ASTM D381-03

(Test Method)Standard Test Method for Gum Content in Fuels by Jet Evaporation

Standard Test Method for Gum Content in Fuels by Jet Evaporation

SCOPE

1.1 This test method covers the determination of the existent gum content of aviation fuels, and the gum content of motor gasolines or other volatile distillates in their finished form, (including those containing alcohol and ether type oxygenates and deposit control additives) at the time of test.

1.2 Provisions are made for the determination of the heptane insoluble portion of the residue of non-aviation fuels.

1.3 The accepted SI unit of pressure is the Pascal (Pa); the accepted SI unit for temperature is degrees Celsius.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.4, 7.4, and 9.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 381 – 03

Designation: 131/99

Standard Test Method for

1

Gum Content in Fuels by Jet Evaporation

This standard is issued under the fixed designation D 381; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3. Terminology

1.1 This test method covers the determination of the existent 3.1 Definitions of Terms Specific to This Standard:

gum content of aviation fuels, and the gum content of motor 3.1.1 existent gum—the evaporation residue of aviation

gasolines or other volatile distillates in their finished form, fuels, without any further treatment.

(including those containing alcohol and ether type oxygenates 3.2 For non-aviation fuels, the following definitions apply.

and deposit control additives) at the time of test. 3.3 solvent washed gum content—the residue remaining

1.2 Provisions are made for the determination of the heptane when the evaporation residue (see 3.4) has been washed with

insoluble portion of the residue of non-aviation fuels. heptane and the washings discarded.

1.3 The values stated in SI units are to be regarded as the 3.3.1 Discussion—For motor gasoline or non-aviation gaso-

standard. The accepted SI unit of pressure is the Pascal (Pa); line, solvent washed gum content was previously referred to as

the accepted SI unit for temperature is degrees Celsius. existent gum.

1.4 This standard does not purport to address all of the 3.4 unwashed gum content—the evaporation residue of the

safety concerns, if any, associated with its use. It is the product or component under test, without any further treat-

responsibility of the user of this standard to establish appro- ment.

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use. For specific hazard

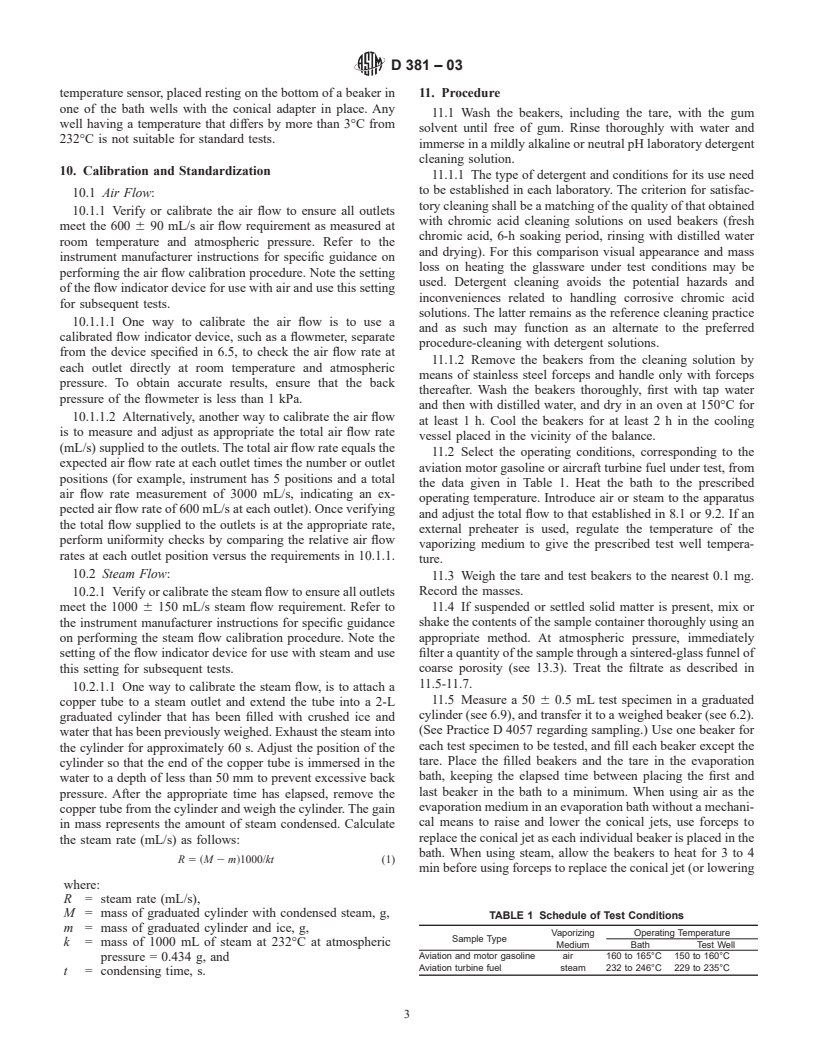

4.1 A measured quantity of fuel is evaporated under con-

statements, see 6.4, 7.4, and 9.1.

trolled conditions of temperature and flow of air or steam. For

2. Referenced Documents

aviation gasoline and aviation turbine fuel, the resulting

2.1 ASTM Standards: residue is weighed and reported as milligrams per 100 mL. For

D 4057 Practice for Manual Sampling of Petroleum and motor gasoline, the residue is weighed before and after

2

Petroleum Products extracting with heptane and the results reported as milligrams

3

E 1 Specification for ASTM Thermometers per 100 mL.

E 29 Practice for Using Significant Digits in Test Data to

4 5. Significance and Use

Determine Conformance with Specification

2.2 IP Standard: 5.1 The true significance of this test method for determining

gum in motor gasoline is not firmly established. It has been

Standard Methods for Analysis and Testing of Petroleum

5

Products proved that high gum can cause induction-system deposits and

sticking of intake valves, and in most instances, it can be

assumed that low gum will ensure absence of induction-system

difficulties. The user should, however, realize that the test

1

This test method is under the jurisdiction of ASTM Committee D02 on

method is not of itself correlative to induction-system deposits.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.14 on Stability and Cleanliness of Liquid Fuels. The primary purpose of the test method, as applied to motor

Current edition approved July 10, 2003. Published September 2003. Originally

gasoline, is the measurement of the oxidation products formed

approved in 1934. Last previous edition approved in 2001 as D 381– 01.

in the sample prior to or during the comparatively mild

In the IP, this test method is under the jurisdiction of the Standardization

conditions of the test procedure. Since many motor gasolines

Committee. This test method was issued as a joint ASTM-IP standard in 1965.

2

Annual Book of ASTM Standards, Vol 05.02.

are purposely blended with nonvolatile oils or additives, the

3

Annual Book of ASTM Standards, Vol 14.03.

heptane extraction step is necessary to remove these from the

4

Annual Book of ASTM Standards, Vol 14.02.

5

evaporation residue so that the deleterious material, gum, may

Available from Institute of Petroleum, 61 New Cavendish St., London, WIG

7AR, England. be determined. With respect to aviation turbine fuels, large

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D381–03

quantities of gum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.