ASTM D6877-03

(Test Method)Standard Test Method for Monitoring Diesel Particulate Exhaust in the Workplace

Standard Test Method for Monitoring Diesel Particulate Exhaust in the Workplace

SCOPE

1.1 This test method covers determination of organic and elemental carbon in the particulate fraction of diesel engine exhaust, hereafter referred to as diesel particulate matter (DPM). Samples of workplace atmospheres are collected on quartz-fiber filters. The method also is suitable for other types of carbonaceous aerosols, but it is not appropriate for sampling volatile or semi-volatile components. These components require sorbents for efficient collection.

Note 1—Sample collection and handling procedures for environmental samples differ from occupational samples. This standard addresses occupational monitoring of DPM in workplaces where diesel-powered equipment is used.

1.2 The method is based on a thermal-optical technique (1, 2). Speciation of organic and elemental carbon is achieved through temperature and atmosphere control, and an optical feature that corrects for sample charring.

1.3 A portion of a 37-mm, quartz-fiber filter sample is analyzed. Results for the portion are used to calculate the total mass of organic and elemental carbon on the filter. The portion must be representative of the entire filter deposit. If the deposit is uneven, two or more representative portions should be analyzed for an average. Open-faced cassettes give even deposits but are often not practical. Closed-face cassettes give equivalent results if other dusts are absent. Other samplers may be required, depending on the sampling environment (2-5).

1.4 The calculated limit of detection ( LOD) depends on the level of contamination of the media blanks (). A LOD of approximately 0.2 g carbon per cm2 of filter was estimated when analyzing a sucrose standard solution applied to filter portions cleaned immediately before analysis. LODs based on media blanks stored after cleaning are usually higher. LODs based on a set of media blanks from a commercial laboratory were OC = 1.2 g/cm2, EC = 0.4 g/cm2, and TC = 1.3 g/cm 2, where OC, EC, and TC refer to organic, elemental, and total carbon, respectively.

1.5 OC-EC methods are operational, which means the analytical procedure defines the analyte. The test method offers greater selectivity and precision than thermal techniques that do not correct for charring of organic components. The analysis method is simple and relatively quick (about 15 min). The analysis and data reduction are automated, and the instrument is programmable (different methods can be saved as methods for other applications).

1.6 A method (5040) for DPM based on thermal-optical analysis has been published by the National Institute for Occupational Safety and Health (NIOSH). Method updates (3, 4) have been published since its initial (1996) publication in the NIOSH Manual of Analytical Methods (NMAM). Both OC and EC are determined by NMAM 5040. An EC exposure marker was recommended because EC is a more selective measure of exposure. A comprehensive review of the method and rationale for selection of an EC marker are provided in a recent Chapter of NMAM (5).

1.7 The thermal-optical instrument required for the analysis is manufactured by a private laboratory. As with most instrumentation, design improvements continue to be made. Different laboratories may be using different instrument models.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 7.1.5, 8.3, and 12.12.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6877–03

Standard Test Method for

Monitoring Diesel Particulate Exhaust in the Workplace

This standard is issued under the fixed designation D 6877; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope greater selectivity and precision than thermal techniques that

donotcorrectforcharringoforganiccomponents.Theanalysis

1.1 This test method covers determination of organic and

method is simple and relatively quick (about 15 min). The

elemental carbon in the particulate fraction of diesel engine

analysis and data reduction are automated, and the instrument

exhaust, hereafter referred to as diesel particulate matter

is programmable (different methods can be saved as methods

(DPM). Samples of workplace atmospheres are collected on

for other applications).

quartz-fiber filters. The method also is suitable for other types

1.6 A method (5040) for DPM based on thermal-optical

of carbonaceous aerosols, but it is not appropriate for sampling

analysis has been published by the National Institute for

volatile or semi-volatile components. These components re-

Occupational Safety and Health (NIOSH). Method updates (3,

quire sorbents for efficient collection.

4)havebeenpublishedsinceitsinitial(1996)publicationinthe

NOTE 1—Samplecollectionandhandlingproceduresforenvironmental

NIOSH Manual ofAnalytical Methods (NMAM). Both OC and

samples differ from occupational samples. This standard addresses occu-

EC are determined by NMAM 5040. An EC exposure marker

pational monitoring of DPM in workplaces where diesel-powered equip-

was recommended because EC is a more selective measure of

ment is used.

exposure.Acomprehensive review of the method and rationale

1.2 The method is based on a thermal-optical technique (1,

for selection of an EC marker are provided in a recent Chapter

2) . Speciation of organic and elemental carbon is achieved

of NMAM (5).

through temperature and atmosphere control, and an optical

1.7 The thermal-optical instrument required for the analysis

feature that corrects for sample charring. 3

is manufactured by a private laboratory. As with most instru-

1.3 A portion of a 37-mm, quartz-fiber filter sample is

mentation, design improvements continue to be made. Differ-

analyzed. Results for the portion are used to calculate the total

ent laboratories may be using different instrument models.

mass of organic and elemental carbon on the filter.The portion

1.8 This standard does not purport to address all of the

must be representative of the entire filter deposit. If the deposit

safety concerns, if any, associated with its use. It is the

is uneven, two or more representative portions should be

responsibility of the user of this standard to establish appro-

analyzed for an average. Open-faced cassettes give even

priate safety and health practices and determine the applica-

deposits but are often not practical. Closed-face cassettes give

bility of regulatory limitations prior to use. Specific precau-

equivalentresultsifotherdustsareabsent.Othersamplersmay

tionary statements are given in 7.1.5, 8.3, and 12.12.2.

be required, depending on the sampling environment (2-5).

1.4 The calculated limit of detection (LOD) depends on the

2. Referenced Documents

level of contamination of the media blanks (5). A LOD of 4

2.1 ASTM Standards:

approximately 0.2 µg carbon per cm of filter was estimated

D 1356 Terminology Relating to Sampling and Analysis of

when analyzing a sucrose standard solution applied to filter

Atmospheres

portions cleaned immediately before analysis. LODs based on

media blanks stored after cleaning are usually higher. LODs 3. Terminology

based on a set of media blanks from a commercial laboratory

3.1 Definitions:

2 2 2

were OC=1.2µg/cm , EC=0.4µg/cm ,and TC=1.3µg/cm ,

where OC, EC, and TC refer to organic, elemental, and total

carbon, respectively.

The carbon analyzer used in the development and performance evaluation of

1.5 OC-EC methods are operational, which means the th

this test method was manufactured by Sunset Laboratory, 2017 19 Avenue, Forest

analyticalproceduredefinestheanalyte.Thetestmethodoffers Grove, Oregon 97116, which is the sole source of supply of the instrument known

to the committee at this time. If you are aware of alternative suppliers, please

provide this information to ASTM Headquarters. Your comments will receive

This test method is under the jurisdiction of ASTM Committee D22 on carefulconsiderationatameetingoftheresponsibletechnicalcommitteewhichyou

Sampling and Analysis of Atmospheres and is the direct responsibility of Subcom- may attend.

mittee D22.04 on Workplace Atmospheres. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 10, 2003. Published June 2003. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to references at the end of this test Standards volume information, refer to the standard’s Document Summary page on

method. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6877–03

3.2 For definitions of terms used in this practice, refer to control. In addition, the analyzer is equipped with an optical

Terminology D 1356. feature that corrects for the char formed during the analysis of

3.3 limit of detection, LOD—Avalue for which exceedence some materials. Optical correction is made with a pulsed diode

by measured mass indicates the presence of a substance at laser and photodetector that permit continuous monitoring of

given false-positive rate: 3 3 estimated standard deviation of the filter transmittance.

estimated mass. 4.2 The main instrument components are illustrated in Fig.

3.4 Definitions of Terms Specific to This Standard:

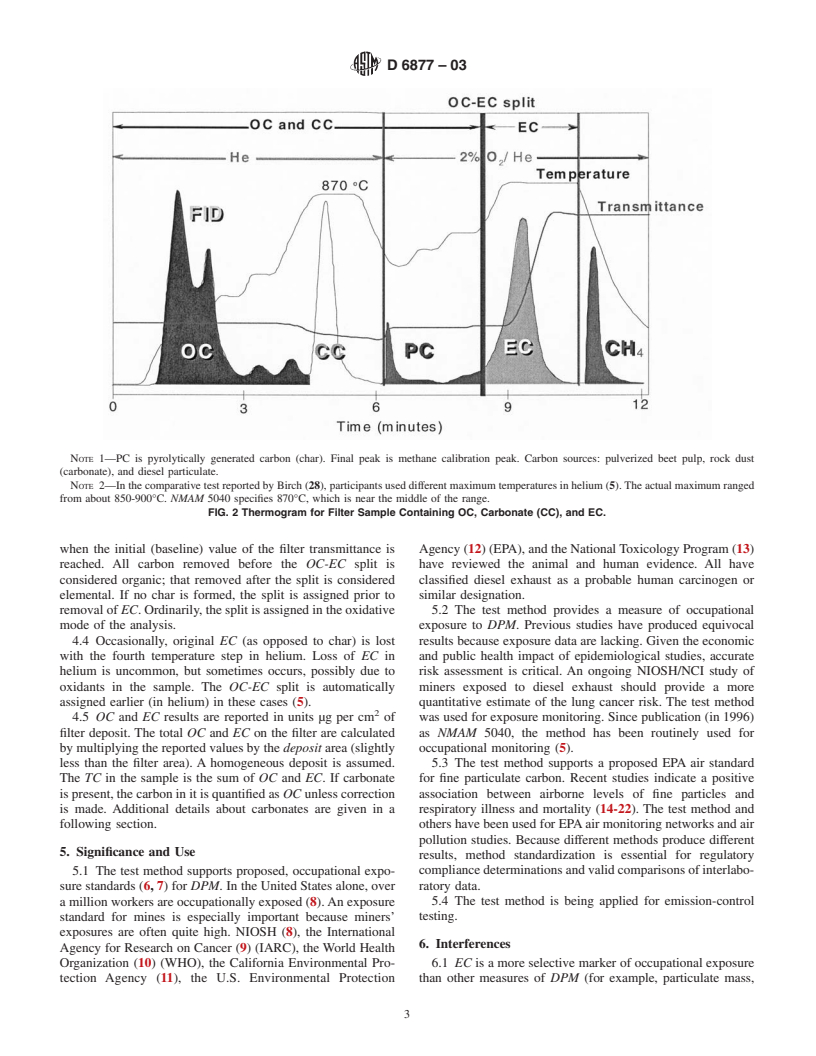

1. The instrument output, called a thermogram, is shown in

3.4.1 organic carbon (OC)—Carbon volatilized in helium Fig. 2. For analysis, a known area (normally 1.5 cm)ofthe

while heating a quartz-fiber filter sample to 870°C. Includes

quartz-fiber filter sample is removed with a sharp metal punch.

carbonates, if present, unless quantified separately. Also in- Quartz-fiber filters are required because temperatures in excess

cludes char formed during pyrolysis of some materials.

of 850°C are employed.The portion is inserted into the sample

3.4.2 elemental carbon (EC)—Excluding char, light- oven, and the oven is tightly sealed. The analysis proceeds in

absorbing carbon that is not removed from a filter sample

inert and oxidizing atmospheres. First, OC (and carbonate, if

heated to 870°C in an inert atmosphere. present) is removed in helium as the temperature is stepped to

3.4.3 total carbon (TC)—Sum of organic and elemental a preset maximum (about 870°C in NMAM 5040). Evolved

carbon.

carbon is catalytically oxidized to CO in a bed of granular

3.4.4 thermogram—Digitized output signal of thermal- MnO . The CO is then reduced to CH in a Ni/firebrick

2 2 4

optical instrument. Shows detector and filter transmittance

methanator, and CH is quantified by a FID. Next, the sample

signals at different temperatures in nonoxidizing and oxidizing oven temperature is lowered, an oxygen-helium mix (2 %

atmospheres.

oxygen after dilution of the 10 % oxygen in helium supply) is

3.5 Symbols and Abbreviations: introduced, and the temperature is increased to 900°C (or

3.5.1 DPM—diesel particulate matter

higher) to remove the residual carbon. At the end of each

3.5.2 LOD (µg/cm )—limit of detection: 3 3 s analysis, calibration is made through automatic injection of a

w

3.5.3 s (µg/cm )—estimate of sw

fixed volume of methane.

w

3.5.4 s (µg/cm )—standard deviation in collected mass

4.3 Some samples contain components (for example, ciga-

w

loading determination

rette and wood smokes) that carbonize (convert to carbon) or

3.5.5 OC, EC, TC (µg/cm or µg)—organic, elemental, and

char in helium during the first part of the analysis. Like EC

total carbon

initially present in the sample, char strongly absorbs light,

3.5.6 RSD—relative standard deviation

particularlyinthered/infraredregion.Thecharformedthrough

3.5.7 V (L)—sampled volume

pyrolysis (thermal decomposition) of these components causes

3.5.8 W (µg)—field blank filter’s EC mass reading

the filter transmittance to decrease. Charring can begin at

b

3.5.9 W (µg)—active filter’s EC mass reading

300°C; the process may continue until the maximum tempera-

EC

ture is reached. After OC removal, an oxygen-helium mix is

4. Summary of Test Method

introduced to effect combustion of residual carbon, which

4.1 The thermal-optical analyzer has been described previ- includes char and any EC originally present.As oxygen enters

ously (1-5). Design improvements have been made over time, the oven, light-absorbing carbon is oxidized and a concurrent

but the operation principle remains unchanged. OC-EC quan- increase in filter transmittance occurs. The split (vertical line

tification is accomplished through temperature and atmosphere prior to EC peak in Fig. 2) between OC and EC is assigned

FIG. 1 Schematic of Thermal-Optical Instrument (V=valve) for Determination of Organic and Elemental Carbon in DPM and Other

Carbonaceous Aerosols.

D6877–03

NOTE 1—PC is pyrolytically generated carbon (char). Final peak is methane calibration peak. Carbon sources: pulverized beet pulp, rock dust

(carbonate), and diesel particulate.

NOTE 2—In the comparative test reported by Birch (28), participants used different maximum temperatures in helium (5).The actual maximum ranged

from about 850-900°C. NMAM 5040 specifies 870°C, which is near the middle of the range.

FIG. 2 Thermogram for Filter Sample Containing OC, Carbonate (CC), and EC.

when the initial (baseline) value of the filter transmittance is Agency (12) (EPA), and the NationalToxicology Program (13)

reached. All carbon removed before the OC-EC split is have reviewed the animal and human evidence. All have

considered organic; that removed after the split is considered classified diesel exhaust as a probable human carcinogen or

elemental. If no char is formed, the split is assigned prior to similar designation.

removal of EC. Ordinarily, the split is assigned in the oxidative 5.2 The test method provides a measure of occupational

mode of the analysis. exposure to DPM. Previous studies have produced equivocal

4.4 Occasionally, original EC (as opposed to char) is lost results because exposure data are lacking. Given the economic

with the fourth temperature step in helium. Loss of EC in and public health impact of epidemiological studies, accurate

helium is uncommon, but sometimes occurs, possibly due to risk assessment is critical. An ongoing NIOSH/NCI study of

oxidants in the sample. The OC-EC split is automatically miners exposed to diesel exhaust should provide a more

assigned earlier (in helium) in these cases (5). quantitative estimate of the lung cancer risk. The test method

4.5 OC and EC results are reported in units µg per cm of was used for exposure monitoring. Since publication (in 1996)

filter deposit. The total OC and EC on the filter are calculated as NMAM 5040, the method has been routinely used for

by multiplying the reported values by the deposit area (slightly occupational monitoring (5).

less than the filter area). A homogeneous deposit is assumed. 5.3 The test method supports a proposed EPA air standard

The TC in the sample is the sum of OC and EC. If carbonate for fine particulate carbon. Recent studies indicate a positive

is present, the carbon in it is quantified as OC unless correction association between airborne levels of fine particles and

is made. Additional details about carbonates are given in a respiratory illness and mortality (14-22). The test method and

following section. others have been used for EPAair monitoring networks and air

pollution studies. Because different methods produce different

5. Significance and Use

results, method standardization is essential for regulatory

compliancedeterminationsandvalidcomparisonsofinterlabo-

5.1 The test method supports proposed, occupational expo-

sure standards (6, 7) for DPM. In the United States alone, over ratory data.

5.4 The test method is being applied for emission-control

a million workers are occupationally exposed (8).An exposure

standard for mines is especially important because miners’ testing.

exposures are often quite high. NIOSH (8), the International

6. Interferences

Agency for Research on Cancer (9) (IARC), the World Health

Organization (10) (WHO), the California Environmental Pro- 6.1 EC is a more selective marker of occupational exposure

tection Agency (11), the U.S. Environmental Protection than other measures of DPM (for example, particulate mass,

D6877–03

total carbon). As defined by the test method, EC is the carbon 7.1.6 Valve box/calibration loop—for control of gas flow

determined during the second stage of the analysis (after and automatic injection of methane internal standard.

pyrolysis correction). If the sample contains no pyrolyzable

8. Reagents and Materials

material, all carbon evolved during this stage is considered

elemental. Inorganic dusts, carbonates, and wood and cigarette

8.1 Organic Carbon (OC) Standards—Sucrose stock solu-

smokes ordinarily do not interfere in the EC determination

tion having carbon concentration of 25 mg/mL. Working

(2-5). OC can be contributed by smokes, fumes and other

standards (dilutions of stock) with concentrations of 0.1 to 3

sources.

mg C per mL solution. Ensure carbon loadings of standards

6.2 If high levels of other dusts are present, a size classifier

spiked onto filter punches bracket the range of the samples.

(for example, impactor, or cyclone, or both) should be used. If

8.2 Ultrapure water, Type I, (for preparation of sucrose

the dust is carbonaceous, a size classifier provides a more

standard solution).

selective measure of the diesel-source OC. It also provides a

8.3 Sucrose—reagent grade (99+ %).

better measure of the diesel-source EC if the dust contains EC

8.4 Helium-UHP (99.999%). Scrubber also required for

(for example, carbon black, coal), which is less common. A

removal of trace oxygen.

finely ground sample of the bulk material can be analyzed to

8.5 Hydrogen—purified (99.995%). Cylinder or hydrogen

determinewhetheradustposespotentialinterference.Depend-

generator source. Warning—Hydrogen is a flammable gas.

ing on the dust concentration, size distribution, and target

Users must be familiar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.