ASTM D6227-99

(Specification)Standard Specification for Grade 82 Unleaded Aviation Gasoline

Standard Specification for Grade 82 Unleaded Aviation Gasoline

SCOPE

1.1 Grade 82 unleaded aviation gasoline defined by this specification is for use only in engines and associated aircraft that are specifically approved by the engine and aircraft manufacturers, and certified by the National Certifying Agencies to use this fuel. This fuel is not considered suitable for use in other engines and associated aircraft that are certified to use aviation gasolines meeting Specification D910.

1.2 A fuel may be certified to meet this specification by a producer as Grade 82 UL aviation gasoline, only if blended from component(s) approved for use in Grade 82 UL aviation gasoline by the refiner(s) of such components because only the refiner(s) can attest to the component source and processing, absence of contamination, and the additives used and their concentrations. Consequently, re-classifying and any other product to Grade 82 UL aviation gasoline does not meet this specification.

1.3 Appendix XI contains an explanation for the rationale of the specification. Appendix X2 details the reasons for the individual specification requirements.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6227 – 99 An American National Standard

Standard Specification for

Grade 82 Unleaded Aviation Gasoline

This standard is issued under the fixed designation D 6227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 910 Specification for Aviation Gasolines

D 1266 Test Method for Sulfur in Petroleum Products

1.1 Grade 82 unleaded aviation gasoline defined by this

(Lamp Method)

specification is for use only in engines and associated aircraft

D 2386 Test Method for Freezing Point of Aviation Fuels

that are specifically approved by the engine and aircraft

D 2392 Test Method for Color of Dyed Aviation Gasolines

manufacturers, and certified by the National Certifying Agen-

D 2622 Test Method for Sulfur in Petroleum Products by

cies to use this fuel. This fuel is not considered suitable for use

X-Ray Spectrometry

in other engines and associated aircraft that are certified to use

D 2700 Test Method for Motor Octane Number of Spark-

aviation gasolines meeting Specification D 910.

Ignition Engine Fuel

1.2 A fuel may be certified to meet this specification by a

D 3120 Test Method for Trace Quantities of Sulfur in Light

producer as Grade 82 UL aviation gasoline, only if blended

Liquid Petroleum Hydrocarbons by Oxidative Microcou-

from component(s) approved for use in Grade 82 UL aviation

lometry

gasoline by the refiner(s) of such components because only the

D 3231 Test Method for Phosphorus in Gasoline

refiner(s) can attest to the component source and processing,

D 3237 Test Method for Lead in Gasoline by Atomic

absence of contamination, and the additives used and their

Absorption Spectroscopy

concentrations. Consequently, re-classifying of any other prod-

D 3338 Test Method for Estimation of Heat of Combustion

uct to Grade 82 UL aviation gasoline does not meet this

of Aviation Fuels

specification.

D 4057 Practice for Manual Sampling of Petroleum and

1.3 Appendix X1 contains an explanation for the rationale

Petroleum Products

of the specification. Appendix X2 details the reasons for the

D 4171 Specification for Fuel System Icing Inhibitors

individual specification requirements.

D 4294 Test Method for Sulfur in Petroleum Products by

1.4 The values stated in SI units are to be regarded as the

Energy Dispersive X-Ray Fluorescence Spectroscopy

standard. The values given in parentheses are provided for

D 4529 Test Method for Estimate of Net Heat of Combus-

information only.

tion of Aviation Fuels

2. Referenced Documents

D 4809 Test Method for Heat of Combustion of Liquid

Hydrocarbon Fuels by Bomb Calorimeter (Intermediate

2.1 ASTM Standards:

Precision Method)

D 86 Test Method for Distillation of Petroleum Products

D 4815 Test Method for Determination of MTBE, ETBE,

D 130 Test Method for Detection of Copper Corrosion from

TAME, DIPE, tertiary-Amyl Alcohol, and C to C Alco-

Petroleum Products by the Copper Strip Tarnish Test 1 4

hols in Gasoline by Gas Chromatography

D 357 Method of Test for Knock Characteristics of Motor

D 4953 Test Method for Vapor Pressure of Gasoline and

Fuels Below 100 Octane Number by the Motor Method

Gasoline Oxygenate Blends (Dry Method)

D 381 Test Method for Existent Gum in Fuels by Jet

D 5059 Test Method for Lead in Gasoline by X-Ray Spec-

Evaporation

troscopy

D 873 Test Method for Oxidation Stability of Aviation Fuels

D 5190 Test Method for Vapor Pressure of Petroleum Prod-

(Potential Residue Method)

ucts (Automatic Method)

D 909 Test Method for Knock Characteristics of Aviation

D 5191 Test Method for Vapor Pressure of Petroleum Prod-

Gasolines by the Supercharge Method

ucts (Mini Method)

D 5453 Test Method for Determination of Total Sulfur in

This test method is under the jurisdiction of ASTM Committee D-2 on

Light Hydrocarbons, Motor Fuels, and Oils by Ultra Violet

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

Fluorescence

D02.J0.02 on Aviation Gasoline Specifications.

Current edition approved June 10, 1999. Published August 1999. Originally D 5482 Test Method for Vapor Pressure of Petroleum Prod-

published as D 6227-98. Last previous edition D 6227-98.

ucts (Mini Method/Atmospheric)

Annual Book of ASTM Standards, Vol 05.01.

Discontinued 1969, See Annual Book of ASTM Standards, Part 17, Replaced by

D 2700. Annual Book of ASTM Standards, Vol 05.02.

4 6

Annual Book of ASTM Standards, Vol 05.04. Annual Book of ASTM Standards, Vol 05.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 6227

D 5599 Test Method for Determination of Oxygenates in total concentration not to exceed 12 mg of inhibitor (not

Gasoline by Gas Chromatography and Oxygen Selective including weight of solvent) per litre of fuel.

Flame Ionization Detection 6.2.1.1 2,6 - ditertiary-butyl-phenol.

D 5845 Test Method for Determination of MTBE, ETBE, 6.2.1.2 2,6 - ditertiary-butyl-4-methyl-phenol.

TAME, DIPE, Methanol, Ethanol, and tert-Butanol in 6.2.1.3 2,4 - dimethyl-6- tertiary-butyl - phenol.

Gasoline by Infrared Spectroscopy 6.2.1.4 2,6 - ditertiary - butyl - phenol, 75 % min.

D 5983 Specification for Methyl tertiary-Butyl Ether Tertiary and tritertiary - butyl - phenols, 25 % max.

(MTBE) for Downstream Blending for Use in Automotive 6.2.1.5 2,4-dimethyl-6-tertiary-butyl-phenol, 55 % min;

Spark-ignition Engine Fuel 4-methyl-2,6-ditertiary-butyl phenol 15 % min; the remainder

E 29 Practice for Using Significant Digits in Test Data to as a mixture of monomethyl and dimethyl-tertiary-butyl-

Determine Conformance with Specifications phenols.

2.2 Military Standard: 6.2.1.6 2,4 - dimethyl-6-tertiary-butyl-phenol, 72 % min.

MIL-PRF-25017F Performance Specification for Inhibitor, Mixture of tertiary-butyl-methyl-phenols and tertiary-butyl-

Corrosion/Lubricity Improver, Fuel Soluble dimethyl-phenols, 28 % max.

QPL-25017 Qualified Products List of Products Qualified 6.2.1.7 2,6-ditertiary-butyl-4-methyl-phenol, 35 % min.

Under Performance Specification MIL-PRF-25017F Mixed methyl, ethyl, and dimethyl tertiary-butyl-phenols,

65 % max

3. Terminology

6.2.1.8 2,4-di-tertiary butyl-phenol, 60 % min.

3.1 Definitions:

Mixed tertiary-butyl-phenol, 40 % max.

3.1.1 aviation gasoline, n—gasoline possessing specific 6.2.1.9 Butylated ethyl-phenols, 55 % min.

properties suitable for fueling aircraft powered by reciprocat-

Butylated methyl and dimethyl-phenols, 45 % max.

ing spark ignition engines. 6.2.1.10 Mixture of a di- and tri-isopropyl-phenols, 75 %

3.1.1.1 Discussion—The principal properties of aviation

min.

gasoline include volatility limits, stability, detonation-free

Mixture of di- and tri-tertiary butyl-phenols, 25 % max.

performance in the engine for which it is intended, and

6.2.1.11 N,N’ di-secondary butyl-para phenylene diamine.

suitability for low temperature performance.

6.2.1.12 N,N’ di-isopropyl-para-phenylene-diamine.

6.2.1.13 N-secondary butyl, N’- phenyl ortho - phenylene-

4. Grades

diamine.

4.1 The specification covers one grade of unleaded aviation

6.2.2 Metal Deactivators—A metal deactivator, N,N’ -

gasoline designated Grade 82 UL. Grade 82 UL is the only

disalicylidene - 1,2- propane diamine may be added to the

aviation gasoline defined by this specification and the grade

gasoline in an amount not to exceed 3.0 mg/L.

shows the minimum motor octane rating.

6.2.3 Corrosion Inhibitors—Corrosion inhibitors that con-

form to MIL-PRF-25017F may be added to the gasoline in

5. General

amounts not exceeding the maximum allowable concentrations

5.1 This specification, unless otherwise provided, prescribes

listed in the latest revision of QPL-25017.

the required properties of unleaded aviation gasoline at the

6.2.4 Fuel System Icing Inhibitor:

time and place of delivery.

6.2.4.1 Diethylene glycol monomethyl ether, conforming to

the requirements of Specification D 4171 (Type III), may be

6. Material

used in concentrations of 0.10 to 0.15 volume %.

6.1 Aviation gasoline, except as otherwise specified in this

6.2.4.2 Isopropyl alcohol conforming to the requirements of

specification, shall consist of blends of refined hydrocarbons

Specification D 4171 (Type II) may be used in concentrations

derived from crude petroleum, natural gasoline or blends,

recommended by the aircraft manufacturers when required by

thereof, with specific aliphatic ethers, synthetic hydrocarbons,

the aircraft owner operator.

or aromatic hydrocarbons. When applicable, methyl tertiary-

butyl ether (MTBE) shall conform to the requirements of

7. Detailed Requirements

Specification D 5983. Types and quantities of trace alcohols

7.1 The aviation gasoline shall conform to the requirements

shall meet the requirements of Table 1 and 6.2.4.2.

in Table 1.

6.2 Only additives approved by this specification are per-

mitted. In addition to identification dyes, corrosion inhibitors,

8. Workmanship

antioxidants, and metal deactivators, fuel system icing inhibitor

8.1 The finished fuel shall be visually free of water, sedi-

additives are permitted under 6.2.4. Permitted additives may be

ment, and suspended matter.

added to aviation gasoline in the amount and of the composi-

tion specified in the following list of approved materials.

NOTE 1—See Practice D 4057 for appropriate sampling procedures.

6.2.1 Antioxidants— The following oxidation inhibitors

9. Reports

may be added to the gasoline separately or in combination in

9.1 The type and number of reports to ensure conformance

with the requirements of this specification shall be mutually

Annual Book of ASTM Standards, Vol 14.02.

agreed to by the purchaser and the supplier of the aviation

Available from Standardization Document Order Desk, 700 Robbins Ave.,

Bldg. 4D, Philadelphia, PA 19111–5094 Attn: NPODS. gasoline.

D 6227

A

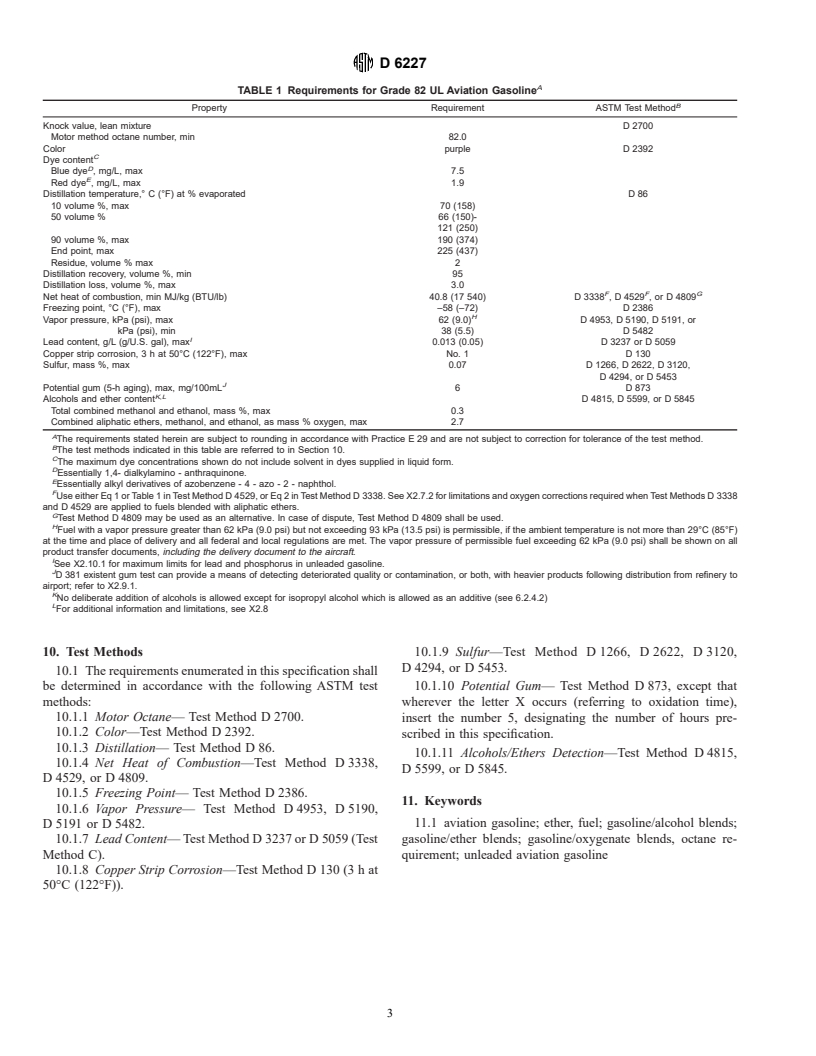

TABLE 1 Requirements for Grade 82 UL Aviation Gasoline

B

Property Requirement ASTM Test Method

Knock value, lean mixture D 2700

Motor method octane number, min 82.0

Color purple D 2392

C

Dye content

D

Blue dye , mg/L, max 7.5

E

Red dye , mg/L, max 1.9

Distillation temperature,° C (°F) at % evaporated D86

10 volume %, max 70 (158)

50 volume % 66 (150)-

121 (250)

90 volume %, max 190 (374)

End point, max 225 (437)

Residue, volume % max 2

Distillation recovery, volume %, min 95

Distillation loss, volume %, max 3.0

F F G

Net heat of combustion, min MJ/kg (BTU/lb) 40.8 (17 540) D 3338 , D 4529 , or D 4809

Freezing point, °C (°F), max –58 (–72) D 2386

H

Vapor pressure, kPa (psi), max 62 (9.0) D 4953, D 5190, D 5191, or

kPa (psi), min 38 (5.5) D 5482

I

Lead content, g/L (g/U.S. gal), max 0.013 (0.05) D 3237 or D 5059

Copper strip corrosion,3hat 50°C (122°F), max No. 1 D 130

Sulfur, mass %, max 0.07 D 1266, D 2622, D 3120,

D 4294, or D 5453

J

Potential gum (5-h aging), max, mg/100mL 6 D 873

K,L

Alcohols and ether content D 4815, D 5599, or D 5845

Total combined methanol and ethanol, mass %, max 0.3

Combined aliphatic ethers, methanol, and ethanol, as mass % oxygen, max 2.7

A

The requirements stated herein are subject to rounding in accordance with Practice E 29 and are not subject to correction for tolerance of the test method.

B

The test methods indicated in this table are referred to in Section 10.

C

The maximum dye concentrations shown do not include solvent in dyes supplied in liquid form.

D

Essentially 1,4- dialkylamino - anthraquinone.

E

Essentially alkyl derivatives of azobenzene-4-azo-2- naphthol.

F

Use either Eq 1 or Table 1 in Test Method D 4529, or Eq 2 in Test Method D 3338. See X2.7.2 for limitations and oxygen corrections required when Test Methods D 3338

and D 4529 are applied to fuels blended with aliphatic ethers.

G

Test Method D 4809 may be used as an alternative. In case of dispute, Test Method D 4809 shall be used.

H

Fuel with a vapor pressure greater than 62 kPa (9.0 psi) but not exceeding 93 kPa (13.5 psi) is permissible, if the ambient temperature is not more than 29°C (85°F)

at the time and place of delivery and all federal and local regulations are met. The vapor pressure of permissible fuel exceeding 62 kPa (9.0 psi) shall be shown on all

product transfer documents, including the delivery document to the aircraft.

I

See X2.10.1 for maximum limits for lead and phosphorus in unleaded gasoline.

J

D 381 existent gum test can provide a means of detecting deteriorated quality or contamination, or both, with heavier products following distribution from refinery to

airport; refer to X2.9.1.

K

No deliberate addition of alcohols is allowed except for isopropyl alcohol which is allowed as an additive (see 6.2.4.2)

L

For additional information and limitations, see X2.8

10. Test Methods 10.1.9 Sulfur—Test Method D 1266, D 2622, D 3120,

D 4294, or D 5453.

10.1 The requirements enumerated in this specification shall

be determined in accordance with the following ASTM test 10.1.10 Potential Gum— Test Method D 873, except that

methods: wherever the letter X occurs (referring to oxidation time),

10.1.1 Motor Octane— Test Method D 2700.

insert the number 5, designating the number of hours pre-

10.1.2 Color—Test Method D 2392.

scribed in this specification.

10.1.3 Distillation— Test Method D 86.

10.1.11 Alcohols/Ethers Detection—Test Method D 4815,

10.1.4 Net Heat of Combustion—Test Method D 3338,

D 5599, or D 5845.

D 4529, or D 4809.

10.1.5 Freezing Point— Test Method D 2386.

11. Keywords

10.1.6 Vapor Pressure— Test Method D 4953, D 5190,

11.1 aviation gasoline; ether, fuel; gasoline/alcohol blends;

D 5191 or D 5482.

10.1.7 Lead Content— Test Method D 3237 or D 5059 (Test gasoline/ether blends; gasoline/oxygenate blends, octane re-

Method C).

quirement; unleaded aviation gasoline

10.1.8 Copper Strip Corrosion—Test Method D 130 (3 h at

50°C (122°F)).

D 6227

APPENDIXES

(Nonmandatory Information)

X1. REASONS FOR SPECIFICATION

X1.1 Introduction—Aviation gasoline defined by this speci- X1.2 To ensure ready identification of fuel meeting this

fication is for use only in engines and associated aircraft specification, it is dyed purple.

specifically designed to operate on Grade 82 UL defined by this

specification.

X2. SIGNIFICANT FACTORS FOR UNLEADED AVIATION GASOLINE

X2.1 Introduction: engines certified for low octane fuels. Rich mixture ratings by

Test Method D 909 were developed for older large displace-

X2.1.1 This specification was developed to identify broad

ment, high output engines for which this fuel is not suitable.

distillation range refinery products, including refined hydrocar-

X2.2.3 The motor Test Method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.