ASTM D5706-97(2002)e1

(Test Method)Standard Test Method for Determining Extreme Pressure Properties of Lubricating Greases Using A High-Frequency, Linear-Oscillation (SRV) Test Machine

Standard Test Method for Determining Extreme Pressure Properties of Lubricating Greases Using A High-Frequency, Linear-Oscillation (SRV) Test Machine

SCOPE

1.1 This test method covers a procedure for determining extreme pressure properties of lubricating greases under highfrequency linear-oscillation motion using the SRV test machine. This test method can also be used for evaluating extreme pressure properties of lubricating fluid.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D5706–97 (Reapproved 2002)

Standard Test Method for

Determining Extreme Pressure Properties of Lubricating

Greases Using A High-Frequency, Linear-Oscillation (SRV)

Test Machine

This standard is issued under the fixed designation D5706; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Warnings were moved from notes to section text editorially January 2003.

1. Scope both, which are uncharacteristic of the given tribological

system’s long-term behavior. G40

1.1 This test method covers a procedure for determining

3.1.2 coeffıcient of friction, µ or f, n—in tribology, the

extreme pressure properties of lubricating greases under high-

dimensionless ratio of the friction force (F) between two

frequency linear-oscillation motion using the SRV test ma-

bodies to the normal force (N) pressing these bodies together.

chine.Thistestmethodcanalsobeusedforevaluatingextreme

G40

pressure properties of lubricating fluid.

3.1.3 Hertzian contact area, n—theapparentareaofcontact

1.2 The values stated in SI units are to be regarded as the

between two nonconforming solid bodies pressed against each

standard. The values given in parentheses are for information

other, as calculated from Hertz’ equations of elastic deforma-

only.

tion. G40

1.3 This standard does not purport to address all of the

3.1.4 Hertzian contact pressure, n—the magnitude of the

safety concerns, if any, associated with its use. It is the

pressure at any specified location in a Hertzian contact area, as

responsibility of the user of this standard to establish appro-

calculated from Hertz’ equations of elastic deformation.

priate safety and health practices and determine the applica-

G40

bility of regulatory limitations prior to use.

3.1.5 lubricant, n—any material interposed between two

2. Referenced Documents surfaces that reduces the friction or wear, or both, between

them. D 4175

2.1 ASTM Standards:

3.1.6 lubricating grease, n—a semifluid to solid product of

D217 Test Methods for Cone Penetration of Lubricating

a dispersion of a thickener in a liquid lubricant. D 217

Grease

3.1.6.1 Discussion—Thedispersionofthethickenerformsa

D4175 Terminology Relating to Petroleum, Petroleum

two-phase system and immobilizes the liquid lubricant by

Products, and Lubricants

surfacetensionandotherphysicalforces.Otheringredientsare

G40 Terminology Relating to Wear and Erosion

commonly included to impart special properties.

2.2 Other Standard:

3.1.7 thickener, n—in lubricating grease, a substance com-

DIN 17230 Roller Bearing Steels

posed of finely divided solid particles dispersed in a liquid

3. Terminology

lubricant to form the grease structure. D 217

3.1.7.1 Discussion—The thickener can be fibers (such as

3.1 Definitions:

various metallic soaps) or plates or spheres (such as certain

3.1.1 break-in, n—in tribology, an initial transition process

non-soapthickeners)whichareinsolubleor,atmost,onlyvery

occurring in newly established wearing contacts, often accom-

slightly soluble in the liquid lubricant. The general require-

panied by transients in coefficient of friction or wear rate, or

mentsarethatthesolidparticlesbeextremelysmall,uniformly

dispersed, and capable of forming a relatively stable, gel-like

structure with the liquid lubricant.

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.8 Ra, n—in measuring surface finish, the arithmetic

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.G0.04 on Functional Tests—Tribology. average of the absolute distances of all profile points from the

Current edition approved June 10, 1997. Published October 1997. Originally

mean line for a given distance.

published as D5706–95. Last previous edition D5706–95.

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 03.02.

5 6

Available from Beuth Verlog GmbH, Burggrafenstrasse 6, 1000 Berlin 30, Amstutz, Hu, “Surface Texture: The Parameters,” Bulletin MI-TP-003-0785,

Germany. Sheffield Measurement Division, Warner and Swasey, 1985, p. 21.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D5706–97 (2002)

FIG. 1 SRV Test Machine

3.1.9 Rz (DIN), n—in measuring surface finish, the average incrementsuntilseizureoccurs.Theload,immediatelypriorto

of all Ry values (peak to valley heights) in the assessment

the load at which seizure occurs, is measured and reported.

length.

NOTE 1—Test frequency, stroke length, temperature, and ball and disk

3.1.10 Ry, n—in measuring surface finish, the vertical

material can be varied to simulate field conditions. The test ball yields

distance between the top of the highest peak and the bottom of

point-contact geometry. To obtain line or area contact, test pieces of

the deepest valley in one sampling length.

differing configurations can be substituted for the test balls.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 extreme pressure, adj—in lubrication—characterized

5. Significance and Use

by metal surfaces in contact under high-stress rubbing condi-

5.1 This laboratory test method can be used to quickly

tions.

determine extreme pressure properties of lubricating greases at

3.2.2 seizure, n—localized fusion of metal between the

selected temperatures specified for use in applications where

rubbing surfaces of the test pieces.

high-speed vibrational or start-stop motions are present with

3.2.2.1 Discussion—Inthistestmethod,seizureisindicated

high Hertzian point contact. This test method has found wide

by a rise in the coefficient of friction, over steady state, of

application in qualifying lubricating greases used in constant

greater than 0.2. In severe cases, a stoppage in the motor will

velocity joints of front-wheel-drive automobiles. Users of this

occur.

test method should determine whether results correlate with

3.2.3 SRV, n—Schwingung, Reibung, Verschleiss (Ger-

man); oscillating, friction, wear (English translation). field performance or other applications.

4. Summary of Test Method

6. Apparatus

4.1 This test method is performed on an SRV test machine

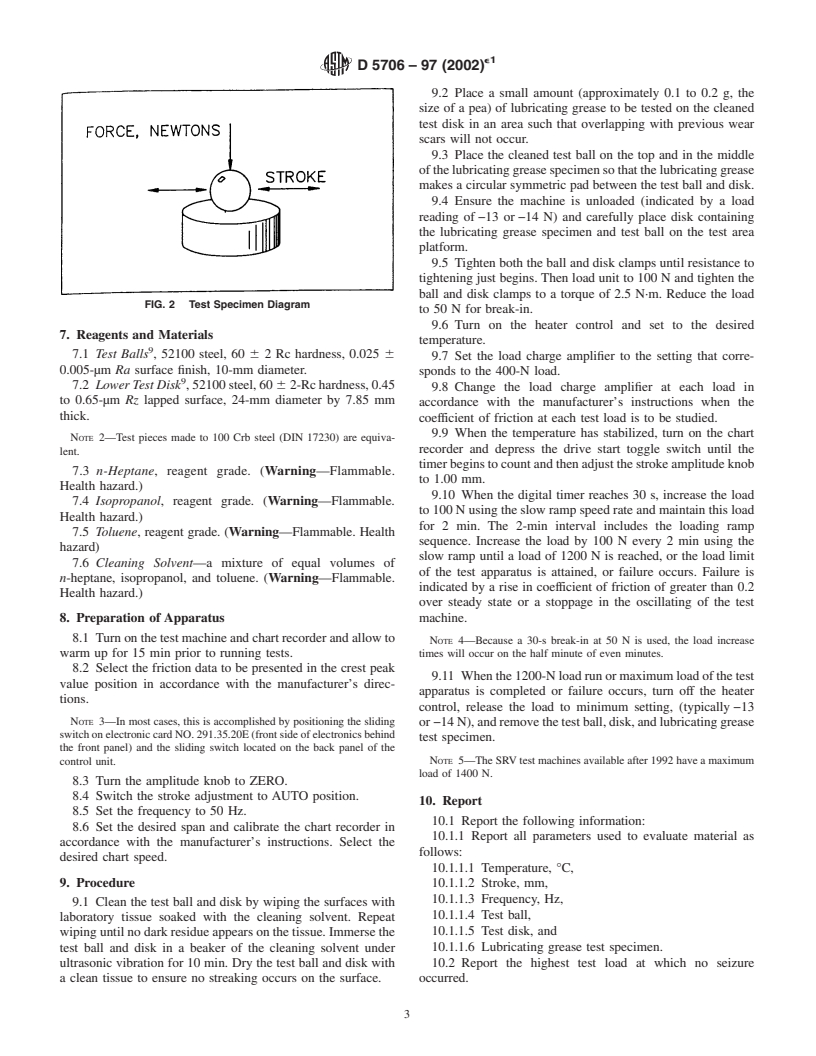

6.1 SRV Test Machine , illustrated in Fig. 1 and Fig. 2.

using a steel test ball oscillating against a steel test disk with

lubricant between them. Test load is increased in 100-N

The sole source of supply of the apparatus known to the committee at this time

Amstutz, Hu, “Surface Texture: The Parameters,” Bulletin MI-TP-003-0785, is Optimal Instruments GmbH, Friedenstrasse 10, D-81671 Munich, Germany. If

Sheffield Measurement Division, Warner and Swasey, 1985, pp. 31, 29. you are aware of alternative suppliers, please provide this information to ASTM

Amstutz, Hu, “Surface Texture: The Parameters,” Bulletin MI-TP-003-0785, Headquarters.Your comments will receive careful consideration at a meeting of the

Sheffield Measurement Division, Warner and Swasey, 1985, p. 25. responsib

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.