ASTM D721-97

(Test Method)Standard Test Method for Oil Content of Petroleum Waxes

Standard Test Method for Oil Content of Petroleum Waxes

SCOPE

1.1 This test method covers the determination of oil in petroleum waxes having a congealing point of 30°C (86°F) or higher as determined in accordance with Test Method D938, and containing not more than 15 % of oil.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only. Note 1-With some types of waxes, of oil contents greater than 5 %, there may be an incompatibility with MEK resulting in the formation of two liquid phases. If this occurs, the method is not applicable to the material under test.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 721 – 97

Designation: 158/69(85)

Standard Test Method for

1

Oil Content of Petroleum Waxes

This standard is issued under the fixed designation D 721; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method was prepared jointly by the Technical Association of Pulp and Paper Industry and the American Society for Testing

and Materials.

This test method was issued as a joint ASTM-IP tentative in 1964.

This test method has been adopted for use by government agencies to replace Method 5431 of Federal Test Method Standard No. 79lb.

4

1. Scope Dispersion of Hydrocarbon Liquids

D 1364 Test Method for Water in Volatile Solvents (Karl

1.1 This test method covers the determination of oil in

3

Fischer Reagent Titration Method)

petroleum waxes having a congealing point of 30°C (86°F) or

D 1613 Test Method for Acidity in Volatile Solvents and

higher as determined in accordance with Test Method D 938,

2 Chemical Intermediates Used in Paint, Varnish, Lacquer,

and containing not more than 15 % of oil.

3

and Related Products

1.2 The values stated in inch-pound units are to be regarded

5

E 1 Specification for ASTM Thermometers

as the standard. The values in parentheses are for information

E 128 Test Method for Maximum Pore Diameter and Per-

only.

6

meability of Rigid Porous Filters for Laboratory Use

NOTE 1—With some types of waxes, of oil contents greater than 5%,

there may be an incompatibility with MEK resulting in the formation of

3. Summary of Test Method

two liquid phases. If this occurs, the method is not applicable to the

3.1 The sample is dissolved in methyl ethyl ketone, the

material under test.

solution cooled to –32°C (–25°F) to precipitate the wax, and

1.3 This standard does not purport to address all of the

filtered. The oil content of the filtrate is determined by

safety concerns, if any, associated with its use. It is the

evaporating the methyl ethyl ketone and weighing the residue.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4. Significance and Use

bility of regulatory limitations prior to use.

4.1 The oil content of a wax may have significant effects on

several of its properties, such as strength, hardness, flexibility,

2. Referenced Documents

scuff resistance, coefficient of friction, coefficient of expansion,

2.1 ASTM Standards:

melting point and oil straining. The importance of these effects

3

D 740 Specification for Methyl Ethyl Ketone

may be dependent upon the ultimate use of the wax.

D 938 Test Method for Congealing Point of Petroleum

4

Waxes, Including Petrolatum

5. Apparatus

D 1078 Test Method for Distillation Range of Volatile

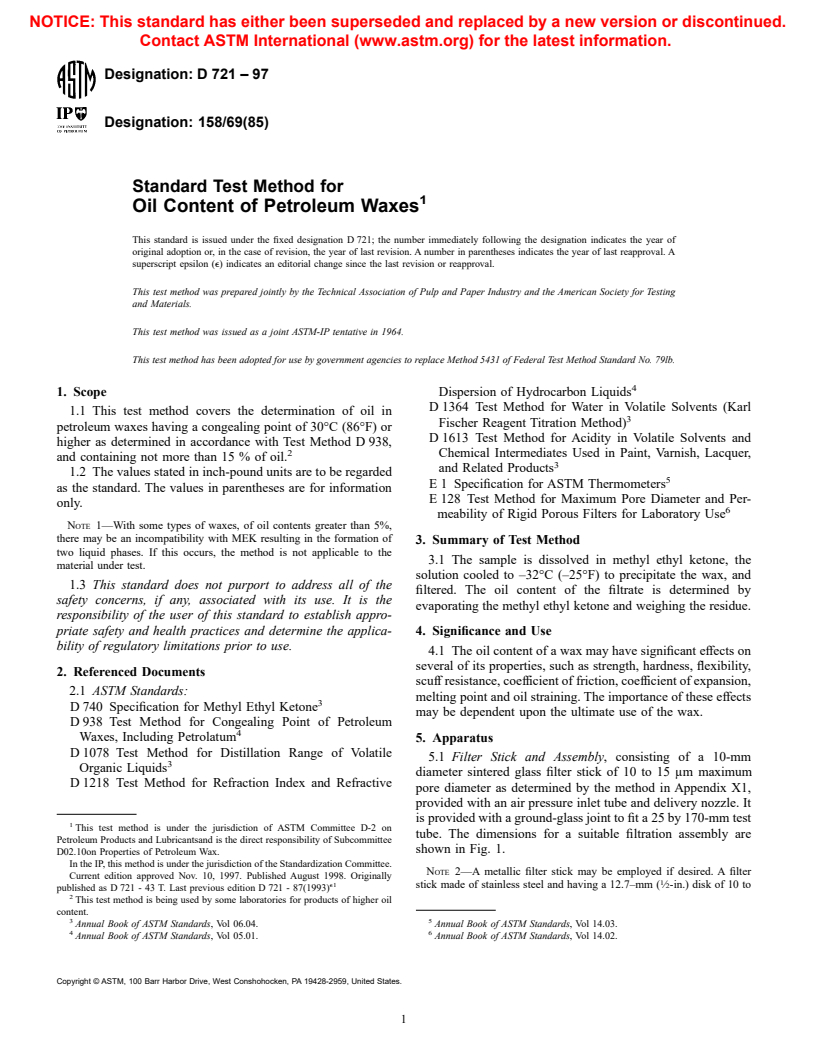

5.1 Filter Stick and Assembly, consisting of a 10-mm

3

Organic Liquids

diameter sintered glass filter stick of 10 to 15 μm maximum

D 1218 Test Method for Refraction Index and Refractive

pore diameter as determined by the method in Appendix X1,

provided with an air pressure inlet tube and delivery nozzle. It

is provided with a ground-glass joint to fit a 25 by 170-mm test

1

This test method is under the jurisdiction of ASTM Committee D-2 on

tube. The dimensions for a suitable filtration assembly are

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

shown in Fig. 1.

D02.10on Properties of Petroleum Wax.

In the IP, this method is under the jurisdiction of the Standardization Committee.

NOTE 2—A metallic filter stick may be employed if desired. A filter

Current edition approved Nov. 10, 1997. Published August 1998. Originally

1

e1

stick made of stainless steel and having a 12.7–mm ( ⁄2-in.) disk of 10 to

published as D 721 - 43 T. Last previous edition D 721 - 87(1993)

2

This test method is being used by some laboratories for products of higher oil

content.

3 5

Annual Book of ASTM Standards, Vol 06.04. Annual Book of ASTM Standards, Vol 14.03.

4 6

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 721

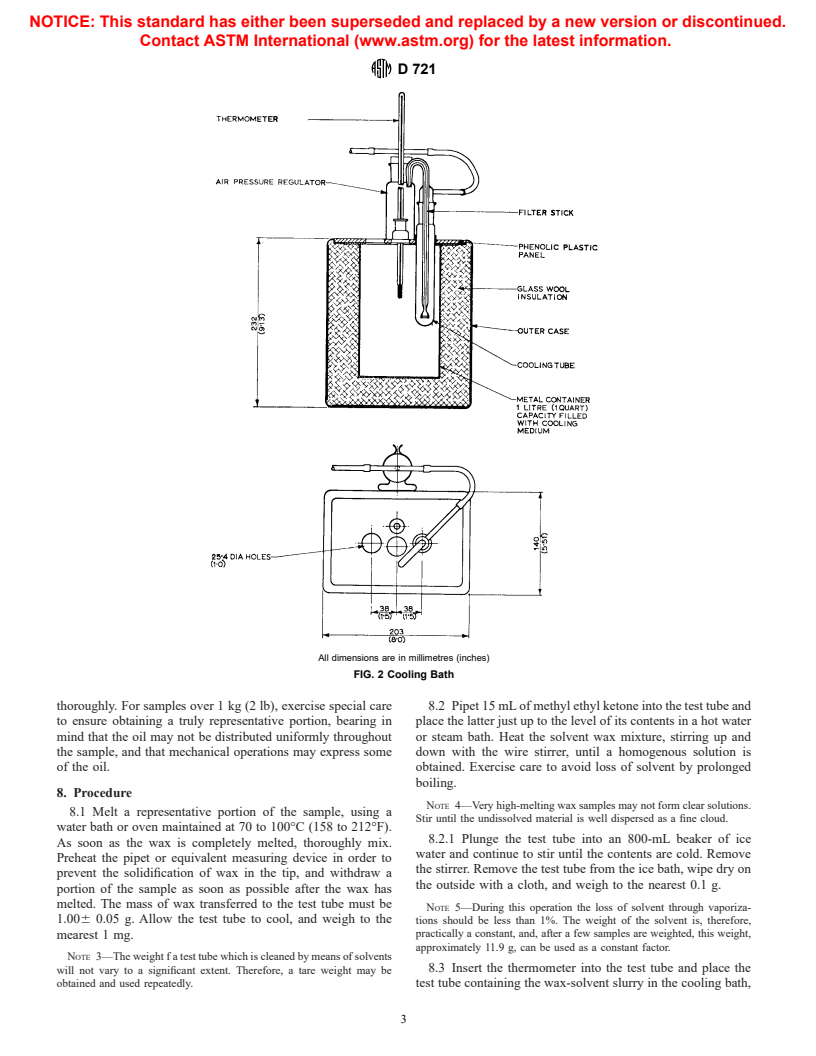

pressure regulatory is connected to the filter stick and assembly

by means of rubber tubing.

5.6 Thermometer, having a range as shown below and

conforming to the requirements as prescribed in Specification

E 1, or in the Specification for IP Standard Thermometers.

Thermometer Number

Temperature Range ASTM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.