ASTM D5306-92(2018)

(Test Method)Standard Test Method for Linear Flame Propagation Rate of Lubricating Oils and Hydraulic Fluids

Standard Test Method for Linear Flame Propagation Rate of Lubricating Oils and Hydraulic Fluids

SIGNIFICANCE AND USE

5.1 The linear flame propagation rate of a sample is a property that is relevant to the overall assessment of the flammability or relative ignitability of fire resistance lubricants and hydraulic fluids. It is intended to be used as a bench-scale test for distinguishing between the relative resistance to ignition of such materials. It is not intended to be used for the evaluation of the relative flammability of flammable, extremely flammable, or volatile fuels, solvents, or chemicals.

SCOPE

1.1 This test method covers the determination of the linear flame propagation rates of lubricating oils and hydraulic fluids supported on the surfaces of and impregnated into ceramic fiber media. Data thus generated are to be used for the comparison of relative flammability.

1.2 This test method should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test method may be used as elements of fire risk which takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5306 − 92 (Reapproved 2018)

Standard Test Method for

Linear Flame Propagation Rate of Lubricating Oils and

Hydraulic Fluids

This standard is issued under the fixed designation D5306; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the determination of the linear

2.2 Military Specifications:

flame propagation rates of lubricating oils and hydraulic fluids

MIL-H-83282C Hydraulic Fluid, Fire Resistant, Synthetic

supported on the surfaces of and impregnated into ceramic

Hydrocarbon Base, Aircraft NATO Code Number H-537

fiber media. Data thus generated are to be used for the

MIL-H-46170B Amm.1, Hydraulic Fluid, Rust Inhibited,

comparison of relative flammability.

Fire Resistant, Synthetic Hydrocarbon Base

1.2 Thistestmethodshouldbeusedtomeasureanddescribe

the properties of materials, products, or assemblies in response

3. Terminology

to heat and flame under controlled laboratory conditions and

3.1 Definitions of Terms Specific to This Standard:

shouldnotbeusedtodescribeorappraisethefirehazardorfire

3.1.1 linear flame propagation rate, n—the average quotient

risk of materials, products, or assemblies under actual fire

of the distance of flame travel and the time required for the

conditions.However,resultsofthistestmethodmaybeusedas

flame front to travel that distance.

elements of fire risk which takes into account all of the factors

that are pertinent to an assessment of the fire hazard of a

4. Summary of Test Method

particular end use.

4.1 A section of a ceramic fiber support medium (string) is

1.3 The values stated in SI units are to be regarded as

impregnated with the sample under specific conditions. The

standard. No other units of measurement are included in this

impregnated fiber is placed on a standard support. The sample

standard.

is ignited and the time required for the flame front to propagate

1.4 This standard does not purport to address all of the

across a measured distance is determined by use of a thermo-

safety concerns, if any, associated with its use. It is the

electricsystem.Theaveragepropagationrateisthencalculated

responsibility of the user of this standard to establish appro-

from the measured distance of flame travel and the time

priate safety, health, and environmental practices and deter-

required for the flame front to propagate over that distance.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

5. Significance and Use

dance with internationally recognized principles on standard-

5.1 The linear flame propagation rate of a sample is a

ization established in the Decision on Principles for the

property that is relevant to the overall assessment of the

Development of International Standards, Guides and Recom-

flammability or relative ignitability of fire resistance lubricants

mendations issued by the World Trade Organization Technical

and hydraulic fluids. It is intended to be used as a bench-scale

Barriers to Trade (TBT) Committee.

test for distinguishing between the relative resistance to igni-

tion of such materials. It is not intended to be used for the

2. Referenced Documents

evaluationoftherelativeflammabilityofflammable,extremely

2.1 ASTM Standards:

flammable, or volatile fuels, solvents, or chemicals.

This test method is under the jurisdiction of ASTM Committee D02 on 6. Apparatus

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

6.1 Apparatus for measurement of linear flame propagation

Subcommittee D02.N0 on Hydraulic Fluids.

Current edition approved Oct. 1, 2018. Published November 2018. Originally rates:

approved in 1992. Last previous edition approved in 2013 as D5306 – 92 (2013).

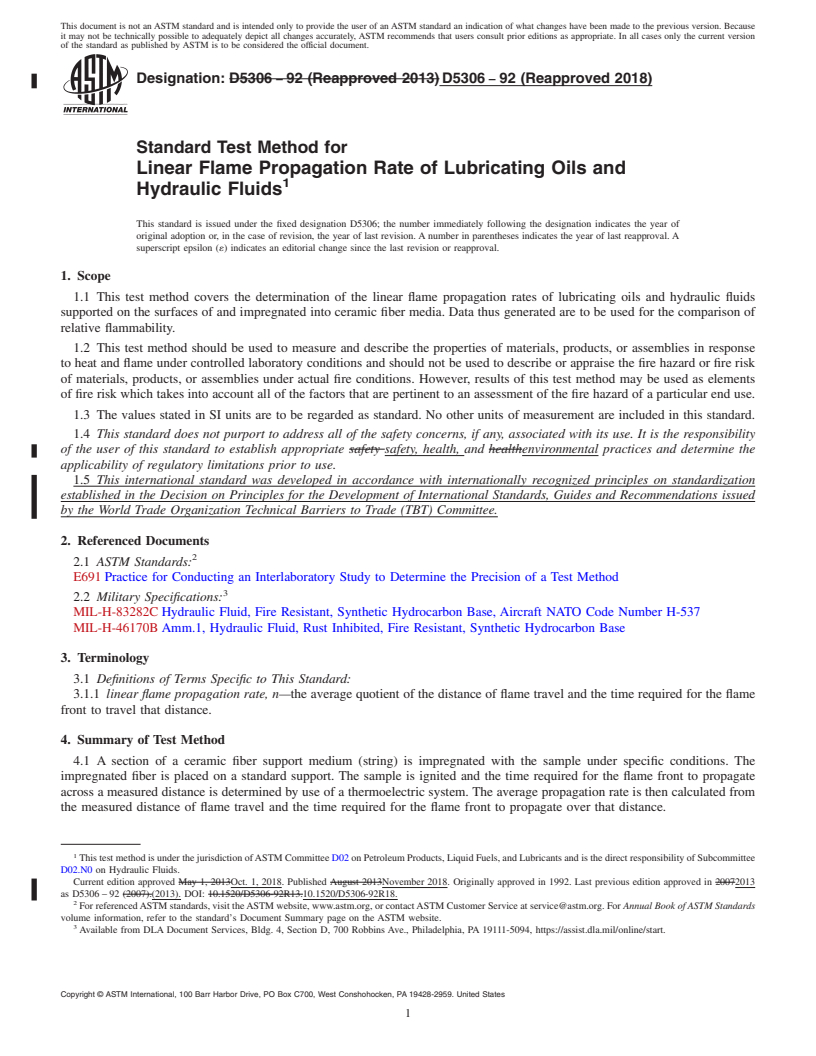

6.1.1 Open Top Stainless Steel Box, as shown in Fig. 1.

DOI: 10.1520/D5306-92R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Bldg. 4, Section D, 700 Robbins

the ASTM website. Ave., Philadelphia, PA 19111-5094, https://assist.dla.mil/online/start.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5306 − 92 (2018)

8.2 While the ceramic fiber support (string) is immersed in

thesample,carefullywrapanabsorbentpaperwiperaroundthe

15 mm diameter chrome plated rod. Leave one end of the rod

uncovered by the wiper.

8.3 Remove the ceramic fiber support (string) section from

the liquid sample and attach a 50 g weight to the loop at each

end. Fix the chrome-plated rod with its absorbent paper

wrapping in a horizontal position and hang the soaked string

section with attached weights over the unwrapped section of

the rod. Press down gently on the uppermost weight to cause

the soaked string to pass over the bare rod, flexing gently as it

moves. When the lower weight has been drawn up to the rod,

reverse the process until the first weight has again been drawn

FIG. 1 Apparatus for Determination of Linear Flame Propagation up the rod. Repeat the cycle four times to work the sample

Rates

thoroughly into the string.

8.4 Transfer the string with attached weights to the covered

portion of the chrome-plated rod. Pass the string over the

absorbent paper in the manner described in 8.3. After each

6.1.2 Recorder, stripchart, fast responses. A zero-centered

complete double cycle, lift the string from the paper, rotate it

recorder with a 65 mV range and a one-half second full-scale

through 180° as it is held taut in a vertical position and then

deflection capacity has been found to be satisfactory. A chart

replace it on a fresh area of the absorbent medium.Again pass

speed of at least 1 in.⁄min has been used for most studies.

thestringoverthepaperinthemannerdescribedin8.3.Repeat

6.1.3 Differential Thermocouple Pair, 30 gauge with bare

until four double cycles have been completed.

junctions and double fiberglass wrap insulation, ISA, Type J or

Type K may be prepared from any premium grade thermo- 8.5 Place the string support and thermocouple holder in a

couple wire. draft-free hood with the ventilation turned off. Level the

6.1.4 Fume Hood, draft-free when ventilation system is not apparatus with a spirit level. Place the prepared string on the

operative. string supports. The attached weights should be left in place to

6.1.5 Weights, 50 g 6 0.01 g, with attached hooks; two provide tension in the string. Adjust the differential thermo-

required. couple junctions so that they are exactly 2 mm directly above

6.1.6 Chrome-Plated Tube or Rod, 15 mm diameter by the string. Connect the differential thermocouple pair to the

375 mm long. fast-response, zero-centered strip chart recorder.

6.1.7 Porcelain or Glass Dish, approximately 135 mL ca-

8.6 Start the recorder chart after an appropriate warm-up

pacity.

period. With an ignition source, ignite the sample on the string

near its support at one end of the apparatus. Permit the flame to

7. Materials

advance along the string past each thermocouple until it

7.1 Absorbent Paper Wipers, 375 mm by 213 mm.

extinguishes itself upon reaching the opposite string support.

Stop the recorder and start the hood ventilator to exhaust the

7.2 Ceramic Fiber, twisted yarn type 390/312, 4/5, 2.72 or

combustion products of the sample. (Warning—Take extreme

type390/312,3/4,2.72.Ceramicfibersizeusedshallbeagreed

care to avoid inhalation of the combustion products as ex-

upon by supplier and consumer and shall be specified in test

tremely toxic substances are formed during the combustion of

report.

some synthetic materials, especially halogenated and

7.3 Ignition Source, any paper book matches or wooden

phosphorus-based compounds.)

kitchen matches can be used.

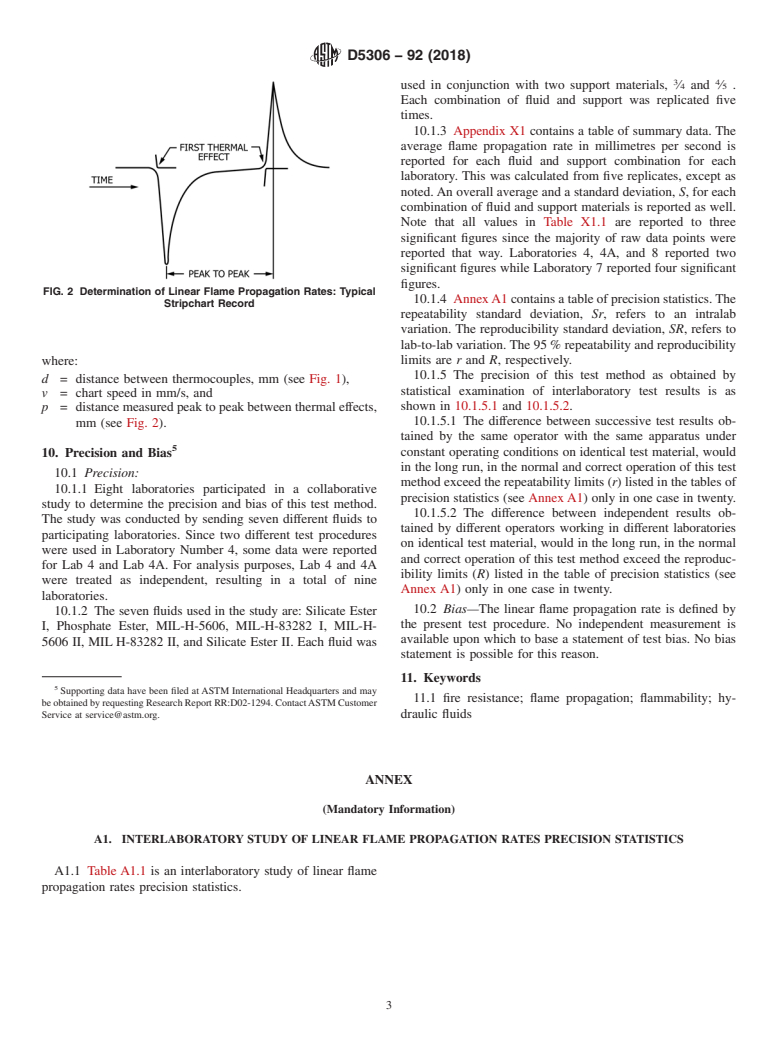

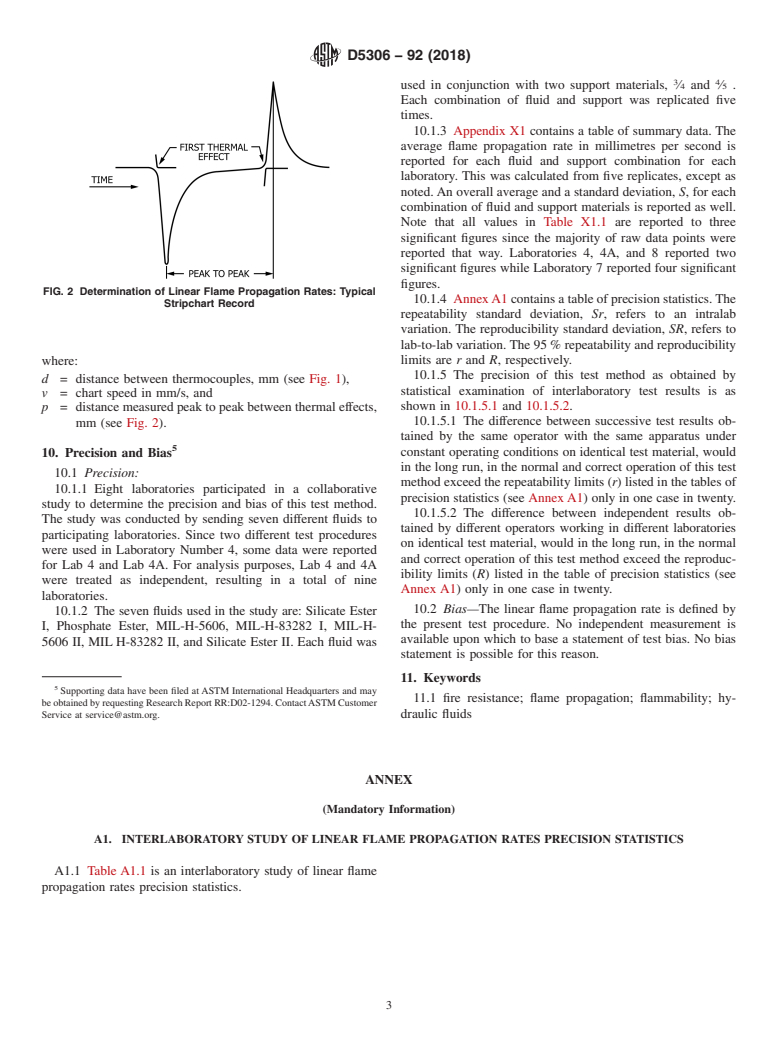

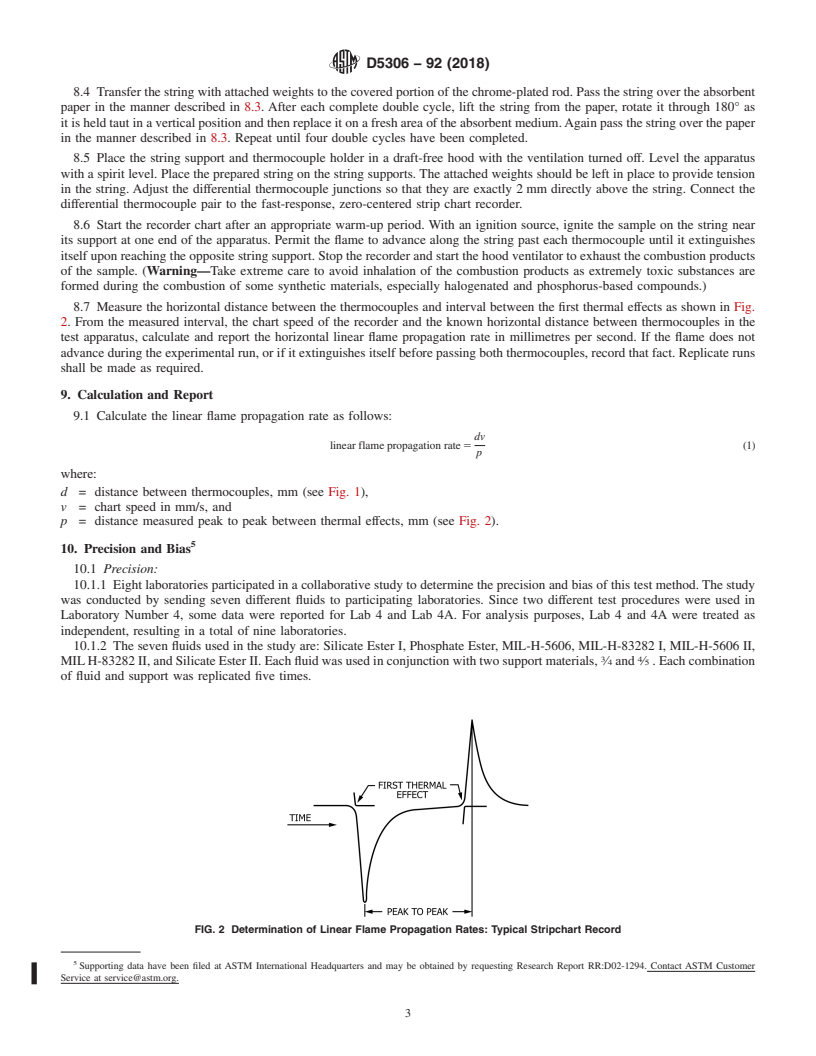

8.7 Measure the horizontal distance between the thermo-

couples and interval between the first thermal effects as shown

8. Procedure

in Fig. 2. From the measured interval, the chart speed of the

8.1 Tie small loops in each end of a 500 mm section of

recorder and the known horizontal distance between thermo-

ceramic fiber support (string). Place a few millilitres of the

couplesinthetestapparatus,calculateandreportthehorizontal

sample to be studied in an evaporating dish. Immerse the

line

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5306 − 92 (Reapproved 2018)

Standard Test Method for

Linear Flame Propagation Rate of Lubricating Oils and

Hydraulic Fluids

This standard is issued under the fixed designation D5306; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the determination of the linear

2.2 Military Specifications:

flame propagation rates of lubricating oils and hydraulic fluids

MIL-H-83282C Hydraulic Fluid, Fire Resistant, Synthetic

supported on the surfaces of and impregnated into ceramic

Hydrocarbon Base, Aircraft NATO Code Number H-537

fiber media. Data thus generated are to be used for the

MIL-H-46170B Amm.1, Hydraulic Fluid, Rust Inhibited,

comparison of relative flammability.

Fire Resistant, Synthetic Hydrocarbon Base

1.2 This test method should be used to measure and describe

the properties of materials, products, or assemblies in response

3. Terminology

to heat and flame under controlled laboratory conditions and

3.1 Definitions of Terms Specific to This Standard:

should not be used to describe or appraise the fire hazard or fire

3.1.1 linear flame propagation rate, n—the average quotient

risk of materials, products, or assemblies under actual fire

of the distance of flame travel and the time required for the

conditions. However, results of this test method may be used as

flame front to travel that distance.

elements of fire risk which takes into account all of the factors

that are pertinent to an assessment of the fire hazard of a

4. Summary of Test Method

particular end use.

4.1 A section of a ceramic fiber support medium (string) is

1.3 The values stated in SI units are to be regarded as

impregnated with the sample under specific conditions. The

standard. No other units of measurement are included in this

impregnated fiber is placed on a standard support. The sample

standard.

is ignited and the time required for the flame front to propagate

1.4 This standard does not purport to address all of the

across a measured distance is determined by use of a thermo-

safety concerns, if any, associated with its use. It is the

electric system. The average propagation rate is then calculated

responsibility of the user of this standard to establish appro-

from the measured distance of flame travel and the time

priate safety, health, and environmental practices and deter-

required for the flame front to propagate over that distance.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

5. Significance and Use

dance with internationally recognized principles on standard-

5.1 The linear flame propagation rate of a sample is a

ization established in the Decision on Principles for the

property that is relevant to the overall assessment of the

Development of International Standards, Guides and Recom-

flammability or relative ignitability of fire resistance lubricants

mendations issued by the World Trade Organization Technical

and hydraulic fluids. It is intended to be used as a bench-scale

Barriers to Trade (TBT) Committee.

test for distinguishing between the relative resistance to igni-

tion of such materials. It is not intended to be used for the

2. Referenced Documents

evaluation of the relative flammability of flammable, extremely

2.1 ASTM Standards:

flammable, or volatile fuels, solvents, or chemicals.

6. Apparatus

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

6.1 Apparatus for measurement of linear flame propagation

Subcommittee D02.N0 on Hydraulic Fluids.

rates:

Current edition approved Oct. 1, 2018. Published November 2018. Originally

approved in 1992. Last previous edition approved in 2013 as D5306 – 92 (2013).

6.1.1 Open Top Stainless Steel Box, as shown in Fig. 1.

DOI: 10.1520/D5306-92R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Bldg. 4, Section D, 700 Robbins

the ASTM website. Ave., Philadelphia, PA 19111-5094, https://assist.dla.mil/online/start.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5306 − 92 (2018)

8.2 While the ceramic fiber support (string) is immersed in

the sample, carefully wrap an absorbent paper wiper around the

15 mm diameter chrome plated rod. Leave one end of the rod

uncovered by the wiper.

8.3 Remove the ceramic fiber support (string) section from

the liquid sample and attach a 50 g weight to the loop at each

end. Fix the chrome-plated rod with its absorbent paper

wrapping in a horizontal position and hang the soaked string

section with attached weights over the unwrapped section of

the rod. Press down gently on the uppermost weight to cause

the soaked string to pass over the bare rod, flexing gently as it

moves. When the lower weight has been drawn up to the rod,

reverse the process until the first weight has again been drawn

FIG. 1 Apparatus for Determination of Linear Flame Propagation

up the rod. Repeat the cycle four times to work the sample

Rates

thoroughly into the string.

8.4 Transfer the string with attached weights to the covered

portion of the chrome-plated rod. Pass the string over the

absorbent paper in the manner described in 8.3. After each

6.1.2 Recorder, stripchart, fast responses. A zero-centered

complete double cycle, lift the string from the paper, rotate it

recorder with a 65 mV range and a one-half second full-scale

through 180° as it is held taut in a vertical position and then

deflection capacity has been found to be satisfactory. A chart

replace it on a fresh area of the absorbent medium. Again pass

speed of at least 1 in. ⁄min has been used for most studies.

the string over the paper in the manner described in 8.3. Repeat

6.1.3 Differential Thermocouple Pair, 30 gauge with bare

until four double cycles have been completed.

junctions and double fiberglass wrap insulation, ISA, Type J or

Type K may be prepared from any premium grade thermo- 8.5 Place the string support and thermocouple holder in a

couple wire. draft-free hood with the ventilation turned off. Level the

6.1.4 Fume Hood, draft-free when ventilation system is not apparatus with a spirit level. Place the prepared string on the

operative. string supports. The attached weights should be left in place to

6.1.5 Weights, 50 g 6 0.01 g, with attached hooks; two provide tension in the string. Adjust the differential thermo-

required. couple junctions so that they are exactly 2 mm directly above

6.1.6 Chrome-Plated Tube or Rod, 15 mm diameter by the string. Connect the differential thermocouple pair to the

375 mm long. fast-response, zero-centered strip chart recorder.

6.1.7 Porcelain or Glass Dish, approximately 135 mL ca-

8.6 Start the recorder chart after an appropriate warm-up

pacity.

period. With an ignition source, ignite the sample on the string

near its support at one end of the apparatus. Permit the flame to

7. Materials

advance along the string past each thermocouple until it

7.1 Absorbent Paper Wipers, 375 mm by 213 mm. extinguishes itself upon reaching the opposite string support.

Stop the recorder and start the hood ventilator to exhaust the

7.2 Ceramic Fiber, twisted yarn type 390/312, 4/5, 2.72 or

combustion products of the sample. (Warning—Take extreme

type 390/312, 3/4, 2.72. Ceramic fiber size used shall be agreed

care to avoid inhalation of the combustion products as ex-

upon by supplier and consumer and shall be specified in test

tremely toxic substances are formed during the combustion of

report.

some synthetic materials, especially halogenated and

7.3 Ignition Source, any paper book matches or wooden

phosphorus-based compounds.)

kitchen matches can be used.

8.7 Measure the horizontal distance between the thermo-

couples and interval between the first thermal effects as shown

8. Procedure

in Fig. 2. From the measured interval, the chart speed of the

8.1 Tie small loops in each end of a 500 mm section of

recorder and the known horizontal distance between thermo-

ceramic fiber support (string). Place a few millilitres of the

couples in the test apparatus, calculate and report the horizontal

sample to be studied in an evaporating dish. Immerse the

linear flame propagation rate in millimetres per second. If

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5306 − 92 (Reapproved 2013) D5306 − 92 (Reapproved 2018)

Standard Test Method for

Linear Flame Propagation Rate of Lubricating Oils and

Hydraulic Fluids

This standard is issued under the fixed designation D5306; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the linear flame propagation rates of lubricating oils and hydraulic fluids

supported on the surfaces of and impregnated into ceramic fiber media. Data thus generated are to be used for the comparison of

relative flammability.

1.2 This test method should be used to measure and describe the properties of materials, products, or assemblies in response

to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk

of materials, products, or assemblies under actual fire conditions. However, results of this test method may be used as elements

of fire risk which takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 Military Specifications:

MIL-H-83282C Hydraulic Fluid, Fire Resistant, Synthetic Hydrocarbon Base, Aircraft NATO Code Number H-537

MIL-H-46170B Amm.1, Hydraulic Fluid, Rust Inhibited, Fire Resistant, Synthetic Hydrocarbon Base

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 linear flame propagation rate, n—the average quotient of the distance of flame travel and the time required for the flame

front to travel that distance.

4. Summary of Test Method

4.1 A section of a ceramic fiber support medium (string) is impregnated with the sample under specific conditions. The

impregnated fiber is placed on a standard support. The sample is ignited and the time required for the flame front to propagate

across a measured distance is determined by use of a thermoelectric system. The average propagation rate is then calculated from

the measured distance of flame travel and the time required for the flame front to propagate over that distance.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.N0 on Hydraulic Fluids.

Current edition approved May 1, 2013Oct. 1, 2018. Published August 2013November 2018. Originally approved in 1992. Last previous edition approved in 20072013

as D5306 – 92 (2007).(2013). DOI: 10.1520/D5306-92R13.10.1520/D5306-92R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from DLA Document Services, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, https://assist.dla.mil/online/start.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5306 − 92 (2018)

5. Significance and Use

5.1 The linear flame propagation rate of a sample is a property that is relevant to the overall assessment of the flammability or

relative ignitability of fire resistance lubricants and hydraulic fluids. It is intended to be used as a bench-scale test for distinguishing

between the relative resistance to ignition of such materials. It is not intended to be used for the evaluation of the relative

flammability of flammable, extremely flammable, or volatile fuels, solvents, or chemicals.

6. Apparatus

6.1 Apparatus for measurement of linear flame propagation rates:

FIG. 1 Apparatus for Determination of Linear Flame Propagation Rates

6.1.1 Open Top Stainless Steel Box, as shown in Fig. 1.

6.1.2 Recorder, stripchart, fast responses. A zero-centered recorder with a 65 mV range and a one-half second full-scale

deflection capacity has been found to be satisfactory. A chart speed of at least 1 in. ⁄min has been used for most studies.

6.1.3 Differential Thermocouple Pair, 30 gauge with bare junctions and double fiberglass wrap insulation, ISA, Type J or Type

K may be prepared from any premium grade thermocouple wire.

6.1.4 Fume Hood, draft-free when ventilation system is not operative.

6.1.5 Weights, 50 g 6 0.01 g, with attached hooks; two required.

6.1.6 Chrome-Plated Tube or Rod, 15 mm diameter by 375 mm long.

6.1.7 Porcelain or Glass Dish, approximately 135 mL capacity.

7. Materials

7.1 Absorbent Paper Wipers, 375 mm by 213 mm.

7.2 Ceramic Fiber, twisted yarn type 390/312, 4/5, 2.72 or type 390/312, 3/4, 2.72. Ceramic fiber size used shall be agreed upon

by supplier and consumer and shall be specified in test report.

7.3 Ignition Source, any paper book matches or wooden kitchen matches can be used.

8. Procedure

8.1 Tie small loops in each end of a 500 mm section of ceramic fiber support (string). Place a few millilitres of the sample to

be studied in an evaporating dish. Immerse the ceramic fiber support (string) in the liquid sample for 60 s. Avoid immersion of

the loops at the end of the string.

8.2 While the ceramic fiber support (string) is immersed in the sample, carefully wrap an absorbent paper wiper around the

15 mm diameter chrome plated rod. Leave one end of the rod uncovered by the wiper.

8.3 Remove the ceramic fiber support (string) section from the liquid sample and attach a 50 g weight to the loop at each end.

Fix the chrome-plated rod with its absorbent paper wrapping in a horizontal position and hang the soaked string section with

attached weights over the unwrapped section of the rod. Press down gently on the uppermost weight to cause the soaked string

to pass over the bare rod, flexing gently as it moves. When the lower weight has been drawn up to the rod, reverse the process

until the first weight has again been drawn up the rod. Repeat the cycle four times to work the sample thoroughly into the string.

The sole source of supply of the ceramic fiber known to the committee at this time is Nextel Ceramic Fiber, manufactured by the 3M Company, 219-1-1, 3M Center,

St. Paul, MN 55144. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful

consideration at a meeting of the responsible technical committee, which you may attend.

D5306 − 92 (2018)

8.4 Transfer the string with attached weights to the covered portion of the chrome-plated rod. Pass the string over the absorbent

paper in the manner described in 8.3. After each complete double cycle, lift the string from the paper, rotate it through 180° as

it is held taut in a vertical position and then replace it on a fresh area of the absorbent medium. Again pass the string over the paper

in the manner described in 8.3. Repeat until four double cycles have been completed.

8.5 Place the string support and thermocouple holder in a draft-free hood with the ventilation turned off. Level the apparatus

with a spirit level. Place the prepared string on the string supports. The attached weights should be left in place to provide tension

in the string. Adjust the differential thermocouple junctions so that they are exactly 2 mm directly above the string. Connect the

differential thermocouple pair to the fast-response, zero-centered strip chart recorder.

8.6 Start the recorder chart after an appropriate warm-up period. With an ignition source, ignite the sample on the string near

its support at one end of the apparatus. Permit the flame to advance along th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.