ASTM D5769-98

(Test Method)Standard Test Method for Determination of Benzene, Toluene, and Total Aromatics in Finished Gasolines by Gas Chromatography/Mass Spectrometry

Standard Test Method for Determination of Benzene, Toluene, and Total Aromatics in Finished Gasolines by Gas Chromatography/Mass Spectrometry

SCOPE

1.1 This test method covers the determination of benzene, toluene, and total aromatics in finished motor gasoline, including reformulated gasoline (RFG) containing oxygenated blending components, by gas chromatography/mass spectrometry (GC/MS).

1.2 This test method is applicable to the following concentration ranges, in liquid volume %, for the following aromatics: benzene, 0.1 to 3%; toluene, 1 to 15%; and total (C6-C12) aromatics, 10 to 40%. The test method has not been tested by ASTM for gasoline samples containing a concentration of uncalibrated C10-C12 aromatic compounds greater than approximately 3 volume %. Also, the test method has not been tested by ASTM for individual hydrocarbon process streams in a refinery, such as reformates, fluid catalytic cracked naphthas, etc., used in blending of gasolines.

1.3 Results are reported to the nearest 0.01% for benzene and 0.1% for the other aromatics by either mass or liquid volume.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation:D5769–98

Standard Test Method for

Determination of Benzene, Toluene, and Total Aromatics in

Finished Gasolines by Gas Chromatography/Mass

Spectrometry

This standard is issued under the fixed designation D 5769; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of benzene, 3.1 Definitions of Terms Specific to This Standard:

toluene, other specified individual aromatic compounds, and 3.1.1 aromatic—any hydrocarbon compound containing a

total aromatics in finished motor gasoline, including gasolines benzene or naphthalene ring.

containing oxygenated blending components, by gas 3.1.2 split ratio— in capillary gas chromatography, the

chromatography/mass spectrometry (GC/MS). ratio of the total flow of carrier gas to the sample inlet versus

1.2 This test method has been tested for the following theflowofthecarriergastothecapillarycolumn,expressedby

concentration ranges, in liquid volume %, for the following

split ratio 5 ~S1C!/C (1)

aromatics: benzene, 0.1 to 4 %; toluene, 1 to 13 %; and total

(C6 to C12) aromatics, 10 to 42 %. The round-robin study did where:

S = flow rate at the splitter vent, and

not test the method for individual hydrocarbon process streams

C = flow rate at the column outlet.

in a refinery, such as reformates, fluid catalytic cracked

3.1.3 wall coated open tubular (WCOT)—a type of capil-

naphthas, and so forth, used in the blending of gasolines.

lary column prepared by coating or bonding the inside wall of

1.3 Results are reported to the nearest 0.01 % for benzene

the capillary with a thin film of stationary phase.

and 0.1 % for the other aromatics by liquid volume.

3.1.4 cool on-column injector—in gas chromatography,a

1.4 SIunitsofmeasurementarepreferredandusedthrough-

direct sample introduction system that is set at a temperature at

out this standard.

orbelowtheboilingpointofsolutesorsolventoninjectionand

1.5 This standard does not purport to address all of the

then heated at a rate equal to or greater than the column.

safety concerns, if any, associated with its use. It is the

Normally used to eliminate boiling point discrimination on

responsibility of the user of this standard to establish appro-

injection or to reduce adsorption on glass liners within injec-

priate safety and health practices and determine the applica-

tors, or both. The sample is injected directly into the head of

bility of regulatory limitations prior to its use.

the capillary column tubing.

2. Referenced Documents

3.1.5 open split interface—GC/MS interface used to main-

tain atmospheric pressure at capillary column outlet and to

2.1 ASTM Standards:

eliminate mass spectrometer vacuum effects on the capillary

D 1298 Practice for Density, Relative Density (Specific

column. Can be used to dilute the sample entering the mass

Gravity),oraAPIGravityofCrudePetroleumProductsby

spectrometer to maintain response linearity.

Hydrometer Method

3.1.6 retention gap—in gas chromatography, refers to a

D 4052 Test Method for Density and Relative Density of

deactivated precolumn which acts as a zone of low retention

Liquids by Digital Density Meter

power for reconcentrating bands in space. The polarity of the

D 4057 Practice for Manual Sampling of Petroleum and

precolumn must be similar to that of the analytical column.

Petroleum Product

3.1.7 total ion chromatogram (TIC)—mass spectrometer

D 4307 PracticeforPreparationofLiquidBlendsforUseas

computer output representing either the summed intensities of

Analytical Standards

all scanned ion currents or a sample of the current in the ion

beam for each spectrum scan plotted against the corresponding

This test method is under the jurisdiction of ASTM Committee D02 on

spectrum number. Generally, it can be correlated with a flame

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

ionization detector chromatogram.

D.02.04 on Hydrocarbon Analysis.

Current edition approved July 10, 1998. Published October 1998. Last previous 3.1.8 reconstructed ion chromatogram (RIC)—a limited

edition D 5769 – 95.

mass chromatogram representing the intensities of ion mass

Annual Book of ASTM Standards, Vol 05.01

spectrometric currents for only those ions having particular

Annual Book of ASTM Standards, Vol 05.02

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D5769–98

mass to charge ratios. Used in this test method to selectively a thicker film of stationary phase, such as 4–5 µm, is recom-

extract or identify aromatic components in the presence of a mended to prevent column sample overload.

complex hydrocarbon matrix, such as gasoline.

Resolution R between 1,3,5-

2~t2– t1!

R 5

trimethylbenzene and 1-methyl-2-

1.699~y2 1 y1!

3.1.9 calibrated aromatic component—the individual aro-

ethylbenzene at the 3 mass % level

matic components that have a specific calibration.

each must be equal to or greater than

t2 = retention time of 1,3,5-

3.1.10 uncalibrated aromatic component—individual aro- 2.0

trimethylbenzene

t1 = retention time of 1-methyl-2-

matics for which a calibration is not available. These compo-

ethylbenzene

nents are estimated from the calibration of several calibrated

y2 = peak width at half height of 1,3,5-

aromatic components.

trimethylbenzene

y1 = peak width at half height 1-methyl-

2-ethyl benzene

4. Summary of Test Method

6.2 Mass Spectrometry:

4.1 A gas chromatograph equipped with a dimethylpolysi-

6.2.1 Mass spectrometer capable of producing electron

loxane WCOT column is interfaced to a fast scanning mass

impactspectraat70,orhigher,electronvoltsorequivalent,and

spectrometer that is suitable for capillary column GC/MS

capable of scanning the range of the specified quantitation

analyses. The sample is injected either through a capillary

masses or m/e. The mass scan range shall cover the masses of

splitter port or a cool-on-column injector capable of introduc-

interest for quantitation and should yield at least 5 scans across

ing a small sample size without overloading the column. The

the peak width at half peak width fora1to3 mass % toluene

capillarycolumnisinterfaceddirectlytothemassspectrometer

and cover the masses of interest for quantitation.Ascan range

orbywayofanopensplitinterfaceorotherappropriatedevice.

of 41 to 200 daltons is adequate.

4.2 Calibrationisperformedonamassbasis,usingmixtures

6.2.2 The mass spectrometer must be capable of being

of specified pure aromatic hydrocarbons. Volume % data is

interfaced to a gas chromatograph and WCOT columns. The

calculated from the densities of the individual components and

interface must be at a high enough temperature to prevent

thedensityofthesample.Amultipointcalibrationconsistingof

condensationofcomponentsboilingupto220°C,usually20°C

at least five levels and bracketing the expected concentrations

above the final column temperature is adequate. Direct column

of the specified individual aromatics is required. Specified

interface to the mass spectrometer can be used. An open split

deuterated hydrocarbons are used as the internal standards, for

interfacewithcomputercontrolledprogrammableflowcontrol-

example, d6-benzene for quantitating benzene. Unidentified

ler(s) can also be used, particularly with cool on-column

aromatic hydrocarbons present that have not been specifically

injections, to maintain all aromatic components within the

calibrated for are quantitated using the calibration of an

linearity of the mass spectrometer and at the same time

adjacent calibrated compound and summed with the other

maintain detectability of lower concentration aromatic compo-

aromatic components to obtain a total aromatic concentration

nents. For example, a higher open-split-interface make-up gas

of the sample.

flow can be used for the high concentration components, such

4.3 Specified quality control mixture(s), such as synthetic

as toluene and xylenes, and a lower make-up gas flow rate may

quality control mixtures must be analyzed to monitor the

be used during the elution of the lower concentration benzene

performance of the calibrated GC/MS system. Analysis of a

and C9+ components. Other interfaces may be used provided

gasoline as a reference material is strongly recommended.

the criteria specified in Sections 9 and 10 are met.

6.2.3 A computer system shall be interfaced to the mass

5. Significance and Use

spectrometer to allow acquisition of continuous mass scans or

5.1 Test methods to determine benzene and the aromatic

total ion chromatogram (TIC) for the duration of the chromato-

content of gasoline are necessary to assess product quality and

graphic program and be able to analyze repeatedly 0.01 mass

to meet fuel regulations.

% 1,4-diethylbenzene with the specified signal/noise ratio of 5.

5.2 This test method can be used for gasolines that contain

Software must be available to allow searching any GC/MS run

oxygenates (alcohols and ethers) as additives. It has been

for specific ions or reconstructed ions and plotting the intensity

determined that the common oxygenates found in finished

of the ions with respect to time or scan number. The ability to

gasolinedonotinterferewiththeanalysisofbenzeneandother

integrate the area under a specific ion plot peak is essential for

aromatics by this test method.

quantitation. The quantitation software must allow linear least

squares or quadratic nonlinear regression and quantitation with

6. Apparatus

multiple internal standards. It is also recommended that soft-

6.1 Gas Chromatography:

ware be available to automatically perform the identification of

6.1.1 System equipped with temperature-programmable gas

aromatic components as specified in 13.1.1.

chromatographsuitableforsplitinjectionswithWCOTcolumn

7. Reagents and Materials

or cool-on-column injector that allows the injection of small

(for example, 0.1 µL) samples at the head of the WCOT 7.1 Carrier Gas—Helium and hydrogen have been used

columnoraretentiongap.Anautosamplerismandatoryforthe successfully. The recommended minimum purity of the carrier

on-column injections. gas used is 99.999 mol %. Additional purification using

6.1.2 WCOT column containing dimethylpolysiloxane commercially available scrubbing reagents may be necessary

bonded stationary phase, meeting the specification in the to remove trace oxygen, which may deteriorate the perfor-

followingtable.Foron-columninjections,acolumncontaining mance of the GC WCOT.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D5769–98

NOTE 1—Warning: Helium and hydrogen are supplied under high

spectral match (see 13.1.1). Naphthalene is hygroscopic and

pressure. Hydrogen can be explosive and requires special handling.

should be stored away from high humidity.

Hydrogen monitors that automatically shut off supply to the GC in case of

serious leaks are available from GC supply manufacturers.

8. Sampling

7.2 Dilution Solvents—Reagent grade 2,2,4-

8.1 Every effort should be made to ensure that the sample is

trimethylpentane (iso-octane), n-heptane, n-nonane, cyclo- representative of the fuel source from which it is taken. Follow

hexane, or toluene, or a combination thereof, used as a solvent the recommendations of Practice D 4057D 4057, or its equiva-

in the preparation of the calibration mixtures.

lent, when obtaining samples from bulk storage or pipelines.

Sampling to meet certain regulatory specifications may require

NOTE 2—Toluene should be used as a solvent only for the preparation

the use of specific sampling procedures. Consult appropriate

of C9+ components and shall be free from interfering aromatics.

regulations.

NOTE 3—Warning: The gasoline samples and solvents used as re-

8.2 Appropriate steps should be taken to minimize the loss

agents such as iso-octane, cyclohexane, n-heptane, n-octane, and toluene,

are flammable and may be harmful or fatal if ingested or inhaled. Benzene oflighthydrocarbonsfromthegasolinesamplewhilesampling

is a known carcinogen. Use with proper ventilation. Safety glasses and

and during analyses. Upon receipt in the laboratory, chill the

gloves are required while preparing samples and standards. Samples

sample in its original container to between 0 to 5°C (32 to

should be kept in well ventilated laboratory areas.

40°F)beforeandafterasamplealiquotisremovedforanalysis.

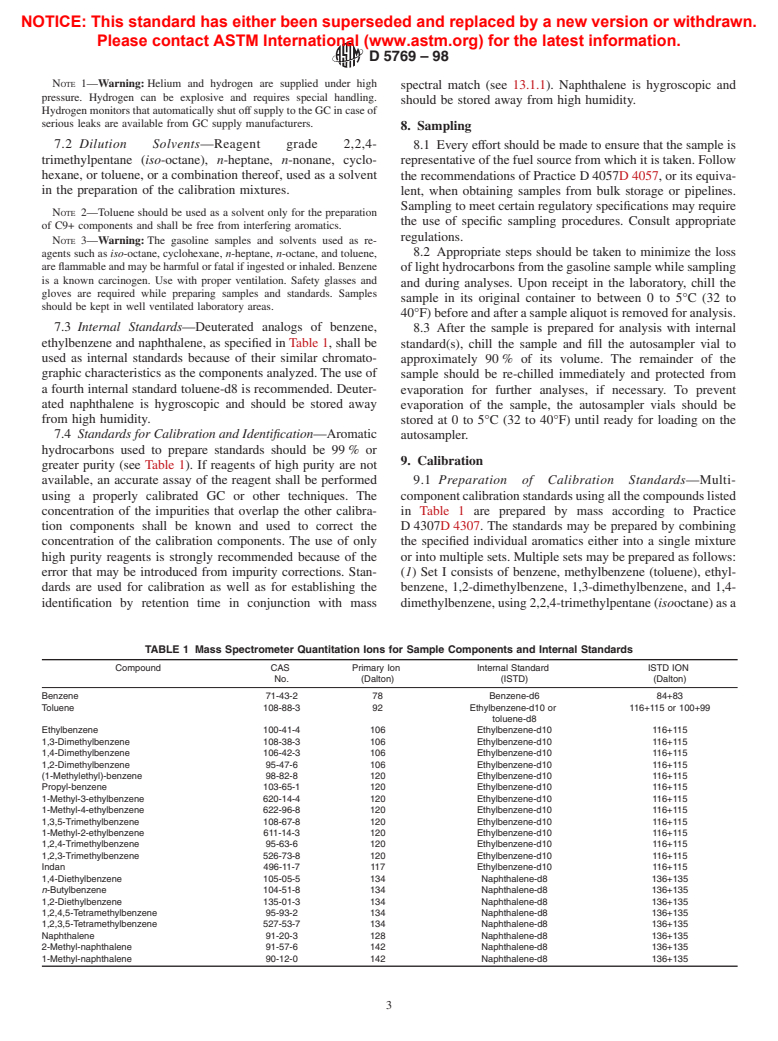

7.3 Internal Standards—Deuterated analogs of benzene,

8.3 After the sample is prepared for analysis with internal

ethylbenzene and naphthalene, as specified in Table 1, shall be

standard(s), chill the sample and fill the autosampler vial to

used as internal standards because of their similar chromato-

approximately 90 % of its volume. The remainder of the

graphic characteristics as the components analyzed. The use of

sample should be re-chilled immediately and protected from

a fourth internal standard toluene-d8 is recommended. Deuter-

evaporation for further analyses, if necessary. To prevent

ated naphthalene is hygroscopic and should be stored away

evaporation of the sample, the autosampler vials should be

from high humidity.

stored at 0 to 5°C (32 to 40°F) until ready for loading on the

7.4 Standards for Calibration and Identification—Aromatic

autosampler.

hydrocarbons used to prepare standards should be 99 % or

9. Calibration

greater purity (see Table 1). If reagents of high purity are not

available, an accurate assay of the reagent shall be performed 9.1 Preparation of Calibration Standards—Multi-

using a properly calibrated GC or other techniques. The componentcalibrationstandardsusingallthecompoundslisted

concentration of the impurities that overlap the other calibra- in Table 1 are prepared by mass according to Practice

tion components shall be known and used to correct the D 4307D 4307. The standards may be prepared by combining

concentration of the calibration components. The use of only the specified individual aromatics either into a single mixture

high purity reagents is strongly recommended because of the or into multiple sets. Multiple sets may be prepared as follows:

error that may be introduced from impurity corrections. Stan- (1) Set I consists of benzene, methylbenzene (toluene), ethyl-

dards are used for calibration as well a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.