ASTM D3910-98(2004)

(Practice)Standard Practices for Design, Testing, and Construction of Slurry Seal

Standard Practices for Design, Testing, and Construction of Slurry Seal

SCOPE

1.1 These practices cover the design, testing, and construction of mixtures for surface treatment of pavements. It is written as a guide and should be used as such. End-use specifications should be adapted to conform to job and user requirements.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3910–98 (Reapproved 2004)

Standard Practices for

Design, Testing, and Construction of Slurry Seal

This standard is issued under the fixed designation D 3910; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

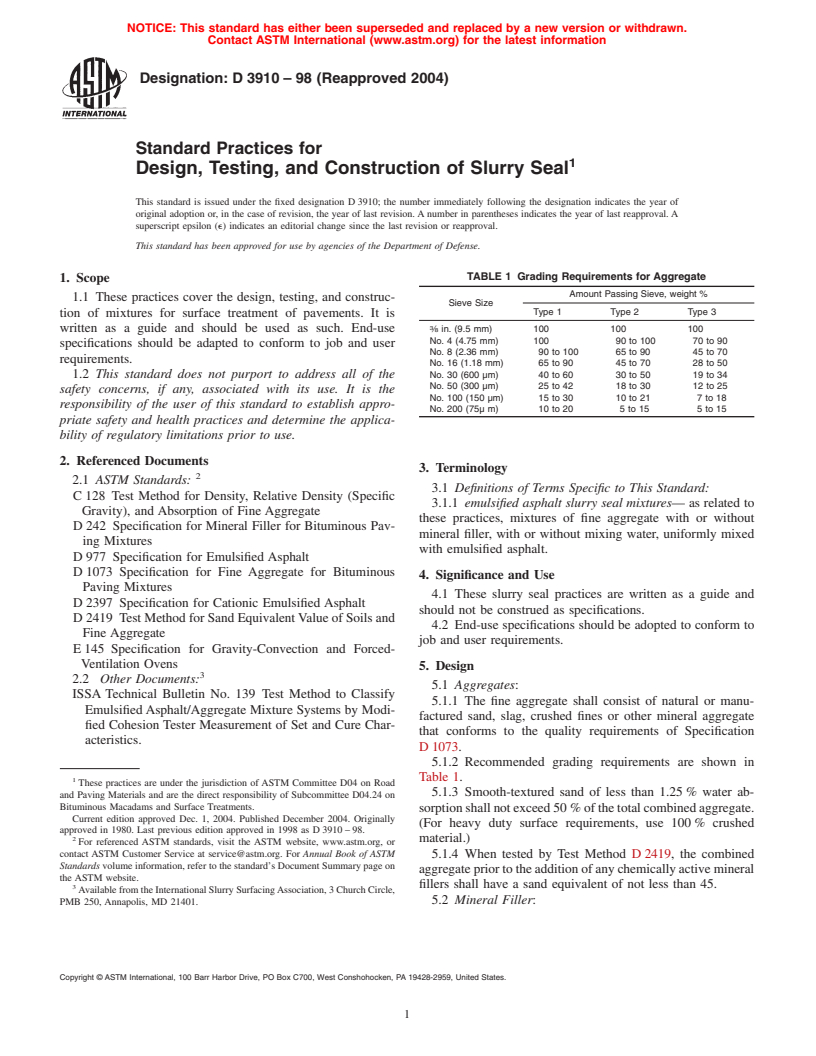

TABLE 1 Grading Requirements for Aggregate

1. Scope

Amount Passing Sieve, weight %

1.1 These practices cover the design, testing, and construc-

Sieve Size

Type 1 Type 2 Type 3

tion of mixtures for surface treatment of pavements. It is

written as a guide and should be used as such. End-use

⁄8 in. (9.5 mm) 100 100 100

No. 4 (4.75 mm) 100 90 to 100 70 to 90

specifications should be adapted to conform to job and user

No. 8 (2.36 mm) 90 to 100 65 to 90 45 to 70

requirements.

No. 16 (1.18 mm) 65 to 90 45 to 70 28 to 50

1.2 This standard does not purport to address all of the No. 30 (600 µm) 40 to 60 30 to 50 19 to 34

No. 50 (300 µm) 25 to 42 18 to 30 12 to 25

safety concerns, if any, associated with its use. It is the

No. 100 (150 µm) 15 to 30 10 to 21 7 to 18

responsibility of the user of this standard to establish appro-

No. 200 (75µ m) 10 to 20 5 to 15 5 to 15

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions of Terms Specific to This Standard:

C 128 Test Method for Density, Relative Density (Specific

3.1.1 emulsified asphalt slurry seal mixtures— as related to

Gravity), and Absorption of Fine Aggregate

these practices, mixtures of fine aggregate with or without

D 242 Specification for Mineral Filler for Bituminous Pav-

mineral filler, with or without mixing water, uniformly mixed

ing Mixtures

with emulsified asphalt.

D 977 Specification for Emulsified Asphalt

D 1073 Specification for Fine Aggregate for Bituminous

4. Significance and Use

Paving Mixtures

4.1 These slurry seal practices are written as a guide and

D 2397 Specification for Cationic Emulsified Asphalt

should not be construed as specifications.

D 2419 Test Method for Sand EquivalentValue of Soils and

4.2 End-use specifications should be adopted to conform to

Fine Aggregate

job and user requirements.

E 145 Specification for Gravity-Convection and Forced-

Ventilation Ovens

5. Design

2.2 Other Documents:

5.1 Aggregates:

ISSA Technical Bulletin No. 139 Test Method to Classify

5.1.1 The fine aggregate shall consist of natural or manu-

EmulsifiedAsphalt/Aggregate Mixture Systems by Modi-

factured sand, slag, crushed fines or other mineral aggregate

fied Cohesion Tester Measurement of Set and Cure Char-

that conforms to the quality requirements of Specification

acteristics.

D 1073.

5.1.2 Recommended grading requirements are shown in

Table 1.

These practices are under the jurisdiction of ASTM Committee D04 on Road

5.1.3 Smooth-textured sand of less than 1.25 % water ab-

and Paving Materials and are the direct responsibility of Subcommittee D04.24 on

Bituminous Macadams and Surface Treatments.

sorptionshallnotexceed50 %ofthetotalcombinedaggregate.

Current edition approved Dec. 1, 2004. Published December 2004. Originally

(For heavy duty surface requirements, use 100 % crushed

approved in 1980. Last previous edition approved in 1998 as D 3910 – 98.

2 material.)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 5.1.4 When tested by Test Method D 2419, the combined

Standards volume information, refer to the standard’s Document Summary page on

aggregatepriortotheadditionofanychemicallyactivemineral

the ASTM website.

fillers shall have a sand equivalent of not less than 45.

Available from the International Slurry SurfacingAssociation, 3 Church Circle,

5.2 Mineral Filler:

PMB 250, Annapolis, MD 21401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3910–98 (2004)

5.2.1 Mineral fillers are of two types, chemically active and mix-designedslurryshouldbesetattheendof12h.-hsettime

chemically inactive. Both shall conform to Specification is considered acceptable for a quick setting slurry (see 6.2).

D 242. 5.4.6 Cure Time—This test is used to determine initial

cohesion of slurry mat and resistance to traffic. A properly

5.2.2 Chemically active mineral fillers such as portland

designed slurry mix should be completely cured at the end of

cement, hydrated lime, and ammonium sulfate are used to

24 h after placement (see 6.3).

improve the workability, regulate the setting time and, in some

5.4.7 Wet Track Abrasion Test—This test method covers

cases, to alter the aggregate gradation.

measurement of the wearing qualities of slurry seal under wet

5.2.3 Chemically inactive mineral fillers such as limestone

abrasion conditions.

dust, flyash, and rock dust are used mainly to alter aggregate

gradation.

NOTE 1—As a guide, slurry shall not show a loss of more than 807.44

2 2

g/m (75 g/ft ).

5.3 Emulsified Asphalt—The emulsified asphalt shall con-

form to Grade SS-1h of Specification D 977, for emulsified

6. Test Methods for Emulsified Asphalt Slurry Seal

asphalt, or Grade CSS-1h of Specification D 2397, for cationic

6.1 Consistency Test:

emulsified asphalt.

6.1.1 This test method is used to determine the proper

5.3.1 Quick-Set emulsified asphalts, QS-1h and CQS-1h

consistency (mix design) for a slurry seal mixture.

may also be used. They conform to Specifications D 977 and

6.1.2 The consistency test should be performed as a method

D 2397 respectively, except that the test requirements for

of determining the optimum mix design (proper ratio of

cement mixing and storage stability shall not apply. Refer to

aggregate, filler, water, and emulsion) as related to proper

the International Slurry Surfacing Association (ISSA) Bulletin

consistencyforpavementsurfaceplacement.Severalmixesare

No. 139.

made using dried aggregate and various ratios of portland

5.4 Composition of Slurry Seal Mixtures:

cement, or hydrated lime and or chemical modifier, water and

5.4.1 A job mixture shall be selected that conforms to the

asphalt emulsion. Mix time shall be for no less than 1 min and

specification limits, and that is suitable for the traffic, climatic

not longer than 3 min when mixed at 25 6 1°C (77 6 3°F).

conditions, curing conditions, and final use.All materials to be

NOTE 2—Ideal relative humidity for this test is 50 6 5 %. Results will

used shall be pretested for their suitability in the mixture as

vary at different relative humidity values.

described in Section 6.

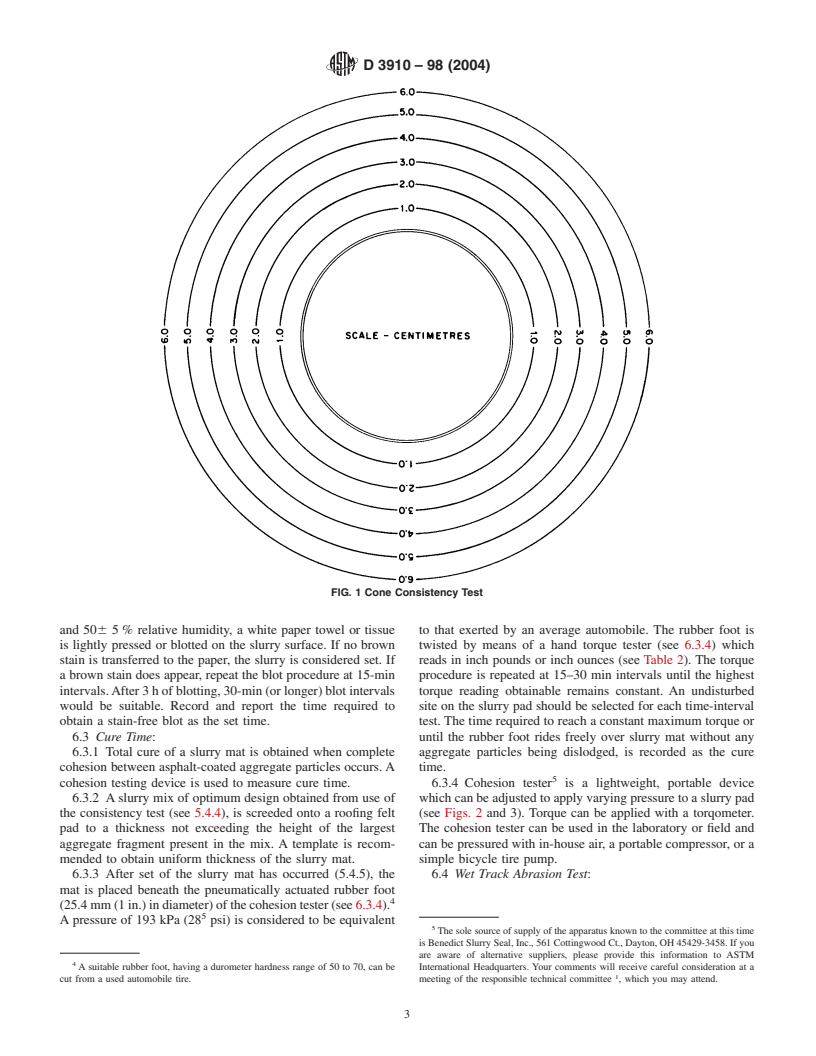

6.1.3 Mold, metal or plastic, in the form of a frustum of a

5.4.2 The mixture shall attain an initial set in not less than

1 1

cone 38 mm (1 ⁄2 in.) in diameter at the top, 89 mm (3 ⁄2 in.) in

15 min nor more than 12 h. The setting time may be regulated

diameter at the bottom and 76 mm (3 in.) in height (see Test

by the addition of mineral fillers or chemical agents.

Method C 128 and Fig. 1).

5.4.3 The mixture shall be one of three types, whose

6.1.4 The center of a 228 by 228-mm (9 by 9-in.) piece of

combined aggregates conform to the gradation requirements of

3-mm( ⁄8-in.)thickmetalplateisinscribedwithacircle89mm

Table 1.

(3 ⁄2 in.) in diameter. Three to four additional circles, each 13

5.4.3.1 Type 1 is suitable to seal cracks, fill voids, and

mm ( ⁄2 in.) greater in diameter than the preceding circle, are

correct surface erosion conditions.The residual asphalt content

inscribed on the metal plate around the center circle.

shall be from 10 to 16 weight % of dry aggregate. It shall be

2 2

NOTE 3—Plasticplatesaresubjecttoeventualcrazingandabrasionloss

applied at a rate of 3.3 to 5.4 kg/m (6 to 10 lb/yd ). This type

of the inscribed circles.

is used on airfields where surface sealing and skid resistance

are the primary needs.

6.1.5 The mold as described in 6.1.3 is loosely filled with a

test slurry mix and struck off. The mold and contents are then

5.4.3.2 Type 2 is suitable to fill surface voids, correct severe

invertedinthecenterofthemetalplateasdescribedin6.1.4by

surface erosion conditions, and provide a minimum wearing

placing the inscribed surface of the metal plate on the slurry-

surface. The residual asphalt content shall be from 7.5 to 13.5

filledconewhich,whileholdingconeandplatefirmlytogether,

weight % of dry aggregate. It shall be applied at a rate of 5.4

2 2

is quickly inverted. The mold is removed and the contents

to 8.2 kg/m (10 to 15 lb/yd ).This type is used on airfields and

allowed to flow over the inscribed circles until flow of the

pavements that are severely eroded, or have numerous cracks.

slurry stops. Project aggregate and emulsion grade are consid-

It may also be used as wearing surface on bituminous base

ered essential for proper relevancy of the method.

courses or soil-cement bases, or as a sealer on stabilized base

courses.

NOTE 4—Referenced ISSATechnical Bulletin No. 106 titled “Measure-

5.4.3.3 Type 3 is suitable to provide a new wearing surface

ment of Slurry Seal Consistency.”

or build up a crown. The residual asphalt content shall be from

6.2 Set Time:

6.5to12weight %ofdryaggregate.Itshallbeappliedatarate

6.2.1 Thistestmethodisusedtodeterminethetimerequired

2 2

of 8.2 or more kg/m (15 or more lb/yd ).

for the slurry mat to reach initial set (resistance to paper blot).

5.4.4 Consistency Test—This test is used to determine

6.2.2 The slurry mix or mixtures that provide the desired

optimum mix design for aggregate, filler, water, and emulsion.

consistency shall be repeated to determine their setting char-

A flow of 2 to 3 cm (1 in.) is considered to be the consistency

acteristics.Amix passing the consistency test is poured onto a

normally required for a workable field mix (see 6.1).

152 by 152-mm (6 by 6-in.) asphalt felt pad (13.6 kg (30 lb)

5.4.5 Set Time—This test determines the time required for roofing felt) and screeded to 6 mm ( ⁄4 in.) thickness using a

slurry to reach initial set with paper blot method. A properly 6-mm template.At the end of 15 min, at 25 6 1°C (77 6 3°F)

D3910–98 (2004)

FIG. 1 Cone Consistency Test

and 506 5 % relative humidity, a white paper towel or tissue to that exerted by an average automobile. The rubber foot is

is lightly pressed or blotted on the slurry surface. If no brown twisted by means of a hand torque tester (see 6.3.4) which

stain is transferred to the paper, the slurry is considered set. If reads in inch pounds or inch ounces (see Table 2). The torque

a brown stain does appear, repeat the blot procedure at 15-min procedure is repeated at 15–30 min intervals until the highest

intervals.After3hofblotting,30-min(orlonger)blotintervals torque reading obtainable remains constant. An undisturbed

would be suitable. Record and report the time required to site on the slurry pad should be selected for each time-interval

obtain a stain-free blot as the set time. test. The time required to reach a constant maximum torque or

6.3 Cure Time: until the rubber foot rides freely over slurry mat without any

6.3.1 Total cure of a slurry mat is obtained when complete aggregate particles being dislodged, is recorded as the cure

cohesion between asphalt-coated aggregate particles occurs.A time.

cohesion testing device is used to measure cure time. 6.3.4 Cohesion tester is a lightweight, portable device

6.3.2 Aslurry mix of optimum design obtained from use of which can be adjusted to apply varying pressure to a slurry pad

the consistency test (see 5.4.4), is screeded onto a roofing felt (see Figs. 2 and 3). Torque can be applied with a torqometer.

pad to a thickness not exceeding the height of the largest The cohesion tester can be used in the laboratory or field and

aggregate fragment present in the mix. A template is recom- can be pressured with in-house air, a portable compressor, or a

mended to obtain uniform thickness of the slurry mat. simple bicycle tire pump.

6.3.3 After set of the slurry mat has occurred (5.4.5), the 6.4 Wet Track Abrasion Test:

mat is placed beneath the pneumatically actuated rubber foot

(25.4mm(1in.)indiameter)ofthecohesiontester(see6.3.4).

A pressure of 193 kPa (28 psi) is considered to be equivalent

The sole source of supply of the apparatus known to the committee at this time

is Benedict Slurry Seal, Inc., 561 Cottingwood Ct., Dayton, OH 45429-3458. If you

are aware of alternative suppliers, please provide this information to ASTM

A suitable rubber foot, having a durometer hardness range of 50 to 70, can be International Headquarters. Your comments will receive careful consideration at a

cut from a used automobile tire. meeting of the responsible technical committee , which you may attend.

D3910–98 (2004)

TABLE 2 Pneumatic Cohesion Tester Chart

6.4.2.8 Oven,forced-draftconstanttemperaturethermostati-

kPa (psi on foot) cally controlled at 60 6 3°C (1406 5°F) see Specification

psi (on gage) psi (on foot)

multiplied by 6.894

E 145 Type II B.

4.5 5 34.5

6.4.2.9 Water Bath, constant-temperature, controlled at 256

8.9 10 68.9

1°C (77 6 2°F).

13.3 15 103.4

,

5 7

6.4.2.10 Reinforced Rubber Hose, with a 19-mm ( ⁄4-in.)

17.7 20 137.9

22.1 25 172.4

inside diameter and 31-mm (1 ⁄32-in.) outside diameter (two

24.8 28 193.0

braid, 300 psi, green oil-resistant cover). The hose shall be cut

26.6 30 206.8

into 127-mm (5-in.) lengths and drilled with two paired 9-mm

31.0 35 241.3

35.4 40 275.8

( ⁄8-in.) holes aligned on 102-mm (4-in.) centers. Drill holes

39.9 45 310.2

through convex and concave sides of hose.

44.3 50 344.7

6.4.2.11 Wooden Prop Block or equivalent for supporting

platform assembly into position during testing (see Fig. 7 and

Fig. 8).

6.4.1 Summary of Test Method:

6.4.3 Preparation of Test Specimen:

6.4.1.1 A slurry mixture of fine graded aggregate, asphalt

6.4.3.1 The proper ratio of portland cement (or hydrated

emulsion, and water is prepared to a homogeneous flowing

lime or other additives), water, and asphalt emulsion to the dry

consistency (see consistency test). The slurry is formed into a

weight of the aggregate shall be predetermined in the labora-

disk by pouring in the circular opening of a poly(methyl)

tory or by a functional field mix design previously accepted by

methacrylate (PMMA) template resting on a larger circlet of

project engineer.

13.62-kg (30-lb) roofing felt.

6.4.3.2 Quarter a sufficient amount of the air-dried aggre-

6.4.1.2 After removal of the template, the disk-shaped

gate passing No. 4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.