ASTM E2624-09

(Practice)Standard Practice for Torque Calibration of Testing Machines and Devices

Standard Practice for Torque Calibration of Testing Machines and Devices

SIGNIFICANCE AND USE

Testing machines that apply and indicate torque are used in many industries, in many ways. They may be used in a research laboratory to measure material properties, and in a production line to qualify a product for shipment. No matter what the end use of the machine may be, it is necessary for users to know the amount of torque that is applied, and that the accuracy of the torque value is traceable to the National Standards. This standard provides a procedure to verify these machines and devices, in order that the indicated torque values may be traceable. A key element to having traceability is that the devices used in the calibration produce known torque characteristics, and have been calibrated in accordance with Practice E 2428.

This standard may be used by those using, those manufacturing, and those providing calibration service for torque capable testing machines or devices and related instrumentation.

SCOPE

1.1 This practice covers procedures and requirements for the calibration of torque for static and quasi-static torque capable testing machines or devices. These may, or may not, have torque indicating systems and include those devices used for the calibration of hand torque tools. Testing machines may be calibrated by one of the three following methods or combination thereof:

1.1.1 Use of standard weights and lever arms.

1.1.2 Use of elastic torque measuring devices.

1.1.3 Use of elastic force measuring devices and lever arms.

1.1.4 Any of the methods require a specific uncertainty of measurement and a traceability derived from national standards of mass and length.

1.2 The procedures of 1.1.1, 1.1.2, and 1.1.3 apply to the calibration of the torque-indicating systems associated with the testing machine, such as a scale, dial, marked or unmarked recorder chart, digital display, etc. In all cases the buyer/owner/user must designate the torque-indicating system(s) to be calibrated and included in the report.

1.3 Since conversion factors are not required in this practice, either english units, metric units, or SI units can be used as the standard.

1.4 Torque values indicated on displays/printouts of testing machine data systems—be they instantaneous, delayed, stored, or retransmitted—which are Calibrated with provisions of 1.1.1, 1.1.2 or 1.1.3 or a combination thereof, and are within the ±1 % of reading accuracy requirement, comply with this practice.

1.5 The following applies to all specified limits in this standard: For purposes of determining conformance with these specifications, an observed value or a calculated value shall be rounded “to the nearest unit” in the last right-hand digit used in expressing the specification limit, in accordance with the rounding method of Practice E 29, for Using Significant Digits in Test Data to Determine Conformance with Specifications.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2624 − 09

StandardPractice for

Torque Calibration of Testing Machines and Devices

This standard is issued under the fixed designation E2624; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice covers procedures and requirements for

responsibility of the user of this standard to establish appro-

the calibration of torque for static and quasi-static torque

priate safety and health practices and determine the applica-

capable testing machines or devices. These may, or may not,

bility of regulatory limitations prior to use.

have torque indicating systems and include those devices used

for the calibration of hand torque tools. Testing machines may

2. Referenced Documents

be calibrated by one of the three following methods or

combination thereof: 2

2.1 ASTM Standards:

1.1.1 Use of standard weights and lever arms.

E6Terminology Relating to Methods of MechanicalTesting

1.1.2 Use of elastic torque measuring devices.

E29Practice for Using Significant Digits in Test Data to

1.1.3 Useofelasticforcemeasuringdevicesandleverarms.

Determine Conformance with Specifications

1.1.4 Any of the methods require a specific uncertainty of

E74Practice of Calibration of Force-Measuring Instruments

measurementandatraceabilityderivedfromnationalstandards

for Verifying the Force Indication of Testing Machines

of mass and length.

E2428Practice for Calibration of Torque-Measuring Instru-

1.2 The procedures of 1.1.1, 1.1.2, and 1.1.3 apply to the

ments for Verifying the Torque Indication of Torque

calibrationofthetorque-indicatingsystemsassociatedwiththe Testing Machines

testing machine, such as a scale, dial, marked or unmarked

2.2 NIST Technical Notes:

recorderchart,digitaldisplay,etc.Inallcasesthebuyer/owner/

NIST Technical Note 1297Guidelines for Evaluating and

user must designate the torque-indicating system(s) to be

Expressing the Uncertainty of NIST Measurement Re-

calibrated and included in the report. 3

sults

1.3 Since conversion factors are not required in this

practice, either english units, metric units, or SI units can be

3. Terminology

used as the standard.

3.1 Definitions:

1.4 Torque values indicated on displays/printouts of testing

3.1.1 accuracy—accuracy is defined in Terminology E6.

machine data systems—be they instantaneous, delayed, stored,

3.1.1.1 Discussion—Atestingmachineissaidtobeaccurate

or retransmitted—which are Calibrated with provisions of

if the indicated torque is within the specified permissible

1.1.1, 1.1.2 or 1.1.3 or a combination thereof, and are within

variation from the actual torque in these methods the word

the 61% of reading accuracy requirement, comply with this

“accurate” applied to a testing machine is used without

practice.

numerical values, for example, “An accurate testing machine

1.5 The following applies to all specified limits in this

was used for the investigation.” The accuracy of a testing

standard: For purposes of determining conformance with these

machine should not be confused with sensitivity. For example,

specifications, an observed value or a calculated value shall be

a testing machine might be very sensitive; that is, it might

rounded“tothenearestunit”inthelastright-handdigitusedin

indicate quickly and definitely small changes in torque, but

expressing the specification limit, in accordance with the

nevertheless, be very inaccurate. On the other hand, the

rounding method of Practice E29, for Using Significant Digits

accuracy of the results is in general limited by the sensitivity.

in Test Data to Determine Conformance with Specifications.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ThispracticeisunderthejurisdictionofASTMCommitteeE28onMechanical contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Testing and is the direct responsibility of Subcommittee E28.01 on Calibration of Standards volume information, refer to the standard’s Document Summary page on

Mechanical Testing Machines and Apparatus. the ASTM website.

Current edition approved April 1, 2009. Published May 2009. DOI: 10.1520/ Available from National Institute of Standards and Technology (NIST), 100

E2624-09. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2624 − 09

3.1.2 calibrated range of torque—in the case of testing

B = reference value of the applied torque, N-m (lbf-in.), as

machines, the range of indicated torque for which the testing

determined by the calibration device.

machine gives results within the permissible variations speci-

3.1.12 permissible variation (or tolerance)— in the case of

fied.

testing machines, the maximum allowable error in the value of

3.1.3 calibration torque—a torque with traceability derived

the quantity indicated.

from national standards of mass and length and of specific

3.1.12.1 Discussion—Itisconvenienttoexpresspermissible

uncertainty of measurement, which can be applied to torque

variation in terms of percentage of error. The numerical value

measuring devices.

of the permissible variation for a testing machine is so stated

3.1.4 capacity range—in the case of testing machines, the

hereafter in these practices.

rangeoftorqueforwhichitisdesigned.Sometestingmachines

3.1.13 reference standard—astandardusedtogenerateorto

have more than one capacity range, that is, multiple ranges.

measure torque applied to the testing machine to be calibrated.

3.1.5 correction—in the case of testing machines, the

NOTE 2—Torque may be generated by a length calibrated arm and

difference obtained by subtracting the indicated torque from

calibrated masses used to produce known torque. Alternatively, torque

the reference value of the applied torque.

appliedtoatorquemeasuringdevicetobecalibratedmaybemeasuredby

the use of a reference torque measurement device, i.e., an elastic torque

3.1.6 elastic torque-measuring device—a device or system

calibration device, or a length calibrated arm and an elastic force

consisting of an elastic member combined with a device for

measuring device.

indicating the measured values (or a quantity proportional to

3.1.14 resolution of analog type torque indicators (scales,

the measured value) of deformation of the member under an

dials, recorders, etc.)—the resolution is the smallest change in

applied torque.

torque indicated by a displacement of a pointer, or pen line.

NOTE 1—The instrumentation for the elastic devices may be either an

The resolution is calculated by multiplying the torque corre-

electrical or a mechanical device, i.e., a scale or pointer system.

sponding to one graduation by the ratio of the width of the

3.1.7 error (or the deviation from the reference value)—in

pointerorpenlinetothecentertocenterdistancebetweentwo

the case of a testing machine or device,thedifferenceobtained

adjacent graduation marks.

by subtracting the torque indicated by the calibration device

3.1.15 resolution of digital type torque indicators (numeric,

from the torque indicated by the testing machine or device.

displays, printouts, etc.)—the resolution is the smallest change

3.1.7.1 Discussion—The word “error” shall be used with

in torque that can be displayed on the digital torque indicator,

numericalvalues,forexample,“Atatorqueof3000lbf-in.,the

at any applied torque. Appendix X1 describes a method for

error of the testing machine was +10 lbf-in.”

determining resolution.

3.1.8 expanded uncertainty—a statistical measurement of

3.1.15.1 Discussion—Ifthetorqueindication,foreithertype

the probable limits of error of a measurement. NISTTechnical

of torque indicator, fluctuates by more than twice the

Note 1297 treats the statistical approach including the ex-

resolution, as described in 3.1.15 or 3.1.16, the resolution,

panded uncertainty.

expressed as torque, shall be equal to one-half the range of the

3.1.9 lower torque limit of calibration range—the lowest

fluctuation.

value of torque at which a torque measuring system can be

3.1.16 resolution of the torque indicator—smallest change

calibrated.

of torque that can be estimated or ascertained on the torque

3.1.10 parasitic torque—torque that bypasses a desired

indicating apparatus of the testing machine or device, at any

torquepaththatcancauseerrorsindeterminingthevalueofthe

appliedtorque.AppendixX1describesamethodfordetermin-

torque in that path. It is usually caused by cables, conduit, or

ing resolution.

hydraulic lines attached to objects that are in the torque path.

3.1.17 torque—vector product of force and length, ex-

These attachments absorb torque and cause subsequent errors

pressed in terms of N-m, lbf-in., etc.

in the measured torque.

3.1.18 torque capable testing machine—a testing machine

3.1.11 percent error—in the case of a testing machine or

or device that has provision for applying a torque to a

device, the ratio, expressed as a percent, of the error to the

specimen.

reference value of the applied torque.

3.1.11.1 Discussion—The test torque, as indicated by the

4. Significance and Use

testing machine, and the applied torque, as computed from the

readingsofthecalibrationdevice,shallberecordedateachtest

4.1 Testingmachinesthatapplyandindicatetorqueareused

point.Theerror,E,andthepercenterror,E ,shallbecalculated

in many industries, in many ways. They may be used in a

p

from this data as follows:

research laboratory to measure material properties, and in a

production line to qualify a product for shipment. No matter

E 5 A 2 B (1)

what the end use of the machine may be, it is necessary for

E 5 A 2 B /B 3100

~~ ! ! userstoknowtheamountoftorquethatisapplied,andthatthe

p

accuracy of the torque value is traceable to the National

where:

Standards. This standard provides a procedure to verify these

A = torque indicated by the machine being calibrated, N-m

machinesanddevices,inorderthattheindicatedtorquevalues

(lbf-in.), and

may be traceable. A key element to having traceability is that

E2624 − 09

the devices used in the calibration produce known torque where:

characteristics, and have been calibrated in accordance with

M = mass of the weight,

Practice E2428.

g = local acceleration due to gravity, m/s ,

d = air density (approximately 0.0012 Mg/m ),

4.2 This standard may be used by those using, those

D = density of the weight in the same units as d (Note

manufacturing, and those providing calibration service for

3), and

torque capable testing machines or devices and related instru-

9.80665 = the factor converting SI units of force into the

mentation.

customary units of force. For SI units, this factor

is not used.

5. Calibration Devices

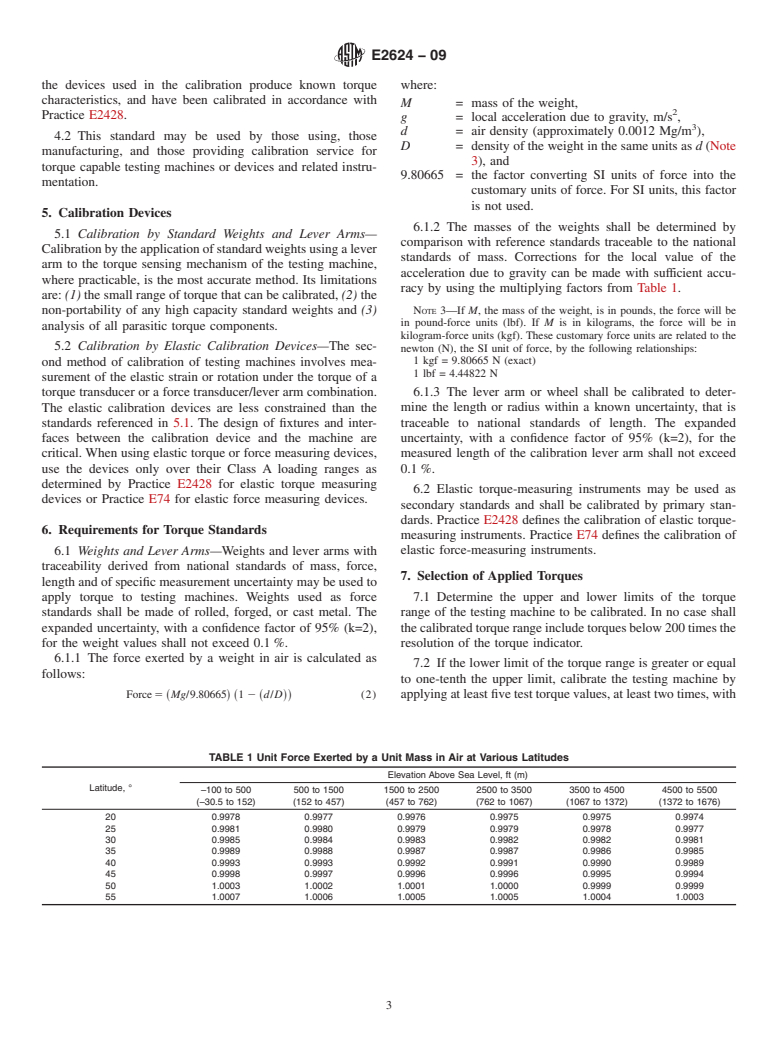

6.1.2 The masses of the weights shall be determined by

5.1 Calibration by Standard Weights and Lever Arms—

comparison with reference standards traceable to the national

Calibrationbytheapplicationofstandardweightsusingalever

standards of mass. Corrections for the local value of the

arm to the torque sensing mechanism of the testing machine,

acceleration due to gravity can be made with sufficient accu-

where practicable, is the most accurate method. Its limitations

racy by using the multiplying factors from Table 1.

are: (1)thesmallrangeoftorquethatcanbecalibrated, (2)the

NOTE 3—If M, the mass of the weight, is in pounds, the force will be

non-portability of any high capacity standard weights and (3)

in pound-force units (lbf). If M is in kilograms, the force will be in

analysis of all parasitic torque components.

kilogram-force units (kgf). These customary force units are related to the

5.2 Calibration by Elastic Calibration Devices—The sec-

newton (N), the SI unit of force, by the following relationships:

1 kgf = 9.80665 N (exact)

ond method of calibration of testing machines involves mea-

1 lbf = 4.44822 N

surement of the elastic strain or rotation under the torque of a

torque transducer or a force transducer/lever arm combination. 6.1.3 The lever arm or wheel shall be calibrated to deter-

The elastic calibration devices are less constrained than the mine the length or radius within a known uncertainty, that is

standards referenced in 5.1. The design of fixtures and inter- traceable to national standards of length. The expanded

faces between the calibration device and the machine are uncertainty, with a confidence factor of 95% (k=2), for the

critical.When using elastic torque or force measuring devices, measured length of the calibration lever arm shall not exceed

use the devices only over their Class A loading ranges as 0.1%.

determined by Practice E2428 for elastic torque measuring

6.2 Elastic torque-measuring instruments may be used as

devices or Practice E74 for elastic force measuring devices.

secondary standards and shall be calibrated by primary stan-

dards. Practice E2428 defines the calibration of elastic torque-

6. Requirements for Torque Standards

measuring instruments. Practice E74 defines the calibration of

6.1 Weights and Lever Arms—Weights and lever arms with elastic force-measuring instruments.

traceability derived from national standards of mass, force,

7. Selection of Applied Torques

lengthandofspecificmeasurementuncertaintymaybeusedto

apply torque to testing machines. Weights used as force 7.1 Determine the upper and lower limits of the torque

standards shall be made of rolled, forged, or cast metal. The range of the testing machine to be calibrated. In no case shall

expanded uncertainty, with a confidence factor of 95% (k=2), thecalibratedtorquerangeincludetorquesbelow200timesthe

for the weight values shall not exceed 0.1%. resolution of the torque indicator.

6.1.1 The force exerted by a weight in air is calculated as

7.2 If the lower limit of the torque range is greater or equal

follows:

to one-tenth the upper limit, calibrate the testing machine by

Force 5 ~Mg/9.80665!~1 2 ~d/D!! (2) applyingatleastfivetesttorquevalues,atleasttwotimes,with

TABLE 1 Unit Force Exerted by a Unit Mass in Air at Various Latitudes

Elevation Above Sea Level, ft (m)

Latitude, °

–100 to 500 500 to 1500 1500 to 2500 2500 to 3500 3500 to 4500 4500 to 5500

(–30.5 to 152) (152 to 457) (457 to 762) (762 to 1067) (1067 to 1372) (1372 to 1676)

20 0.9978 0.9977 0.9976 0.9975 0.9975 0.9974

25 0.9981 0.9980 0.9979 0.9979 0.9978 0.9977

30 0.9985 0.9984 0.9983 0.9982 0.9982 0.9981

35 0.9989 0.9988 0.9987 0.9987 0.9986 0.9985

40 0.9993 0.9993 0.9992 0.9991 0.9990 0.9989

45 0.9998

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.