ASTM D1066-97(2001)

(Practice)Standard Practice for Sampling Steam

Standard Practice for Sampling Steam

SCOPE

1.1 This practice covers the sampling of saturated and superheated steam. It is applicable to steam produced in fossil fired and nuclear boilers or by any other process means that is at a pressure sufficiently above atmospheric to establish representative sample flow. It is also applicable to steam at lower and subatmospheric pressures for which means must be provided to establish representative flow.

1.2 For information on specialized sampling equipment, tests or methods of analysis, reference should be made to the Annual Book of ASTM Standards, Vols 11.01 and 11.02, relating to water.

1.3 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents. Therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D1066–97 (Reapproved 2001)

Standard Practice for

Sampling Steam

This standard is issued under the fixed designation D 1066; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 5540 PracticesforFlowControlandTemperatureControl

for On-Line Water Sampling and Analysis

1.1 This practice covers the sampling of saturated and

superheated steam. It is applicable to steam produced in fossil

3. Terminology

fired and nuclear boilers or by any other process means that is

3.1 Definitions:

at a pressure sufficiently above atmospheric to establish repre-

3.1.1 For definitions of terms used in this practice, refer to

sentative sample flow. It is also applicable to steam at lower

definitions given in Practice D 1129.

and subatmospheric pressures for which means must be pro-

3.2 Definitions of Terms Specific to This Standard:

vided to establish representative flow.

3.2.1 isokinetic sampling—a condition wherein the velocity

1.2 For information on specialized sampling equipment,

of the sample entering the port or ports of the sample nozzle(s)

tests or methods of analysis, reference should be made to the

is the same as the velocity in the stream being sampled.

Annual Book of ASTM Standards, Vols 11.01 and 11.02,

,

2 3 3.2.2 sample cooler—a small heat exchanger designed to

relating to water.

provide cooling/condensing of small process sampling streams

1.3 The values stated in either inch-pound units or SI units

of water or steam.

are to be regarded as standard. Within the text, the inch-pound

3.2.3 sampling—the withdrawal of a representative portion

units are shown in parentheses. The values stated in each

of the steam flowing in the boiler drum lead or pipeline by

system are not exact equivalents. Therefore, each system must

means of a sampling nozzle and the delivery of this portion of

be used independently of the other. Combining values from the

steam in a representative manner for analysis.

two systems may result in nonconformance with this specifi-

3.2.4 saturated steam—a vapor whose temperature corre-

cation.

sponds to the boiling water temperature at the particular

1.4 This standard does not purport to address all of the

existing pressure.

safety concerns, if any, associated with its use. It is the

3.2.5 superheated steam—a vapor whose temperature is

responsibility of the user of this standard to establish appro-

above the boiling water temperature at the particular existing

priate safety and health practices and determine the applica-

pressure.

bility of regulatory limitations prior to use.

4. Summary of Practice

2. Referenced Documents

4.1 This practice describes the apparatus, design concepts

2.1 ASTM Standards:

and procedures to be used in extracting and transporting

A 269 Specification for Seamless and Welded Austenitic

4 samples of saturated and superheated steam. Extraction nozzle

Stainless Steel Tubing for General Service

selection and application, line sizing, condensing requirements

A 335/A 335M Specification for Seamless Ferritic Alloy-

4 and optimization of flow rates are all described in detail.

Steel Pipe for High Temperature Service

3 Condensed steam samples should be handled in accordance

D 1129 Terminology Relating to Water

3 with Practices D 3370 and D 5540.

D 3370 Practices for Sampling Water in Closed Conduits

5. Significance and Use

5.1 It is essential to sample steam representatively in order

This practice is under the jurisdiction ofASTM Committee D19 on Water , and

is the direct responsibility of Subcommittee D19.03 on Sampling of Water and

to determine the amount of impurities, including moisture, in

Water-Formed Deposits, Surveillance of Water and Flow Measurement of Water

it. An accurate measure of the purity of steam provides

Samples.

information, which may be used to determine whether the

Current edition approved July 10, 1997. Published October 1997. Originally

published as D1066-49T. Last previous edition D1066-82 (1990). purity of the steam is within necessary limits to prevent

Annual Book of ASTM Standards, Vol 11.01.

damage or deterioration of subsequent equipment, such as

Annual Book of ASTM Standards, Vol 11.02.

turbines, etc. Impurities in the steam may be derived from

Annual Book of ASTM Standards, Vol 01.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1066–97 (2001)

FIG. 1 Effect of Nono-Isokinetic Sampling

boiler water carryover, inefficient steam separators, natural salt decreasedandthecontaminantsdepositontheinnersurfacesof

solubility in the steam and other factors. the sample line (3). This condition has been found to be

prevalent only in regions of dry wall tube where the tempera-

6. Interferences

ture of the tube wall exceeds the saturation temperature of the

steam.

6.1 Saturated Steam— Sampling of steam presents difficult

extractionandtransportproblemsthataffecttherepresentative- 6.2.1 Interference also occurs when the transport tube tem-

perature is at or below the saturation temperature. The steam

ness of the sample.

6.1.1 Isokinetic sampling requires that the velocity of the loses superheat and dissolved contaminants deposit on the tube

wall. The sample is no longer representative. Superheated

fluid entering the sample nozzle port(s) is the same as the

velocity of the stream being sampled at the location of the steam samples shall be cooled or desuperheated in the sample

nozzle or immediately after extraction to ensure a representa-

sample nozzle. When the sample is not extracted isokinetically

the contaminants in the steam are not properly represented in tive sample. See 7.1.3.3 and 7.2.4.

the sample. The effects of non-isokinetic sampling are illus-

7. Materials and Apparatus

trated in Fig. 1 and can make the sample unrepresentative.

7.1 Extracting the Sample:

6.1.2 Traditionally, saturated steam samples with initial

7.1.1 Saturated Steam— Since saturated steam is normally

steam velocities above 11m/s (36f/s) were considered to

sampled as a two-phase fluid, made up of steam and small

provide adequate turbulent flow to ensure transport of most

droplets of water, isokinetic sampling shall be employed. Since

particulates and ionic components. More recent studies (1)(2)

steam velocities vary with boiler load it normally is not

find that because many sample lines are long and uninsulated,

practical to sample isokinetically throughout the load range.

steam samples are frequently fully condensed prior to reaching

Normally, the load of interest is full load or a guaranteed

thesamplestation.Partiallyorfullycondensedsamplesusually

overload. The sampling system shall be designed to provide

have a velocity too low to prevent excessive deposition and the

isokinetic sampling at this design load.

sample becomes nonrepresentative of the source. Detailed

7.1.1.1 At low velocities, the moisture in wet steam forms a

design of the sample line to control vapor and liquid velocity

film along the inside surface of the steam line that entrains

can minimize this interference but cooling of saturated steam

impurities(4).Table1showstheminimumsteamflowrequired

samples at the source is recommended to assure a representa-

for representative samples at various steam pressures.

tive sample. See Practice D 3370 for further information on

7.1.2 Superheated Steam—Superheated steam is usually

factors that affect liquid sample transport.

regarded as a single phase fluid. Unless particulates are being

6.2 Superheated Steam—Most contaminants can be dis-

measured, isokinetic sampling is not required. Most impurities

solved in superheated steam. However as steam pressure and

in superheated steam are present in vaporous form and are

temperature are reduced the solubility of many contaminants is

thoroughly mixed with the steam vapor. However, an oxide

layer forms on the steam side of superheater and reheater lines

and gets thicker with increased service. Since the physical

The boldface numbers given in parentheses refer to a list of references at the

end of this standard. properties of the oxide are different from the parent metal,

D1066–97 (2001)

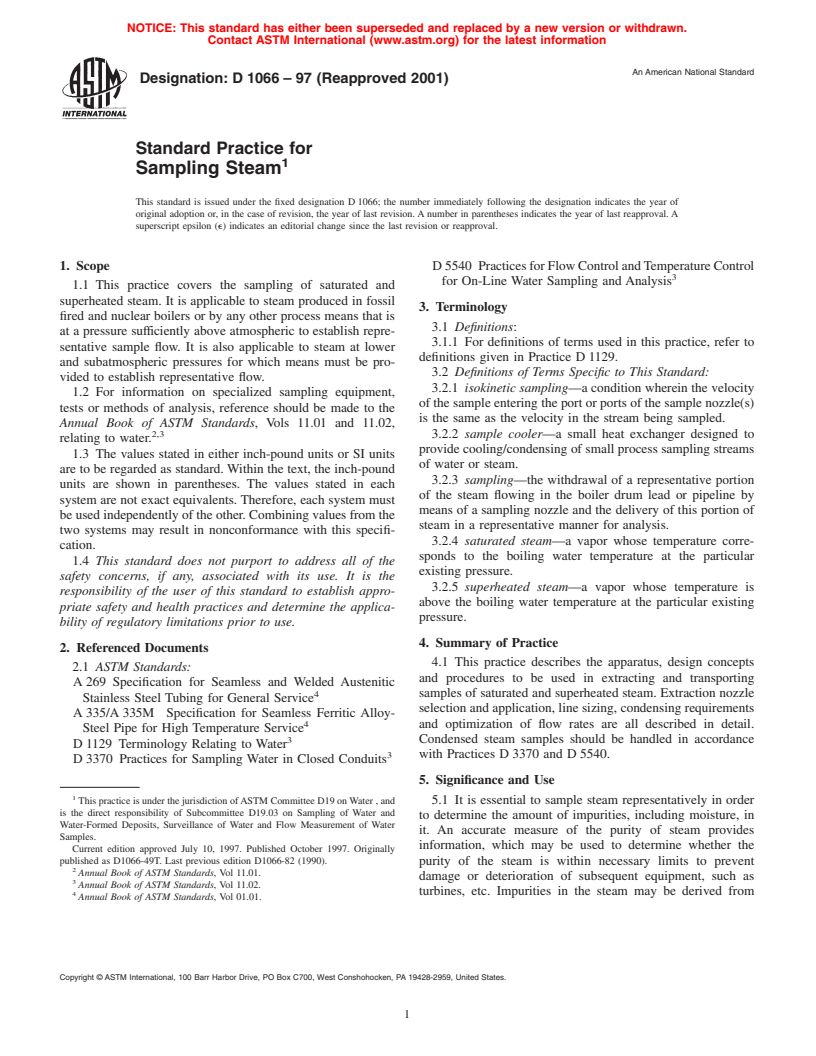

TABLE 1 Minimum Saturated Steam Line Conditions at Point of

Sampling

Saturated Steam Pressure Minimum Steam Flow

psig (kPa) ft/s (m/s)

100 (690) 195 (59.6)

200 (1379) 141 (42.8)

300 (2068) 114 (34.8)

400 (2758) 95 (29.1)

500 (3447) 83 (25.3)

700 (4826) 70 (21.2)

1000 (6895) 54 (16.6)

1500 (10342) 36 (11.0)

2000 (13790) 26 (7.9)

2500 (17237) 18 (5.5)

2800 (19300) 13 (4.1)

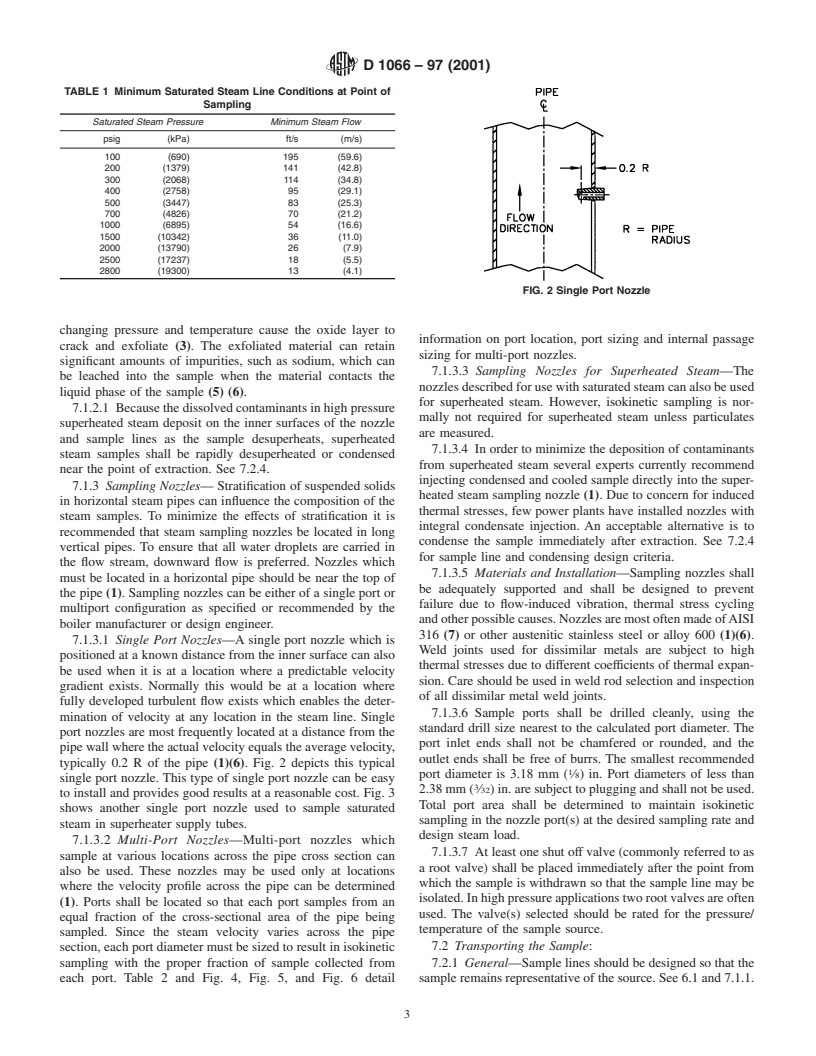

FIG. 2 Single Port Nozzle

changing pressure and temperature cause the oxide layer to

information on port location, port sizing and internal passage

crack and exfoliate (3). The exfoliated material can retain

sizing for multi-port nozzles.

significant amounts of impurities, such as sodium, which can

7.1.3.3 Sampling Nozzles for Superheated Steam—The

be leached into the sample when the material contacts the

nozzles described for use with saturated steam can also be used

liquid phase of the sample (5) (6).

for superheated steam. However, isokinetic sampling is nor-

7.1.2.1 Because the dissolved contaminants in high pressure

mally not required for superheated steam unless particulates

superheated steam deposit on the inner surfaces of the nozzle

are measured.

and sample lines as the sample desuperheats, superheated

7.1.3.4 In order to minimize the deposition of contaminants

steam samples shall be rapidly desuperheated or condensed

from superheated steam several experts currently recommend

near the point of extraction. See 7.2.4.

injecting condensed and cooled sample directly into the super-

7.1.3 Sampling Nozzles— Stratification of suspended solids

heated steam sampling nozzle (1). Due to concern for induced

in horizontal steam pipes can influence the composition of the

thermal stresses, few power plants have installed nozzles with

steam samples. To minimize the effects of stratification it is

integral condensate injection. An acceptable alternative is to

recommended that steam sampling nozzles be located in long

condense the sample immediately after extraction. See 7.2.4

vertical pipes. To ensure that all water droplets are carried in

for sample line and condensing design criteria.

the flow stream, downward flow is preferred. Nozzles which

7.1.3.5 Materials and Installation—Sampling nozzles shall

must be located in a horizontal pipe should be near the top of

be adequately supported and shall be designed to prevent

the pipe (1). Sampling nozzles can be either of a single port or

failure due to flow-induced vibration, thermal stress cycling

multiport configuration as specified or recommended by the

andotherpossiblecauses.NozzlesaremostoftenmadeofAISI

boiler manufacturer or design engineer.

316 (7) or other austenitic stainless steel or alloy 600 (1)(6).

7.1.3.1 Single Port Nozzles—A single port nozzle which is

Weld joints used for dissimilar metals are subject to high

positioned at a known distance from the inner surface can also

thermal stresses due to different coefficients of thermal expan-

be used when it is at a location where a predictable velocity

sion. Care should be used in weld rod selection and inspection

gradient exists. Normally this would be at a location where

of all dissimilar metal weld joints.

fully developed turbulent flow exists which enables the deter-

7.1.3.6 Sample ports shall be drilled cleanly, using the

mination of velocity at any location in the steam line. Single

standard drill size nearest to the calculated port diameter. The

port nozzles are most frequently located at a distance from the

port inlet ends shall not be chamfered or rounded, and the

pipe wall where the actual velocity equals the average velocity,

outlet ends shall be free of burrs. The smallest recommended

typically 0.2 R of the pipe (1)(6). Fig. 2 depicts this typical

port diameter is 3.18 mm ( ⁄8) in. Port diameters of less than

single port nozzle. This type of single port nozzle can be easy

2.38 mm ( ⁄32) in. are subject to plugging and shall not be used.

to install and provides good results at a reasonable cost. Fig. 3

Total port area shall be determined to maintain isokinetic

shows another single port nozzle used to sample saturated

sampling in the nozzle port(s) at the desired sampling rate and

steam in superheater supply tubes.

design steam load.

7.1.3.2 Multi-Port Nozzles—Multi-port nozzles which

7.1.3.7 At least one shut off valve (commonly referred to as

sample at various locations across the pipe cross section can

a root valve) shall be placed immediately after the point from

also be used. These nozzles may be used only at locations

which the sample is withdrawn so that the sample line may be

where the velocity profile across the pipe can be determined

isolated. In high pressure applications two root valves are often

(1). Ports shall be located so that each port samples from an

used. The valve(s) selected should be rated for the pressure/

equal fraction of the cross-sectional area of the pipe being

temperature of the sample source.

sampled. Since the steam velocity varies across the pipe

7.2 Transporting the Sample:

section, each port diameter must be sized to result in isokinetic

sampling with the proper fraction of sample collected from 7.2.1 General—Sample lines should be designed so that the

each port. Table 2 and Fig. 4, Fig. 5, and Fig. 6 detail sample remains representative of the source. See 6.1 and 7.1.1.

D1066–97 (2001)

NOTE 1—Sampling nozzle shall be centered on superheater supply tube.

FIG. 3 Steam Sampling Nozzle, Single-Port Type

TABLE 2 Calculations for Steam Sampling Nozzles for Lines 6 in. (152 mm) and Larger, Equal Size Ports, Unequally Spaced

Nominal pipe size ________ in. ________ cm

D = Pipe OD ________ in. ________ cm

o

D = Pipe ID ________ in. ________ cm

T = Pipe wall thickness ________ in. ________ cm

N = Total number of ports ________

Radii of port circles:

r =(D /2) 1/N ________ in. ________ cm

=

1 1

r =(D /2) 3/N ________ in. ________ cm

=

2 1

r =(D /2) =5/N ________ in. ________ cm

3 1

F = Flow rate of fluid through pipe ________ lb/h ________ m/s

f = Flow rate of total sample extracted ________ lb/h ________ m/s

2 2

A = Traverse area of pipe = 0.7854 D ________ in. ________ cm

2 2

a = Total port area = Af/F ________ in ________ cm

A

________ in. ________ cm

d = Diameter of ports = =a/0.7854N

Use ____ drill Use ____ drill

________ in. ________ cm

b = Diameter of nozzle bore = =3a/1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.