ASTM D3120-96

(Test Method)Standard Test Method for Trace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative Microcoulometry

Standard Test Method for Trace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative Microcoulometry

SCOPE

1.1 This test method covers the determination of sulfur in the range from 3.0 to 100 ppm ([mu]g/g) in light liquid hydrocarbons boiling in the range from 26 to 274°C (80 to 525°F).

1.2 This test method may be extended to liquid materials with higher sulfur concentrations by appropriate dilution.

1.3 The preferred units are micrograms per grams. Values stated in SI units are to be regarded as the standard. Values in inch-pound units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.3, 6.4, 6.8, and 6.10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3120–96

Standard Test Method for

Trace Quantities of Sulfur in Light Liquid Petroleum

1

Hydrocarbons by Oxidative Microcoulometry

This standard is issued under the fixed designation D3120; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Significance and Use

1.1 This test method covers the determination of sulfur in 3.1 This test method is used to determine trace quantities of

the range from 3.0 to 100 ppm (µg/g) in light liquid hydrocar- sulfur in reformer charge stocks and similar petroleum frac-

bons boiling in the range from 26 to 274°C (80 to 525°F). tions where such trace concentrations of sulfur are deleterious

1.2 This test method may be extended to liquid materials to the performance and life of the catalyst used in the process.

with higher sulfur concentrations by appropriate dilution. Higher concentrations of sulfur in products analyzed by this

1.3 The preferred units are micrograms per grams. Values test method after appropriate dilution are often detrimental to

stated in SI units are to be regarded as the standard. Values in the use of the product.

inch-pound units are for information only.

4. Interferences

1.4 This standard does not purport to address all of the

4.1 This test method is applicable in the presence of total

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- halideconcentrationsofupto10timesthesulfurlevelandtotal

nitrogen concentrations of up to 1000 times the sulfur level.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard 4.2 This test method is not applicable in the presence of

total heavy metal concentrations (for example, Ni, V, Pb, etc.)

statements, see 6.3, 6.4, 6.8, and 6.10.

in excess of 500 µg/g (ppm).

2. Summary of Test Method

NOTE 1—To attain the quantitative detectability that the method is

2.1 A liquid sample is injected into a combustion tube

capable of, stringent techniques must be employed and all possible

maintained at about 800°C having a flowing stream of gas

sources of sulfur contamination must be eliminated.

containing about 80 % oxygen and 20 % inert gas (for

2

5. Apparatus

example, nitrogen, argon, etc.). Oxidative pyrolysis converts

thesulfurtosulfurdioxidewhichthenflowsintoatitrationcell

5.1 Pyrolysis Furnace—The sample should be pyrolyzed in

where it reacts with triiodide ion present in the electrolyte.The

an electric furnace having at least two separate and indepen-

triiodide thus consumed, is coulometrically replaced and the

dently controlled temperature zones, the first being an inlet

total current required to replace it is a measure of the sulfur

section that can maintain a temperature sufficient to volatilize

present in the sample injected.

all the organic sample. The second zone shall be a pyrolysis

2.2 The reaction occurring in the titration cell as sulfur

section that can maintain a temperature sufficient to pyrolyze

dioxide enters is:

theorganicmatrixandoxidizealltheorganicallyboundsulfur.

2 2 1 A third outlet temperature zone is optional.

I 1 SO 1 H O→ SO 13I 12H (1)

3 2 2 3

5.1.1 Pyrolysis furnace temperature zones for light liquid

The triiodide ion consumed in the above reaction is gener-

petroleum hydrocarbons should be variable as follows:

ated coulometrically thus:

Inlet zone up to at least 700°C

2 2 2

Center pyrolysis zone 800 to 1000°C

3I → I 12e (2)

3

Outlet zone (optional) up to at least 800°C

2.3 Thesemicroequivalentsoftriiodide(iodine)areequalto

the number of microequivalents of titratable sample ion enter-

ing the titration cell.

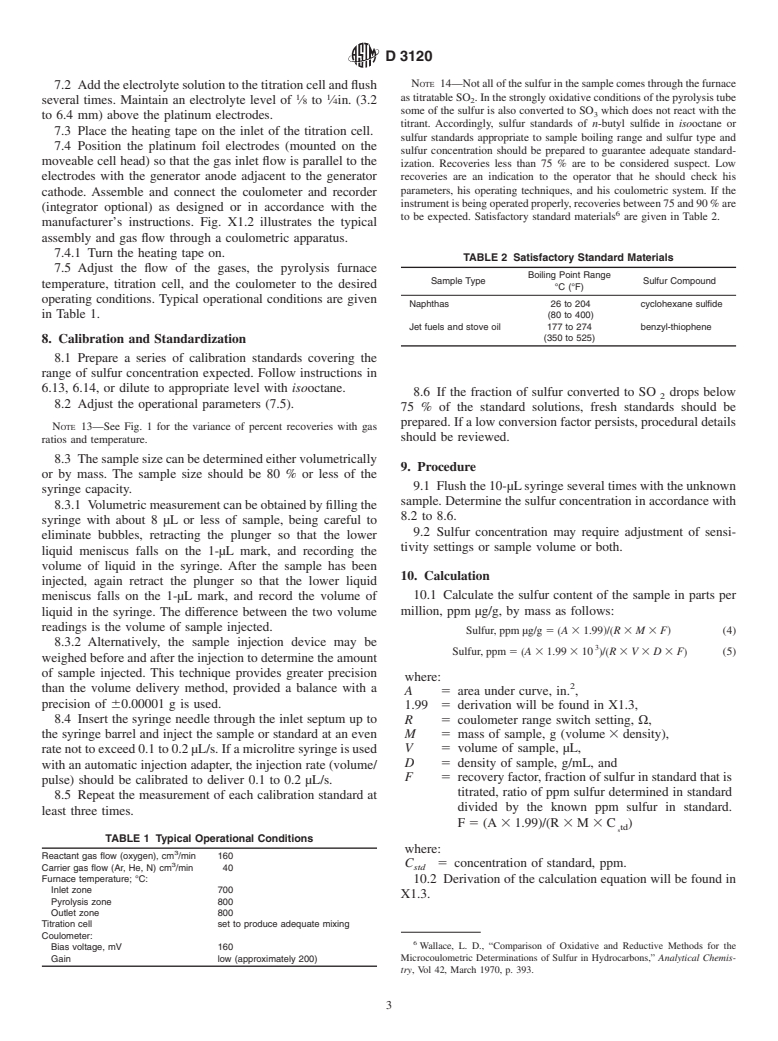

2

The apparatus described in Sections 5.1 to 5.5 inclusive, is similar in

1

This test method is under the jurisdiction of ASTM Committee D-2 on specifications to equipment available from Dohrmann Div. of Rosemount, 3240

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee Scott Blvd., Santa Clara, CA95050. For further detailed discussions, in equipment,

D02.03 on Elemental Analysis. see: Preprints—Division of Petroleum Chemistry,American Chemical Society, Vol

Current edition approved Apr. 10, 1996. Published June 1996. Originally 1, No. 3, Sept. 7–12, 1969, p. B232 “Determination of Sulfur, Nitrogen, and

published as D 3120–72T. Last previous edition D 3120–92. Chlorine in Petroleum by Microcoulometry,” by Harry V. Drushel.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.