ASTM D7891-15

(Test Method)Standard Test Method for Shear Testing of Powders Using the Freeman Technology FT4 Powder Rheometer Shear Cell

Standard Test Method for Shear Testing of Powders Using the Freeman Technology FT4 Powder Rheometer Shear Cell

SIGNIFICANCE AND USE

5.1 The test can be used to evaluate the following:

5.1.1 Classification or Comparison of Powders—There are several parameters that can be used to classify powders relative to each other, the most useful being the measured shear stresses, cohesion, flow function and angle of internal friction.

5.1.2 Sensitivity Analysis—The shear cell can be used to evaluate the relative effects of a range of powder properties and/or environmental parameters such as (but not limited to) humidity, particle size and size distribution, particle shape and shape distribution, moisture content and temperature.

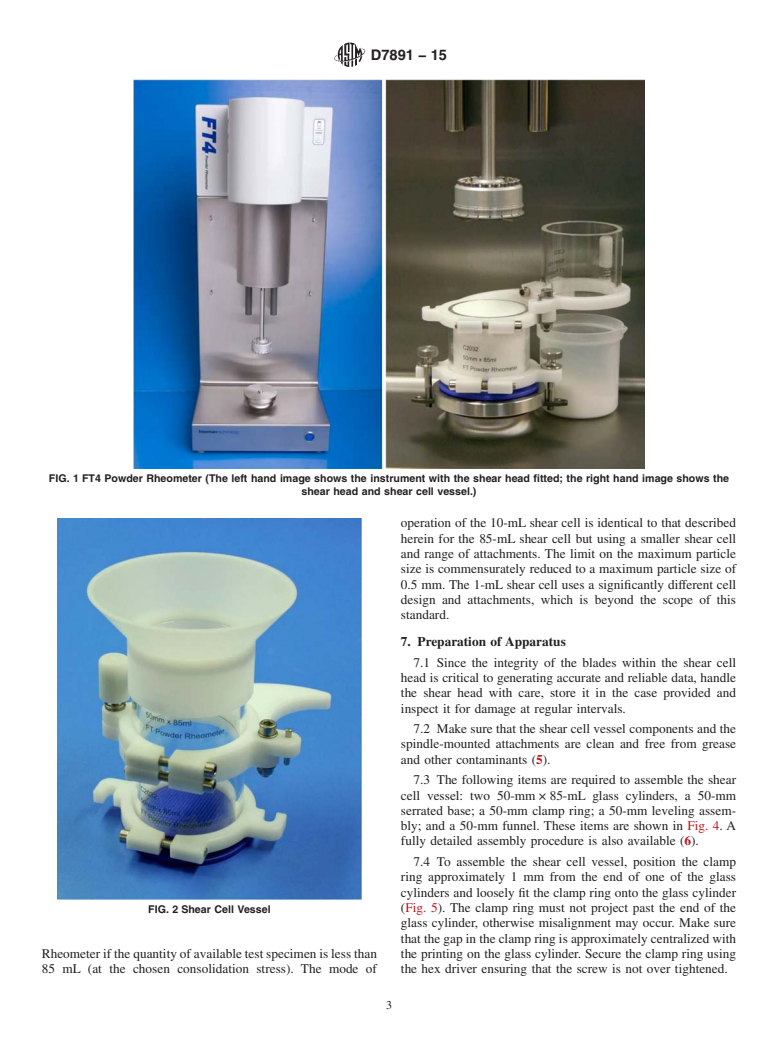

5.1.3 Quality Control—The test can, in some circumstances, be used to assess the flow properties of a raw material, intermediate or product against pre-determined acceptance criteria.

5.1.4 Storage Vessel Design—Mathematical models exist for the determination of storage vessel design parameters which are based on the flow properties of powders as generated by shear cell testing, requiring shear testing at a range of consolidating stresses as well as the measurement of the wall friction angle with respect to the material of construction of the storage vessel. The methods are detailed in Refs. (1-3).2

Note 1: The quality of the result produced by this test method is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this test method are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors (4).

Practice D3740 was developed for agencies engaged in the testing and/or inspection of soil and rock. As such it is not totally applicable to agencies performing this test method. However, users of this test method shou...

SCOPE

1.1 This method covers the apparatus and procedures for measuring the incipient failure properties of a powder as a function of the normal stress for a given level of consolidation. The method also allows the further determination of the unconfined yield strength, internal friction angles, cohesion, flow function, major principal stress and wall friction angle (with the appropriate wall coupon fitted to the correct accessory).

1.2 These parameters are most commonly used for the design of storage hoppers and bins using industry standard calculations and procedures. They can also provide relative classification or comparison of the flow behavior of different powders or different batches of the same powder if similar stress and shear regimes are encountered within the processing equipment.

1.3 The apparatus is suitable for measuring the properties of powders with a maximum particle size of 1 mm. It is possible to test powders which have a small proportion of particles of 1 mm or greater, but they should be present in the bulk sample as no more than 5 % of the total mass in samples with a normal (Gaussian) size distribution.

1.4 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026.

1.4.1 The procedures used to specify how data are collected/recorded or calculated, in this standard are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.5 Units—Th...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7891 − 15

Standard Test Method for

Shear Testing of Powders Using the Freeman Technology

1

FT4 Powder Rheometer Shear Cell

This standard is issued under the fixed designation D7891; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 Units—The values stated in SI units are to be regarded

asstandard.Nootherunitsofmeasurementareincludedinthis

1.1 This method covers the apparatus and procedures for

standard.

measuring the incipient failure properties of a powder as a

1.6 This standard does not purport to address all of the

functionofthenormalstressforagivenlevelofconsolidation.

safety concerns, if any, associated with its use. It is the

The method also allows the further determination of the

responsibility of the user of this standard to establish appro-

unconfined yield strength, internal friction angles, cohesion,

priate safety and health practices and determine the applica-

flow function, major principal stress and wall friction angle

bility of regulatory limitations prior to use.

(with the appropriate wall coupon fitted to the correct acces-

sory).

2. Referenced Documents

1.2 These parameters are most commonly used for the

2.1 ASTM Standards:

design of storage hoppers and bins using industry standard

D653Terminology Relating to Soil, Rock, and Contained

calculations and procedures. They can also provide relative

Fluids

classification or comparison of the flow behavior of different

D2216Test Methods for Laboratory Determination ofWater

powders or different batches of the same powder if similar

(Moisture) Content of Soil and Rock by Mass

stress and shear regimes are encountered within the processing

D3740Practice for Minimum Requirements for Agencies

equipment.

Engaged in Testing and/or Inspection of Soil and Rock as

1.3 Theapparatusissuitableformeasuringthepropertiesof

Used in Engineering Design and Construction

powders with a maximum particle size of 1 mm. It is possible

D6026Practice for Using Significant Digits in Geotechnical

to test powders which have a small proportion of particles of 1

Data

mmorgreater,buttheyshouldbepresentinthebulksampleas

D6128Test Method for Shear Testing of Bulk Solids Using

no more than 5 % of the total mass in samples with a normal

the Jenike Shear Cell

(Gaussian) size distribution.

D6682Test Method for Measuring Shear Stresses of Pow-

ders Using Peschl Rotational Split Level Shear Tester

1.4 All observed and calculated values shall conform to the

D6773Test Method for Bulk Solids Using Schulze Ring

guidelines for significant digits and rounding established in

Shear Tester

Practice D6026.

1.4.1 Theproceduresusedtospecifyhowdataarecollected/

3. Terminology

recorded or calculated, in this standard are regarded as the

3.1 Definitions—For definitions of common technical terms

industry standard. In addition, they are representative of the

in this standard, refer to Terminology D653.

significant digits that generally should be retained. The proce-

dures used do not consider material variation, purpose for

3.2 Definitions of Terms Specific to This Standard:

obtaining the data, special purpose studies, or any consider-

3.2.1 conditioning, v—in powders, the process of homog-

ations for the user’s objectives; and it is common practice to

enizingthestressofapowderspecimenbyuseofaspecialized

increase or reduce significant digits of reported data to be

blade attachment.

commensuratewiththeseconsiderations.Itisbeyondthescope

3.2.2 wall friction coupon, n—in powders, a test piece used

of this standard to consider significant digits used in analysis

in the wall friction test that is manufactured from a material

methods for engineering design.

that represents the material of construction of the silo/bin/

hopper that stores the powder.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.24 on Characterization 4. Summary of Test Method

and Handling of Powders and Bulk Solids.

4.1 Selection of the Appropriate Testing Regime—The par-

Current edition approved March 1, 2015. Published March 2015. DOI: 10.1520/

D7891-15. ticular consolidating stress level or levels used to evaluate the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7891 − 15

dependent on the competence of the personnel performing it, and the

flow properties of the powd

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7891 − 15

Standard Test Method for

Shear Testing of Powders Using the Freeman Technology

1

FT4 Powder Rheometer Shear Cell

This standard is issued under the fixed designation D7891; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 Units—The values stated in SI units are to be regarded

as standard. No other units of measurement are included in this

1.1 This method covers the apparatus and procedures for

standard.

measuring the incipient failure properties of a powder as a

1.6 This standard does not purport to address all of the

function of the normal stress for a given level of consolidation.

safety concerns, if any, associated with its use. It is the

The method also allows the further determination of the

responsibility of the user of this standard to establish appro-

unconfined yield strength, internal friction angles, cohesion,

priate safety and health practices and determine the applica-

flow function, major principal stress and wall friction angle

bility of regulatory limitations prior to use.

(with the appropriate wall coupon fitted to the correct acces-

sory).

2. Referenced Documents

1.2 These parameters are most commonly used for the

2.1 ASTM Standards:

design of storage hoppers and bins using industry standard

D653 Terminology Relating to Soil, Rock, and Contained

calculations and procedures. They can also provide relative

Fluids

classification or comparison of the flow behavior of different

D2216 Test Methods for Laboratory Determination of Water

powders or different batches of the same powder if similar

(Moisture) Content of Soil and Rock by Mass

stress and shear regimes are encountered within the processing

D3740 Practice for Minimum Requirements for Agencies

equipment.

Engaged in Testing and/or Inspection of Soil and Rock as

1.3 The apparatus is suitable for measuring the properties of

Used in Engineering Design and Construction

powders with a maximum particle size of 1 mm. It is possible

D6026 Practice for Using Significant Digits in Geotechnical

to test powders which have a small proportion of particles of 1

Data

mm or greater, but they should be present in the bulk sample as

D6128 Test Method for Shear Testing of Bulk Solids Using

no more than 5 % of the total mass in samples with a normal

the Jenike Shear Cell

(Gaussian) size distribution.

D6682 Test Method for Measuring Shear Stresses of Pow-

ders Using Peschl Rotational Split Level Shear Tester

1.4 All observed and calculated values shall conform to the

D6773 Test Method for Bulk Solids Using Schulze Ring

guidelines for significant digits and rounding established in

Shear Tester

Practice D6026.

1.4.1 The procedures used to specify how data are collected/

3. Terminology

recorded or calculated, in this standard are regarded as the

3.1 Definitions—For definitions of common technical terms

industry standard. In addition, they are representative of the

in this standard, refer to Terminology D653.

significant digits that generally should be retained. The proce-

dures used do not consider material variation, purpose for

3.2 Definitions of Terms Specific to This Standard:

obtaining the data, special purpose studies, or any consider-

3.2.1 conditioning, v—in powders, the process of homog-

ations for the user’s objectives; and it is common practice to

enizing the stress of a powder specimen by use of a specialized

increase or reduce significant digits of reported data to be

blade attachment.

commensurate with these considerations. It is beyond the scope

3.2.2 wall friction coupon, n—in powders, a test piece used

of this standard to consider significant digits used in analysis

in the wall friction test that is manufactured from a material

methods for engineering design.

that represents the material of construction of the silo/bin/

hopper that stores the powder.

1

This test method is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.24 on Characterization 4. Summary of Test Method

and Handling of Powders and Bulk Solids.

4.1 Selection of the Appropriate Testing Regime—The par-

Current edition approved March 1, 2015. Published March 2015. DOI: 10.1520/

D7891-15. ticular consolidating stress level or levels used to evaluate the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7891 − 15

dependent on the competence of the personnel performing it, and the

flow properties of the powder will depend on the reason for

suitability of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.