ASTM D1781-98(2004)

(Test Method)Standard Test Method for Climbing Drum Peel for Adhesives

Standard Test Method for Climbing Drum Peel for Adhesives

SIGNIFICANCE AND USE

This test method may be used to determine comparative rather than fundamental measurements of adhesion and is particularly suitable for process control, some examples of which are listed.

5.1.1 This test method is particularly sensitive to adherend surface preparation and is of value where the adhesive is used in conjunction with a primer.

5.1.2 When a relatively brittle adhesive is used, the peel resistance can often give an indication of the degree of cure, that is, higher values than normally realized may indicate an incomplete cure. Direct comparison of different adhesives or processes can only be made when specimen design and test conditions are identical.

SCOPE

1.1 This test method covers the determination of the peel resistance of adhesive bonds between: a relatively flexible adherend and a rigid adherend; and the relatively flexible facing of a sandwich structure and its core, when tested under specified conditions.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1781– 98(Reapproved2004)

Standard Test Method for

Climbing Drum Peel for Adhesives

This standard is issued under the fixed designation D1781; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This test method covers the determination of the peel 3.1 Definitions—Many of the terms used in this test method

resistance of adhesive bonds between: a relatively flexible are defined in Terminology D907.

adherend and a rigid adherend; and the relatively flexible

4. Summary of Test Method

facing of a sandwich structure and its core, when tested under

specified conditions. 4.1 Determine the peeling force of a conditioned adhesive

bonded sandwich assembly by peeling a face skin around a

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information circular drum. This is done by clamping the assembly in a

universal test machine. The average peeling load is determined

only.

1.3 This standard does not purport to address all of the using a standard formula.

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 This test method may be used to determine comparative

priate safety and health practices and determine the applica-

rather than fundamental measurements of adhesion and is

bility of regulatory limitations prior to use.

particularly suitable for process control, some examples of

2. Referenced Documents

which are listed.

2.1 ASTM Standards: 5.1.1 This test method is particularly sensitive to adherend

surface preparation and is of value where the adhesive is used

B209 Specification for Aluminum and Aluminum-Alloy

Sheet and Plate in conjunction with a primer.

D907 Terminology of Adhesives 5.1.2 When a relatively brittle adhesive is used, the peel

resistance can often give an indication of the degree of cure,

E4 Practices for Force Verification of Testing Machines

2.2 ASTM Adjuncts: that is, higher values than normally realized may indicate an

incomplete cure. Direct comparison of different adhesives or

Climbing Drum Peel Tester

processes can only be made when specimen design and test

conditions are identical.

This test method is under the jurisdiction of ASTM Committee D14 on

Adhesives and is under the jurisdiction of Subcommittee D14.80 on Metal Bonding

6. Apparatus

Adhesives.

Current edition approved April 1, 2004. Published April 2004. Originally 6.1 Peeling Apparatus, consisting of a flanged drum, flex-

approved in 1960. Last previous edition approved in 1998 as D1781 – 98. DOI:

ible loading straps or cables, and suitable clamps for holding

10.1520/D1781-98R04.

the test specimen. The apparatus illustrated in Fig. 1 has been

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

found to be satisfactory.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6.1.1 The outside radius of the drum is 51.00 6 0.13 mm

the ASTM website.

(2.000 6 0.005 in.), and the radius of the flange, including one

Detailed working drawings for the apparatus illustrated are available from

half of the thickness of the loading straps or cables, is 12.70 6

ASTM International, 100 Barr Harbor Drive, West Conshohocken PA 19428-2959.

Request ADJD1781. 0.13mm(0.500 60.005in.)largerthantheradiusofthedrum.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1781– 98 (2004)

6.1.2 Use a suitable top clamp (Fig. 2) for supporting the

specimen, and a drum clamp (Fig. 3) to hold the adherend

against the face of the drum.

6.1.3 Balance the drum about the axis by the use of

counterweights (as shown in Fig. 1) placed diametrically

opposite the drum clamp to compensate for the weight of this

clamp.

6.1.4 The drum and flanges with the drum clamp and its

compensating weight weighs# 3.6 kg (8 lb), a lighter weight

,

4 3

being preferable to facilitate handling of the apparatus.

6.2 Testing Machine, capable of applying tensile loads

under the conditions prescribed in Section 11 and with the

following further requirements:

6.2.1 The rate of movement between heads of the testing

machine remains essentially constant under fluctuating loads

(Note 1).

6.2.2 The testing machine weighs the load to within 1 %.

The testing machine and range are selected such that the

FIG. 1 Assembly of Peeling Apparatus

maximum load on the specimen falls between 15 and 85 % of

the full-scale capacity.

6.2.3 The use of autographic equipment to record load

versus head movement is recommended.

6.2.4 Verification of the testing machine is made in accor-

dance with the recommendations of Practices E4.

NOTE 1—It is difficult to meet this requirement when loads are

measured with a spring-type or pendulum-type weighing device.

7. Test Specimen

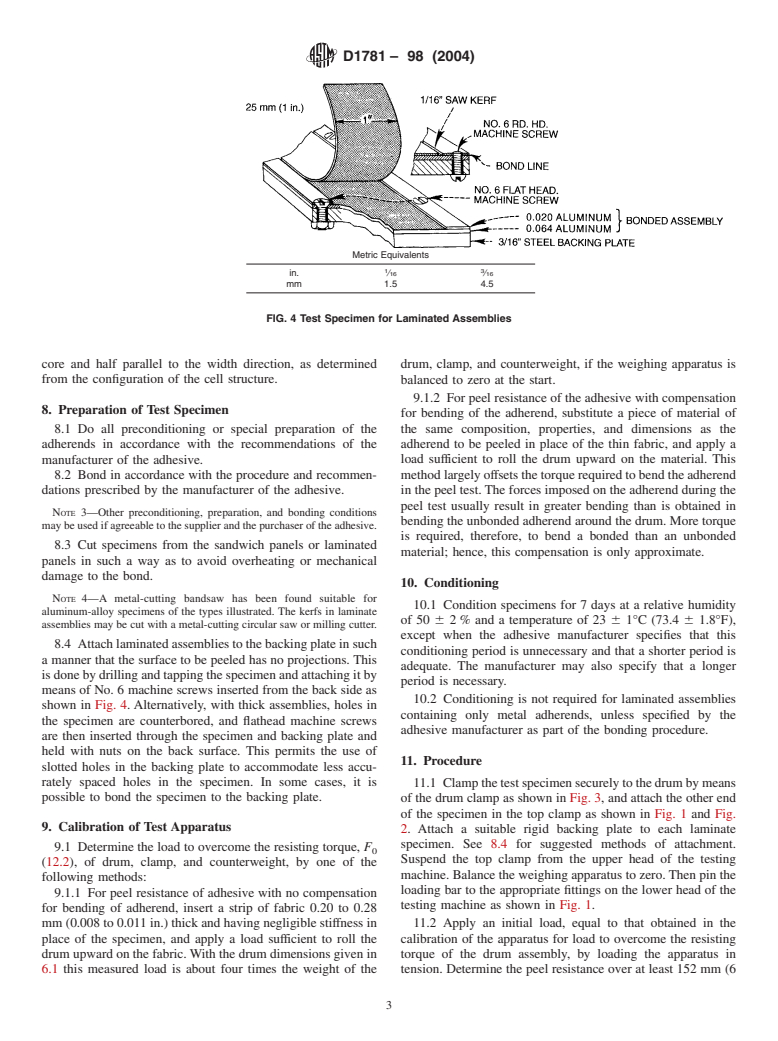

7.1 For evaluation of adhesives in laminated assemblies, a

specimen of the type shown in Fig. 4 has been found to be

satisfactory. The specimen is 25 mm (1 in.) wide between saw

kerfs and at least 254 mm (10 in.) long. The specimen may be

cut from larger bonded panels if desired.

7.2 For evaluation of adhesives in sandwich constructions,

make the test specimens in conformance to the general form of

the specimen shown in Fig. 1. The specimen is 76 mm (3 in.)

FIG. 2 Top Clamp

wide by at least 305 mm (12 in.) long, including about a

25-mm (1-in.) overhang of one facing at each end. Thickness

of the core is not important, except in the sense that the

sandwich specimen does not bend while the facing is being

peeled. For comparative evaluation of adhesives in bonding

metal-facedsandwichconstructions,afacingofcladaluminum

alloy meeting the requirements of Specification B209, Alloy

2024-T3, 0.51 mm (0.020 in.) thick with a core 12.7 mm (0.5

in.) thick, has been found to be suitable. Other metal facings of

comparable flexibility may also be used. The specimens may

be cut from larger bonded panels if desired.

NOTE 2—Direct comparisons of different adhesives can be made only

when specimen design and test conditions are identical.

7.3 Test at least six specimens, for example, two or more

from each of three bonded panels, for each adhesive sample.

FIG. 3 Drum Clamp

7.4 For sandwich constructions based on orthotropic cores,

peel half of the specimens parallel to the length direction of the

This 12.70 6 0.13 mm (0.500 6 0.005 in.) less half the

thickness of the adherend to be peeled, is the effective torque

A suitable climbing drum peel apparatus is available from Custom Scientific

arm of the apparatus. Instruments, Inc., 13 Wing Drive, Whippany, NJ, 07981.

D1781– 98 (2004)

Metric Equivalents

1 3

in. ⁄16 ⁄16

mm 1.5 4.5

FIG. 4 Test Specimen for Laminated Assemblies

core and half parallel to the width direction, as determined drum, clamp, and counterweight, if the weighing apparatus is

from the configuration of the cell structure. balanced to zero at the start.

9.1.2 For peel resistance of the adhesive with compensation

8. Preparation of Test Specimen

for bending of the adherend, substitute a piece of material of

the same composition, properties, and dimensions as the

8.1 Do all preconditioning or special preparation of the

adherends in accordance with the recommendations of the adherend to be peeled in place of the thin fabric, and apply a

manufacturer of the adhesive. load sufficient to roll the drum upward on the material. This

8.2 Bond in accordance with the procedure and recommen- method largely offsets the torque required to bend the adherend

dations prescribed by the manufacturer of the adhesive. in the peel test. The forces imposed on the adherend during the

peel test usually result i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.