ASTM D6682-01(2006)

(Test Method)Standard Test Method for Measuring Shear Stresses of Powders Using Peschl Rotational Split Level Shear Tester

Standard Test Method for Measuring Shear Stresses of Powders Using Peschl Rotational Split Level Shear Tester

SIGNIFICANCE AND USE

The test method is useful for the following:

5.1.1 Classification of Powders—The cohesion and angle of internal friction are flowability indicators of powders and can be used to classify the powders.

5.1.2 Quality Control—For a number of industrial applications flowability factors are used to compare the material flowability at different times during production. The material produced has to be held within given limits for each application and each powder so as to ensure trouble-free operation.

5.1.3 Material Engineering—Powder properties are influenced by particle size, particle size distribution, fat content, humidity and other parameters. By selecting the correct parameters and the correct mixtures of powders, the required mechanical properties of the product are achieved.

5.1.4 Design of Handling Equipment—For certain storage and conveyor equipment there are mathematical models exist which require the mechanical properties of powders.

SCOPE

1.1 This test method is applied to the measurement of the mechanical properties of powders as a function of normal stress.

1.2 This apparatus is suitable measuring the properties of powders and other bulk solids, up to a particle size of 5000 micron.

1.3 This method comprises four different test procedures for the determination of powder mechanical properties:

1.3.1 Test A - Measurement of INTERNAL FRICTION as a function of normal stress.

1.3.2 Test B - Measurement of WALL FRICTION as a function of normal stress.

1.3.3 Test C - Measurement of BULK DENSITY as a function of normal stress and time.

1.3.4 Test D - Measurement of DEGRADATION as a function of normal stress.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6682–01 (Reapproved 2006)

Standard Test Method for

Measuring Shear Stresses of Powders Using Peschl

Rotational Split Level Shear Tester

This standard is issued under the fixed designation D 6682; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 consolidation normal stress—the maximal normal

stress applied to the specimen for executing an yield locus.

1.1 This test method is applied to the measurement of the

3.1.3 consolidation step—shearing repeated under the con-

mechanical properties of powders as a function of normal

solidation normal stress until the shear stress reaches a maxi-

stress.

mum t value followed by a steady state value t . This step is

m s

1.2 This apparatus is suitable measuring the properties of

performed before each shear step.

powders and other bulk solids, up to a particle size of 5000

3.1.4 degradation—change of particle size as result of

micron.

shearing.

1.3 This method comprises four different test procedures for

3.1.5 dynamic wall friction—calculated from the measured

the determination of powder mechanical properties:

normal stress and the steady state shear stress after certain

1.3.1 TestA—Measurement of INTERNALFRICTION as a

shearing.

function of normal stress.

3.1.6 dynamic yield locus—line calculated from measured

1.3.2 Test B—Measurement of WALL FRICTION as a

values of normal stress and steady values of the shear stress.

function of normal stress.

3.1.7 peak shear stress (t )—maximum shear stress at the

m

1.3.3 Test C—Measurement of BULK DENSITYas a func-

beginningofyield-atthetransitionbetweenelasticandplastic

tion of normal stress and time.

deformation.

1.3.4 Test D—Measurement of DEGRADATION as a func-

3.1.8 pre-consolidation normal stress (s )—normal stress

np

tion of normal stress.

applied during the first part of the test in order to densify the

1.4 This standard does not purport to address all of the

specimen.

safety concerns, if any, associated with its use. It is the

3.1.9 shear step—shear after the consolidation step, per-

responsibility of the user of this standard to establish appro-

formed under the normal stress which is equal to or lower than

priate safety and health practices and determine the applica-

the consolidation normal stress, until the shear stress reaches

bility of regulatory limitations prior to use.

the peak value followed by a steady state value t .

s

2. Referenced Documents

3.1.10 split level—level between the bottom and top cover

of the shear cell defined by the transition of the cell base and

2.1 ASTM Standards:

ring where in the specimen the shear plane occurs.

D 653 Terminology Relating to Soil, Rock, and Contained

3.1.11 static wall friction—calculated from the measured

Fluids

normalstressandthemaximumshearstressatthebeginningof

3. Terminology

yield.

3.1.12 static yield locus—line calculated from measured

3.1 Definitions of Terms Specific to This Standard:

values of normal stress and peak values of the shear stress.

3.1.1 adhesion—shear stress between the wall sample and

3.1.13 steady shear stress (t )—steady state shear stress

powder at a normal stress of zero. s

during the steady state (plastic) deformation.

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland 4. Summary of Test Method

Rock and is the direct responsibility of Subcommittee D18.24 on Characterization

4.1 Measurement of Internal Friction as a Function of

and Handling of Powders and Bulk Solids.

Normal Stress:

Current edition approved Dec. 1, 2006. Published January 2007. Originally

approved in 2001. Last previous edition approved in 2001 as D 6682 – 01.

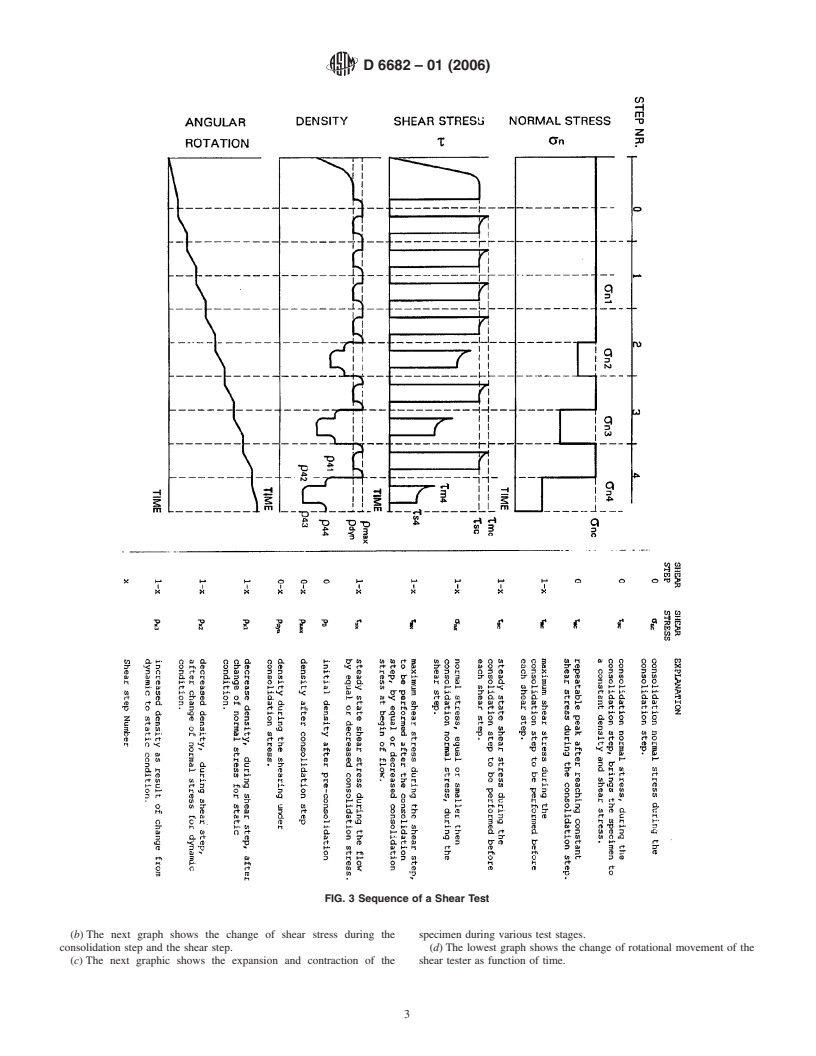

2 NOTE 1—Sequence of a standard shear test (Fig. 3):

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(a) The upper graph shows the change of normal stress as a function of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

time. Before each shear step, a consolidation normal stress s is applied

Standards volume information, refer to the standard’s Document Summary page on

n

the ASTM website. to the specimen, to reestablish the consolidation condition.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6682–01 (2006)

FIG. 1 Schematic View of a Rotational Split Level Shear Cell

FIG. 2 Shear Resistance as Function of Time (Angular Rotation) in Relation to the Steady Shear Stress

D6682–01 (2006)

FIG. 3 Sequence of a Shear Test

(b) The next graph shows the change of shear stress during the specimen during various test stages.

consolidation step and the shear step. (d) The lowest graph shows the change of rotational movement of the

(c) The next graphic shows the expansion and contraction of the shear tester as function of time.

D6682–01 (2006)

4.1.1 Foreachindividualtest,thepowderiscompactedwith 6.1.1 Cell Base, is cylindrical and has a knurled interior

the pre-consolidation normal stress. It is then pretreated by bottom surface.

applying a shear stress until steady state is achieved. The shear

6.1.2 CellRing,isaring-formedelementtobeplacedonthe

stressisrepeatedlyappliedandremoveduntilconsistentresults cell base.

areobtained.Next,thenormalstressisreducedinsteps.Before

6.1.3 Loading Lid, is a knurled interior cover surface for

each shear step, the consolidation normal stress is reapplied.

loading of the specimen, to be placed on the specimen.

The measurements provide a measure of the instantaneous

6.1.4 Shear Plane, shown in Fig. 1, occurs at the transition

static and dynamic yield loci.

plane between the cell base and the cell ring.

4.1.1.1 During the entire shear test the height of the speci-

6.1.5 Several shear cell sizes are available to accommodate

men is measured simultaneously in order to determine the

a variety of particle sizes. The selected shear cell diameter

compaction and expansion of the specimen.

should be at least 25 times larger than the average particle

4.1.2 The instantaneous static and dynamic yield loci are

diameter. The most frequently used shear cell is a nominal 60

determined using the procedure outlined in the above section

mm diameter and would accommodate powders with an

without any delay between the various stages of the test.

average particle diameter smaller than 2400 microns.

4.1.3 The time dependent static yield locus is measured as a

6.2 Rotating Table, on which the Cell Base is fixed causes

function of time by preconditioning the specimen for various

the Cell Base to rotate against the Loading Lid.

times under consolidation normal stress conditions; the peak

6.2.1 In Fig. 1, the cross section shows the cell base, ring

shear stress is then measured.

and loading lid. The cell base rotates. The loading lid is placed

4.2 Measurement of Wall Friction as a Function of the

on the specimen and loaded with predetermined weights. The

Normal Stress—By placing a wall specimen under the cell

shear resistance is measured by measuring the moment on the

ring,theshearstresses(wallfriction)aremeasuredbetweenthe

loading lid.

wall specimen and the powder.

4.2.1 The instantaneous static and dynamic friction are

7. Selection of Test Parameters

determined.

7.1 Sampling:

4.3 Measurement of Degradation as a Function of Normal

7.1.1 Prepare and store the test specimens in accordance

Stress—The influence of shearing on particle degradation is

with any valid safety and environmental regulations.

measured by particle size analysis after shearing the specimen

7.1.2 Prepare the specimens in accordance with the operat-

at a predetermined normal stress. Particle size degradation is

ing conditions expected during the application; i.e. tempera-

measured from the change of particle size distribution before

ture, humidity and other conditions. Use an adequate climate

and after test (see 10.4.3).

chamber to condition the specimen as necessary.

7.1.3 If a powder contains large particles which are uni-

5. Significance and Use

formly distributed in a mixture, which otherwise meets the

5.1 The test method is useful for the following:

criteria of 6.1.5, the large particles may be sieved out. It is

5.1.1 Classification of Powders—Thecohesionandangleof

acceptable to sieve out the large particles until the proportion

internal friction are flowability indicators of powders and can

of large particles does not exceed about 5 % of the test

be used to classify the powders.

specimen. Beyond this limit a larger diameter of the shear cell

5.1.2 Quality Control—For a number of industrial applica-

should be used according 6.1.5 to retain the large particles in

tions flowability factors are used to compare the material

the mixture.

flowability at different times during production. The material

7.2 Determination of Test Parameters:

producedhastobeheldwithingivenlimitsforeachapplication

and each powder so as to ensure trouble-free operation.

NOTE 2—The selected consolidation normal stress should match the

5.1.3 Material Engineering—Powder properties are influ- expected stress in the actual process specified by an engineer/scientist

having a knowledge of shear testing and a theoretical background.

enced by particle size, particle size distribution, fat content,

humidityandotherparameters.Byselectingthecorrectparam-

7.2.1 For the measurement of internal friction, the consoli-

eters and the correct mixtures of powders, the required me-

dation normal stress is the same during both, the pre-

chanical properties of the product are achieved.

consolidation s and the consolidation steps s . See Fig. 3.

np n

5.1.4 Design of Handling Equipment—For certain storage

7.2.1.1 The normal stress during the shear stepisequaltoor

and conveyor equipment there are mathematical models exist

lower than the consolidation normal stress. See s in Fig. 3.

nx

which require the mechanical properties of powders.

7.2.1.2 In the absence of specified values of consolidation

normal stress the test should be performed with consolidation

6. Apparatus

normal stress of 5.0 kPa, 15.0 kPa and 25.0 kPa.

6.1 The Rotational Split Level Shear tester is schematically

7.2.1.3 In the absence of specified values of normal stress

shown in Fig. 1 and the specimen is contained in the following

duringtheshearstepsthetestshouldbeperformedwithnormal

shear cell components.

stress equal to 100 %, 80 %, 60 %, 40 % and 20 % of the

consolidation normal stress.

7.2.2 The measurement of density is performed by applying

the predetermined normal stress to the specimen (see 7.2.1). In

Available from Dr. I. Peschl, Post Box 399, NL-5600 AJ Eindhoven, The

Netherlands. the absence of specified values for normal stress, the test

D6682–01 (2006)

should be performed at 1 kPa, 5 kPa, 10 kPa, 15 kPa, 25 kPa. 8.1.1 Place the shear cell ring on top of the cell base. Center

15 kPa, 10 kPa, 5 kPa, and 1 kPa. the shear cell ring with the three centering screws.

7.2.3 The measurement of wall friction is performed by

8.1.2 Determine the mass of the empty shear cell including

applying the predetermined normal stress to the specimen. In

the shear cell ring. Use a scale with the accuracy of 0.1 gram.

the absence of specified values for normal stress, the test

8.1.3 Place the fill ring on top of the shear cell ring.

should be performed at 1 kPa, 10 kPa, 15 kPa and 25 kPa.

8.1.4 Fill the shear cell, as uniformly as possible, with

7.2.4 The degradation test should simulate the normal stress

powder to be tested. Use a sieve for filling the shear cell in

and time during which the shearing takes place. For a good

order to remove lumps and agglomerates from the specimen.

simulation, a number of such steps might be necessary in order

8.1.5 Scrape off the surplus material in small amounts by

to simulate the stresses and the time during which they are

scraping off with a blade as shown in Fig. 10.The blade should

acting throughout the whole process. In the absence of speci-

be scraped across the ring with a zigzag motion. Prevent

fied values for normal stress, the test should be performed at 5

downward forces from acting on the specimen.

kPa during 10 min.

8.1.6 Center the consolidation lid on top of the material in

8. Specimen Preparation for Measurement

the shear cell.

8.1 Preparation for the Measurement of the Internal 8.1.7 Load the specimen uniaxially by placing weights on

Friction—Shear Test (Fig. 5): the consolidation lid so as to achieve a pre-consolidation

FIG. 4 Instantaneous and Time Yield Loci

D6682–01 (2006)

FIG. 5 Shear Cell Assembly for Filling

normal stress corresponding to one of the predetermined 8.3 Preparation for Measuring the Density :

consolidation normal stresses specified in 7.2. 8.3.1 Perform 8.1.1-8.1.4.

8.1.8 Consolidate the powder with the predetermined pre- 8.3.2 Remove the fill ring.

consolidation normal stress until the consolidation is com- 8.3.3 Perform 8.1.5 and 8.1.11-8.1.13.

pleted.The time required to consolidate the specimen will vary 8.4 Preparation for Measurement of Degradation:

with the material. Take 10 min for the first trial. 8.4.1 Perform a sieve analysis or particle size analysis,

8.1.9 Remove the weights, consolidation lid and the fill before running the degradation test.

ring. 8.4.2 Prepare the shear cell in accordance with 7.2.4.

8.1.10 Perform 8.1.5. 8.4.3 Perform 8.1.1-8.1.13.

8.1.11 Determine the mass of the shear cell filled with

9. Procedures for Executing the Test

powder.

8.1.12 Calculate the mass of material in the shear cell by

NOTE 3—The procedures are similar for carrying out manual and

subtracting the net value in 8.1.2 from value in 8.1.11. automatic testers. Both shear testers can be controlled by hand or by

computer, only in the case of the manual shear tester should the weight be

8.1.13 Place the loading lid assembly on the cell base and

changed manually.

tighten the three clamp screws.

8.2 Preparation for Measurement of Wall Friction: 9.1 Mount the Shear Cell on the Turntable of the Shear

8.2.1 Mount the specimen of wall material on the cell base Tester:

and secure it with the centering screws as shown in Fig. 7. 9.1.1 Place the shear cell assembly on the shear tester as

8.2.2 Place the cell ring on the wall specimen. shown in Fig. 6.

8.2.3 Perform 8.1.4-8.1.10 and 8.1.13. 9.1.2 Tighten the clamp screws of the turntable.

D6682–01 (2006)

FIG. 6 Shear Cell Assembly Mounted on Shear Tester

FIG.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.