ASTM D246-04

(Test Method)Standard Test Method for Distillation of Creosote and Creosote-Coal Tar Solutions

Standard Test Method for Distillation of Creosote and Creosote-Coal Tar Solutions

SCOPE

1.1 This test method covers a procedure for the distillation of creosote and creosote-coal tar solution. Test Methods D38 covers the sampling of wood preservatives prior to testing.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

Designation: D 246 – 04 Highway Transportation Officials Standard

AASHTO No. T 62

Standard Test Method for

1

Distillation of Creosote and Creosote-Coal Tar Solutions

This standard is issued under the fixed designation D 246; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers a procedure for the distillation 4.1 Creosote quality is defined by the boiling ranges of its

of creosote and creosote-coal tar solution. Test Methods D 38 distillation fractions. The boiling limits of the fractions as

covers the sampling of wood preservatives prior to testing. determined by this test method must conform to the limits

1.2 This standard does not purport to address all of the established by Specifications D 390 and D 391 to qualify the

safety concerns, if any, associated with its use. It is the creosote as an acceptable preservative for its intended appli-

responsibility of the user of this standard to establish appro- cation.

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use.

5.1 Flask—Distillation flask, 300 mL, specified as Type II,

2. Referenced Documents

Class 2 in Specification E 1405.

2

2.1 ASTM Standards: 5.2 Condenser Tube—A tapered glass condenser, as shown

D 38 Test Methods for Sampling Wood Preservatives Prior in Figs. 1 and 2, conforming to the following dimensions:

to Testing

Diameter of small end, outside 12.5 6 1.5 mm

Diameter of large end, outside 28.5 6 3.0 mm

D 370 Practice for Dehydration of Oil-Type Preservatives

Length 360 64mm

D 390 Specification for Coal-Tar Creosote for the Preserva-

Length of tapered part 100 65mm

tive Treatment of Piles, Poles, and Timbers for Marine,

5.3 Source of Heat—A source of heat consisting of a

Land, and Freshwater Use

Bunsen or Meker type gas burner or an electric heater. The

D 391 Specification for Creosote-Coal Tar Solution

3

electric heater shall have an output variable to 600 or 750 W

E 1 Specification for ASTM Liquid-in-Glass Thermometers

and removable upper and lower refractories as illustrated in

E 1404 Specification for Laboratory Glass Conical Flasks

Fig. 3. The temperature of the heater shall be controlled by a

E 1405 Specification for Laboratory Glass Distillation

variable transformer or rheostat suitable for the voltage used,

Flasks

and shall be fitted with a clamp for mounting on a vertical

3. Summary of Test Method support rod.

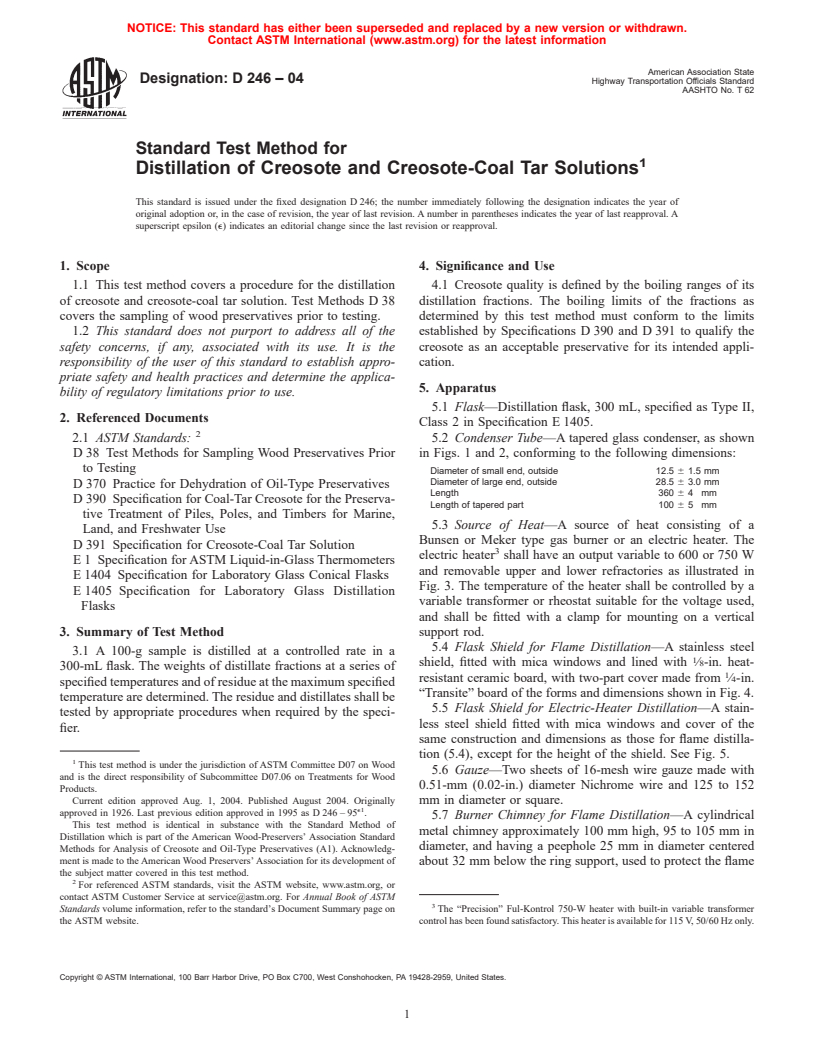

5.4 Flask Shield for Flame Distillation—A stainless steel

3.1 A 100-g sample is distilled at a controlled rate in a

1

shield, fitted with mica windows and lined with ⁄8-in. heat-

300-mL flask. The weights of distillate fractions at a series of

1

resistant ceramic board, with two-part cover made from ⁄4-in.

specified temperatures and of residue at the maximum specified

“Transite” board of the forms and dimensions shown in Fig. 4.

temperature are determined. The residue and distillates shall be

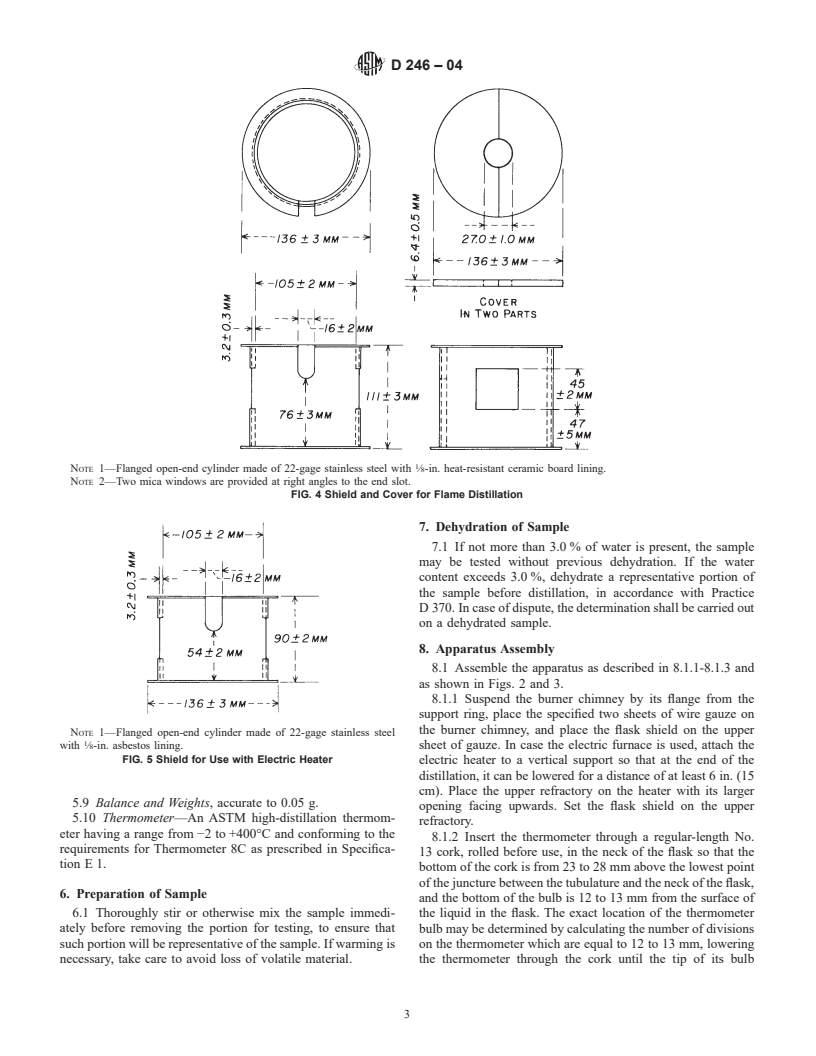

5.5 Flask Shield for Electric-Heater Distillation—A stain-

tested by appropriate procedures when required by the speci-

less steel shield fitted with mica windows and cover of the

fier.

same construction and dimensions as those for flame distilla-

tion (5.4), except for the height of the shield. See Fig. 5.

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood

5.6 Gauze—Two sheets of 16-mesh wire gauze made with

and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood

0.51-mm (0.02-in.) diameter Nichrome wire and 125 to 152

Products.

Current edition approved Aug. 1, 2004. Published August 2004. Originally

mm in diameter or square.

e1

approved in 1926. Last previous edition approved in 1995 as D 246 – 95 .

5.7 Burner Chimney for Flame Distillation—A cylindrical

This test method is identical in substance with the Standard Method of

metal chimney approximately 100 mm high, 95 to 105 mm in

Distillation which is part of the American Wood-Preservers’ Association Standard

diameter, and having a peephole 25 mm in diameter centered

Methods for Analysis of Creosote and Oil-Type Preservatives (A1). Acknowledg-

ment is made to the American Wood Preservers’ Association for its development of

about 32 mm below the ring support, used to protect the flame

the subject matter covered in this test method.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The “Precision” Ful-Kontrol 750-W heater with bu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.