ASTM D6063-96(2001)

(Guide)Standard Guide for Sampling of Drums and Similar Containers by Field Personnel

Standard Guide for Sampling of Drums and Similar Containers by Field Personnel

SCOPE

1.1 This guide covers information, including flow charts, for field personnel to follow in order to collect samples from drums and similar containers.

1.2 The purpose of this guide is to help field personnel in planning and obtaining samples from drums and similar containers, using equipment and techniques that will ensure that the objectives of the sampling activity will be met. It can also be used as a training tool.

1.3This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6063–96 (Reapproved 2001)

Standard Guide for

Sampling of Drums and Similar Containers by Field

Personnel

This standard is issued under the fixed designation D 6063; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 5088 Practice for Decontamination of Field Equipment

Used at Nonradioactive Waste Sites

1.1 Thisguidecoversinformation,includingflowcharts,for

D 5283 Practice for Generation of Environmental Data

field personnel to follow in order to collect samples from

Related to Waste Management Activities: Quality Assur-

drums and similar containers.

ance and Quality Control Planning and Implementation

1.2 The purpose of this guide is to help field personnel in

D 5358 Practice for Sampling with a Dipper or Pond

planning and obtaining samples from drums and similar

Sampler

containers, using equipment and techniques that will ensure

D 5451 Practice for Sampling Using a Trier Sampler

that the objectives of the sampling activity will be met. It can

D 5495 Practice for Sampling with a Composite Liquid

also be used as a training tool.

Waste (COLIWASA) Sampler

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety and health practices and determine the applica-

3.1.1 bung, n—usually a 2-in. (5-cm) or ⁄4-in. (1.3-cm)

bility of regulatory limitations prior to use.

diameter threaded plug specifically designed to close a bung

2. Referenced Documents hole.

3.1.2 bung hole, n—an opening in a barrel or drum through

2.1 ASTM Standards:

which it can be filled, emptied or vented.

C 783 Practice for Core Sampling of Graphite Electrodes

3.1.3 consolidated solid, n—as used in this guide, a com-

D 1452 Practice for Soil Investigation and Sampling by

pact solid not easily compressed or broken into smaller

Auger Borings

portions.

D 1586 Test Method for Penetration Test and Split-Barrel

3.1.4 drum, n—when used in the flow charts in this guide,

Sampling of Soils

thewordimpliesanydrum,barrelornon-bulkcontainerof5to

D 1587 Practice for Thin-Walled Tube Geotechnical Sam-

110 gal (19 to 400 L) capacity.

pling of Soils

3.1.5 representative sample, n—a sample collected such

D 2113 Practice for Diamond Core Drilling for Site Inves-

that it reflects one or more characteristics of interest of the lot

tigation

or population from which it was collected.

D 4448 Guide for Sampling Groundwater MonitoringWells

3.1.6 sample, n—one or more items or portions collected

D 4687 Guide for General Planning of Waste Sampling

from a lot or population.

D 4700 Guide for Soil Sampling from the Vadose Zone

3.1.7 sampler, n—the device used to obtain a sample.

D 4823 Guide for Core-Sampling Submerged, Unconsoli-

3.1.8 sludge, n—as used in this guide, any mixture of solids

dated Sediments

that settles out of solution; sludges contain liquids that are not

D 4840 Guide for Sample Chain of Custody Procedures

apparent as free liquids.

3.1.9 unconsolidated solid, n—as used in this guide, unce-

This guide is under the jurisdiction of ASTM Committee D34 on Waste

mented or uncompacted material that is easily separated into

Management and is the direct responsibility of Subcommittee D34.01.02 on

smaller portions.

Sampling Techniques.

3.1.10 work plans, n—plans that are specific to sampling at

Current edition approved Dec. 10, 1996. Published February 1997.

a particular site; examples are Health and Safety Plans and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Sampling and Analysis Plans.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6063–96 (2001)

4. Summary of Guide addressed before, during, and after taking a sample. It provides

guidance in choosing the sampling technique and equipment

4.1 This guide uses a decision-tree format to lead persons

suitableforspecificsituations.Itcanserveasatrainingtoolfor

intending to sample waste materials from drums and similar

those who are unfamiliar with sampling. It is recommended

containers through a series of questions. The answers to the

that this guide be used as a supplement to a written workplan.

questions result in recommended actions, including the selec-

5.3 Some sections of this guide contain flow charts (see

tion of appropriate sampling equipment. Brief instructions on

Figs.1-5)thatmustbeworkedthrough,startingfromthetopof

the use of the equipment are included.

each page. By answering the questions in the diamond-shaped

4.2 This guide addresses commonly used sampling equip-

boxes, and following the appropriate arrows, the person

ment and devices; it is not intended to cover all that might be

planning to sample will be guided towards the most suitable

purchased or custom made.

procedures and equipment.The numbers at the bottom of some

boxes refer to corresponding paragraphs in the text, which

5. Significance and Use

provide information to help the person sampling answer the

5.1 This guide is intended to assist field personnel in

questions.

obtaining samples from drums and similar containers for

5.4 Figs. 6-15 are examples of types of equipment. Similar

laboratory analysis. The costs associated with sampling and

devices that do the same job in the same way are not intended

analysis make it essential that samples be taken correctly

to be excluded.

before submitting them for chemical analysis or physical

testing, or both. Incorrect sampling can invalidate resulting

6. Objectives of Sampling

data.

5.2 This guide may be used by personnel who have no 6.1 The purpose of sampling is to collect a representative

formal workplan. It draws their attention to issues that must be sample of all or part of the contents of the drum or similar

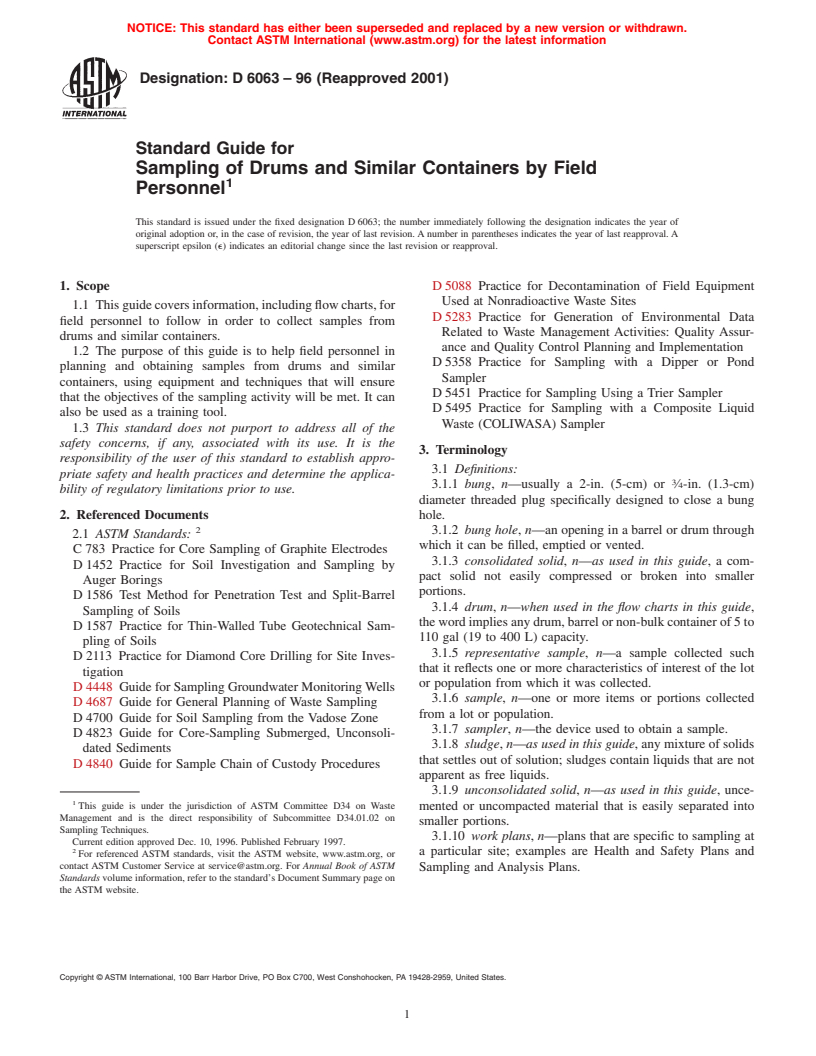

NOTE 1—This flow chart should be used with Section 6 in the text.

FIG. 1 Objectives of Sampling

D6063–96 (2001)

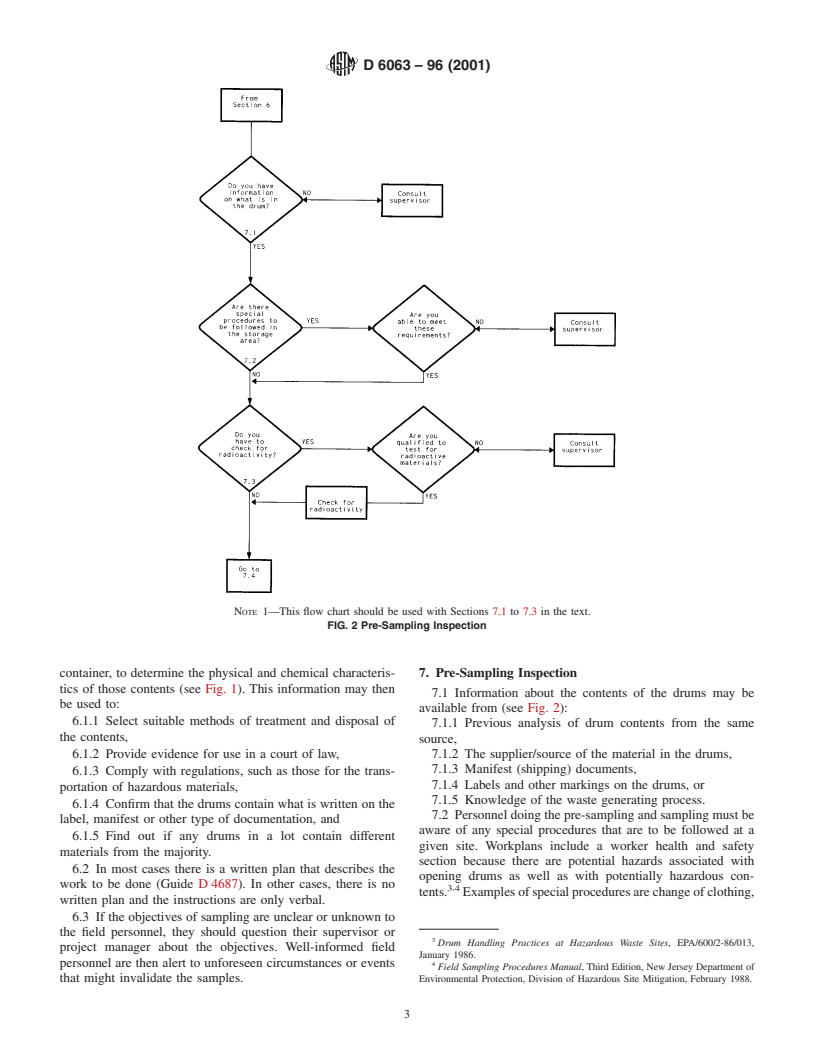

NOTE 1—This flow chart should be used with Sections 7.1 to 7.3 in the text.

FIG. 2 Pre-Sampling Inspection

container, to determine the physical and chemical characteris- 7. Pre-Sampling Inspection

tics of those contents (see Fig. 1). This information may then

7.1 Information about the contents of the drums may be

be used to:

available from (see Fig. 2):

6.1.1 Select suitable methods of treatment and disposal of

7.1.1 Previous analysis of drum contents from the same

the contents,

source,

6.1.2 Provide evidence for use in a court of law, 7.1.2 The supplier/source of the material in the drums,

7.1.3 Manifest (shipping) documents,

6.1.3 Comply with regulations, such as those for the trans-

7.1.4 Labels and other markings on the drums, or

portation of hazardous materials,

7.1.5 Knowledge of the waste generating process.

6.1.4 Confirm that the drums contain what is written on the

7.2 Personnel doing the pre-sampling and sampling must be

label, manifest or other type of documentation, and

aware of any special procedures that are to be followed at a

6.1.5 Find out if any drums in a lot contain different

given site. Workplans include a worker health and safety

materials from the majority.

section because there are potential hazards associated with

6.2 In most cases there is a written plan that describes the

opening drums as well as with potentially hazardous con-

work to be done (Guide D 4687). In other cases, there is no

,

3 4

tents. Examplesofspecialproceduresarechangeofclothing,

written plan and the instructions are only verbal.

6.3 If the objectives of sampling are unclear or unknown to

the field personnel, they should question their supervisor or

Drum Handling Practices at Hazardous Waste Sites, EPA/600/2-86/013,

project manager about the objectives. Well-informed field

January 1986.

personnel are then alert to unforeseen circumstances or events

Field Sampling Procedures Manual, Third Edition, New Jersey Department of

that might invalidate the samples. Environmental Protection, Division of Hazardous Site Mitigation, February 1988.

D6063–96 (2001)

NOTE 1—This flow chart should be used with Sections 7.3 to 7.5 in the text.

FIG. 2 Pre-Sampling Inspection (continued)

use of safety equipment of various kinds, evacuation proce- that the monitor has been calibrated correctly, according to the

dures, fire and explosion procedures and vehicle cleaning

manufacturer’s instructions. Monitoring should be done only

procedures such as water washing before leaving the site or

by those with the appropriate written procedures, training and

storage area, and many others that would be site or storage

equipment.

specific.

7.3.3 It is prudent to monitor a storage area before entering

7.3 If you are certain that the drum does not contain

it. If radioactive material is found to be present when it should

radioactive material and the workplan does not require you to

not be, leave the area immediately, post warning signs to alert

check for radioactivity, proceed to 7.4.

other workers, and consult your supervisor.

7.3.1 Many facilities are not licensed to handle radioactive

7.4 Drums may contain flammable materials, strong oxidiz-

materials and are legally obliged to prove that they do not

ers or reducing materials, light-sensitive materials, corrosive

knowingly accept them. Some facilities are licensed to handle

acids or bases, and materials sensitive to moisture.All of these

radioactive materials; they need to have a measure of how

drums require special handling, including segregation.

radioactive the material is for the safety of their workers.

7.4.1 Many solvents, like benzene, evaporate into air space

7.3.2 Hand-held monitors that check for radioactivity

in and around the drum where the vapour may be easily

should always be used if you suspect that radioactive material

might be present or if the workplan requires it. It is important ignited.

D6063–96 (2001)

NOTE 1—This flow chart should be used with Sections 7.6 to 7.8 in the text.

FIG. 2 Pre-Sampling Inspection (continued)

7.4.2 If you are sampling a potentially flammable or un- 7.4.4 Labels on drums of waste materials may not be

known material, non-sparking tools should be used and the accurate. Unless the drums come from a reliable source, for

example, the generator of the material and the process that

drums should be grounded.

created the waste are known to you, it is prudent to assume that

7.4.3 If the drums are stored in a closed room or confined

the labels may not match the contents.

space, the air in the area should be tested by a hand-held

monitor to check for flammable vapors. It is important that the

NOTE 2—Precaution: Attempting to open a drum that is in poor

monitor has been calibrated according to the manufacturer’s

condition can expose a worker to the possibility of a serious, even fatal,

instructions. The monitoring should be done by those with the

accident. Special precautions should be taken when the bungs are rusted

appropriate training and written procedures. or corroded since the drum top may give way, exposing the worker to

vapor or liquid. Overpacking before sampling should be considered for

NOTE 1—Warning: Flammable materials should be sampled in a

drums in poor condition.

well-ventilated area. There are other safety considerations that must be

7.5 It is not always necessary to sample every drum in a lot.

considered regarding confined spaces. It may be necessary to check for

explosivity or oxygen levels. The workplans provide direction as to how many, and possibly

D6063–96 (2001)

NOTE 1—This flow chart should be used with Sections 8.1 to 8.5 in the text.

FIG. 3 Selection of Suitable Sampling Procedure

which, drums should be sampled. Each drum that will be carriers, which lock on the drum lip, should not be used to

sampled must be identified in a unique way in case a second move the drum if the condition is poor.

sample has to be taken later. Colored labels, crayons, paint 7.8 Materials in layers, such as oil with water, can become

sticksorpens,orstencilledpaintcanbeusedtoidentifydrums. mixed together when moved. If you want to sample each layer

Any new identification system should not cover the existing separately, the material may need time to settle before opening

labels or identifiers. and sampling the drum.

7.6 Sometimes drums have to be moved to another location

8. Selection of Suitable Sampling Procedure

for sampling; this is known as “drum staging”.This is required

if:

8.1 The physical state(s) of the material(s) being sampled is

7.6.1 Sampling the drum in its present location poses a high

an important criterion when sampling (see Fig. 3).

risk to surrounding property and individuals,

8.2 A drum containing one liquid, such as water, or a

7.6.2 The drum cannot be accessed for sampling in its

mixture of liquids, such as a stable emulsion like hand cream,

current location, or

that does not separate into two layers regardless of time, is said

7.6.3 Exposure to climatic conditions alter the sample, for

to contain one phase. A drum containing two liquids, such as

example,formationofice;orcreateahealthandsafetyrisk,for

oil and water, which form two distinct layers when they are not

example, the sun heating a drum containing solvents.

stirred is said to contain two phases.

7.7 The physical condition of drums must be evaluated 8.3 When it is necessary to know the amounts of solid and

before attempting to open or move them (see Note 2). Drum liquid layers in a drum, a calibrated measuring device or the

D6063–96 (2001)

NOTE 1—This flow chart should be used with Sections 8.6 to 8.8 in the text.

FIG. 3 Selection of Suitable Sampling Procedure (continued)

sampling equipment (for example, a COLIWASA) can be 8.6.2 The equipment will have to be replaced frequently,

inserted into the opened drum (see Section 12) and the liquid adding costs to the project.

level measured. 8.7 Whenselectingequipment,itisimportanttobeawareof

8.4 Although sludges behave like sticky solids and are not the limitations of the tools. The design of some equipment can

usually pumped, they can contain quite a high proportion of result in part of the material not being sampled. For example,

l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.