrocarbon types can be useful in determining the effects of petroleum processes on production of various finished fuels. This information can also be useful for indicating the quality of fuels and for assessing the relative combustion properties of finished fuels.

SCOPE

1.1 This test method covers a high performance liquid chromatographic test method for the determination of mono-aromatic and di-aromatic hydrocarbon contents in aviation kerosenes and petroleum distillates boiling in the range from 50 °C to 300 °C, such as Jet A or Jet A-1 fuels. The total aromatic content is calculated from the sum of the individual aromatic hydrocarbon-types.

Note 1: Samples with a final boiling point greater than 300 °C that contain tri-aromatic and higher polycyclic aromatic compounds are not determined by this test method and should be analyzed by Test Method D6591 or other suitable equivalent test methods.

1.2 This test method is applicable to distillates containing from 0.8 % to 44.0 % by mass mono-aromatic hydrocarbons, 0.23 % to 6.20 % by mass di-aromatic hydrocarbons, and 0.7 % to 50 % by mass total aromatics. Although this method generates results in m/m, results may also be quoted in v/v.

1.3 The precision of this test method has been established for kerosene boiling range distillates containing from 0.40 % to 44.0 % by mass mono-aromatic hydrocarbons, 0.02 % to 6.20 % by mass di-aromatic hydrocarbons, and 0.40 % to 50.0 % by mass total aromatics. If results are quoted in volume, the precision is 0.3 % to 41.4 % by volume mono-aromatics, 0.01 % to 5.00 % by volume di-aromatics, and 0.30 % to 46.3 % by volume total aromatics. As calculated by IP 367-1.

1.4 Compounds containing sulfur, nitrogen, and oxygen are possible interferents. Mono-alkenes do not interfere, but conjugated di- and poly-alkenes, if present, are possible interferents.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Frequently Asked Questions

ASTM D6379-21 is a standard published by ASTM International. Its full title is "Standard Test Method for Determination of Aromatic Hydrocarbon Types in Aviation Fuels and Petroleum Distillates-High Performance Liquid Chromatography Method with Refractive Index Detection". This standard covers: SIGNIFICANCE AND USE 5.1 Accurate quantitative information on aromatic hydrocarbon types can be useful in determining the effects of petroleum processes on production of various finished fuels. This information can also be useful for indicating the quality of fuels and for assessing the relative combustion properties of finished fuels. SCOPE 1.1 This test method covers a high performance liquid chromatographic test method for the determination of mono-aromatic and di-aromatic hydrocarbon contents in aviation kerosenes and petroleum distillates boiling in the range from 50 °C to 300 °C, such as Jet A or Jet A-1 fuels. The total aromatic content is calculated from the sum of the individual aromatic hydrocarbon-types. Note 1: Samples with a final boiling point greater than 300 °C that contain tri-aromatic and higher polycyclic aromatic compounds are not determined by this test method and should be analyzed by Test Method D6591 or other suitable equivalent test methods. 1.2 This test method is applicable to distillates containing from 0.8 % to 44.0 % by mass mono-aromatic hydrocarbons, 0.23 % to 6.20 % by mass di-aromatic hydrocarbons, and 0.7 % to 50 % by mass total aromatics. Although this method generates results in m/m, results may also be quoted in v/v. 1.3 The precision of this test method has been established for kerosene boiling range distillates containing from 0.40 % to 44.0 % by mass mono-aromatic hydrocarbons, 0.02 % to 6.20 % by mass di-aromatic hydrocarbons, and 0.40 % to 50.0 % by mass total aromatics. If results are quoted in volume, the precision is 0.3 % to 41.4 % by volume mono-aromatics, 0.01 % to 5.00 % by volume di-aromatics, and 0.30 % to 46.3 % by volume total aromatics. As calculated by IP 367-1. 1.4 Compounds containing sulfur, nitrogen, and oxygen are possible interferents. Mono-alkenes do not interfere, but conjugated di- and poly-alkenes, if present, are possible interferents. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 5.1 Accurate quantitative information on aromatic hydrocarbon types can be useful in determining the effects of petroleum processes on production of various finished fuels. This information can also be useful for indicating the quality of fuels and for assessing the relative combustion properties of finished fuels. SCOPE 1.1 This test method covers a high performance liquid chromatographic test method for the determination of mono-aromatic and di-aromatic hydrocarbon contents in aviation kerosenes and petroleum distillates boiling in the range from 50 °C to 300 °C, such as Jet A or Jet A-1 fuels. The total aromatic content is calculated from the sum of the individual aromatic hydrocarbon-types. Note 1: Samples with a final boiling point greater than 300 °C that contain tri-aromatic and higher polycyclic aromatic compounds are not determined by this test method and should be analyzed by Test Method D6591 or other suitable equivalent test methods. 1.2 This test method is applicable to distillates containing from 0.8 % to 44.0 % by mass mono-aromatic hydrocarbons, 0.23 % to 6.20 % by mass di-aromatic hydrocarbons, and 0.7 % to 50 % by mass total aromatics. Although this method generates results in m/m, results may also be quoted in v/v. 1.3 The precision of this test method has been established for kerosene boiling range distillates containing from 0.40 % to 44.0 % by mass mono-aromatic hydrocarbons, 0.02 % to 6.20 % by mass di-aromatic hydrocarbons, and 0.40 % to 50.0 % by mass total aromatics. If results are quoted in volume, the precision is 0.3 % to 41.4 % by volume mono-aromatics, 0.01 % to 5.00 % by volume di-aromatics, and 0.30 % to 46.3 % by volume total aromatics. As calculated by IP 367-1. 1.4 Compounds containing sulfur, nitrogen, and oxygen are possible interferents. Mono-alkenes do not interfere, but conjugated di- and poly-alkenes, if present, are possible interferents. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D6379-21 is classified under the following ICS (International Classification for Standards) categories: 71.040.50 - Physicochemical methods of analysis; 75.160.20 - Liquid fuels. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase ASTM D6379-21 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6379 − 21

Designation: 436/20

Standard Test Method for

Determination of Aromatic Hydrocarbon Types in Aviation

Fuels and Petroleum Distillates—High Performance Liquid

1,2

Chromatography Method with Refractive Index Detection

This standard is issued under the fixed designation D6379; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method is intended to be technically equivalent to IP 436-20 with an identical title. The

ASTM format for test methods has been used, and where possible, equivalent ASTM test methods

have replaced the IP or ISO standards.

The test method is intended to be used as one of several possible alternative instrumental test

methods that are aimed at quantitative determination of hydrocarbon types in fuels. This does not

imply that a correlation necessarily exists between this and any other test method intended to give this

information, and it is the responsibility of the user to determine such correlation if necessary.

1. Scope* 0.7 % to 50 % by mass total aromatics. Although this method

generates results in m/m, results may also be quoted in v/v.

1.1 This test method covers a high performance liquid

chromatographic test method for the determination of mono-

1.3 The precision of this test method has been established

aromatic and di-aromatic hydrocarbon contents in aviation

forkeroseneboilingrangedistillatescontainingfrom0.40 %to

kerosenes and petroleum distillates boiling in the range from

44.0 % by mass mono-aromatic hydrocarbons, 0.02 % to

50 °C to 300 °C, such as Jet A or Jet A-1 fuels. The total

6.20 % by mass di-aromatic hydrocarbons, and 0.40 % to

aromatic content is calculated from the sum of the individual

50.0 %bymasstotalaromatics.Ifresultsarequotedinvolume,

aromatic hydrocarbon-types.

the precision is 0.3 % to 41.4 % by volume mono-aromatics,

0.01 % to 5.00 % by volume di-aromatics, and 0.30 % to

NOTE 1—Samples with a final boiling point greater than 300 °C that

46.3 % by volume total aromatics. As calculated by IP 367-1.

contain tri-aromatic and higher polycyclic aromatic compounds are not

determined by this test method and should be analyzed by Test Method

1.4 Compounds containing sulfur, nitrogen, and oxygen are

D6591 or other suitable equivalent test methods.

possible interferents. Mono-alkenes do not interfere, but con-

1.2 This test method is applicable to distillates containing

jugated di- and poly-alkenes, if present, are possible interfer-

from 0.8 % to 44.0 % by mass mono-aromatic hydrocarbons,

ents.

0.23 % to 6.20 % by mass di-aromatic hydrocarbons, and

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

This test method is under the jurisdiction of ASTM Committee D02 on

responsibility of the user of this standard to establish appro-

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

priate safety, health, and environmental practices and deter-

Subcommittee D02.04.0C on Liquid Chromatography. The technically equivalent

standardasreferencedisunderthejurisdictionoftheEnergyInstituteSubcommittee

mine the applicability of regulatory limitations prior to use.

SC-G-2.

1.6 This international standard was developed in accor-

Current edition approved July 15, 2021. Published September 2021. Originally

dance with internationally recognized principles on standard-

approved in 1999. Last previous edition approved in 2019 as D6379 – 11 (2019).

DOI: 10.1520/D6379-21.

ization established in the Decision on Principles for the

This test method has been developed through the cooperative effort between

Development of International Standards, Guides and Recom-

ASTM and the Energy Institute, London.ASTM and IPstandards were approved by

mendations issued by the World Trade Organization Technical

ASTMandEItechnicalcommitteesasbeingtechnicallyequivalentbutthatdoesnot

imply both standards are identical. Barriers to Trade (TBT) Committee.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6379 − 21

2. Referenced Documents thearomatichydrocarbonsareseparatedfromthenon-aromatic

3 hydrocarbons into distinct bands in accordance with their ring

2.1 ASTM Standards:

structure, that is, MAHs and DAHs.

D4052 Test Method for Density, Relative Density, and API

Gravity of Liquids by Digital Density Meter 4.2 The column is connected to a refractive index detector

D4057 Practice for Manual Sampling of Petroleum and that detects the components as they elute from the column.The

Petroleum Products electronic signal from the detector is continually monitored by

D4177 Practice for Automatic Sampling of Petroleum and a data processor. The amplitudes of the signals (peak areas)

Petroleum Products from the sample aromatics are compared with those obtained

D6591 Test Method for Determination of Aromatic Hydro- from previously-run calibration standards in order to calculate

carbon Types in Middle Distillates—High Performance the percent m/m MAHs and DAHs in the sample. The sum of

Liquid Chromatography Method with Refractive Index the MAHs and DAHs is reported as the total aromatic content

Detection (percent m/m) of the sample. Although this method generates

2.2 Energy Institute Standards: results in m/m, results can also be quoted in percent v/v either

by calibrating in v/v or by converting m/m to v/v by using the

IP 367–1 (EN ISO 4259 Part 1) Petroleum and related

products – Precision of measurement methods and re- densities of the sample and standards.

sults – Part 1: Determination of precision data in relation

5. Significance and Use

to methods of test

IP 436 Test method for determination of automatic hydro-

5.1 Accurate quantitative information on aromatic hydro-

carbon types in aviation fuels and petroleum distillates—

carbon types can be useful in determining the effects of

High performance liquid chromatography method with

petroleum processes on production of various finished fuels.

refractive index

Thisinformationcanalsobeusefulforindicatingthequalityof

fuels and for assessing the relative combustion properties of

3. Terminology

finished fuels.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 di-aromatic hydrocarbons (DAHs), n—compounds 6. Apparatus

that have a longer retention time on the specified polar column

6.1 High Performance Liquid Chromatograph (HPLC)—

than the MAHs.

Any high performance liquid chromatograph capable of pump-

3.1.2 mono-aromatic hydrocarbons (MAHs),

ing the mobile phase at flow rates between 0.5 mL⁄min and

n—compounds that have a longer retention time on the

1.5 mL⁄min with a precision better than 0.5 % and a pulsation

specifiedpolarcolumnthanthenon-aromatichydrocarbonsbut

of<1 %fullscaledeflectionunderthetestconditionsdescribed

a shorter retention time than the di-aromatic hydrocarbons.

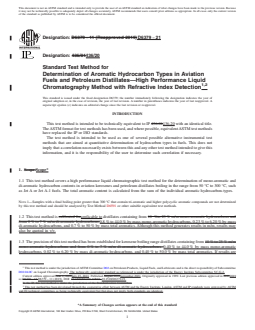

in Section 9. See Fig. 1.

3.1.3 non-aromatic hydrocarbons, n—compounds that have

6.2 Sample Injection System—The sample injection system

a shorter retention time on the specified polar column than the

capable of injecting 5 µL (nominal) of sample solution with a

mono-aromatic hydrocarbons.

repeatability better than 2 %.

6.2.1 An equal and constant volume of the calibration and

3.1.4 total aromatic hydrocarbons, n—sum of the MAHs

sample solutions shall be injected into the chromatograph.

and DAHs.

Both manual and automatic sample injection systems (using

NOTE 2—The elution characteristics of aromatic and non-aromatic

either complete or partial filling of the sample loop) will, when

compounds on the specified polar column have not been specifically

used correctly, meet the repeatability requirements laid down

determined for this test method. Published and unpublished data indicate

the major constituents for each hydrocarbon type as follows: (1) Non- in 6.2. When using the partial loop filling mode, it is recom-

aromatic hydrocarbons: acyclic and cyclic alkanes (paraffins and

mended that the injection volume should be less than half the

naphthenes), mono-alkenes (if present). (2) MAHs: benzenes, tetralins,

total loop volume. For complete filling of the loop, best results

indanes, thiophenes, conjugated poly-alkenes. (3) DAHs: naphthalenes,

are obtained by overfilling the loop at least six times.

biphenyls, indenes, fluorenes, acenaphthenes, benzothiophenes.

6.2.2 Sampleinjectionvolumesotherthan5 µL(typicallyin

4. Summary of Test Method the range from 3 µLto 20 µL) may be used provided they meet

the requirements laid down for injection repeatability (see 6.2),

4.1 The test portion is diluted 1:1 with the mobile phase,

refractive index sensitivity and linearity (see 9.4 and 10.1), and

such as heptane, and a fixed volume of this solution injected

column resolution (see 9.4)

into a high performance liquid chromatograph fitted with a set

of polar columns. These columns have little affinity for the 6.3 Sample Filter (Optional)—A microfilter of porosity

non-aromatic hydrocarbons and exhibits a pronounced selec-

0.45 µm or less, which is chemically-inert towards hydrocar-

tivity for aromatic hydrocarbons.As a result of this selectivity, bon solvents, is recommended for the removal of particulate

matter from the sample solutions.

6.4 Column System—Any stainless steel HPLC column(s)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

packed with an approved amino-bonded (or polar amino/

Standards volume information, refer to the standard’s Document Summary page on

cyano-bonded) silica stationary phase is suitable. The col-

the ASTM website.

umn(s)usedshallsatisfytheresolutionrequirementslaiddown

Available from Energy Institute, 61 New Cavendish St., London, W1G 7AR,

U.K., http://www.energyinst.org. in 9.4.3. Column lengths from 150 mm to 300 mm with an

D6379 − 21

FIG. 1 Example Chromatogram of an Aviation Fuel Showing Integration Points and Aromatic Hydrocarbon Type Groups

internal diameter from 4 mm to 5 mm and packed with 3 µm or 6.7 Computer or Computing Integrator—Any data system

5 µm particle size stationary phase have been found to be can be used provided it is compatible with the refractive index

satisfactory. The use of a guard column (for example, 30 mm detector, has a minimum sampling rate of 1 Hz, and is capable

by 4.6 mm internal diameter) packed with silica or amino- of peak area and retention time measurement. The data system

bonded silica is recommended but not essential. It has been should also have minimum facilities for post-analysis data

found that the use of a 2-column set provides the required processing, such as baseline correction and reintegration. The

separation and resolution for this method. Those used for the ability to perform automatic peak detection and identification

Inter-Laboratory study to generate the precision statements and to calculate sample concentrations from peak area mea-

were SphereClone 5 µm NH2 (250 mm by 4.6 mm) coupled surements is recommended but not essential.

with the Zorbax SB-CN 5 µm (150 mm by 4.6 mm). Other

6.8 Volumetric Flasks, Grade A, of 10 mL and 100 mL

columns are known to work when the separation (9.4.1) and

capacity.

resolution (9.4.3) criteria are met or exceeded prior to use.

6.9 Analytical Balance, accurate to 60.0001 g.

When joining two columns together, minimize the dead-

volume between the columns.

7. Reagents

6.5 HPLC Column Oven—Any suitable HPLC column oven

7.1 Cyclohexane, ≥99 % pure.

(block heating or air circulating) capable of maintaining a

constant temperature (61 °C) within the range from 20 °C to

NOTE 5—Cyclohexane may contain benzene as an impurity.

40 °C.

7.2 Heptane, HPLC Grade. For use as HPLC mobile phase.

NOTE 3—The refractive index detector is sensitive to both sudden and

(Warning—Hydrocarbon solvents are highly flammable and

gradual changes in the temperature of the eluent. All necessary precau-

may cause irritation by inhalation, ingestion, or skin contact.)

tions should be taken to establish constant temperature conditions

throughout the liquid chromatograph system.

NOTE 6—It is recommended practice to degas the HPLC mobile phase

NOTE 4—Alternative forms of temperature control, for example,

before use.

temperature-controlled laboratories, are permitted.

7.3 1-Methylnaphthalene, ≥97 % pure. (Warning—Gloves

6.6 Refractive Index Detector—Any refractive index detec-

should be worn when handling aromatic compounds (for

tor may be used provided it is capable of being operated over

example, disposable vinyl gloves).)

the refractive index range from 1.3 to 1.6, meets the sensitivity

requirement specified in 9.4.2, gives a linear response over the

NOTE 7—Purity is determined by gas chromatography with flame

calibration range, and has a suitable output signal for the data ionization detection. The highest purity standards available should be

used. Standards of ≥98 % purity are commercially available from all

system. If the refractive index detector has a facility for

major suppliers.

independent temperature control, it is recommended that this is

set at the same temperature as the column oven. 7.4 o-Xylene (1,2-Dimethylbenzene), ≥98 % pure.

D6379 − 21

TABLE 1 Concentration Standards

7.5 1-phenyldodecane ≥97 %.

Calibration Standard

7.6 hexamethylbenzene ≥97 %.

AB C D

Cyclohexane g/100 mL 5.0 2.0 0.5 0.1

8. Sampling o-xylene g/100 mL 15.0 5.0 1.0 0.1

1-Methylnaphthalene g/100 mL 5.0 1.0 0.2 0.05

8.1 The laboratory fuel sample from which an aliquot is

being drawn for the purposes of this test method shall be

representative of the lot of fuel. The laboratory sample should

be obtained by following Practice D4057 or D4177,ora

Cyclohexane, 1-phenyldodecane, 1,2-dimethylbenzene,

similar standard.

hexamethylbenzene, 1-methylnaphthalene.

9.4.2 Ensurethatthedatasyst

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6379 − 11 (Reapproved 2019) D6379 − 21

Designation: 436/01436/20

Standard Test Method for

Determination of Aromatic Hydrocarbon Types in Aviation

Fuels and Petroleum Distillates—High Performance Liquid

1,2

Chromatography Method with Refractive Index Detection

This standard is issued under the fixed designation D6379; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method is intended to be technically equivalent to IP 436-01436-20 with an identical title.

The ASTM format for test methods has been used, and where possible, equivalent ASTM test methods

have replaced the IP or ISO standards.

The test method is intended to be used as one of several possible alternative instrumental test

methods that are aimed at quantitative determination of hydrocarbon types in fuels. This does not

imply that a correlation necessarily exists between this and any other test method intended to give this

information, and it is the responsibility of the user to determine such correlation if necessary.

1. Scope Scope*

1.1 This test method covers a high performance liquid chromatographic test method for the determination of mono-aromatic and

di-aromatic hydrocarbon contents in aviation kerosenes and petroleum distillates boiling in the range from 50 °C to 300 °C, such

as Jet A or Jet A-1 fuels. The total aromatic content is calculated from the sum of the individual aromatic hydrocarbon-types.

NOTE 1—Samples with a final boiling point greater than 300 °C that contain tri-aromatic and higher polycyclic aromatic compounds are not determined

by this test method and should be analyzed by Test Method D6591 or other suitable equivalent test methods.

1.2 This test method is calibrated forapplicable to distillates containing from 10 %to 25 % m/m mono-aromatic hydrocarbons and

from 0 % to 7 % m/m di-aromatic hydrocarbons.0.8 % to 44.0 % by mass mono-aromatic hydrocarbons, 0.23 % to 6.20 % by mass

di-aromatic hydrocarbons, and 0.7 % to 50 % by mass total aromatics. Although this method generates results in m/m, results may

also be quoted in v/v.

1.3 The precision of this test method has been established for kerosene boiling range distillates containing from 10 % to 25 % m/m

mono-aromatic hydrocarbons and from 0 % to 7 % m/m di-aromatic hydrocarbons. 0.40 % to 44.0 % by mass mono-aromatic

hydrocarbons, 0.02 % to 6.20 % by mass di-aromatic hydrocarbons, and 0.40 % to 50.0 % by mass total aromatics. If results are

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.04.0C on Liquid Chromatography. The technically equivalent standard as referenced is under the jurisdiction of the Energy Institute Subcommittee SC-G-2.

Current edition approved June 1, 2019July 15, 2021. Published August 2019September 2021. Originally approved in 1999. Last previous edition approved in 20112019

as D6379 – 11.D6379 – 11 (2019). DOI: 10.1520/D6379-11R19. 10.1520/D6379-21.

In the IP, this test method is under the jurisdiction of the Standardization Committee.

This test method has been developed through the cooperative effort between ASTM and the Energy Institute, London. ASTM and IP standards were approved by ASTM

and EI technical committees as being technically equivalent but that does not imply both standards are identical.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6379 − 21

quoted in volume, the precision is 0.3 % to 41.4 % by volume mono-aromatics, 0.01 % to 5.00 % by volume di-aromatics, and

0.30 % to 46.3 % by volume total aromatics. As calculated by IP 367-1.

1.4 Compounds containing sulfur, nitrogen, and oxygen are possible interferents. Mono-alkenes do not interfere, but conjugated

di- and poly-alkenes, if present, are possible interferents.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6591 Test Method for Determination of Aromatic Hydrocarbon Types in Middle Distillates—High Performance Liquid

Chromatography Method with Refractive Index Detection

2.2 Energy Institute Standards:

IP 367–1 (EN ISO 4259 Part 1) Petroleum and related products – Precision of measurement methods and results – Part 1:

Determination of precision data in relation to methods of test

IP 436 Test method for determination of automatic hydrocarbon types in aviation fuels and petroleum distillates—High

performance liquid chromatography method with refractive index

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 di-aromatic hydrocarbons (DAHs), n—compounds that have a longer retention time on the specified polar column than the

MAHs.

3.1.2 mono-aromatic hydrocarbons (MAHs), n—compounds that have a longer retention time on the specified polar column than

the non-aromatic hydrocarbons but a shorter retention time than the di-aromatic hydrocarbons.

3.1.3 non-aromatic hydrocarbons, n—compounds that have a shorter retention time on the specified polar column than the

mono-aromatic hydrocarbons.

3.1.4 total aromatic hydrocarbons, n—sum of the MAHs and DAHs.

NOTE 2—The elution characteristics of aromatic and non-aromatic compounds on the specified polar column have not been specifically determined for

this test method. Published and unpublished data indicate the major constituents for each hydrocarbon type as follows: (1) Non-aromatic hydrocarbons:

acyclic and cyclic alkanes (paraffins and naphthenes), mono-alkenes (if present). (2) MAHs: benzenes, tetralins, indanes, thiophenes, conjugated

poly-alkenes. (3) DAHs: naphthalenes, biphenyls, indenes, fluorenes, acenaphthenes, benzothiophenes.

4. Summary of Test Method

4.1 The test portion is diluted 1:1 with the mobile phase, such as heptane, and a fixed volume of this solution injected into a high

performance liquid chromatograph fitted with a polar column. This column hasset of polar columns. These columns have little

affinity for the non-aromatic hydrocarbons and exhibits a pronounced selectivity for aromatic hydrocarbons. As a result of this

selectivity, the aromatic hydrocarbons are separated from the non-aromatic hydrocarbons into distinct bands in accordance with

their ring structure, that is, MAHs and DAHs.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Energy Institute, 61 New Cavendish St., London, W1G 7AR, U.K., http://www.energyinst.org.

D6379 − 21

FIG. 1 Example Chromatogram of an Aviation Fuel Showing Integration Points and Aromatic Hydrocarbon Type Groups

4.2 The column is connected to a refractive index detector that detects the components as they elute from the column. The

electronic signal from the detector is continually monitored by a data processor. The amplitudes of the signals (peak areas) from

the sample aromatics are compared with those obtained from previously-run calibration standards in order to calculate the percent

m/m MAHs and DAHs in the sample. The sum of the MAHs and DAHs is reported as the total aromatic content (percent m/m)

of the sample. Although this method generates results in m/m, results can also be quoted in percent v/v either by calibrating in v/v

or by converting m/m to v/v by using the densities of the sample and standards.

5. Significance and Use

5.1 Accurate quantitative information on aromatic hydrocarbon types can be useful in determining the effects of petroleum

processes on production of various finished fuels. This information can also be useful for indicating the quality of fuels and for

assessing the relative combustion properties of finished fuels.

6. Apparatus

6.1 High Performance Liquid Chromatograph (HPLC)—Any high performance liquid chromatograph capable of pumping the

mobile phase at flow rates between 0.5 mL ⁄min and 1.5 mL ⁄min with a precision better than 0.5 % and a pulsation of <1 % full

scale deflection under the test conditions described in Section 9. See Fig. 1.

6.2 Sample Injection System—The sample injection system shall be capable of injecting 10 μL5 μL (nominal) of sample solution

with a repeatability better than 2 %.

6.2.1 An equal and constant volume of the calibration and sample solutions shall be injected into the chromatograph. Both manual

and automatic sample injection systems (using either complete or partial filling of the sample loop) will, when used correctly, meet

the repeatability requirements laid down in 6.2. When using the partial loop filling mode, it is recommended that the injection

volume should be less than half the total loop volume. For complete filling of the loop, best results are obtained by overfilling the

loop at least six times.

6.2.2 Sample injection volumes other than 10 μL5 μL (typically in the range from 3 μL to 20 μL) may be used provided they meet

the requirements laid down for injection repeatability (see 6.2), refractive index sensitivity and linearity (see 9.4 and 10.1), and

column resolution (see 9.4)

D6379 − 21

6.3 Sample Filter (Optional)—A microfilter of porosity 0.45 μm or less, which is chemically-inert towards hydrocarbon solvents,

is recommended for the removal of particulate matter from the sample solutions.

6.4 Column System—Any stainless steel HPLC column(s) packed with an approved amino-bonded (or polar amino/cyano-bonded)

silica stationary phase is suitable, provided it meets suitable. The column(s) used shall satisfy the resolution requirements laid down

in 9.4.3. Column lengths from 150 mm to 300 mm with an internal diameter from 4 mm to 5 mm and packed with 3 μm or 5 μm

particle size stationary phase have been found to be satisfactory. The use of a guard column (for example, 30 mm by 4.6 mm

internal diameter) packed with silica or amino-bonded silica is recommended but not essential. It has been found that the use of

a 2-column set provides the required separation and resolution for this method. Those used for the Inter-Laboratory study to

generate the precision statements were SphereClone 5 μm NH2 (250 mm by 4.6 mm) coupled with the Zorbax SB-CN 5 μm

(150 mm by 4.6 mm). Other columns are known to work when the separation (9.4.1) and resolution (9.4.3) criteria are met or

exceeded prior to use. When joining two columns together, minimize the dead-volume between the columns.

6.5 HPLC Column Oven—Any suitable HPLC column oven (block heating or air circulating) capable of maintaining a constant

temperature (61 °C) within the range from 20 °C to 40 °C.

NOTE 3—The refractive index detector is sensitive to both sudden and gradual changes in the temperature of the eluent. All necessary precautions should

be taken to establish constant temperature conditions throughout the liquid chromatograph system.

NOTE 4—Alternative forms of temperature control, for example, temperature-controlled laboratories, are permitted.

6.6 Refractive Index Detector—Any refractive index detector may be used provided it is capable of being operated over the

refractive index range from 1.3 to 1.6, meets the sensitivity requirement specified in 9.4.2, gives a linear response over the

calibration range, and has a suitable output signal for the data system. If the refractive index detector has a facility for independent

temperature control, it is recommended that this is set at the same temperature as the column oven.

6.7 Computer or Computing Integrator—Any data system can be used provided it is compatible with the refractive index detector,

has a minimum sampling rate of 1 Hz, and is capable of peak area and retention time measurement. The data system should also

have minimum facilities for post-analysis data processing, such as baseline correction and reintegration. The ability to perform

automatic peak detection and identification and to calculate sample concentrations from peak area measurements is recommended

but not essential.

6.8 Volumetric Flasks, Grade B, or better, A, of 10 mL and 100 mL capacity.

6.9 Analytical Balance, accurate to 60.0001 g.

7. Reagents

7.1 Cyclohexane, ≥99 % pure.

NOTE 5—Cyclohexane may contain benzene as an impurity.

7.2 Heptane, HPLC Grade. For use as HPLC mobile phase. (Warning—Hydrocarbon solvents are highly flammable and may

cause irritation by inhalation, ingestion, or skin contact.)

NOTE 6—It is recommended practice to degas the HPLC mobile phase before use.

7.3 1-Methylnaphthalene, ≥98 %≥97 % pure. (Warning—Gloves should be worn when handling aromatic compounds (for

example, disposable vinyl gloves).)

NOTE 7—Purity is determined by gas chromatography with flame ionization detection. The highest purity standards available should be used. Standards

of ≥98 % purity are commercially available from all major suppliers.

7.4 o-Xylene (1,2-Dimethylbenzene), ≥98 % pure.

D6379 − 21

7.5 1-phenyldodecane ≥97 %.

7.6 hexamethylbenzene ≥97 %.

8. Sampling

8.1 The laboratory fuel sample from which an aliquot is being drawn for the purposes of this test method shall be representative

of the lot of fuel. The laboratory sample should be obtained by following Practice D4057 or D4177, or a similar standard.

9. Apparatus Preparation

9.1 Set up the chromatograph, injection system, column and column oven, refractive index detector, and computing integrator in

accordance with the appropriate equipment manuals. The HPLC column shall be installed in the column oven.

NOTE 8—The column oven is optional if alternative arrangements are made to maintain a constant temperature environment, for example, a

temperature-controlled laboratory (see 6.5).

9.2 Adjust the flow rate of the mobile phase to a constant 1.0 mL ⁄min 6 0.2 mL ⁄min and ensure that the reference cell of the

refractive index detector is full of mobile phase (see 6.6). Allow the temperature of the column oven (and refractive index detector

if equipped with temperature control) to stabilize.

9.2.1 To minimize drift, it is essential to make sure that the reference cell is full of solvent. The best way to accomplish this is

either to (1) flush the mobile phase through the r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...